Leaderboard

Popular Content

Showing content with the highest reputation on 03/11/24 in all areas

-

The different rate at crown left on my Longines was bugging me. So as golf was rained off yesterday, I decided to have another go at dynamic balancing. After 9 iterations I got the numbers below. I could have had one more go to get even closer, but when wearing the watch it will mostly be CL and CD, and as these are -4 and +5, they should cancel out. And it takes time. Each iteration is taking timegrapher readings in all positions at full wind and about 160° amplitude. Remove the balance and remove some metal from the appropriate screw, put it back together and repeat. In my previous figures I had the hairspring pushing on one regulator pins too much. After correcting the vertical amplitudes are much better. Amp +/-s Du 296 3 DD 299 -4 Cu 275 -6 CL 283 -4 CD 284 5 And now I should be both accurate AND precise. (After 8 hours wear today, still within 1s of true time) I won't be doing this with many of my watches, it's hard work! ....... and of course there's other effects - partial winding, temperature, the watch actually moving on the wrist. Maybe I'll try swinging it on the timegrapher! Edit: As an afterthought - I posted previously about how flat the end of the balance pivots look on these movements. This has the effect of more closely matching vertical and horizontal amplitudes, as can be seen in the figures. I read that this technique is used in some high end pocket watches.4 points

-

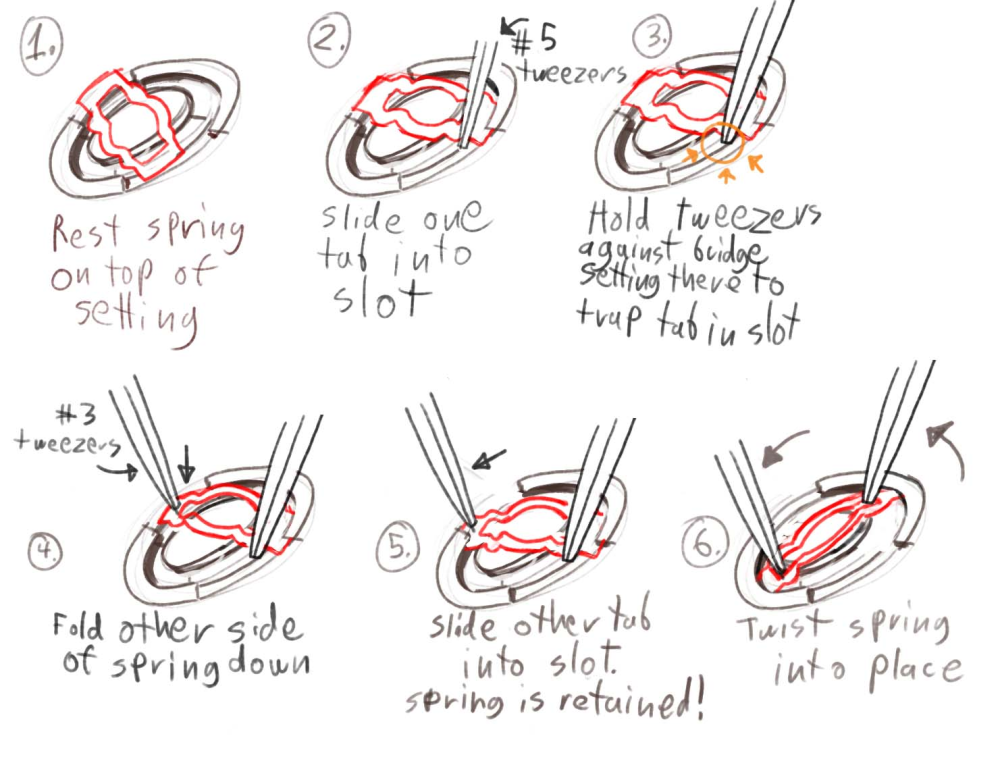

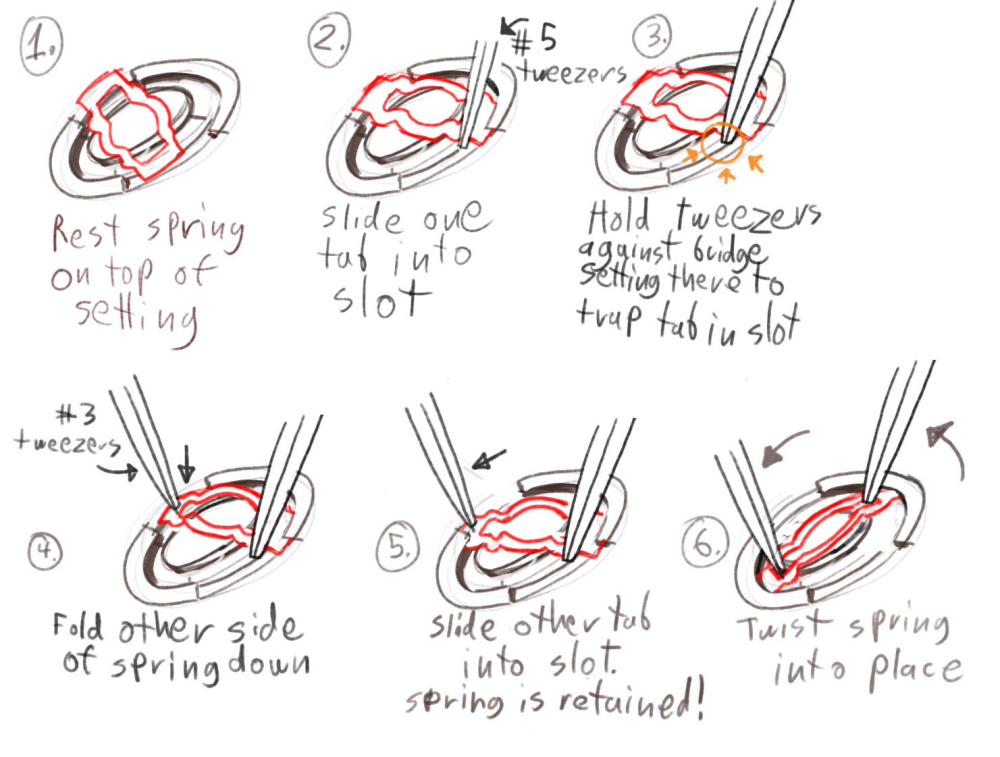

Those things were designed by a sadist. Using this technique i've had even the small bridge train ones down to a science for awhile. Even with being able to set them in seconds i STILL lost one last week. The nice thing about them is if you practice practice practice and can set them easily almost anything else you gotta do with tweezers seems like a cake walk.3 points

