Leaderboard

Popular Content

Showing content with the highest reputation on 02/07/24 in all areas

-

Rob Got news for you. You are definitely the man for the hobby. What you are doing, exactly as I did, is learning to get you motor skill correct. You will probably do quite a few more 'flaming hecks' before you get to the lighter touch sensation stage. I'm as the stage where I can 'feel' the screws. You don't know that you are getting there, but I can assure you, you are. Even last week I had to remove a bridge 4 times, even though every wheel did spin nicely, it did not 'feel' good. On one occasion I thought the pallet fork was the culprit. Took it out and, 'well I never'. That train doesn't feel right. Try again. Feels good on the spin now. Tomorrow's job. Rebuild the dial side. It's another Seiko. A Bellmatic 4006. Same principles as the 7S26 on the trainwheel bridge. Don't forget, you can tell us what you are doing and what you feel. And, hey! You'll get the feedback to tell you that we have all been there, and still do the same even now. Great pleasure in this hobby. Good man you are.4 points

-

Hello Murks; If I were you, I would start to sort and take out all the screws. I would buy some compartmentalized boxes and put all the pocket-watch screws (3rd compartment from the bottom left) in one compartment and the smaller watch screws (3rd top compartment from the left) in another. Later, a box full of screws may come in very handy. From the balances which have broken pivots, I would take out the balance timing screw (top right) and cut off the hair-spring studs c/w fixing pins. These timing screw and fixing pins may come in handy. From all the train-wheels and balances, I would select the ones which are good and would keep those. These come in handy when to learn polishing pivots on the Jacot tool. I would keep the pocket-watch hands, to learn how to blue watch-hands and they may come handy as a replacement. Instead of trying to put things back together, I would scavenge the parts which may be of use later, the rest goes in the bin and I would start all over again. I would see this as a beginner mistake and swallow my losses; "learning money". I would start with a clean slate. From now on, I would buy only movements which are complete and in good shape. I would forget about all these "tinkered to death", "incomplete" & "rusted junk" movements. Waste of time and money. I would keep each movement that I strip in special watch-trays, like these; I would strip only one or two moments at the time and concentrate on these only, until I'm done with them. Too many projects at one time becomes overwhelming and I would lose track of which is what, what was the problem and which movement needs what? I would learn all the parts, their names, how to work systematically and precise. But that is if I were you ....... Perhaps other members do have different suggestions ...... Suc6 in this beautiful hobby3 points

-

Hi Guys here is a little reading. some may find it interesting some may find it usefull so help yourselves 01-OFFICIAL CATALOGUE Of Genuine Swiss Watch Repair Parts_1949_Main Document-Introduction.pdf 02-OFFICIAL CATALOGUE Of Genuine Swiss Watch Repair Parts_1949_Main Document_A-Z.pdf 03-OFFICIAL CATALOGUE Of Genuine Swiss Watch Repair Parts-Supplement N°1 - 1953.pdf 04-OFFICIAL CATALOGUE Of Genuine Swiss Watch Repair Parts-Supplement N°2 - 1959-1A.pdf 05-OFFICIAL CATALOGUE Of Genuine Swiss Watch Repair Parts-Supplement N°2 - 1959-1B.pdf3 points

-

Ok so before i get involved, can i just say that this last picture looks like a jewel burger, i mean there's even a fork to eat it with. McDonald's only not as appetising. Omg we had fish jokes a few months ago , i wonder whats in store for this one. For starters that endshake is unlike anything I've seen before and the balance is missing all of its components, and that pallet fork well thats completely in the wrong position. Believe it or not unbeknown to this discussion group i have actually been helpful today in other ways elsewhere .2 points

