Search the Community

Showing results for 'accutron' in topics.

-

Hi, Some of the first watches I worked on were accutron 214's and I have always liked them. Anyway a week or so ago I was searching the web and came across this one. It was described as humming but the hour and minute hands were hanging up as well as being 14kt gold. I decided to take a chance and put a $550.00 bid on it. It is turning into one of my favorites .

-

After Geo started the time to hum topichttp://www.watchrepairtalk.com/topic/426-time-to-hum-again/?hl=accutron#entry2872 I had to have one! I brought this little number yesterday & it arrived this morning. these are a really pleasing watch, prices are VERY reasonable & there's loads of history available about them online & the buzz from the tuning folk is lovely to listen to. I'm amazed these aren't dearer to buy. Anyway mines a 1969 (year I was born) Accutron spaceview, with the Swiss 770 case, wide gray chapter rings & orange second hand. the wider chapter ring & orange second hand tie in with it being a later 1969 as they changed these details due to falling sales against the increasingly popular 218 models. also my case back is missing the mention of water resistance which was taken off later in the 1969 year so its quite easy to date. Lee

-

Hi, my name is Mike. I have been a collector for over 20 years. I was in the process of teaching myself watchmaking when neuropathy in my hands kind of put a stop to it for the most part. I still try to tinker with my Timex watches as they are not quite as expensive if I goof. (Though that seems to be changing!). I still have a pretty big collection. I like Soviet era watches, and Accutron watches too. I have a running Soviet Slava Transistor (a virtual copy of the Accutron 214) that is one of my prized watches. I find it difficult to type so I wont be posting a bunch. I be happy to answer any questions if I can. Thanks all.

-

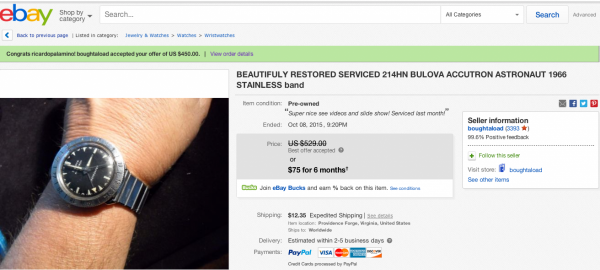

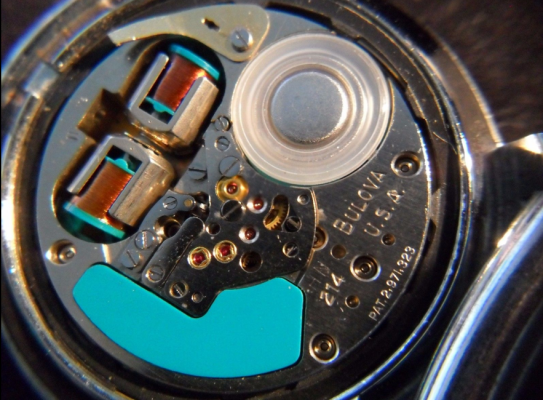

Hi All . Well I finally got an Astronaut !! I had been searching for a while , and bidding once in a while , but just missing on closing the deal at the last seconds a couple of times . I had this one in my Ebay watch-list and decided to pay a little more for one that had just been serviced by a watchmaker that specializes in accutrons , in New York . I made an offer that the seller accepted . The seller lives in Virginia . When I got the watch I could not set the hands so I contacted the seller . He in turn contacted the watchmaker who said he guarantees his work , so send it to him and he would take care of the problem . The seller paid for the postage and $500 insurance to New York and the watchmaker paid for the postage to get the watch back to me . It was delivered today and runs great . I had a new crystal waiting for it and I Installed it this evening .... I'm stoked . The attachments are the sellers pics ....... The watchmaker installed an Accucell 1.35 volt battery , which is the original operating voltage for the Accutrons . The actual watch with new crystal and the watchband look much better than the pics .