-

You could have found it! The hairspring was OK, but at some stage I must have touched the terminal coil and not noticed. It's hard to see under the cock, it's a big one (), but It's bunched up on the side of the stud - see stationary pic below. It looks like the coils could be touching each other at some point at high amplitude. When vertical they separate out more, hence the slower rate. That explains why the rates look so consistent at very low amplitude. How did I not notice that I feel foolish now, D'oh2 points

-

I managed to safely remove the rotor from the bearing, but the bearing remained stuck in a blind hole, so I tried the old bread trick, and it worked! Physics--it's not just for physicists! The bearing were pretty bound up, and rather than try to repack 75-year-old bearings, I've ordered a couple replacements.1 point

-

The Horolovar 400 day repair guide has a lot of errors see here https://mb.nawcc.org/threads/horolovar-400-day-clock-repair-guide-10th-edition-errors-and-updates.178946/ but for anyone new to repairing torsion clocks it’s invaluable I have over 30 in my collection and have probably done over a hundred but they can still be frustrating sometimes. A few more of my clocks the last picture is a Schatz 1000 day can run on one wind for three years. Dell1 point

-

The low amplitude is specifically chosen Joe. Both low amplitudes below 220° and high amplitudes above 220° will amplify any out of balance of the wheel, making it easier to find. There wlll come a point of too low an amplitude that makes the readings unreliable, too much portion of the swing taken up by the escapement.1 point

