Leaderboard

Popular Content

Showing content with the highest reputation on 03/21/24 in all areas

-

You didn‘t respond to John‘s request, did you? We need the size: is it a tiny ladies watch or a gents watch? Who knows? Frank3 points

-

3 points

-

you don't because the file size would be too big for the message board. It is also not one of the supported file types. That means you can upload it to YouTube because I think anybody can have a YouTube account and just upload anything they feel like or you find some other source or location to put your video file it and give a link for people can download it.2 points

-

What Mr. Wyler didn‘t know: the real danger is not the Eiffel tower - it‘s the amateur watch repairer . These balance wheels really look spectacular. But the wheel is stopped in a very harsh manner by its huge lever arm, compared to usual shock protections. And the pivots still get stressed. But a great watch, no question. A broken pivot can be replaced. I suppose, it is the upper one, that will be tricky. Frank2 points

-

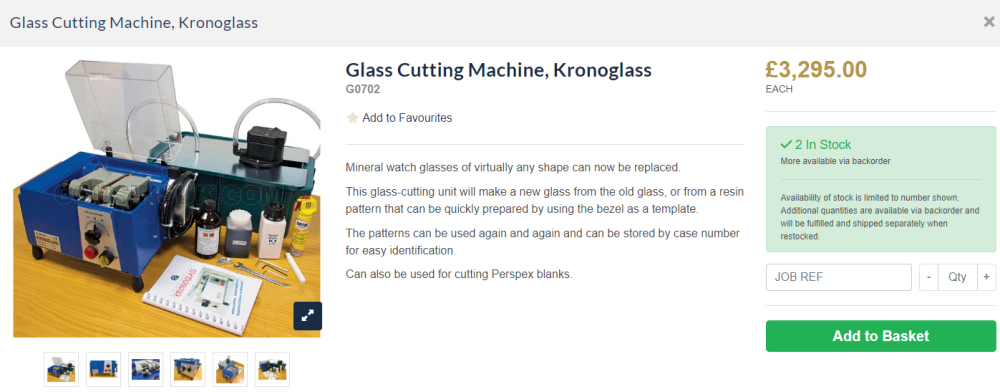

Here it is (Kristall 2000S Glass Grinder), was around £200 as I remember: I assume the S stands for the red 'sports - stripe' on the box Thinking that maybe the best way to do it would be to 3D print a dummy plastic crystal, and tweak until it is the perfect shape then superglue this dummy onto the rough cut crystal and then finish the shaping on the grinder - if you start grinding plastic you have gone too far. Once ground to the correct size you could dissolve off the plastic/superglue dummy with acetone leaving you with a pretty good crystal?2 points

-

A guy i worked wih years ago his wife made stained glass lead tarariums . To shape the glass she used a bench glass grinder, which is like a spindle moulder that i use for shaping timber, basically a drum sander fed through a hole in a table. You could make a miniature version of something similar using a dremel tool, if you could add a water feed that will reduce airborne glass particles, or just keep wetting down with a sprayer. Or work in a pan that holds a little water using a cordless dremmel.2 points

-

I found these guys in the UK, I haven't used them, so don't know if they can cut a new crystal without a blank, or what their prices are like, but they have an email address so may be worth asking - would be interested to know: https://www.crystalfit.co.uk/ I also found this web site which gives some basic instructions on hand making a crystal: https://german242.com/en/rectangular-bale-shape-watch-crystal-cutting/2 points

-

I can't open the links you provided, seems some sort of Microsoft were one has to log-in I'm using a Mac. However, I do have a Zeno wrist-watch with a ETA 2783 Wyler modified movement. Servicing was no different than any other watch. But it's a very interesting concept indeed ! Here some info you may find interesting; https://www.watchonista.com/articles/technology/wyler-and-revolutionary-incaflex-system-part-1 Pictures are better and long lasting. Links are questionable if they work, now or in the future. Forums a full of broken links.2 points

-

Yours looks a tad more stylish than my dresser. My wife wanted me to get rid of it as it was only holding clothes we no longer had a use for and it was taking up space. I was about to put a 'free' sign on it and put it by the curb but then realized it would work perfectly in my little watchmaking space.2 points

