Leaderboard

Popular Content

Showing content with the highest reputation on 07/05/16 in all areas

-

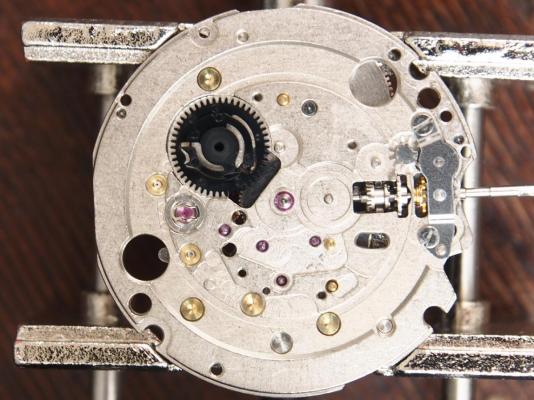

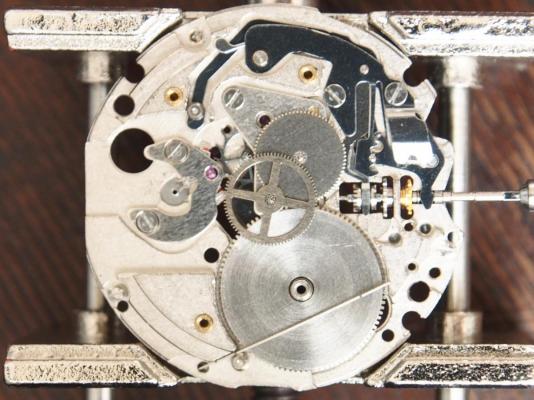

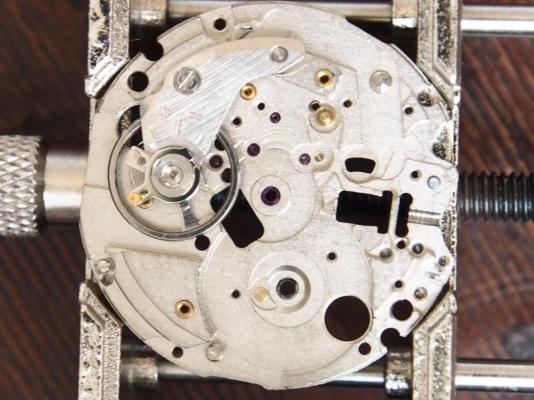

This is my first service walk-through, for which I've chosen this well know Seiko movement. It has a lot of similarities and common parts with the 7S and 4R families. The most notable differences are a separate bridge for the auto winding, and a better mainspring giving 50 hours power reserve. Also, the tiny anti-shock for the train wheels (of debatable usefulness) are not present. Some version have a cotes de Geneve finishing, the one pictured does not. Just like the others it is quite easy to work on. Find attached the technical guide for the SII version, which is named NE15B, In this walk-trough my intent is to give practical advice on certain aspects, which comes from my personale experience and reasoning, Reassembly and lubrication will be covered in the 2nd part. Let's start with the disassembly for which the absolutely indispensable tools are: Movement holder Hand remover tool 1.4mm and 2.0mm flat head drivers Seiko cross-head driver Fine or medium tip tweezers First, I recommend to remove rotor weight with the movement stil in the case, as it it of impediment for all the work to be done later. The movement is kept in case with 2 screws and 2 tabs (not pictured). Remove these, case ring and stem (usual pressing point with crown full in), the movement can now drop from the case - unlike the 7S and 4R where the plastic ring keep it place with some friction. You can now place movement on holder, reinsert stem as it's needed to hold related wheels in place until the very end. Remove hands with your favorite tool, then keeping movement in hand or placing it on the holder with a plastic protection, quarter-run dial the feet retainers at 3 and 10. Gently push the dial out, I recommend to place it in a plastic bag for additional protection. The movement ring goes with other parts not to be washed. Tip: label the tray sectors as in last picture to make it easier to sort and find small parts. Of course some parts will get mixed for cleaning, more on that later. First, remove the balance cock to protect balance wheel and hairspring from any possible incident during subsequent work. When removing the balance push gently the wheel from below to set it free from the fork, and avoid as much as possible suspending the balance by the hairspring. Store it wheel up with pivot set in hole. Turn movement over again to remove all dial side parts, starting with date maintaining plate screws. These can be four flat head screws, or three screws 'A' and one screw 'B' which requires the Seiko or equivalent small cross-head driver. Lift the date maintaining plate and the underneath parts will be exposed You can now remove: Date dial Date corrector wheel (white plastic) Date corrector wheel E (metal) Date jumper Intermediate date wheel (white plastic) Date driving wheel (black plastic) Hour wheel Minute wheel Cannon pinion Now, remove two date corrector wheel guard screws, wheel guard and corrector wheel C. Note: depending on versions the date corrector wheel B can be either a separate part, or attached to the guard. Turn over the movement and referring to 1st picture removing the two automatic bridge screws and bridge, and 2nd reduction wheel. Now we can let down any tension left in the mainspring. Just keep the tip of pegwood on the barrel to prevent it from spinning to fast, with push away the click away from from the ratchet wheel. Now we can remove in order: Ratchet wheel screw and wheel Three train bridge screws Train bridge And will be presented with the train system From