-

The hairspring is favoring the inside pin, but I don't think that's the issue. How does it look from the top with power off? From the vid there could be a chance it's just touching the stud at high amplitude, that would cause a significant gain, which would show up as a significant loss at lower amplitude; what's the rate horizontal at low amplitude? Sometimes there's a bit of spring sticking out the stud that can get bent toward the spring body and touch.1 point

-

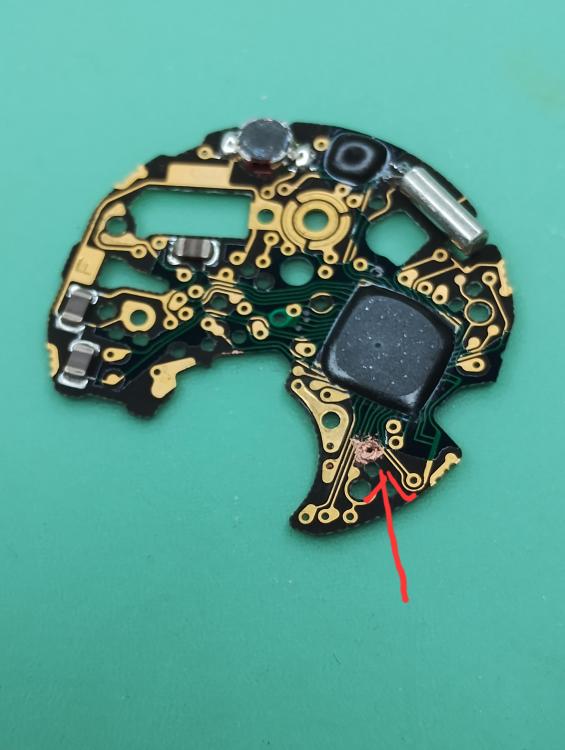

Hi I have attached another book which might help. On your circuit board there is a pad marked. Plus. +. And next to it is another marked minus. - Theses two pads are the power input to the board, without the right tools diagnosis of the board on its own is very difficult. In its disassembled state all you can check is the coils and visually check the tracks on the board. To check the board on its own requires a power source, a load and probably an oscilloscope plus circuit diagram. Have a read of the attachment as it outlines quartz watch workings ant testing equipment and meter usage and understanding. ElectricWatchRepairManual.pdf1 point

-

Hi this book by Henry B Fried goes so way to explaining magnetism it’s als worth a read. Electric_Watch_Repair_Manual.pdf1 point

-

1 point

-

Thought you had. Dynamic balancing is interesting, but you can spend a lot of time getting a watch right. The link you posted is my main reference point. Worth a read if you are interested. What I really need are some small timing washers. Very hard to find. I've been looking on ebay for ages, but it's usually pocket watch washers that come up.1 point

-

1 point

-

Unfortunately videos didn't open on my tablet. Amplitude drop in vertical positions is expected cuz pivots ride on jewels ( hole jewels), therefore friction increase thus lower amp, but 160 is uncommonly low, so Are numbers regarded as valid with 160 amp? Side shakes algebrically add up in vertical positions, which can result in heavy pallete lock, affect guard pin' roller table clearance. I would give another clean to jewels in escapement plus check side shakes therein. Rgds1 point

-

Hi Khan if you haven’t got the technical document I have enclosed it for you if you put a meter on the ohms range and short the points you will get full scale deflection. So likewise if you place the probes on a wire coil if the coil is intact get the same if no reading at all the coil is said to be open circuit, a break in the wire , it is conceivable that the CMOS is dead that’s why you need to verify the circuit is getting power. 6M15A&6M91A.pdf1 point