-

2 points

-

Self adhesive diamond lapping film would be a better option. I've altered bevel angles to glass to remove damage using diamond plates and polished the edge with emery paper. Heat does build up with the emery once the abrasive has worn so the paper has to be kept moving. The grit needs to be relatively high to start with anything below 800ish causes micro chips on the glass edge, grind from the front face to the inside just in case, the odd internal chip will be less visible. When it comes to innuendo and double entendre i will forever be extremely childish.1 point

-

1 point

-

1 point

-

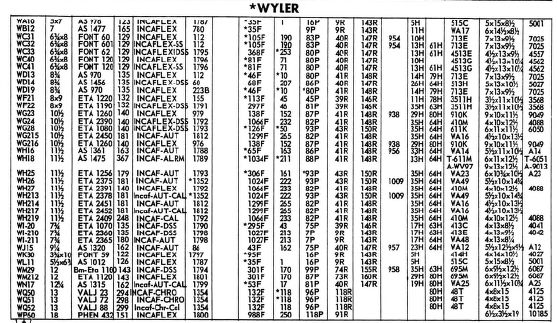

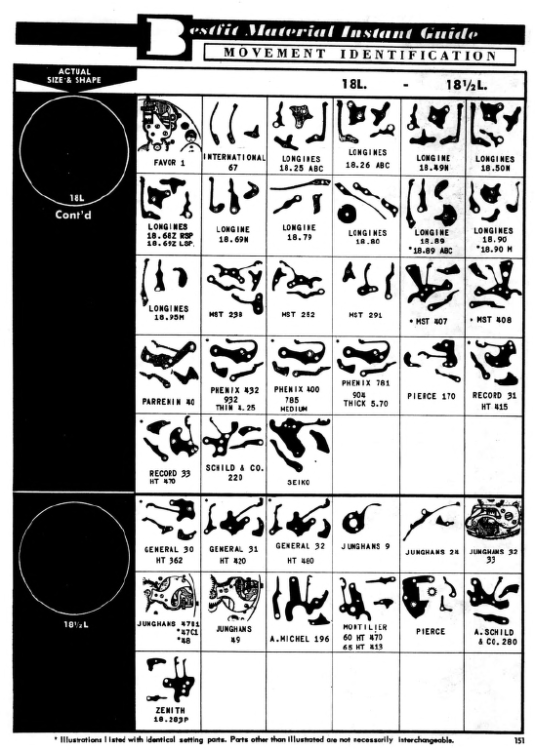

in watch repair the something called the fingerprint system. It has issues in that we have to have the right reference books and they tend to not go back that far the most common book used is the bestfit book which did come in various additions so if it's a vintage will need an earlier edition. Is a couple of different ways we can work the problem if we know the brand we can look through the list and providing it's not a big list like we have here we might observe that well there's only one pocket watch. then one of the columns indicates the page numbers were we could find the fingerprints this particular case it's page 151 where you see that the left-hand side diameters measured in ligne. If you don't have one of those gauges to do this no problem you just measuring your favorite measurement inches or metric go to the PDF which I've attached and see if it corresponds to anything. Size becomes a much bigger problem if it's a smaller watch because then there's way way more these to look at? In other words if you didn't have a starting point other than the size he would just go through the fingerprints to see if anything matches your watch and if somebody wasn't being helpful that would give us the size and then it gives way more things to look at or maybe not look at at all. So size really is important here as your watch doesn't appear to be on page 151. Which means I need to go look at older book to see if it's there but I'm not wasting my time unless I have a size. watch-ligne-size-chart.pdf1 point

-

The keyless works is quite unusual, with the diameter, as long as it's in the Bestfit books, it should be easy.1 point

-

Hi Robert. Had a look at the bits I have, 90 cm clock by ADMougin strike barrel missing, size between plates is 30.36mm, the arbour is 2.3 mm , wheel diameter 31.2mm, from thpivot ends 35.1 mm Teeth 78. Pinion leaves 12 As the tooth count differs it’s a non starter I am afraid.. what I would do is to undercut the slot where the teeth are missing to a dovetail shape and them if to can find a segment the same size nd pitch solder that in. Being dove tailed it will give a better hold regarding the rotational torque and be less likely to pull out. Once done cleaned up and polished it should be almost invisible.1 point