which we will remove Click and barrel Fourth and third wheels Escape wheel Pallet bridge screws, bridge and pallet fork. Note: I recommend to not disassemble the barrel on the 6R15 movement, because a special material (SPRON 510) mainspring is used link, for which one would not find an exact replacement, and the barrel is sealed and lubricated for life. If there is any issue with the mainspring, replace the barrel complete. Now, undo the single screw for central wheel bridge to remove bridge, and wheel itself. Next the keyless system, which is kept in place with two screws. There is not much tension in it but is always better to keep the setting lever in place with a stick and then lift the parts, which are: Yoke spring Yoke Setting lever Balance stop lever My tip for last remaining parts (clutch, winding pinion and date corrector wheel A) is to just pull out the stem and pick them up from the mat to place directly in mesh basket. You can now place back the balance back in the movement to protect it during cleaning, and in preparation for the next step, which is removing anti-shock upper and lower balance jewels (Diafix) . My recommended technique is the following: place the tip of the tweezers on the inside of the spring, and rotate the entire holder and movement. Once the spring is out of the frame, close tweezers and store spring in tray, pick up the jewel with Rodico, and place it directly in the metal mesh basket. There is one last task which is removing the 1st reduction wheel and pawl, as well the lower plate from barrel from the automatic train. Just pay attention to not lose the C-clip while pushing it out as shown in the technical guide. My recommendation about cleaning is that with a movement which is spotless like the one in these pictures, I do not wash all the parts, but only those that have jewels, or are to be lubricated. That means you can leave screws, some plates, plastic wheel in the tray, saving time and minimizing chances of losing them during handling. A small mesh closed basket and a larger plastic one are enough. For cleaning I use an household ultrasonic machine, and isopropylic alcohol only, then blow briefly with an hairdryer. Again the reason is that we only need to clean any old oil. Note: although alcohol is detrimental to shellac, I've found that even 10 minutes in there do no harm to the pallet fork jewels, but leave all parts perfectly clean without no residue whatsoever. This concludes the 1st part of this walk-through. NE15-TG.pdf1 point

-

Hello, I have just joined the forum. My name is Deborah Bell and I run a mechanical watch and clock museum with my mother, in Haltwhistle Northumberland- 'Mr George's Museum of Time'. The museum is based around a series of children's stories which my mum wrote about her father who was a watch and clock repairer in Northumberland- the 'Mr George the clockman stories'. My mum became a repairer herself and has a huge collection of watches, clocks, tools and parts so we decided to bring everything together so children could learn all about mechanical "proper" time and Mr George, and adults could look at the collection and reminisce. She still repairs both watches and clocks now and has her workshop on our museum premises! Hope to chat to a few of you on here!1 point

-

Vintage Cherry bench from the Joseph Bulova School of Watchmaking in Woodside, New York My Bulova Watchmaster ultrasonic and an older L&R cleaner Work in progress: Parts and supplies: Larger tools and more supplies: Various Horotec presses - Crystal, case, hands, crown/pusher tube press. Some other crystal presses including a BB. Timing machine is on the right. Ultrasonic and steamer Lathe - in parts awaiting cleaning.... Waiting their turn:1 point