-

New type of balance

LittleWatchShop replied to AshF's topic in Chat About Watches & The Industry Here

Having spent the last 45 years as a technologist, seeing novel innovations like this is exciting. However, technology for the sake of itself may be little more than titillating. So...what have they done with this new innovation? Well, they merged two established arts: mechanical movements, with MEMs ((microelectromechanical systems) technology. MEMs stands on the shoulders of 60 years of silicon (not silicone, btw) fabrication technology. All of you have MEMs in your life already. It is in every one of your phones. Some of you (on another thread) are playing with MEMs microphones for watch timers. If it sounds like I am dumping on these guys, I am not. This is clever innovation. One market served by this innovation is the one where people desire a sweep second hand in a thin, low-power watch. This is the niche where they will thrive IMO. Accutron was the early sweep solution, but there were problems. Accutron now has a high-frequency watch with a sweep second, but I think it is power hungry and thick (correct me if I am wrong...going from memory). Is there another sweep-second solution out there? I have a friend who wears a Rolex. Probably worth 15 grand. Sends it in once a year for service at $600 a pop. There is much I do not understand about this business!! -

Nice. Impressive boom. I have been playing around with different configurations for magnification and for now am using a Bulova Accutron microscope (30x). For awhile, I had a setup similar to yours (different style boom) but I never got the viewing angle and body position right. Probably should revisit that someday. Using stereo magnification just cannot be beat.

-

A 344 has the same dimensions as a 343. That's what I use in my Accutron 214s. Is this an electromechanical balance watch or a tuning fork watch?

- 56 replies

-

- 1

-

-

- benrus

- electronic

-

(and 2 more)

Tagged with:

-

Update on my earlier comments about Accutron test gear. I found this picture of my Dad's watch bench (after he sold his business and was working from home). I believe that black unit is the Accutron test meter. I forgot about him having it and I do not know what happened to it--he probably sold it. Incidentally, that is the watch bench and equipment I inherited (sans the meter).

-

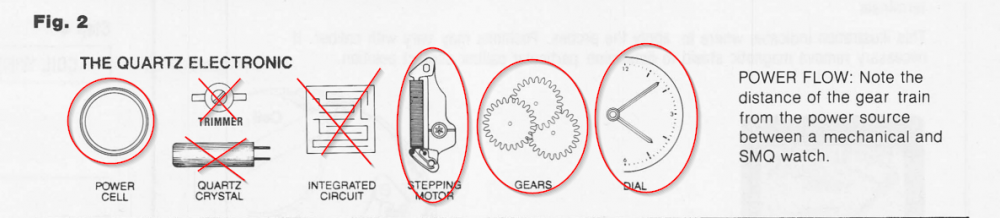

Re Tuning Fork watches: I have never worked on one. However, my father was trained to work on them--I have his certificate of training above the watch bench where I work. I have lots of Accutron coil assemblies that he labeled as "bad." I frankly do not know if they are bad and I wonder if he knew. He did not use any exotic equipment to test and repair Accutrons other than a Bulova monocular microscope. He used a Radio Shack analog volt-ohm meter and only used it for checking batteries (it is good for that). So I refer to the diagram in the SMQ service manual which I have attached with annotations. Those items encircled CAN be repaired. The X-marked items cannot (maybe the crystal for the fearless). So the only testing that needs to be done is that which points you to those items that can be repaired (as I alluded to in an earlier post). Back to the Accutron modules. There is a transistor, resistor and a capacitor as I recall. All three of those can be replaced if you have a fine soldering iron and sufficient skill. The equipment to test the transistor is, at worst, a curve tracer ($$$), and at best, a multimeter that has a transistor tester built in (cheap). But to test it you would need to remove it and extend the leads to fit in the transistor test socket (there are other ways...but). Can you find the transistor to replace a bad one??? I really do not know. I doubt it is a conventionally marked 2Nxxxx device. Resistors and capacitors are trivial to find. Measuring current to troubleshoot the gear train is a good idea, but why not do it the same way you do for mechanical watches?