-

Hi without the size identifying it is nigh on impossible. Armed with the size we can reference the keyless work via the BestFit books even then it’s not a certainty.1 point

-

1 point

-

You could use double sided tape to stick finer grit paper to a velcro pad.1 point

-

1 point

-

My wife makes stained glass, always been in the back of my mind to see if her grinding tool could be used for this purpose.... only down side is that it may open the door to her borrowing my tools as a quid pro quo deal1 point

-

This place lists a number of Wyler balance staffs, but by part number: https://sdemanuele.com/shop/balance-staff-3401 point

-

1 point

-

1 point

-

. The good old days when watchmakers could be authorized to be service providers are centers. Citizen was interesting because one time to time care packages would come with all these nifty packages of citizen parts. So that means we would've had all the books but I also have a universal book with a whole bunch of stuff then as far as cutting crystals goes I also worked in a material house cutting glass crystals so yes it can be done but maybe we could find an original so in my universal book of a whole bunch a watch companies the way it's explained for citizen numbers is there's a four digit number that we could care less about and then there's the rest of the number that we care about no idea of the letters are important or not. 54 – 18714 that is the crystal number and minor confusion at least for me in the book is that in this particular section of cases for the crown in the stem well for the crown there's variations as it appears to be three different crowns with two different stems then the case number reference from the book doesn't translate to the website we needed this number. Unfortunately the number it yields does not translate to the main website as to an item? http://cgi.julesborel.com/cgi-bin/matcgi2?ref=CIT_CS^37-1017 looks like your little late but we get a picture and it looks like the right crystal so that means no show up again https://www.ebay.com/itm/134939666624 found another one that hasn't in stock apparently but I bet should be pricey to just order one Crystal. http://www.stsupply.com/watch-parts/parts-by-brand/citizen-parts/crystals/54-18174h-citizen-crystal.html1 point

-

Here is the machine they use to professionally to cut new crystals and how they do it, these machines are probably way to expensive (see below) for the hobbyist who will use it infrequently. The video also explains how to cut a new crystal even if you don't have the original or it is too damaged to act as a template as in your case. I I saw a video by Nekkid watchmaker where he cut one by hand using hand tools (can't find the youtube right now), the results were not great and took him several attempts to get a passible crystal. Perhaps the best solution may be if someone on here knows a friendly shop with such a device that would cut a new one for you, or you could find one locally? If you win the lottery and feel like buying a machine:1 point

-

Yes, I've seen that; 40mm x 40mm in several glass thicknesses. They are cheap too; £1.50 The inner edge of the Citizen measures ≈ 30 x 30 mm, so that seems quite some work, including the "rounded" edges Have you ever attempted to cut a crystal?1 point

-

Several companies sell crystals cut to size, cousins sell blanks.1 point

-

1 point

-

I know nothing about this watch but I wouldn't be surprised if your only option would be to find a donor. Of course, anything can be manufactured, it's only a matter of time and money If you can figure out the calibre number you might be able to find another calibre using the same escape wheel. That should make it easier to find a donor. https://www.emmywatch.com/db/search/?search=wyler&image=&type=movement1 point

-

Hi, I'm Dan - I tend to go by the internet handle of gutted. I'm a bit of a car nerd, and am quite into British cars from the 80s (my passion is for Austin Rover and MGs from the 80s). Other than having a passion for car mechanics, I'm a bit of a collector (my wife might use the word "hoarder"): I have quite a collection of CDs, and every once in a while I'll try and hunt down a CD to add to my collection; I have a decent collection of Target books from when I used to be into Doctor Who when I was a kid; and I still have all my old 'Zoids' toys from when I was a kid. I've not been caching for a while, but I occasionally go hunting for geocaching. So: 80s cars, CDs, Doctor Who, 'Zoids' and geocaching. AKA a bit of a nerd. I stumbled on an old Timex quartz watch (MG-branded, from the 80s!) and I've signed up here to see if I can learn how to bring it back to life. I'm keen to learn, but I'm starting from zero - please go easy on me if I ask daft questions! Dan.1 point