-

1 point

-

Here is my latest, Industry Action Fund Update 5 July 2016 Dear Contributor, It is four months since I wrote to you last with any form of update on progress, and I am aware that my last communication left things on something of a ‘cliff hanger’. Happily I am now able to bring you up to date, and I am sure you will be pleased with the news. If you have not already seen it, attached is a copy of an announcement released yesterday by Cousins Material House in regard to legal action they are engaged in with Swatch Group. Part of the reason that Cousins has gone to law comes from what we learned from the research that I did whilst funded by the IAF, also from the meeting that I organised with the Department of Business, Innovation and Skills (BIS), and the subsequent advice we had from the Competition and Markets Authority (CMA). Our original intention with the IAF was to fund an industry survey, so that ultimately we would have the necessary data to present a credible formal complaint to the CMA about restrictive practices in our trade, and ask them to investigate what we believe are clear breaches of British and EU law. However, circumstances changed in two ways, and a vastly superior path opened to us. Firstly, the act of setting up the IAF and asking people to contribute produced a substantial quantity of relevant evidence and intelligence. Much of my time was taken up sifting this and learning about precisely what the relevant law was, and what had gone on so far. This was the work that enabled me to assemble the dossier that we took to BIS, and their subsequent referral of us direct to the CMA meant that we had achieved the access to the regulator that we had been after far faster than we had originally thought we could, and without having done the survey first. Secondly, and in parallel with this work, Cousins Material House and their solicitors were consulting a top London Barrister in regard to their application to the EU Courts to become an Intervener in the on-going case between CEAHR and the EU Commission. With both Anthony and Sam Cousins being members of the IAF Management Team, it made eminent sense to all of us to combine our efforts, and share the dossier we had given to BIS with the Barrister, and obtain some valuable legal advice in return. What emerged from all this was a very effective team that quickly grasped the legal fundamentals of the case, and as the course of action that Cousins is now on became ever increasingly likely, the IAF Management Team took the decision to make the project dormant. It was apparent to all of us that a direct legal challenge to Swatch is likely to be far faster in achieving the end objective than asking the CMA to take the matter on. Therefore, since the start of this year, I have been contracted as a full time Consultant to Cousins, using the knowledge that we have gained to support the preparations for the action that they are now engaged in. Whilst the IAF for now is dormant, I remain the Project Manager, and along with the Management Team we stand ready to reactivate the Fund should it be needed further down the line. The remainder of the funds raised are (as they have always been) safely in the Bank Account under the stewardship of the Guild. I am grateful to all of you for your support, and I am sure that you will agree that as the effective result of your unity and generosity is this matter being heard in a court, then your money has been well spent. I continue to work full time with Cousins on the fight for free and fair competition in this market, and will try and update you as and how I am able. You are welcome to contact me as before, my telephone number remains the same as +44 (0)7831 538975. If you wish to email me, please do so to my business address which is [email protected] . Thank you for having supported this effort. Kind regards Steven Domb1 point

-

1 point

-

1 point

-

1 point

-

As I said, it's a great movement, the case is brilliant. I simply pointed out it had been recased, enjoy wearing it, simply wonderful.1 point

-

Just put it in the drawer for 2 days and get it out in the dark. If still bright, then it has some radioactive compound. If its brightness fades in the dark quickly then it is zinc-sulfide based, if still readable after one day in the dark, then it is amybe strontium-aluminate based. Ra on the dial however is indicating Radium. It is fading to 50% in about 1600 years, so it should be as bright as it was 50 years ago. By the way, one super compressor is my dream. I am jealous1 point

-

1 point

-

Found this nice little staking tool at a "buy out". Needed a good sprucing up but after some "spit and polish" turned out nice. Received a some amount of abuse in the form of well...I don't know how to put it...it seems one of its owners got carried away with a hammer and ruined a few stakes. Replaced of them, polished up the rest and refinished the wood holder. I believe this was a National. As you can see it's missing the pedestal. My instructor tells me watchmakers often removed it as it was awkward to work with. When I have the time and resources I'll turn a new one.1 point