-

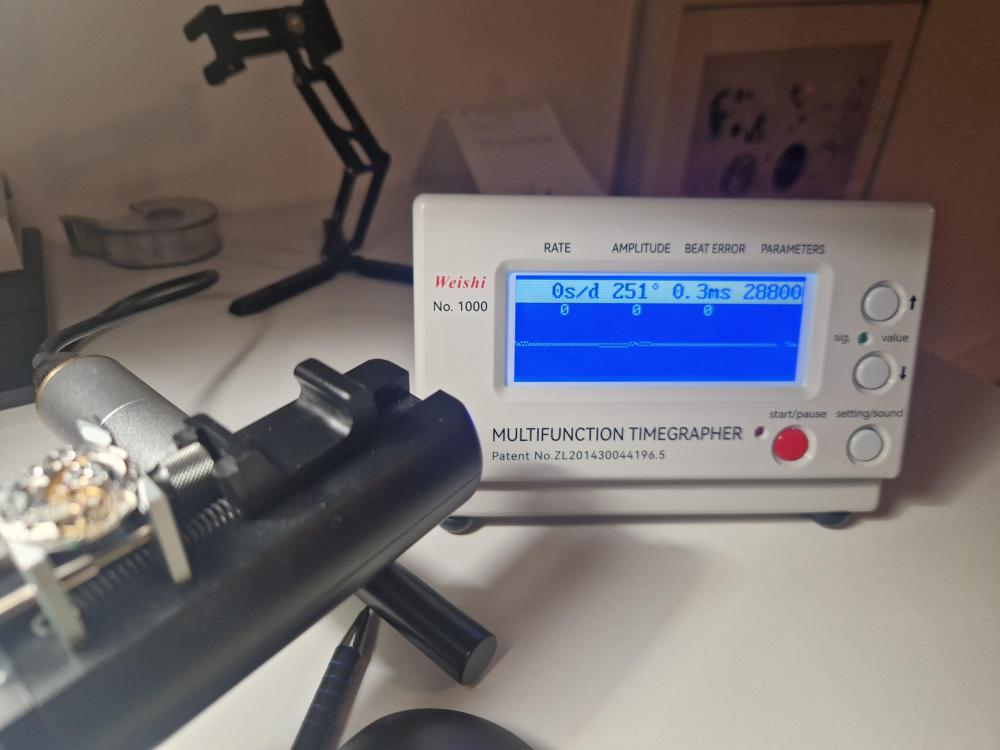

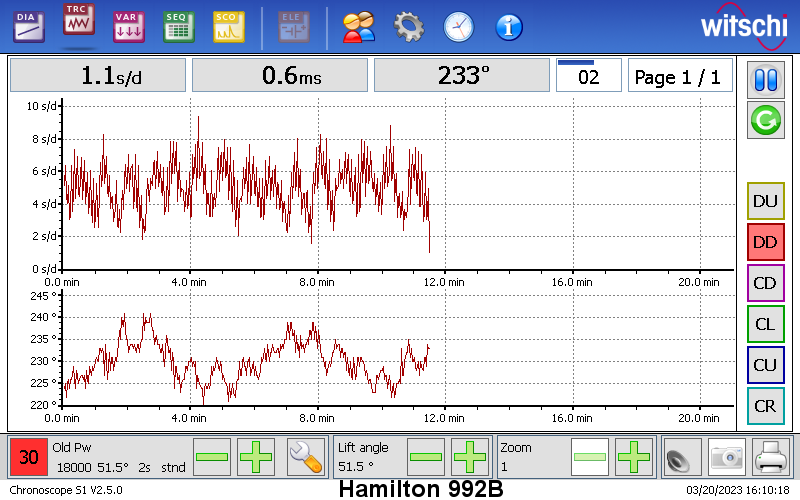

What you will find is with the auto module and rotor off this particular movement you will naturally see a lower amplitude. It appears in your photo that this is the case. If it is, then the amplitude you are getting which is around 250 to 260 degrees is quite natural. Put the auto module and rotor on and give the rotor a few turns when fully wound, this should give you the extra amplitude you are looking for. I know you should time a manual wound watch after an hour, but this is an automatic, so those rules don't apply here, as the watch is running at full wind when on the wrist, so you take your timing at full wind. The auto module and rotor give the movement a little more torque on the mainspring, hence seeing more amplitude. This idiosyncrasy doesn't happen with all automatic watches, but you will be surprised how much more amplitude you'll get. sometimes it can increase by about 30 degrees. If you have been a bit too liberal with the breaking grease then this might have a detrimental effect on the amplitude, due to slipping a little too early. Let us know how you get on?2 points

-

There is nothing better then to have someone next to you at the bench. Getting your hands dirty is the best way. Books can only teach you so much. You dad has come across far more problems then what are in books. He can watch you and tell you how to go about putting the wheels in there respective places and the position the strike and chime warning wheels should be next to the fans, this so you have good warning with out lifting the hammers. Don't for get we can also help you. I love helping with clocks.2 points