-

think about an automobile occasionally people change the oil in the engine because why exactly? In a watch you can't change the oil other than by doing a complete overhaul. This involves disassembly of the watch running all the components through a cleaning machine reassembly with lubrication. Otherwise in a watch the lubrication's typically get sticky with time in the watch. If you're lucky. If you're unlucky it will continue to run and where itself out or if the gaskets fail in the watch case and moisture gets in which is a problem for gaskets that are old then that is also bad. So proper servicing would be cleaning the watch replacing of all the gaskets. It would help if we had the model number of the watch so we know exactly which watch are talking about.1 point

-

After a long delay, I finally got a larger o-ring to seal the crystal. Somehow it's not thick enough to really grab the crystal, despite being the same size as the old one. Either way, the design of the case very firmly seals the crystal against the inside of the case, so I'm just going to wear it and keep it out of the sink. I think Pop-pop would be proud. And just to round out the whole story, mom texted me this after I sent pictures:1 point

-

hello everyone! im new to this forum. i never really used forums before so its a bit new and exciting at the same time. i will be posting my questions and topics later on but in the mean time ill tell a bit about myself. i am a 18 year old guy with a OBSESSION of watch collecting. ive grown up around watches and always had a love and passion for them. ive collected many over the years and will show my collection some time soon. i dont have any "high end luxury" brands like rolex, omega, etc but to me its not always about the brand but simply how the watch looks and some of their features. i have around 20 or 30 so watches all including brands like citizen, seiko, fossil, bulova, and a few others. not the most luxurious but they get the job done and still look incredible. thanks for stopping by to read all that haha hope you all can help me through my journey of the watch world and hope i can share and receive much knowledge from this community.1 point

-

1 point

-

1 point

-

I'm Jeff, live in middle Tennessee USA. Just turned 55. Work from home. Always loved tools and tinkering. Past woodworker, leatherworker. Current IT professional. Not real crazy about 'collecting' or hobbies for hobbies sake. My current hobby is actually trying to declutter and get life back on track. Never really considered watch repair/making as a hobby or pass time. Graduated college in the 90's with an art degree and did some jewelry making back then. Watches were always a mystery of science and technology that I didn't think were approachable. Well, now I've been gathering some cheap tools and movements. I've changed some batteries on quartz movements but haven't turned a screwdriver on anything mechanical yet. I'm afraid of losing or breaking a part and rendering something I paid for useless. Plus, one of the big rules in this is to remain calm, put yourself in a clear frame of mind and relax before starting a project. I have not been able to get there yet. Also, my vision sucks and I'm pondering what type of visual assistant I need. I've got some cheap loupes, but I would like something with a clear view where I can use both hands to work.1 point