-

Hi and greetings I have been given the instrument shown below. It was the property of a deceased watchmaker who like myself was also a radio ham. The donor believed it might be an item of radio equipment. The instrument says VEGAL made in England. No other marks or serial numbers. When plugged in the unit hums, I don't think it's mains hum as the frequency sounds too high, the loudness being controlled by the volume knowb. The switch is marked WATCHES, CLOCKS CLOCKS + 10 and T. FORK plus various numbers. The display ("Nixie tubes" ) displays numbers, could be frequency, time etc. The jack socket is simply marked INPUT I recall back in the 60's (yes I'm that old) an acquaintance had a Bulova accutron watch who's mechanism was controlled by a vibrating tuning fork, which could be heard humming if held near the ear. SO!! flash of inspiration. 1) The insrument was owned by a watchmaker and the switch positions obviously relate to timepieces 2) It has a setting marked T Fork 3) It hums Is it some sort of frequenct standard/calibration device/diagnostic aid for tuning fork watches ? Can anyone help Many thanks in advance Geoff

-

Assembling the Bulova Astronaut 214 bezel

clockboy replied to Blubarb's topic in Watch Repairs Help & Advice

Found this showing assembly sequence https://www.thewatchforum.co.uk/index.php?/topic/115197-accutron-astronaut-variant-guide-and-reference-info/ -

Library of Horology DVD...any good?

HectorLooi replied to LittleWatchShop's topic in Chat About Watches & The Industry Here

I have something similar bought off eBay. Except for the Accutron service manuals, I've not really explored the contents of the rest of my disc. But at $15.... you can't really complain much. -

As these Manuals are in the Public Domain I thought I would upload them. Hope they may be of use. Vich Accutron 218 service manual2.pdf Accutron218ServiceManual.pdf

-

I am in the process of building a custom tester based on the Accutron 600 test set. I choose the 600 because I have a pristine 700 and dont mind hacking the 600. I like the test set because of the huge 25ua meter! I am designing a variable battery source using a miniature digital volt meter mounted on a 3D printed module that plugs into the hole in the 600 test set (where the leads are stored). This is not a "does everything" tester either. It will let me test for low and high battery voltages, and also test pulse current. The picture shows the current state of the module--basically got the 3D print done. The electronics will be trivial.

-

https://hackaday.com/2021/02/13/tuning-fork-keeps-this-throwback-digital-clock-ticking/ https://www.secretbatcave.co.uk/projects/electromechanical-clock/ I stumbled on these in one of my newsfeeds the other day. Macro scale Accutron clock project. A third clock project popped up at the same time, but it's not exactly a time based clock. I guess these are cool all of a sudden maybe? Meanwhile, back at the lab, I've been learning about analog electronics. Building a 100% analog phono preamp on the side of my desk not occupied by work related detritus (watchmaking, unfortunately, commands nearly entirety of my desk surface, so it's been playing 3rd fiddle at best lately). Anyway, digging into the first one got me thinking. He mentions at the end of the video that accuracy varies according to ambient temperature, and there's some conversation in the comments about ways of compensating for that. My knee jerk reaction to an image of the final project was that the 7 segment displays could be replaced with nixies. The schematic for the tuning fork regulator part of the clock could easily be done with a simple and readily available dual triode. I'm not sure about the rest of the circuit yet, but those are bridges that can be crossed. The interesting thought involved the intersection of the analog electronics, the heat they produce, and the regulation of the tuning fork. The heating elements in the tubes put off a lot of heat. Especially if the entire thing were to be executed in analog circuitry (rectification, amplification, display, and I haven't figured out the totalizing/counting aspect of it yet). If all of that could be crammed under a double walled glass bell, there'd be some serious heat in there. Possibly enough to cause problems. BUT I think it might be self regulating.... As the heating coils get hotter, resistance drops. If the ambient temperature is higher, they consume less power, yadda, yadda, and I think you'd end up with a pretty stable, albeit high, temperature to keep the fork humming along at a pretty steady rate. That rate would NOT be the rate stamped into the side of the fork though, so there'd need to be some means of tuning that regulation... Not really sure about that yet. Not sure I'm going to do this yet. It's a pretty tall leap to get from basic AC rectification and signal amplification to a totalizer circuit of some sort, but I haven't had time to do anything more than read that article/watch the video. I recall having seen another guy on youtube (handle has to do with rabbits in Japanese or something) that might have done something along the lines of a counter/timer. Might be worth looking into that. Videos require less eye strain and concentration than reading, and my toddler likes videos on daddy's computer, meaning I stand a chance at being able to do such a thing. Anyway. Thought I'd drop this here to see what the horological hive mind thinks on the subject.