-

@watchweasol Sure no problem. As I said I couldn't get on with the wire holder for the loupe and had no chance of holding in with my face muscles for any length of time (how do they do that??!) so had an idea when I saw a cheap pair of £2 reading glasses in the chemist. I bought a pair and after taping up the lens with masking tape drilled a 25mm hole in the centre, I only had a wood drill bit so went very gently. I think it helped it was blunt or it would have probably broke the lens. I then ground/filed/sanded out the hole (quite easy as its plastic) until a loupe fitted through (about 27mm for mine). I then removed the other lens . The loupe is removed and changed easily and is comfortable to wear. Hope this helps someone else.2 points

-

2 points

-

All I know is it works. I have a timepiece with it and it is silent, apart from seeing the hands move you wouldn't think it was working, the trouble is I forget to wind the thing up.2 points

-

That would be our very own big hammer guy Thor. ( Adam ) hes come a long way, wish him all the best with his channel .2 points

-

This is what Roby said Translated Good morning everyone. I am an elderly watchmaker, I signed up to be able to communicate and correspond with many of you who are passionate about watchmaking. I am always looking for knowledge, methods, experiences. I live in northern Italy, I'm always at work even if I'm over 75. A warm greeting to all of you. Good work. Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement. In future Roby please type in English.2 points

-

Just to pick up a point on installing the train of wheels bridge. On the YouTube channel from weekend watch repair you see him using a technique where he rapidly taps the movement holder with his tweezers to get the wheels to sit in their jewels. I have copied this and around 75% of the time it works and removes hours of heartache (well it seems like hours at the time). You can see him doing it on most of his videos. Link to the channel below https://www.youtube.com/channel/UCRmSkqKTlLVf9epzW95OaoA2 points

-

2 points

-

Hi Mike. Iam cracking on a bi my self two weeks off the big 80. When I started Horology as a hobby there were no videos and getting your hands# on books wasn’t easy. Tweezers were Dumont no fancy brands then, as the hobby became popular and people could gain access to material houses for parts etc the prices went up accordingly. Over the years I have accumulated quit a bit of kit and bits, don’t throw anything away. I have some information on clocks if I can find it, now on three computers and several flash drives, I will post it up. Cheers2 points

-

Hello friends, I shared a bit about my journey with this watch/movement in this thread already: https://www.watchrepairtalk.com/topic/28505-reminder-on-meticulous-inspection-of-parts/#comment-240623 But since I'm now looking for feedback, I thought it would be ok to start a new thread. Now... the movement is already running quite well. Very consistent across positions and pretty much dead-on. Below are dial up and dial down at full wind (+30min run time). Of I put it on the timegrapher immediately after winding fully, it'll briefly go to 270°. But after a few minutes, it settles at around 250°. I didn't take a picture, but in vertical positions, it also runs consistently with a low delta and amplitude of 230-235. So, nothing of major concern... BUT the amplitude is a tad low for my liking. It does stay above 200° degrees in all positions after 24h, though - which is the Rolex minimum requirement. Still, wondering why it's not higher. I recently did a 2035 movement and it was doing nice 280-290° horizontal, full wind. I already double checked everything and disassembled and reassembled the train. Cleaned and oiled the balance jewels and one of the two escape wheel jewel settings. I gained a few degrees, but not much. There's only two things I can see/imagine at this point: 1. Maybe the mainspring from GR is a bit weaker or my breaking grease (8217) application lets the mainspring slip a bit too early. 2. There might be something going on the the escape wheel or its capped jewel settings. See below picture. Notice how the oil circle is not fully central compared to the pivot? Strangely, this is the case on both sides/jewel settings (dial side and train side). I meticulously re-cleaned the setting on the dial side (cleaned every corner with pegwood etc) and re-oiled. Still same odd oil circle. Does the cap jewel not sit evenly? Would that cause the problems I'm seeing? Or is this within normal margins? Thanks for any feedback on these points OR any other ideas.1 point