-

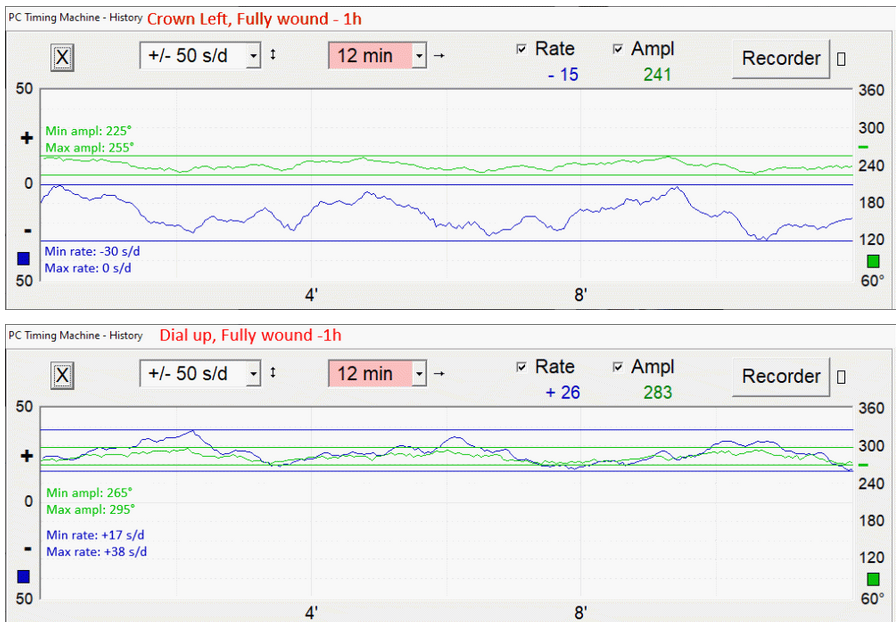

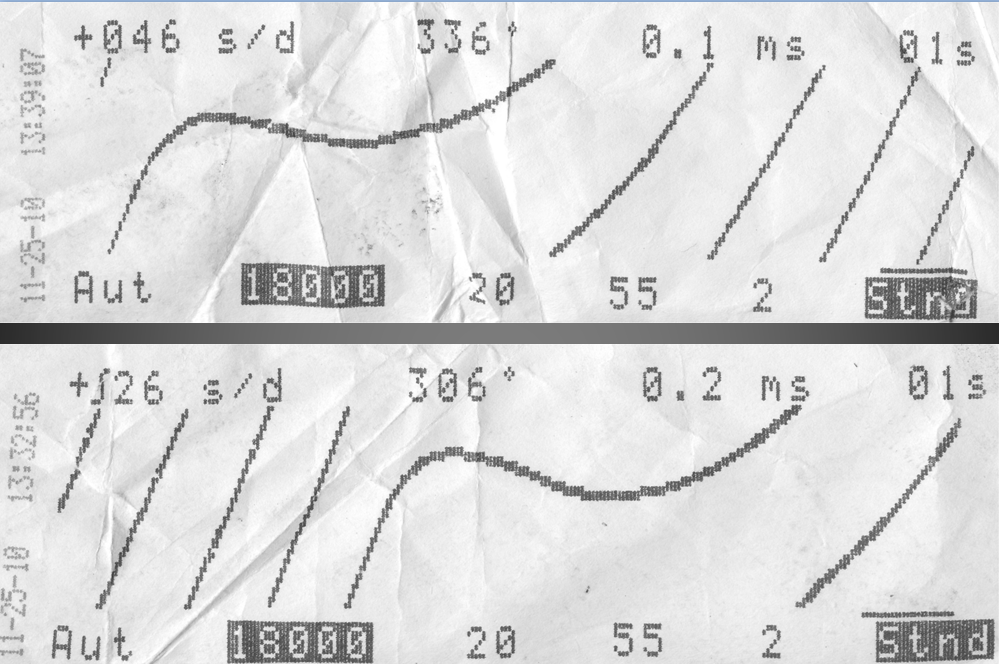

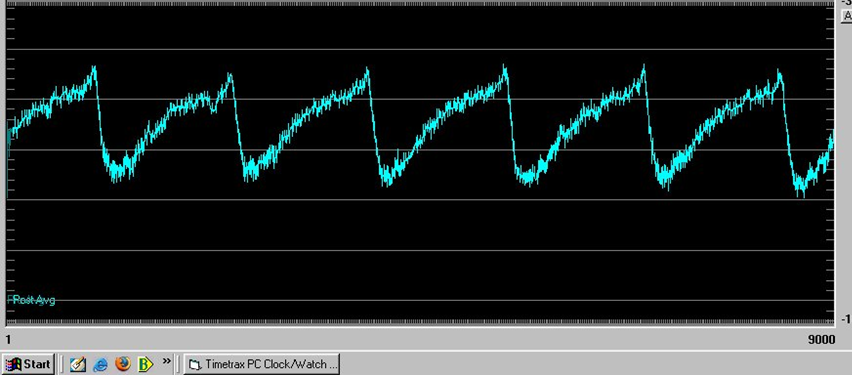

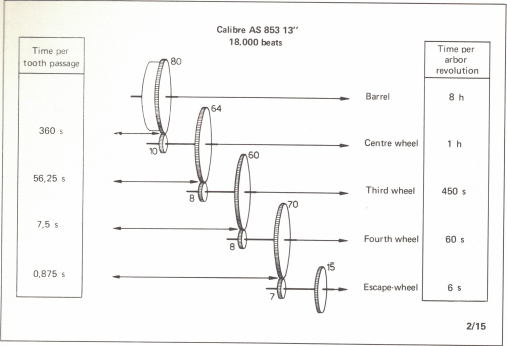

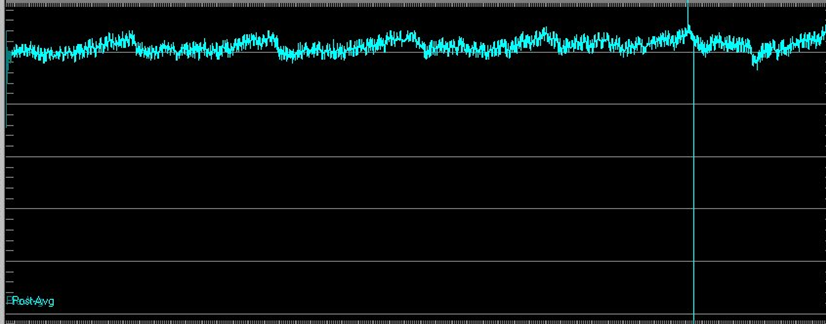

somewhere in the universe although as I'm answering this I remembered which discussion group. Somebody had a similar question loss basically expanded it to the watch would totally disintegrate in my think like 30 years. I'd have to go back and find the original discussion if I can the person seem to think that they hairspring would disintegrate like you describe and just metal on metal wearing out the entire watch. Except of course we all work on watches over 30 years and they obviously do not disintegrate. Plus somebody came along and explained why hairsprings do not have the same issues as mainsprings. Although hairsprings do end up with watchmakers insisting on bending and playing with them and torturing them etc. and that obviously is not good for the metal at all. one of the problems that you're having here it is what is the purpose of the test that started this discussion? Let me go and snip out the original image as you can see from images above this watch is horrible. Or is it? What is the purpose of the images up above in other words what exactly would use this test for? The real purpose this test is show the effect of amplitude on timekeeping. Or specifically you're looking for mechanical issues that are causing fluctuations in amplitude which unfortunately shows up with timekeeping. or basically everything affects timekeeping but amplitude is affected by the mechanical characteristics of the watch from the mainspring to the balance wheel and unfortunately as it's a mechanical watch your always going to have power fluctuations. so how do we rule out unacceptable fluctuations versus the natural characteristic of the watch? Usually if you can find a repeating pattern you can narrow it down to the offending components for instance I'm attaching a PDF. on the second page of the PDF it talks about 21st-century equipment versus paper tape timing machines. Then they give an example of timing problems solely caused by a faulty component. although off you have a user's manual for a paper tape machine it does explain that you can find faulty components by looking at the variations on your paper tape seeing how often they repeat and do the same thing without the fancy software. Even though it was claimed that you couldn't do that in other words you couldn't find a pattern? One of the problems that comes up with modern LCD-based timing machines versus software is limited screen size. In other words it makes it very hard to look for patterns you'll see variations in numbers but it's hard to tell what's going on which is why the display above is really nice to see if there is a problem. for instance here's a paper printout from a witschi timing machine it does look distorted because I changed the speed at which the image would move across the screen. In other words I was trying to figure out a way to extend the screen to being much longer as I was looking