Leaderboard

Popular Content

Showing content with the highest reputation on 03/15/24 in all areas

-

A basic check one does when checking a hairspring is how well centered and flat it is at the collet. Out of flat is visually quite clear in the watch, out of center is harder to describe, mainly the inner 1/2 of the coils look "jumpy" as the balance oscillates. Adjustment is done with the balance out, hairspring on, in ideally a set of hairspring truing calipers. These permit a better view of the spring, and better access, than regular calipers, though those work as well. Adjustment is done on the first 180 degrees or so of the spring from the collet. The caliper is adjusted so the balance can spin with no play. Just slowly turning the balance, follow the first coil/s of the spring from its exit from the collet, and it should make a nice progressive spiral. If it is out of center, it will seem to spiral out, then cease, then out, or even go back-and-forth sort of. As with everything it takes a bit of practice to figure out where and how much to adjust, but the basic rules of hairspring adjusting still apply. Adjustment in the flat is done 180 degrees from maximum error, in the round, 90 degrees. When checking the flat in the caliper, you have to focus on the first 4-5 coils, as the rest are influenced by the weight of the stud and will naturally look low. When all good, those first few coils will look distinctly flat viewed from the side, and the whole spring will look like one of the optical illusion spirals as the balance slowly spins (viewed from above). The effect on timing from a spring out of true at the collet can vary from almost unnoticeable to rather extreme. I was just working on a new-build, first time on the timing machine. I saw there was a little truing needed at the collet, but ran a cycle anyway. In my case, the verticals were slow compared to the horizontal, with an apparent poise error equaling 60s. I trued it at the collet, and the difference in both h/v and the "poise error" were cut in half. Another reason not to chase dynamic poise if everything isn't as perfect as possible. The effect of centering at the collet is used by good regleurs sometimes by introducing an error. Sometimes you find the verticals just want to run slow, with regulator pins adjusted perfectly etc. Like, perfect poise, but 15s slower than horizontal. Sometimes throwing the centering out at the collet by say half a spring thickness can resolve this. It is pretty much unnoticeable visually. Also, you have to guess which way to "throw it out", haha. A Levin hairspring truing caliper and a Swiss simple caliper that works well too3 points

-

whenever I have timing problems at work usually the first thing I look at is the plot like this and the oscilloscope. I use it to explain why I'm having timing problems. But based on my past knowledge of you and a timing machine I would throw all of this away because you're going to lose your mind and become obsessed about a problem that you may or may not ever be able to fix or a problem doesn't actually exist sort of. yes one of the problems with the watch is a set of gears that in order to produce absolutely linear perfect power ideally shouldn't even be gears at all as gears will always produce pulsations of power. Then if everything isn't exactly perfect like the manufacturing the wheels are slightly out around pivots that don't fit absolutely perfectly or even if somebody furnishes the pivots and are slightly too small soup of flopping around in the whole not by very much conceivably will cause power surges as the tiny bit of the wheels moving around binding up with the gear train. Watches are really interesting things in that the average out a lot of their problems. Timing machines though will show all of these problems that may or may not really be a problem. For instance with this watch does it actually keep time with the hands on? I have a interesting book recommendation is that expensive book I have a video of a book review. It has a nice job of reviewing it it's not a perfect book but it sometimes has its moments. Like for instance there's a section on gears. then it even is a section on the faults of gearing fortunately that's only a couple of pages I could probably scanned that in. Where I'm going with this is watches are mechanical devices gear trains produce power fluctuations watches will still keep really good time with power fluctuations up to a certain points. Be careful not to get obsessed about timing machines software or if you think your first experience with a timing machine was a nightmare this will send you straight to the psychiatric ward. Understand why you're using the software and why you're looking at it. it's amazing how a few words can instantaneously cause of flashback to something in the past which I found to be a pain in the ass. One of my friends had centered his hairspring exactly as you describe and had it perfectly centered exactly as you described. But physically centering without the balance wheel in this case with the Hamilton 992 result of the hairspring that was not flat and not right at all with the over coil. I spent hours of time analyzing trying to figure out where he bent looking at another watch to put the hairspring back right because of what I perceive a stupid method of doing things. The preferred centering is with the balance wheel and hairspring together. Exactly what is described in the first quote above. it's one of the objections I have when people have hairspring issues and everyone says take the balance out of the watch hairspring issues with balance wheels typically occur in the watch you have to be able to see the problem in the watch you don't always have to fix it in the watch but you have to see the problem in the watch balance wheels out of the watch a lot of times a look really nice but not in the watch and collets perfectly centered aren't actually centered at all necessarily.3 points