-

I was kinda hoping for a different picture. I once had one of my watchmaker friends have an issue with three separate watches that were entirely mixed up he couldn't do it I couldn't it wasn't that hard. But you don't have the you have? As you do not appear to have running watches you basically the best I think you hope for is categories because you have more than one watch in each category. So all he could do is to separate out all the parts of look the same and whether or not you can ever get any of these watches to run maybe the ones that wristwatches it look like they're more or less complete you might build get them but basically really categorize these and put them in boxes labeled parts watches as that's basically what you have here. Then why should we be annoyed with you? The future important lesson to learn is probably don't work on so many watches all at the same time. Keep them in separate containers instruct the wife not to play with them unless you'd like to come and help you. Sometimes other people have a much better ROI for finding parts the store manager is the best at finding parts even though she claims her eyesight sucks she's extremely good at finding things. Then you're going to get either a dog or cat cats are really good at playing with watch parts then you can blame the cat for all future things like this.1 point

-

Thank you Tom. Found the screwdriver needed. Learning how to do the hairspring now.1 point

-

Hi Ross, I’m no expert as you know. I would think that for a stud screw 0.5mm is probably close then stone it to fit snugly to the screw. Tom1 point

-

Good to know this. Question, But senario 2 or 3 which knebo shows, can actually happen and introduce more friction against mainspring torque. Thanks in advance.1 point

-

Ah ha that would make much more sense, everything except the piece of cutlery, which now also makes sense. Do you think it matters if the oil bubble is not in the centre of the jewes. The bubble is from the capillary action of the oil forming around the two mating surfaces of the cap jewel and the holed jewel. If either or both of the jewels are tilted then it stands to reason that the mating surfaces wont be in the center of the setting.... yes? Does it matter where the pivot picks up oil from within that bubble as long as sideshake still exists. The pivot end might ride differently .1 point

-

With a pegwood add SLIGHT AMOUNT OF FORCE to the barrel ( itself ) in the direction it supplies power to the train, to compensate for insufficient torque due to a weak spring, without putting extra load on mainspring and causing unwanted slips of the spring. The amount of force you apply is a matter of the feel you develope over time and your familiarity wiith the calib ur working on. When you add extra torque to a fully wound spring through the crown, you expectedly will cause the spring to slip unwantedly. so add torque to the barrel itself. Good luck1 point

-

Your oil concentricity on the escape wheel isn't robbing amplitude. Also, I've seen folks eat burgers with fork and knife in Switzerland . Funny, I have a friend who worked for rolex as an instructor, and they actually stipulate (or used to) to: peg jewels, and stick pinions into button pithwood soaked with benzine (lighter fluid) prior to machine cleaning. I had a zenith el primero on the bench with lackluster amplitude, tried this (pinions in pithwood), and dang if I didn't get a good 10 degrees. Maybe it was just the manipulation. Maybe it was the running a bit more. But Rolex does what books from 1905 say to do, must be a reason. But he also said they don't all hit 270+ full wind minus an hour. What they do do (gross!) is keep time really well. Your 24h amps are great and within spec, I would let this one go. Or, start adjusting the escapement (I do this all the time and I'm like the only watchmaker I know who does, haha).1 point

-

Not sure we're understanding each other here. The drawing is of the ESCAPE WHEEL and its jewels, NOT the balance. The Rolex escape wheel has capped jewels and shock springs. That's that I'm talking about. The jewels on the balance have perfectly concentric oil circles. I was hoping someone would get the joke1 point

-

1 point

-

1 point

-

Oh yes that word,it just floats my boat, it just rolls off the tongue. I could say it over and over and over and over. I on the other hand ...... completely agree, this lot is never going to run unless you put in an insane amount of effort and probably money. Seriously more time could be devoted to more viable projects. There is a good amount of generic spare parts there and loads of lessons that can be learnt from the parts that are not identifiable. Swallow your pride, i did when i effed up and move on to better things.1 point

-

All depends what you are working on. If the right mainspring is available and the money to buy one each time isn't an issue then a new one would be the best option. Downside is you dont get to aquire the skill of winding mainsprings. Which eventually if you work on a lot of old watches you will need. Yey old timer, my hero In my eyes leaving it in the barrel isn't an option, when I started i thought about it and i tried it. I soniced the barrel upside down in the hope it would clean it, it did but not to an acceptable level at all. No way are between the coils gonna get clean or all of the bottom of the barrel. You have to bite the bullet and just get stuck in, have it out and hand wind it back in if there's no option of a winder. Practice ,practice and practice and when you're done practicing......... you've guessed it , practice some more.1 point