-

Tuning fork/analog electronic clock idea

spectre6000 replied to spectre6000's topic in All Things Clocks

Current thoughts: Power supply will be 170VDC tube rectified. The heater supply will be split off and rectified (solid state) for 5V and/or 12V depending on how things shake out. Tuning fork pickup/stimulator will be amplified via a dual triode. Preferably something readily available and in current production (though with current events...). Likely a 12AX7 of similar if I can make that work with the 170VDC (preferred by most nixie tubes). I don't know that I'll be able to handle the counter logic work and be tunable without a microcontroller... I have a handful of Arduinos, and another similar microcontroller board or two, so that should be easy. I had a neat idea to control the nixies from the microcontroller: an array of reed relays! They'll click quietly, but for different reasons than your typical clock. Additionally, there will be more information in the ticking, as there will be extra ticks every 10 seconds, minute, ten minutes, etc. It would take a total of 40-something relays (one for each number that is used, plus a few for some neon lamps) if I want to keep it simple. I might be able to figure out a way to multiplex them, but I'm not sure it really gives me any benefits. Enclosing the whole thing will bump up the temp and keep it stable to keep the tuning fork thermally stable. The point of the microcontroller counter is to be able to reduce the frequency being counted to account for this AND any manufacturing variances. Both of these factors will be unknown until it's done and in service, so the ability to control it on the fly is necessary for any accuracy. I'm hoping to be able to figure out how to suspend the tuning fork, pickup, and stimulator magnetically. I know it can be done actively, but I'm not sure it can't be done passively. If it can't be done passively, I'll use a series of springs or something. Total mechanical isolation, so the only way the hum can get out is through the air. Similarly/convesely, if I want the ticking relays to be audible, I'll need to mount them/that assembly (however it works out) either to a soundboard of sorts, or I might be able to get away with just mounting them to the side of the case somehow. So... The big question is accuracy... I'm pretty sure I'll be able to get the accuracy to within half a Hz of whatever frequency the tuning fork oscillates at. 440Hz is sort of the standard tuning fork frequency, but higher frequencies obviously decrease the potential error rate. It needs to be big enough to fit the look I'm going for (I don't know exactly how it's going to work proportionally), and it needs to be magnetic (apparently, a lot of tuning forks are made of aluminum these days). Assuming 400Hz (decreasing the 440Hz for temperature and to make a round number) and spherical chickens in a vacuum, I should be able to just barely edge out an Accutron at +/-1 minute per month. I'll have a higher frequency, more stable temperature, and no motion to account for. If it is close enough that it's not meaningfully out (~+/-5 minutes) over the course of 6 months, I'll be thrilled. I'm 99% sure this is my next big project. I've got another similar project currently in the works that I need to finish to make room though, and there will be some learning curve to this. I intend to prototype a subsystem at a time, probably starting with the tuning fork pickup/stimulator. I'll copy an existing transistor based circuit to start. It's a semi-known quantity, and I'll use it as a baseline. -

Citizen HISONIC movement (3711A date only model)

watchweasol replied to khang's topic in Watch Repairs Help & Advice

Well thats a bit unfortunate, from the enclosed blurb they are based on or exact copies of the bulova accutron made under licence, hope the attached will be of some use in determining the model you have and give you a lead as to the exchange unit if it can be found. One would suppose they are interchange able. I have also attached the sheet for the 214 which will be pretty close to the 218. Also have a look at Ranfft for the Bulova 218 for more tech details. Bulova Accutron 214.pdf Citizen - Electric Watches.html- 3 replies