-

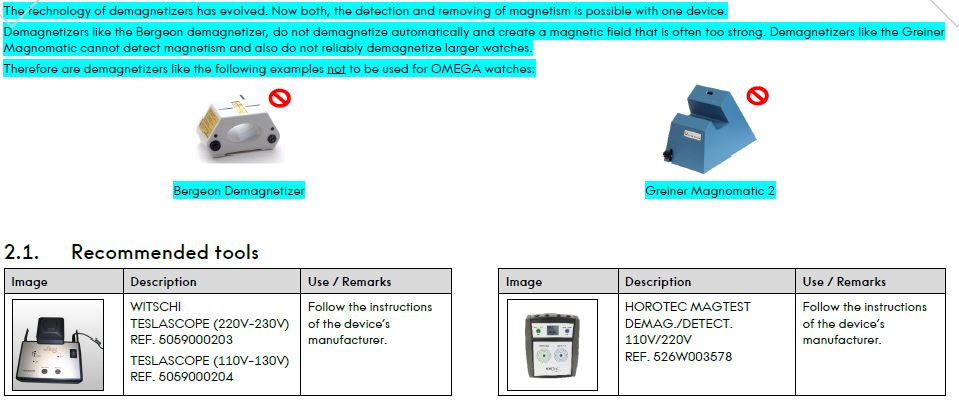

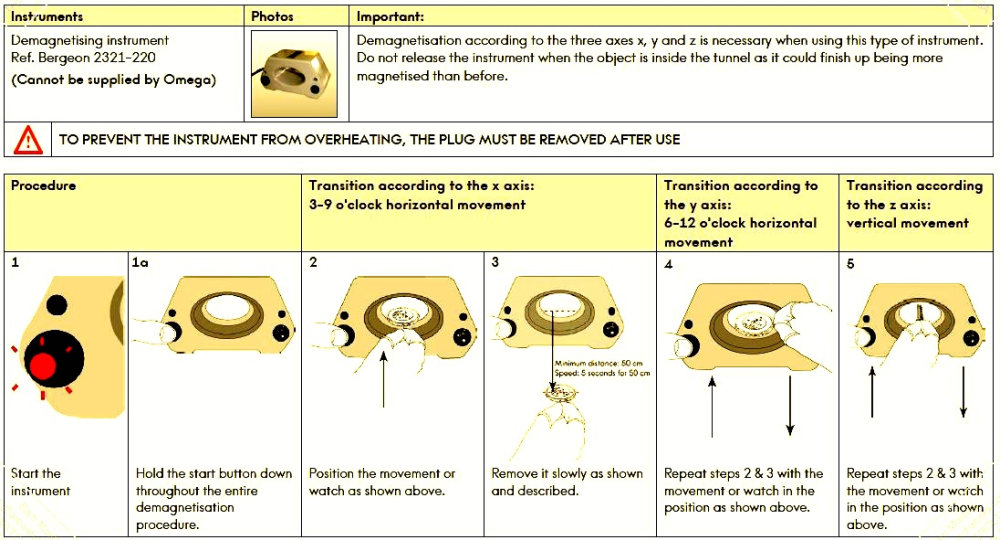

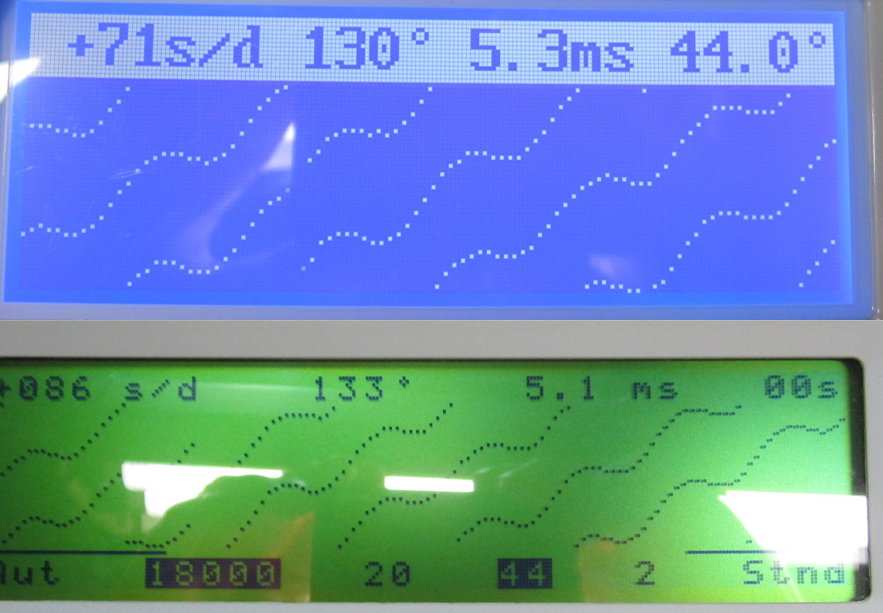

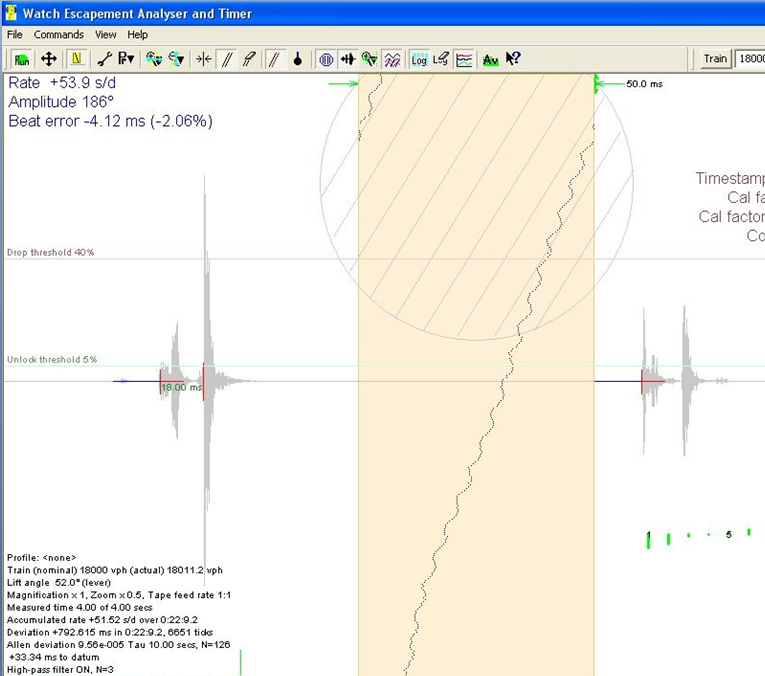

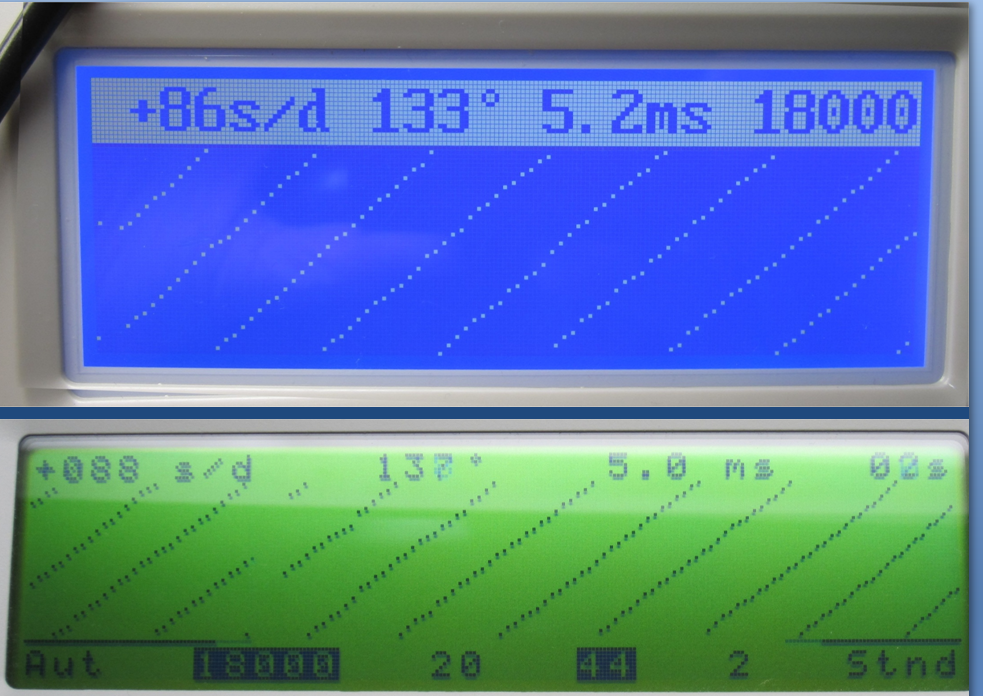

you're not the only one in the make the observation of they work okay and maybe they can work better? Here's an example from a watch company Omega watch companies are interesting continuously changing their thoughts and ideas on how to solve a problem and typically throwing lots of money at the problem. That's because they have a infinite supply of money unlike us. so let's go back to an earlier sheet from Omega where they did recommend one of the tools up above. Basically a much fancier version of your blue box and demonstrates how it has to be used. In other words when you push the button and produces a alternating magnetic field and whatever you're trying to remove the field from has to be slowly withdrawn if you expected to become demagnetized. Otherwise you just place it on her in and push the button ou'll achieve exactly the opposite. These all work by magnetizing the watch with the sine wave of the power going in and as you slowly withdraw you slowly cause the magnetism to diminish to nothing providing you do it correctly. then this is watch repair there is almost never one procedure for anything. So yes there's a whole bunch of different tools for demagnetize ing. I suppose it has to do with how much money you have. Then is it necessary no if you don't care about the watch running or keeping time if you don't care about those things then