Leaderboard

Popular Content

Showing content with the highest reputation on 10/18/16 in all areas

-

The days certainly fly! I've been in school for 13 months now, but there is still so much to learn. I wonder if I'll know enough by the time I graduate? Today was a big day, tool-wise. I got my new Lorch lathe (see box at far right next to bench with closed roll top). It's a beautiful set, probably from the 1970's. It's almost complete. This plus my 1920-vintage Boley allows me to do almost everything. I'm also working on a nice little Japanese wristwatch. It's not very expensive but it has some nice and fairly innovative features and, consequently, is of different design than I usually work on. It has a cracked jewel so, as an exercise using my new lathe, I'm going to make a brash bushing to replace the jewel. I wouldn't normally do this except for practice using my lathe. Also I recently re-jeweled a watch that had brass bushings; so there's a sort of symmetry between the two operations. Finally, we put in the finishing touches to a student workshop off-campus where we can work together practicing various skills. We will work, help and challenge each other and prepare questions to ask our instructor the next day.3 points

-

My wife always accuses me of having lots of half finished projects that I never finish, so every now and then I find a project that has been hanging around for a while and finish it just to prove her wrong. Its nearly about that time for the C15 to be the next project to finish once I can pick up heavy items again which is still 4 weeks away,2 points

-

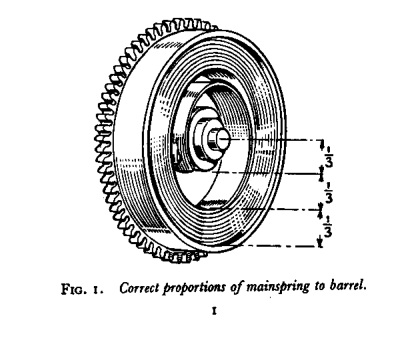

You beat me to it szbalogh I was just going through this last night at my watch repair course so its all thresh in my mind But to just add a bit more there are formulas that go into it deeper For example to work out the correct length of the spring is length = Pi(inner radius of barrel squared - radius of the barrel arbor) / 2 * thickness of mainspring. On average the thickness of the spring is around 1/100th of the inner barrel diameter. A very simple check you can do to see if the spring in the barrel is the correct one and not just one some hack found and stuck in is check the k factor. The k factor is the ratio between he radius of the barrel arbor core and the thickness of the mainspring. This usually falls between 10 and 14 k = radius of barrel arbor / thickness of the mainspring Bottom line, the spring in the barrel will be the best spring for the watch unless some hack has fitted an incorrect spring at some point.2 points

-

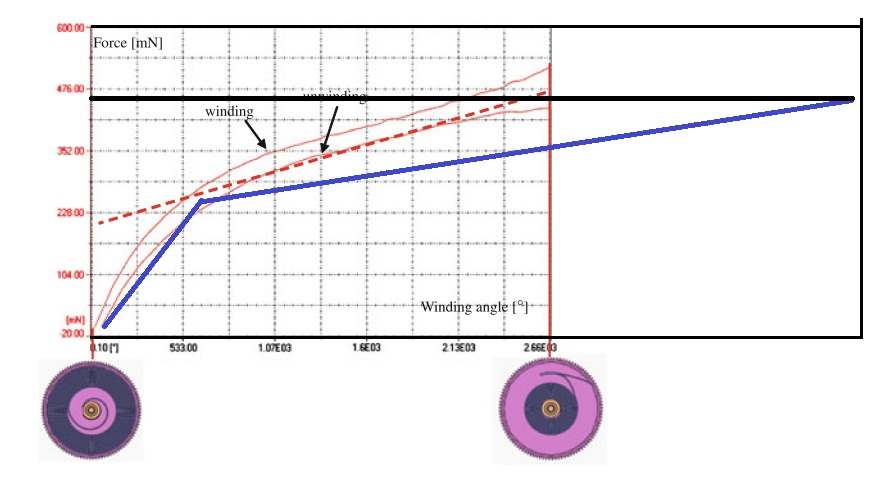

First, one has to consider the characteristic of the spring. The next diagram shows the spring force compared to winding angle (red lines, original spring). The new spring should have the same peak force (blue line) as the old one not to overstrain the gears. The geometry of the barrel hovewer determines the spring length. General rule according to DeCarle: Practical watch adjusting is to have 1/3 space for the spring couils, 1/3 open and 1/3 for the barrel arbor. Coil number of the spring (possible winding angle) can be increased only if the spring material is thinner. I can imagine that there are a newer and more modern spring steels those have the same strength but are thinner than old ones. But the problem is that we have even trouble to find original or similar springs to our watches. To find the required one for this problem seems impossible. And even if there is a source one need to shape the spring to fit in the barrel (make both end hooks). I dont think it worth the time to have +10-30 % more power reserve. On the other hand, manual wound watches are designed to wound every day at the same time. And by knowing your watch and with a daily routine they can be made incredibly accurate since the spring force changing every day the same amount.2 points