for a pattern as you can see there doesn't appear to be a pattern at all so basically we end up with a watch that I cannot time at all they cannot really figure out what the problem is and I actually cannot find a pattern even begin the figure out where the problem might be. Plus I agreed to service this watch for free as I was going to use it for the purposes of a lecture. In other words it's a nice railroad grade pocket watch and I wanted to show before how horrible amplitude is and how wonderful it looks after serviced and after servicing it looked exactly the same still horrible. Then I used software for a clock timing machine and came up with this interesting image one a minor problems we have with time plots and how they look is that they all do things a little bit differently. So this was occurring approximately every five minutes. Then we need another chart then I replaced something in the watch and we now get this one of the things that I was always bothered with was if I had put the hands on after servicing would the watch have Time? Because the pattern was repeating the watch would average that out may it would have Time. Oh and what did I change somebody had swapped the mainspring barrel for something different were getting a binding between the mainspring in the center wheel pinion. so the problem you're having is what exactly is the problem? the purpose of the test image is to look for mechanical problems causing amplitude problems. Because it's a mechanical watch your always going to have variations so are the variations in this watch abnormal or normal for this watch? Once we eliminate the mechanical issues beyond it's a mechanical watch then you can work on timing issues. for timing issues I recommend going back to the normal display that were used to and make sure you have your averaging times set correctly. In other words while the graphical display is basically real time years of the numbers are averaged over time. Anywhere from 20 to 40 seconds depending upon whose specs you're looking at. So basically they will average out the problems were seeing on this time plot. one of my amusements with students that go to the same school is that you have different instructors. So this gives you different experiences like what exactly is tight anyway as I don't remember any thing like this? Then did you know that Rolex at least in Geneva as I visited their service center replace all the screws in the watch every time they service the watch. then why did they do that because they use power screwdrivers and tighten those things down as tight as you can get them which has a problem. How many times can you tighten screw down really tight before the hints break off. So they replace the screws every single time. So personally I don't think they have to be so tight that you're in danger snapping head off that's too tight in my opinion. but the screws definitely shouldn't be falling out either which I've occasionally see and where people just don't tighten their screws tight enough. Horologica Times -- May 2004 From the Workshop witschi time plot.pdf1 point

