Leaderboard

Popular Content

Showing content with the highest reputation on 01/09/17 in all areas

-

We just had our end of year wind up for 2016 (yes I know its already 2017) for the Master Clock and Watch Makers of Western Australia Inc and at that was announced the 3 winners of a $1000 scholarship which can be used to pay this years fees, or buy tools of which I was one of the winners. Looks like I will be getting myself a nice workbench and good light and a few more tools soon which will set me in good stead for my second year studying watch and clock repair.2 points

-

One of my neighbours recently gave me his wife's watch to look at, he just said ''it's not working do you think you could do anything with it ?''. It's a tiny Seiko ladies watch, I took out the movement and found a broken click spring, nothing remarkable about that except it must be the smallest click spring I've ever seen ! barely visible with the naked eye , Cousins even had one ! ( £1.50 ) Watch now working Just thought I'd post it.1 point

-

I started this hobby some 10 years ago and took it up to see if I could get some skills and knowledge so that I would have something worthwhile to do in retirement and also partially because I avoid the telly and need distraction from a job that is stressfull at times. I have never had any formal training, but always liked pulling things apart and fixing them. I have restored/repaired many watches and dont charge for this as long as the watch owner promises to wear Grandads or Dads old watch every now and again. Everyone promises to do this and I do like to see folks wearing these old watches and not having them in the back of a drawer somewhere. OK so thats where I am coming from and as I see many new to watch repair folks here, I though a thread starter might be what skills you thought necessary for the jobs we do, how you managed to develop these skills and where you got your knowledge. I'll start it off. Some of what we are likley to say will be obvious, but it maybe of help to newer folk. I think patience and a reasonably steady hand factors would be important. Just figuring out how to use tweezers and screwdrivers does take time, so take apart and put back together as much as you can. You will get lots of satisfaction through getting something to work and keep reasonable time. Look for old movements, say Bulova - available cheap, which are simple manual wind jobs...you will soon pick it up. A number of devices can assist eyesight these days but if your eyes are good it really makes it easier. I am not known for my patience, but I think I have improved this somewhat. Taking time to source the parts carefully requires this. Some projects take years to finish. You need to recognise when it is not fun any more and take a break. Don't jump to conclusions about a fault, but think things through as best as you can. Of course knowledge can be gained by things like Marks videos...I still watch these and pick up lots. I also think an open mind to repair techniques is important as well, that is, dont get locked into doing things one way as another method may actually be better with less chance of breaking something. The first skills I learnt were the manual dexterity ones. We all talk about breaking parts of the first movments we work on so develop the fine skills you need through repitition. I know we all like pictures, so here are a couple of my workshop.1 point

-

Spent a few hours at a flea-market in Seremban, a town in Malaysia about 50kms or so south of Kuala Lumpur. A lot of junk but that's sometimes good as you may get some bargains here. There is another bigger (better?) flea-market in Kuala Lumpur (in Amcorp Mall) but here the stuff is more 'antique' and priced accordingly. Anyway first one up is an Orient Racer, pretty much the bottom of the barrel when it comes to condition but through the badly scratched crystal I had a hunch that the dial was OK as the dial paint didn't have any visible patches. Back home I got it opened up I was happy to see that the dial was in pretty good shape with just some dust on the surface. The missing minute hand was also in there but the seconds hand was AWOL. ack The caseback is not correct, its too small and won't screw in..damn. On the inside I'm pleased to find an Orient 1942 movement.. nice as this has a full balance bridge as opposed to a balance cock. However the autowind stuff is all gone, since this watch cannot be hand-wound this watch will end up being a donor unless I can find another one with a good case and autowind mechanism. This was a better movement in its day, the escape wheel is capped on the main-bridge. The similarities with Seiko movements can be seen by the balance shock protection and it also has the typical seiko click which is just a piece of stamped steel which functions as the click and spring. The escape wheel cap jewel is also restrained by a typical Seiko spring. The second watch is an Urika. I was inspired by Mick's (Cad101) post and have been on the lookout for one and this was sitting in the same box as the Orient above. Pretty pristine.. In fact not much wear.. original, facetted around the edge, crystal has normal drawer rash,, nothing that can't be polished out,,... Caseback pretty unworn and the bracelet has the full lenght. The remnants of the price tag on the bracelet clasp leads me to think that this was probably unsold stock. Didn't get a picture of the movement but it has the same upside down balance as Mick's watch. Hopefully a clean and service will get this running... will post a write-up when I get round to it. Both of these cost me MYR40... less than USD10. .. simple pleasures..! Anilv1 point