-

The watch movement is designed in a way to run and work with a certain type of mainspring which is height width and strength. Any other mainspring fitted could cause all sorts of damage and effect to parts that make up the movement and the time keeping.2 points

-

It looks like you're trying to put a mainspring in a Waltham Steel barrel? The problem is the original Springs have a taper in the hole and a little bend. So this makes more sense I'm attaching images of a original Waltham Mainspring. The replacements usually have just a punched hole with neither the taper or the bend which isn't going to work with the steel barrel hook. So if you can find a really tiny file or grinding stone usually filing a taper on the edge of the hole will solve the problem.2 points

-

Finished constructing my Watch-o-scope based on Stefan's design and suggestions from this thread. I substituted a TL084 in a TSSOP14 package for the suggested TL071 in a 14-pin DIP. With SMD components, this board fits into a case only slightly larger than a 9V battery (in the background). I am still debugging the board as it stands. Stefan, if your design doesn't evolve much from current state and involves mostly component value changes, then this board layout should accommodate your changes.2 points

-

Since I was working on the Landeron 48 with wrong dial, from which I used the case and a Landeron 151 and correct dial to make a new watch, I saw this Landeron 248 sitting in the drawer at my desk and devided to finally tackle the issue it had: a slipping mainspring. I documented the disassembly of the movement vith 3 videos, the first of which is here below: Hope you enjoy1 point

-

1 point

-

these video seem to be the thing these days, some good, some not. if you can understand all of de carles book; then go for a video. cheers vinn1 point

-

There are lots of good books. Donald de Carle has several good books on both watches and clocks, they are dated in some areas, but still very good books. Or is you would prefer one from an American view point rather than British look for 'The Watch Repairer's Manual' by Henry B Fried If you can find yourself a copy of 'Watch and Clockmakers Handbook Dictionary and Guide' by Britten, its worth getting hold of as it shows many of the tools and gives brief explanations of what they are used for, great for identifying a mystery tool you get in an ebay job lot. It was first published in 1884, but has been reprinted many times. I've got a 1902 copy and a 1938 copy that was my grandfathers. There are many other good books and lots specialising on certain topics such as carriage clocks, 400 day clocks, pocket watches etc, which are books to get after you have got the basics. One other great but expensive book is by George Daniels 'Watchmaking'. It goes into how to actually make a pocket watch from scratch and is full of real gems of information.1 point

-

Hi deeclee, Check out Donald De Carle books. Some of them are free as pdf on line. They are, so to speak, a default for watchmaking. Also, you might want to check on the TimeZone classes. They are on line. Not very much in depth but for starters are OK. The Seiko Servicing class for 7S26 is free and on line also. Search for 7S26 and Hacko. Of course, none of those replace a good hands on watchmaking course with a guiding instructor or an apprenticeship for that matter. Just an idea that might help. Cheers, Bob1 point

-

Just noticed a mistake in my formula, corrected formula below length = Pi(inner radius of barrel squared - radius of the barrel arbor squared) / 2 * thickness of mainspring.1 point

-

I had read a few books and 'dabbled' in the past but at the start of this year I started night classes on watch and clock repair, its a 3 year course so still got a lot to learn. I've had more practice with clocks than watches so far.1 point

-

might be fun to pick up a few non running watches to peactice on "sacrifice" and to learn how to use tweezers. best of luck, vinn1 point

-

Hi, Your one step in front of me, I still don't have a permanent spot set up, or a watch cleaning machine. Look forward to reading your posts. Tony1 point

-

There are a couple of variations on the miyota 2035 series movement stems. Its cheaper to buy a new movement with the stem already fitted than mess about. A couple of pounds on ebay, or from a watch parts supplier such as Cousins UK if you have a trade account.1 point

-

That is an interesting question. The length of the spring determines how long the watch will run (power reserve). I have fitted springs that are just a bit longer than the original because the original size was not available with no issues. The strength is a more complex matter. In my opinion for hand wind watches having a slightly stronger strength spring than the original should not cause any issues. However for auto wind watches this could cause issues as the barrel/spring is just being wound via an oscillating weight. Fitting weaker springs could cause lower amplitude. This is certainly an issue with clocks. I have replaced many tired clock springs that have just lost their effectiveness,so I dare say the same applies to watches.1 point

-

Welcome to the forum deeclee. Looks like a nice place and bench + tools already looking good. My suggestion, add a strip of wood about 1 inch high on the sides and back of the bench/desk surface's edge so as to stop tools and flyers or prevent "overflows". I'm not too articulate for describing stuff but hopefully you get the idea....otherwise, just ask and I'll try to explain better. Cheers, Bob1 point