-

thanks, guys; I really appreciate the help. I totally agree, too; it's far better to gain the experience first-hand. I'm a reader, though; I find it really helps me to study a subject in parallel to practising it.1 point

-

great simple idea, I love it. I was battling with optics when I started. In the end I have a clip on loupe for some work, but recently purchased a stereoscopic microscope from Amscope. Total gamechanger for me. I've been straightening out hairsprings ever since1 point

-

You could just buy a couple of the most common sizes. Best Chinese sets are allegedly good. Manual mainsprings are easy to wind by hand but automatic springs are trickier because of the bridle in the end. Buying new springs is also an option.1 point

-

HI @watchweasol Its primitive but I am grateful for your kind comments. If I wore glasses I would probably have got the clip on ones although these may have held the loupe too far from my eye. With my 'creation' I can adjust the depth as well by sliding the loupe further in or out. One thing I forgot to mention was that before I drilled the hole I took a look at myself in the mirror and marked the centre of my eye on the lens as it will probably be off centre.1 point

-

A quick follow up to the Pai Li 869 fountain pen. I must admit I'm pretty impressed with it. Especially since it cost so little. Here it is compared with a few of my other "go to" pens. Left to right, a "Burnham" probably from the 1960s, with a "Tak Sang" nib, (possibly gold, but who knows), a Lamy clone (possibly a Jinhao, but it could be anything) an Apollo with an Apollo steel nib, also from the 1960s, a Parker 45 with the original gold nib, which is currently in need of a clean, as the nib is writing very dry, and the PaiLi 869. The PaiLi is surprisingly well made, and much heavier than I expected. I assumed it was going to be a flimsy affair, but far from it. It is somewhat longer than the Parker 45 when posted, and also heavier, which I like, but which may not be to everyone's tastes. The nib is almost certainly a "Wing Sung". I've also included a quick scrawl on possibly the worst paper for fountain pens I have ever encountered. As you can see the PaiLi writes just fine. The nib is smooth, and not the least bit scratchy. Arguably the best writer is the Apollo, followed by the Lamy clone and then the PaiLi, but as I say, the paper is terrible, so its not really a fair comparison. The Parker is struggling, so I'm just about to tear it down and clean the feed and nib. I'm back from my travels now, so you should see a few watches again soon.1 point

-

Please don't be annoyed with me a did this when a first started watch repairer had to start somewhere this are all the movements that have lost parts from some of them do have there original parts it just a guessing game a guess Some the movements have lost them through process of time some parts may not have the original movements because then I was just learning the trade so don't be mad at me you asked me to add pictures the movements that's what have done some movements have already there original so the won't need parts a guess it just a want to find out where some of the misleading parts that are mixed belong to I'll be surprised if you can guess them if you do you lot most me really cleaver people.1 point