-

2 points

-

Silly me, been shopping for a Bergeon pinion polisher tool.2 points

-

2 points

-

1 point

-

Hi difficult to see from the picture but the obvious thing to do is to pull out the stem and look for the release nib coming into view as some watches have it hidden untill the stem is pulled out1 point

-

1 point

-

They can work, but you can see how extreme the Levin is in removing the maximum material on the caliper above the spring to allow proper viewing. The Swiss one has more material but works- though it is less handy than the Levin.1 point

-

1 point

-

Hello, I have been unable to respond to the replies here due to personal issues but I appreciate the efforts that you have all made. I have as was suggested through a minute amount of trial and error now managed to get the clock running and in fact it is running close to perfect timing according to my radio controlled quartz wall clock. Thanks again1 point

-

Most likely from the use of a water based cleaner and inadequate drying.1 point

-

1 point

-

Likely nothing new to you but as it has been working so well for me I just thought I'd mention that I got a tip from @nickelsilver to pre-clean the pinions by pressing them into peg wood soaked with a degreaser. It has made a significant difference and has saved a lot of time.1 point

-

A test to check for bent pivot, when you don't have dedicated tools . Remove a cap stone, lock shock spring on chaton, spin the balance, observe the pivot. Replace the cap stone , remove other side's cap stone , to check the other pivot. This test is as accurate as the observer.1 point

-

Just add a drop of oil and mix, you can shape the peg wood to fit between the pinons.1 point

-

Do not heat the the bearings. The heat can affect the temper of the bearing steel and also melt the packing grease inside the bearings. The motor shaft needs to be clean and rust free. Sandpaper and steel wool would do an adequate job. You will need a pipe that fits over the shaft loosely to tap the new bearings into the bearing seat. Watch the video below for a clearer explanation.1 point