-

OK, I have had a look through the clock mainsprings that I have and they are all way too big. The collets are 3mm+ OD x 1.5mm ID and the springs are 0.49mm x 0.12mm and nearly 30mm diameter. I think that I have some pocket watch hair springs somewhere so will dig a little deeper. Bear with me though as it may be a day or two. unfortunately the day job has a tendency to get in the way of the important stuff....1 point

-

1 point

-

@jdrichard I have just had a rummage through my amazing box of spares (referred to by the Wifey as "just another one of my boxes of junk") and dug out a box of assorted round garnet pins. After some fun and games with my micrometer I have found one which measures between 0.45mm and 0.47mm depending on which micrometer I use (the better mic has it at 0.457mm). It is just under 3mm long and will need the ends dressing up on a diamond hone. If it is any use to you then if you pm me your address and I will pop it in the post.1 point

-

measuring the original crystal would work, if you have some calipers for that. otherwise like oldhippy said look for the case numbers1 point

-

1 point

-

Over the Christmas period I went to order a Bergeon 6400 crystal lift £65 ish from Cousins but it said out of stock till mid Febuary, a few day ago I checked again and it said out of stock till March. As I need one for a particular watch I thought I'd get the cheap Indian version ( under £15 ) , expecting it to be a bit rough & tacky I thought I would use it this one time resell it on ebay and buy a proper one later on, When it arrived I was quite surprised how good it was, the fingers are well machined and the finish is good, I think I'll stick with this one.1 point

-

Try here. https://www.cousinsuk.com/product/roller-impulse-pin-jewels-seitz1 point

-

Have yo ever heard the term fitting a round peg into a square hole.1 point

-

again amazing to see what knowledge is under the members, JD1 point

-

That is what I expect to see, looks like a 30 hour movement. With this type of balance staff they tend to lose their point so the action of the balance can be poor, so the balance is put into a lathe minus the hairspring and is sharped into a point on both ends, sometimes with lack of oil the cups wear and have to be repaired or replaced. The hairspring should bounce in the regulator from one end to the other in order for the regulator to work properly.1 point

-

If the crystal lift is half as good as the Chinese screwdrivers I purchased for £5.59 including delivery, he'll be well chuffed. I've done countless watches over the years with them, never had one break or twist, and only had to dress a couple of the tips once. I also have a "cheap" crystal lift that has given years of great service. Why do you always have to jump in and put things down because they are cheap? There is quite a lot of expensive stuff out there that is sub standard as well.1 point

-

That's why I mentioned in my previous post to make sure you have the right type, if the hole is round you need a round impulse pin, what was there before was wrong.1 point

-

It's called a split ferrule and can be seen illustrated in De Carle's Practical Watch Repair at the beginning of the chapter on turning. I have a few in various sizes including a couple that are small enough for some of the larger wrist watch balance staffs but have never used them for the reasons David has stated above. I guess that at a push they would be ok for roughing out the staff on a turns up to the point where the wheel could be riveted on allowing the use of a pulley wheel with a driving pin and then then turning the pivots, but if you were unlucky to subsequently break a pivot you would have to cut the rivet off again to remove the staff and start again. I can't see pivots surviving the lateral loading that the bow would exert on the ferrule. Wrapping the bow around the actual staff would I'm sure be a recipe for disaster.1 point

-

1 point

-

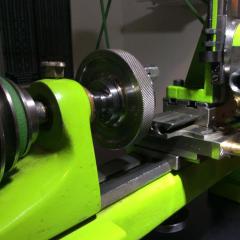

Hello Tom: Here's my setup. I bought a low RPM electric motor and a controller and just mounted the thing on a cheap wood carving board that I bought at Wallmart. Additionally, I bought the pulley and O-ring from eBay as-well-as the motor, the controller, and some rubber feet. The clamps is milled out of aluminum but they could just as easily be made out of wood - there's very little pressure on this operation. If you want more specifics I 'll be glad to provide them. Check out the video and let me know. Thanks! Tom1 point

-

Stabbed myself a number of times with oiler, dropped a pair of tweezers once that stuck in my leg, and nearly very nearly taken my eye out whilst holding tweezers and putting a loup on!!!!1 point

-

1 point