yes it's necessary. Then it depends upon how obsessed you are for when you should do this? When the watchmakers I used to work with when the watch came out the cleaning machine he would demagnetize all of the individual parts baskets before reassembly and I assume he did it after assembly but I don't actually know. somewhere is at a lecture where I'm not sure they actually carried the demagnetize are on the tool belt but if they had a tool belt it would've been on their. In other words they were continuously doing it because it doesn't actually hurts anything for the most part then does it matter? Normally what I been taught in school before putting the watch on the timing machine you always demagnetize but by doing that you miss out on something? I was once doing a comparison of a witschi timing machine and the Chinese 1000. I did not demagnetize I timed the watches loaned to me by the person who loaned the timing machine and found something really fascinating yes this watch desperately needs to be serviced but what else does it have going wrong? here is a timing machine program notice in the simulated paper tape the same affect the scene on the graphical display notice the watch still needs to be serviced but something is changed? then from out of the timing machine manual telling you the same thing we have yes magnetized watch is not a good thing. Really gets bad enough they hairspring coils could stick together in the watch will run insanely fast. So as part of his servicing watch has to be demagnetized that includes even modern watches we do it all the time in the shop is put it on the demagnetizer including watches that claim they can't be magnetized.1 point

-

As long as you can get the jewel holes and the cap jewels spotless, by all means, but I don't think that is possible.1 point

-

A, now I see, it was the ring that holds the spring... Othervice, no problem to put the GR spring in the barrel, even if the barrel size was 7mm1 point

-

Yup. I got one in today using this method. Hasn’t worked yet on the little ones. I only realized after I took them out that I probably didn’t need to. BTW - my theory - this is how the Japanese got back at the rest of the world for the Americans dropping a bomb on them. Long, steady torture.1 point

-

This spot here looks like the conductive paint is shorting out a few tracks. As this is a double sided pcb, things become a lot more complicated because of "through hole vias". This means that the holes have copper in them that connect one side of the pcb to the other. You'll have to check for continuity on one side to the other side wherever there is a hole. There is still the possibility that the IC itself is damaged.1 point

-

That is not swinging well ! You have something wrong with the balance. How much end-shake do you have? Grab the balance with some tweezers (gently) and see how far you can move it up and down. You should be able to move it up and down a small amount. About the same as the thickness of one of the pivots. If that is OK, check that the pivots are straight and not bent. Do you have any pics of the balance? A pic is worth a thousand words.1 point