-

- 1

-

-

- citizen hisonic

- caliber 3711a

-

(and 1 more)

Tagged with:

-

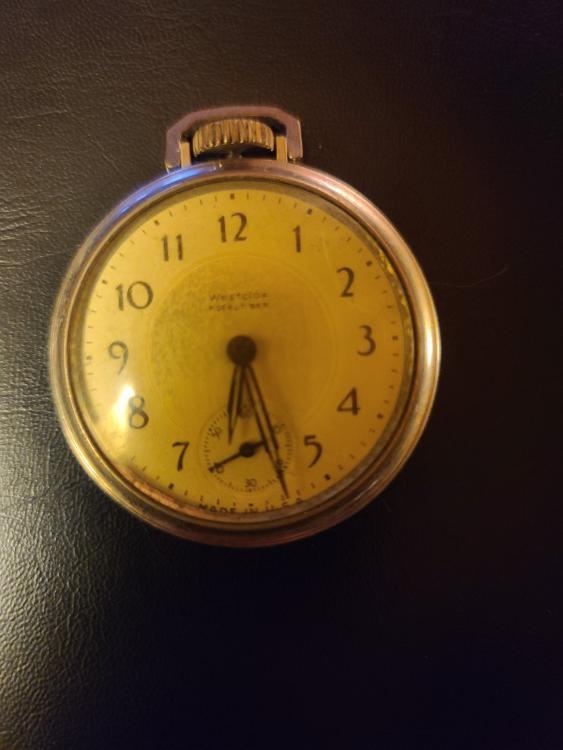

These are the watches I acquired from a local thrift shop, I am trying to figure out what exactly they are. I will try and give as much detail as I can. There is a Seikomatic-p, a Bulova accutron, a eternomatic, a Parker, 4 different Hamilton's, a westclox pocket watch, and a Virtus twin pocket watch. Any help is appreciated,

-

Which Watch Have You Got Coming In The Mail ? Show Us !!!

Jimg1969 replied to SCOTTY's topic in Your Watch Collection

Bought a lot for 16.00, looks to have a vintage bulova, a small accutron and one that looks to be a vintage mido multifort with a rectangle case. Should be here Thursday, can't wait. -

My first fix, almost, Timex, calendar stuck

HectorLooi replied to nickynoodles's topic in Watch Repairs Help & Advice

If you are really looking for a challenge, try an Accutron 214. You already have all the necessary tools for the job. I know you'll eventually succumb to it. -

Technique for pinion alignment for reassembly

HectorLooi replied to MrWhippy's topic in Watch Repairs Help & Advice

I used to use the technique described above by Nucejoe. It was also the technique taught to me by my mentor. But in recent years, I switched to using a technique which I learnt from YouTube. Basically, you put all the wheels into the holes of the bottom plate, stand them as upright as possible, then hover the upper plate over the wheels, trying to align the holes to the pivot and drop it on. There is a chance that you'll get a "hole-in-one" and all the pivots would go home into their respective holes. Failing which, you use the back end of your tweezer and tap lightly on the movement holder while observing the upper plate. The tapping will jar the wheels and when they are all aligned you'll be able to see the upper plate drop home. Sound ridiculously ludicrous, right? But I've been using this technique for the past 2 years, with only an occasional stubborn movement which will require the poke and pray method. And for Accutron movements, mastering this technique is essential to avoid damaging the delicate index wheel. Oh yes! May I add that with this method, I can get most top plates on in under 30 seconds. -

Looks like you've got your hands full. But Accutrons are really interesting. They are the only watches with true burnt coils, unlike quartz watches. Quartz coils normally break when someone slips with a screwdriver and scratch the surface. Accutrons have open coils with absolutely no visible physical damage. If one can repair the burnt coils, Accutron owners will beat a path to his front door.