-

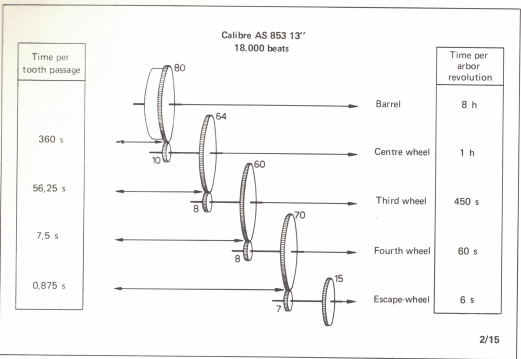

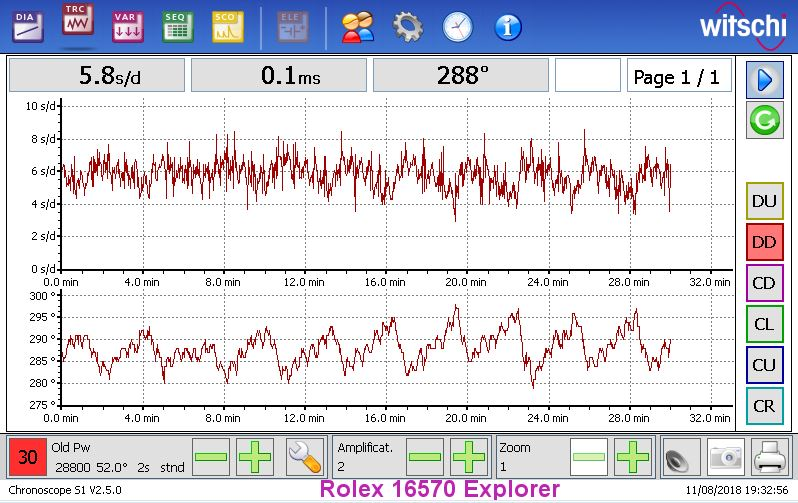

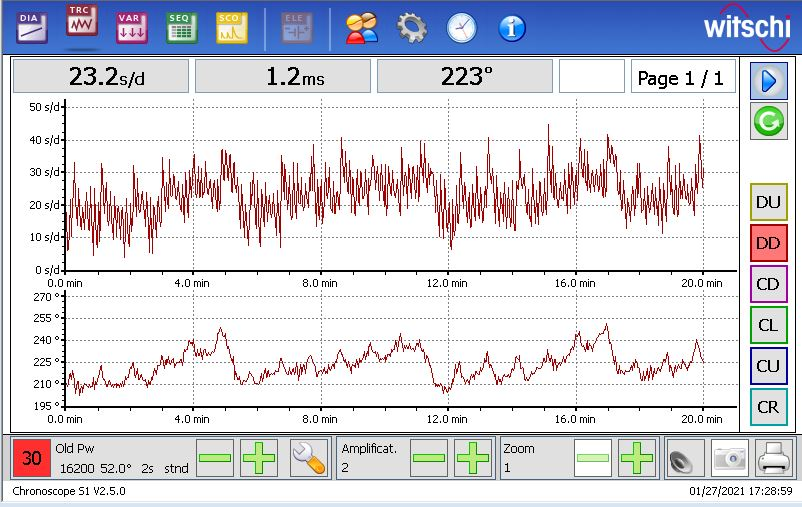

Watch companies normal procedure for fully wound up is not to put it on the timing machine where it's fully wound up. It depends upon whose technical sheets you look at but you're supposed to wait at least 15 minutes basically up to one hour is considered fully wound up. As you can see if you can fully wind the watch up better if it wasn't an automatic if you can wind a manual wind that extra little just before you start breaking something you can get some really nice impressive amplitudes which is not what you're supposed to be doing which is why you're supposed to let the watch settled down a little bit Would you like an answer from the group or my answer? Let's see the groups answer is your amplitude sucks and who cares what Rolex thinks they are only concerned about timekeeping. So you need to get that amplitude up about a stronger mainspring that should do it? Yes the stupid watch companies all they care about is timekeeping what idiots they are Looks like you need a new timing machine or software-based timing machine. The Chinese machines average slightly different than the witschi machines using the watch companies say set the average to 20 seconds to get a smoother rating. Then it's not a measurement error the timing machine it's you need a different timing machine. I'm trying to think of which witschi you could get the cheapest one but you're still looking at thousands of Swiss francs in your case. I was just thinking sincere in Switzerland grab your Rolex and pop over to witschi and see if they can run a demo on one of their machines. Tell them you thinking of purchasing one you want to run a time plot on the watch. I think the cheapest one that would do that is not cheap. Mechanical watches are interesting they tend to have power fluctuations through the gear train ideal a it tends to be random but if you're having a gear issue or some other issue you can get something that's not random. Typically though if you put the hands on and watch the watch you typically wouldn't see the problem because the average out all of this. So for instance this shows the effect of the gearing how often things would repeat Here is an example of one another timing machine would do for you And the lower plot you can very clearly see fluctuations on the other hand the timekeeping is relatively minimal. This is where you'd never see this with your watch hands because this would all get averaged out. But if you want to be obsessed about this I'm attaching a PDF. Ideally you shouldn't be seeing what were seeing in the Rolex up above For instance this comes from a Elgin 17 size pocket watch that hasn't been serviced in no idea when and notice we barely can see a pattern but we can see much greater timing fluctuations. Your Rolex doesn't have regulator pins which is really nice regulator pins will make things Much worse which is why it's nice if you just break them off and throw them away but unfortunately we can't. Another pocket watch example Notice on the 992B example where yes there is fluctuations of amplitude but timekeeping is really really really tight. Same as the fluctuations with the Rolex on timekeeping really isn't affected. But you are seeing the fluctuation on your timing machine which would be a powertrain fluctuation I wonder if witschi has a show room you could go visit? I think you should have longer averaging times in some of these issues might go away. That I see the timing and all positions at 24 hours I don't see the one fully wound up and fully wound up means fully wound up and wait about 15 minutes I just curious what all the positions look like Okay here's what you absolutely must buy I'm sure it can't possibly be that expensive? https://www.witschi.com/en/products/chronomaster-auto/ Sometimes a website could be a bit weird of Fedora cousins here beer cheapest alternative it's only 3000 of whatever your favorite currency is will be close enough you want the Pro version because I think the Pro version adds in all the stuff. Including the trace function which I call a time plot. Then yes you can do some of this with software-based timing machines for a considerably less money but witschi makes it look so nice and pretty and just think how professional you'll be with a $3000 timing machine up your game considerably. Then I'm not sure that the automatic microphone version is available for sale we get I haven't seen it and I bet you it's expensive. But this thing of all the stuff you could be concerned about with your newfangled timing machine. https://www.cousinsuk.com/product/witschi-mechanical-chronomaster-pro Horologica Times -- May 2004 From the Workshop witschi time plot.pdf1 point