-

I use no extra fine 5 brass tweezers dressed extremely sharp and a sharpened sewing needle glued to a piece of dowel. I use the needle to keep it located in position so it can't escape and the tweezers to push and twist the dialshock. One thing I always do is place a piece of plastic film (glad wrap/sandwich wrap) over the top of everything and push the tools through it. If you use the plastic film just place and remove it slowly so you don't drag parts of the movement. Some would say this is amaterish but it stops you losing things which can render a whole movement useless. I know I've spent hours on my hands and knees looking for parts !!! Are you doing it under a microscope? As that is the only way I can do it successfully and see what's going on. Maybe watch a few more videos on Youtube and take your time. Regards CJ1 point

-

1 point

-

Same issue as before. The bearing is seized in the top of the housing. Now, you have some room to wobble the armature back and forth. Should be good enough to break free. OR...pour a copious amount of penetrating oil into the housing and let it sit a day or so. Kroil, for example.1 point

-

Not the bearing splitter but a bearing puller or bearing press. A pretty long one at that. Clamp the legs of the puller around the housing and tighten down the screw on the spindle and push out the rotor. Much safer than using a soft face hammer to tap out the rotor as what many repair shops would do.1 point

-

There are different types of pins, we need to know which one is correct for your bracelet. https://www.cousinsuk.com/category/fittings-pins-tubes-for-watch-bracelets1 point

-

I always disassemble this way hector, only sure way of knowing the capstone is clean. I was curious to know if people were disassembling these tiny seiko cap jewels to clean them first before oiling them from the backside1 point

-

According to Esslinger, the 1A has a tip of just 0.1mm. I bought a China copy from AliExpress and the tip was a sharpened point, like a pencil. I didn't examine it carefully, it might have had a pivot like point which broke off in transport. Anyway, I sharpened the tip to a needle point and it works.1 point

-

1 point

-

Another find at a local flea market: a 1918 Elgin trench watch. It was in sad shape when I found it. Needed a thorough cleaning, might have had dirt from a bloody ditch in France clogging some of the nooks and corners, the hands were bent. But outside of all that, hardly any scuffs and no dents or dings. I did the usual COA, straightened the hands as best I could, did a bit of light cleaning on the dial, and got the old thing going pretty well again. I'm glad I didn't need to swap out any parts because I'm understanding that, particularly with antiques that also count as war memorabilia, it is important for the piece to be as original as possible. That said, it had no strap when I found it so I had to replicate a strap (could not afford a genuine vintage strap). I'm enjoying wearing it, but this one is listed on Ebay because I need the money. Rough patch right now and I am switching to a different day job, which is horrible timing but I can't go along with certain matters of ethics where I am now. But I may wear it now and then until it sells. It's not really my style, but it's an endearing old thing.1 point

-

1 point

-

Boy, did I ever get lucky! I went back to a local antique mall (more of a flea market, really) early this morning to buy something I'd seen several days ago. And it was still there! And this time, I had money! A Girard Perregaux Gyromatic. Not running, so they weren't asking much. I bought it and went straight home to my bench. Cleaned, inspected, oiled, regulated, and now it runs quite nicely. Fitted with a nice patent leather strap, and I've been wearing it this evening. I often turn about and sell many of the watches I rescue and repair, but not this one. Not this time. I took a liking to it rather quickly. Addendum: it has a 17j GP 21.19 plated with gold. It's a jem to look at. And a 14k gf case which took a nice polish. The original crystal is not too terrible at all, so I'm thinking of leaving it on.1 point

-

I need to learn how to identify different types of hairsprings. I can work with them, reshape, remove from the staff etc. what I can’t seem to figure out is... 1. How to tell the difference between hairsprings: size, strength or the proper terms to describe what I’m looking at and may need to order. 2. Where to order a new one. i have looked on J Boral, essinger, Casker, Cousins and Perrin. I can’t seem to find a place to buy replacement springs or balance complete. Well, I did find balance complete on Cousins. But I don’t know the difference between “ordinary” or extraordinary... much less decipher which one I may need. i need to learn about hairspring identification, classification and more. any suggested books, videos, reference or Devine enlightenment? thank you, team!1 point