-

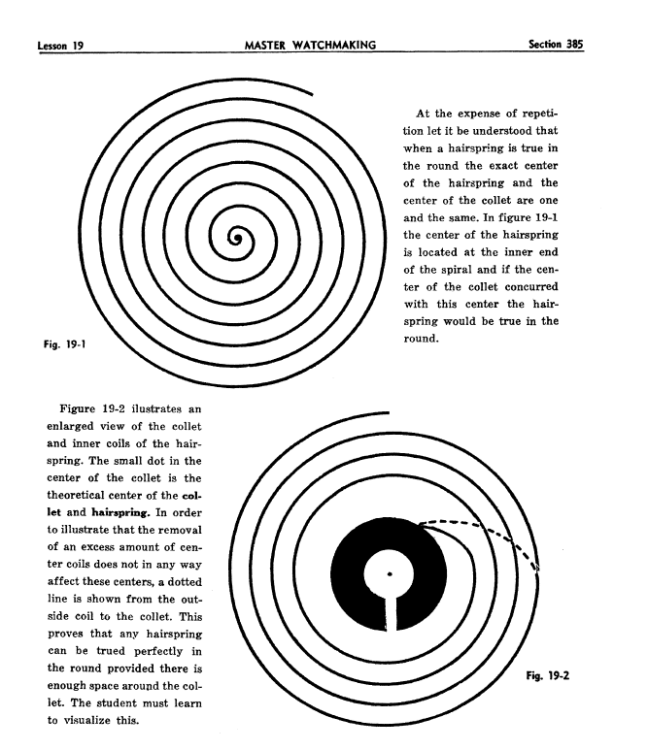

See, the hairspring has a imaginable center. It doesn't exist as some of the spring has been cut to make room for the collet, but even when manufactired, the spring didn't go to it's center. The idea of centering is to adjust the collet position so the collet hole center coincides with the hairspring center. Nothing to do with the spring on the bridge and the collet above the stone. This is done by bending the internal spring coil near the place where it is pinned or attached to the collet. You can imagine the well centered spring as a groove of vinyl record. If the record is centered on the platter, then the arm moves gradually and only to the center when the record plays. If the record has big center hole (45 RPM one) and it is placed not centric on the platter, then the arm constantly moves in/out. Such is the behavior of not centered spring. The centering of the spring to the collet is usually well described in the books where the attaching and pinning the spring to the collet is described. And yes, I mean the spring can touch the collet and this can 'short' the entire internal coil if the spring is not well centered to the collet. Also, not centered to the collet spring brings bad poising to the balance.1 point

-

Watch movements are very complex and inter-related mechanisms. If a tooth is bad, then the periodicity of a problem can simply be related to the time taken for one revolution of that wheel. However, if two interacting wheels have slightly bent pivots, worn jewels or are otherwise less then perfectly centered, it can theoretically be more complex. There can be some points where those problems would add together to bog down the movement, but other times where they could cancel each other out and give better performance. As they rotate at different speeds, those points of deflection would come and go and set up a resonance (for lack of a better term) that would repeatedly occur with a timing different than either of their rotation rates but related to their tooth ratio. Not sure that this would be relevant to your problem, but it seems to me that an issue that occurs somewhat rhythmically over the course of many minutes would be more related to the wheel train than a hairspring problem. But then again, my experience with hairspring manipulation rounds to zero, so you should listen to others!1 point

-

Update to this. I was able to order V105 via UPS ground. I guess the next step is to buy something I can use it on.1 point

-

This is it. I've seen it on other calibers (jlc in particular). Back in the day casebacks could be very thin, and this guards against influence on the movement.1 point

-

I find the website below good for finding parts. the second link has your watch list all the parts and when you click on the parts you can find everything that cross references to that part. this then gives you more watches to look for and then you can take the part number and go to the homepage and do a search there you then get the third link where it looks like it's available. then the fourth link eBay looks like it might be the right thing http://cgi.julesborel.com/ http://cgi.julesborel.com/cgi-bin/matcgi2?ref=ELG_720 http://www.julesborel.com/s.nl/it.A/id.25979/.f https://www.ebay.com/itm/3140968913721 point

-

This is a homemade quartz watch movement assembly aid that I use for those pesky rotors that just won't stay in their holes. It's made from popsicle sticks glued together with a strip of magnet on one side. The magnet holds the stator and the rotor down on the bottom plate and stops them from sticking to each other. You have to try to believe how effective this trick is. Another thing I forgot to mention, anti-magnetic tweezers are an absolute must. I prefer brass or titanium tweezers.1 point

-

Hi. Ca you give us a post of the complete back plate so as to confirm your identification. The kundo junior suspensions are all 0023” or .058mm lengh approx 90 mm measuring the old twisted spring is a no no as its length will be compromised by the twist. The recommended suspension is 5E in the Terwillers 400 day book. It also gives you the block positions , top and bottom when making up the suspension. These clocks look simple and in a way they are but and it’s a big but is they MUST be level and adjusting the beat without the correct tool is possible but not easy to achieve. There are also two styles of anchor post which have to be taken into consideration. Suspension units are available from Cousins UK, Esslingers, and Jules Borel, timesavers in the USA. I cropped springs to fit with no ill effect. The thickness is critical as the clock works by rotating / torsion with minimum friction. It has to be set up properly or it will not run The full height of the suspension including blocks is 94mm measurement taken from the book.1 point