-

1 point

-

Hello Roby Welcome. Hello Roby. Welcome Tried to translate, but failed miserably. However, good to see that you have joined1 point

-

If you don't have a watch cleaning machine. Clean all the parts with Ronsonol lighter fluid, after cleaning put the parts on some tissue and use your watch blower to dry the parts. If jewel caps can be removed then do so. Pocket watch oil fill be fine. Oil the pallet jewels and every other tooth on the escape wheel but do not over oil.1 point

-

In Europe, Lidl have these workshop benches. The height is adjustable in three steps - 85, 95 and 105 centimeters, personally I find the 95 cm height ideal for me. The bench is very sturdy and has a wooden desk, which is not the best quality (not surprisingly, for 150 EUR), there were some gaps and cracks I did not like, so I did some easy filling and grinding job before I started to use the bench. I am a newbie, but so far, I am quite happy with the result. https://www.lidl.de/p/rikta-werkbank-hoehenverstellbar-b-135-x-h-85-105-x-t-60-cm/p1003485001 point

-

As we get numerous questions regarding the escapement of swiss and other watches I thought it would be useful to, post this 370433519_WorkingSwissEscapement.pdf1 point

-

I find IPA and rinse are pretty similar with their evaporation rate. I keep a small jar of IPA on my workbench to dip my tweezers in when they get a bit sticky from lubricants on movements I'm disassembling then push the tweezers into pithwood.1 point

-

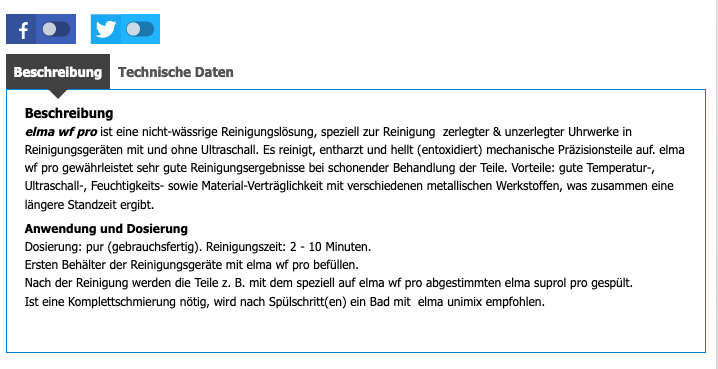

I started off the same as ross using lighter fluid and isopropanol until i watched Alex Hamiltons youtube video, he used elma red 1:9 for cleaning, 1st rinse in destilled water then 2nd rinse in ispropanol, thought i'd give it a try the results on the finished parts i could never have achieved if i'd washed the parts over and and over again in lighter fluid/isopropanol, i should have used the elma from the start, for the balance/pallet fork i use hexane. https://www.cousinsuk.com/product/elma-jewellery-19-concentrate When my bottle of elma red's nearly finished i will the give the elma wf pro and suprol rinse a try that endeavors linked to if i can use it to clean the pallet fork and balance, then i won't need to use hexane as when i use it i always use a respirator to be on the safe side.1 point