-

Update. Ran into a winding problem since some desperate previous repair guy had fitted the wrong winding gear. Cousins had one ! Turns out the movement is the slightly different 022 - 18 Looks like the one LH screw fixing for the crown wheel got updated to the two screw style.1 point

-

A basic check one does when checking a hairspring is how well centered and flat it is at the collet. Out of flat is visually quite clear in the watch, out of center is harder to describe, mainly the inner 1/2 of the coils look "jumpy" as the balance oscillates. Adjustment is done with the balance out, hairspring on, in ideally a set of hairspring truing calipers. These permit a better view of the spring, and better access, than regular calipers, though those work as well. Adjustment is done on the first 180 degrees or so of the spring from the collet. The caliper is adjusted so the balance can spin with no play. Just slowly turning the balance, follow the first coil/s of the spring from its exit from the collet, and it should make a nice progressive spiral. If it is out of center, it will seem to spiral out, then cease, then out, or even go back-and-forth sort of. As with everything it takes a bit of practice to figure out where and how much to adjust, but the basic rules of hairspring adjusting still apply. Adjustment in the flat is done 180 degrees from maximum error, in the round, 90 degrees. When checking the flat in the caliper, you have to focus on the first 4-5 coils, as the rest are influenced by the weight of the stud and will naturally look low. When all good, those first few coils will look distinctly flat viewed from the side, and the whole spring will look like one of the optical illusion spirals as the balance slowly spins (viewed from above). The effect on timing from a spring out of true at the collet can vary from almost unnoticeable to rather extreme. I was just working on a new-build, first time on the timing machine. I saw there was a little truing needed at the collet, but ran a cycle anyway. In my case, the verticals were slow compared to the horizontal, with an apparent poise error equaling 60s. I trued it at the collet, and the difference in both h/v and the "poise error" were cut in half. Another reason not to chase dynamic poise if everything isn't as perfect as possible. The effect of centering at the collet is used by good regleurs sometimes by introducing an error. Sometimes you find the verticals just want to run slow, with regulator pins adjusted perfectly etc. Like, perfect poise, but 15s slower than horizontal. Sometimes throwing the centering out at the collet by say half a spring thickness can resolve this. It is pretty much unnoticeable visually. Also, you have to guess which way to "throw it out", haha. A Levin hairspring truing caliper and a Swiss simple caliper that works well too1 point

-

Watch movements are very complex and inter-related mechanisms. If a tooth is bad, then the periodicity of a problem can simply be related to the time taken for one revolution of that wheel. However, if two interacting wheels have slightly bent pivots, worn jewels or are otherwise less then perfectly centered, it can theoretically be more complex. There can be some points where those problems would add together to bog down the movement, but other times where they could cancel each other out and give better performance. As they rotate at different speeds, those points of deflection would come and go and set up a resonance (for lack of a better term) that would repeatedly occur with a timing different than either of their rotation rates but related to their tooth ratio. Not sure that this would be relevant to your problem, but it seems to me that an issue that occurs somewhat rhythmically over the course of many minutes would be more related to the wheel train than a hairspring problem. But then again, my experience with hairspring manipulation rounds to zero, so you should listen to others!1 point

-

1 point

-

1 point