-

Hi everyone. I'd like to thank you all for helping me discover the type of watch calibre I have and the sources of valuable information regarding its assembly. As of now I have been able to reassemble my watch. I got very lucky and found an exact 2025 on Ebay. The watch was broken and was being offered as parts. I couldn't refuse and finally got my hands on it. All of the pieces that I needed were there for the taking. Anyways, I successfully re-assembled my watch, mostly by trial and error and was able to put it all back the way it should go. Unfortunately, as other members were right in assuming,I lack the oils and tools necessary to give it a proper servicing. When I wind the watch it makes the distinct "clicks" that wind up watches make when you're cranking them. But sadly that's all it would do. On the plus side, every piece is present and the replacements are working. The bad side, it's not exactly working. It winds and the hour and minute and even the second hands are working fine but the hairspring or part that's round and is semi suspended by a coil doesn't pivot back and forth. Research suggests that the problem is lack of oil, friction and foreign particles. I think I will take it to a horologist tomorrow to have it serviced. Hopefully it just needs the servicing to be fully functional again.1 point

-

Welcome deeclee, enjoy this forum and I look forward to reading how you get on in the watch world, I like your enthusiasm, you sound a little like myself, I service and repair watches all day at work then come home and work on them at night and weekends, I find I'm constantly thinking of movements and different mechanical scenarios, sounds crazy but that's what happens. As oldhippy suggested, watch the height of that desk, it will kill your back if it's not correct, if needed even put blocks under the legs and get it lifted up a touch. Feel free to ask questions here, lots of knowledge that you should take advantage of, I'd happily answer anything that I can. Enjoy and welcome, Brian1 point

-

Unfortunately when I first started I had a book on watch repair but I was fairly ignorant. firstly on how to use an oiler correctly, going into the area at a 45° angle with too much oil that probably drew more oil away from the area than lubricate. To compensate I used more oil . Also the grade of oil was too thick. Today for pivots I use 9010 . I go into the area with the oiler vertically. Removing any surplus with rodico. Then I didn't even know what rodico was. At one point I almost just gave up. Years later I'm still learning and this Forum really is an "Oasis in the desert" It's not just about what oil, how much oil but how it's applied, to achieve a successful outcome. Apologies for rambling on Sent from my SM-G920F using Tapatalk1 point

-

I agree with all of the above. Although, my Myota's 2035's came with threaded stems right on if I remember correctly. I might be mistaken since I've had them for some time waiting for a customer in distress with a cheap (or sometimes not so cheap) watch. You can have them in "Gold Supper" or silver for like a dollar extra (US$4 vs. US$5). Also, the Myota 2025 is the same movement minus the seconds hand.1 point

-

unthreaded is on the movement ,but they give usually also a spare threaded one with the movement.1 point

-

I had a wood shop teacher in high school named Mr. Hammer (no really!) who said I should not plan on being a carpenter as a career! He was probably correct.1 point

-

1 point

-

Yes its a miyota 2035 , i found it in my local supplier even lower , 3.5 euros1 point

-

Looks like a 2035. However I personaly would not bother with a new stem. See link below for £5 you can purchase a new movement (with battery) & they are normally supplied with a stem. http://www.ebay.co.uk/itm/like/191067979633?lpid=122&chn=ps&adgroupid=32954122545&rlsatarget=pla-256745055720&adtype=pla&poi=&googleloc=9045000&device=c&campaignid=659583801&crdt=01 point

-

1 point

-

Thanks Bob. To continue to expand on what my main interests are I would say English clocks and American pocket watches, though I am also interested in 'trench watches' though I only own one real true trench watch, English hallmarked with a Swiss movement which is waiting until I feel my skill is up for trying to service a 100 year old watch. I'm also interested in what I would call 'vintage' or traditional watch making tools, primarily used for servicing pocket watches and currently have a pocket watch bezel cleaner in the post heading over to me to add to my collection. Next week when I feel up to it I will drag out all my watches and pocket watches to photograph them most of which are currently waiting on me to learn enough to be able service and repair them, but in the mean time I will share the photograph of my great grandfather Myer Jacobs working over his repair bench which I'm guessing was taken by my grandfather when he was young as I found this negative in amongst some of his camera equipment which I was given when he passed away back in 2001. I only met Myer once when I was thirteen which must of only been a few months before he passed away as I lived in Perth and both my grandfather and great grandfather lived in Sydney.1 point

-

HI, I've got bigger cast iron too, for the bigger stuff as I built myself a workshop around 10 years ago for model engineering. I've got a larger lathe and a milling machine, photos below showing the milling machine set up with its dividing head for drilling the holes to make a lantern pinion. These photos were taken a awhile ago and my workshop isn't so tidy now. I'm very lucky that the night classes I go to are only about 20 minutes drive away. Thanks everyone.1 point

-

1 point

-

The second part of the video is finally ready: Enjoy... The third and final part will be uploaded in a few days.1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)