-

1 point

-

1 point

-

We still need to know is the axial free play normal in any combination of settings/enstone position. I will not be so amused if the free play will be normal when both enstones are put upside down... Well, the fact that when dial side endstone put rouned side to the pivot makes the balance work correctly, only means that the pivot is short for this setting, nothing more. I mean, it is not proven that the pivot is worn. The pivot may be OK, but the setting may be not original. Then, the balance itself may be replaced. Or, someone may have worked on the pivot and then rounding it's head for some reason... For sure will tell, that if a pivot is worn in a manner that it has got that shorter, it's head will not be rounded as it should, but will be flat and even riveted. Furder more, no reason to expect this exactly pivot to be worn. Such wear of pivot one can meet in a pocket watch which has worked 40 years on the table or nightstand lying dial up, but in the hairspring side pivot. So, what we really need is good pictures of the pivots. When using smartphone camera, search for macro mode and find out how to lock the focus (e.g. press the area of the image and hold untill locked padlock symbol appears) and then find the distance from camera to pivot where the image of the pivot is on focus.1 point

-

Until oldhippy gets back to you have a look at this it will give you an idea what needs doing Servicing a Platform.pdf1 point

-

As far as I'm aware, both fluids are shellac "save". That's to say, I do no more than 5 min per ultra-sonic cycle. I have one (165ml) jar with cleaning fluid (Elma WF pro) and two (165ml) jars with Elma Suprol rinse. I give a basket filled with parts 5 minutes in the cleaning fluid (WF pro), blow the basket clean, then the basket goes 5 min in the first Rinse. After 5 min, I blow the basket clean and it goes in the (optional) 2nd rinse. Once that's all done, I hand-dip the basket in the IPA and quickly (especially with the pallet-fork and the balance) take the parts out of the basket and blow them dry. How to do the balance is still a bit of a question mark? I left the balance in situ c/w the anti-shock jewels, I also cleaned the balance separately and I left the balance in situ without the anti-shock jewels. All options went fine, but I'm not sure which of the three options is the best? With the anti-shock jewels separate, I experience this: https://www.watchrepairtalk.com/topic/28547-these-rubber-bellow-hand-blowers-do-suck-/#comment-240948 It seems, and to make sure that the anti-shocks are 100% clean, that one has to do the anti-shock jewels (by hand) separately in IPA. To me the Elma WF pro (cleaning fluid) seems to be the most "aggressive", but that may also be due to the ammonia smell. The Elma Suprol is to flush the Elma WF pro out, and to make sure, I use two rinses in two separated jars; Rinse 1 and Rinse 2. The 2nd rinse seems optional, but I do it anyway, just to make sure. I don't think that any of both Elma chemicals are directly "decremental" to shellac, or at least not so as IPA is. But as I understood from others, you don't want to leave any of the watch parts in the WF pro too long either. Up to 5 minutes cycles seem to be safe. Also these two Elma chemicals are non-water based. One has to make sure that there is no cross-contamination between the water in the ultra-sonic tank and the fluids in the jars. Perhaps other members may have different idea's or other cleaning procedures? I'm a bit experimenting too what's the best procedure. However, from what I've done so far, the results with these chemicals are very good ! Before; After; and the same results I get with the wheel-train, screws etc. Everything comes out sparkling clean If WF Pro was not suitable for ultra-sonic, why do they sell it in shops specialized in ultra-sonic? Perhaps, it is not a good idea in the ultra-sonic tank directly. That would be, due to the volume needed, quite costly too. But in jars .... ? I bought my chemicals by SKsonic in Germany: https://www.sksonic.de/ I do hope that your German is up to spec1 point

-

A huge amount depends on what you’re working on. Many, especially vintage or antique movements will have no technical information whatsoever. I’m afraid at best it’ll be a guess/suck it and see situation. Tom1 point

.thumb.jpg.0cfe95df32edde1c2cad6dddc1fe0d1b.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)