Leaderboard

Popular Content

Showing content with the highest reputation on 02/01/24 in all areas

-

Thanks for the reminder! Once we've been lucky once or twice there is always the risk of starting to suffer from hubris and laziness. My best example is an ETA movement where I missed some very minuscule oxidation on the pivots and the amplitude suffered tremendously. Once taken care of the amplitude was as close to perfection as I've ever gotten. I know the feeling it's mercilessly painful!3 points

-

Quick tip, and knowing you work on Seikos so need RH winders for Swiss and LH winders for the Seikos there is a trick to save £10. Here are the prices on CousinsUK: LH winder and arbor = £51.25 RH winder and arbor = £49.15 LH arbour = £31.35 RH arbour = £19.95 So if you want a set (LH and RH arbor and universal winder) of a particular size and start with the LH winder and arbor set and complete it with the stand alone RH arbor the combined price will be £71.20 If you do it the other way around and start with the RH winder and arbor set and complete it with the stand alone LH arbor the combined price will be £80.50 You end up with exactly the same thing either way: LH and RH arbor and a universal winder, just save yourself £10 by starting with the LH set and completing it with the stand alone RH arbor. Just to clarify, the winder will take both the LH and RH arbor, in fact, in the sets Bergeon only provides one winder per size, and one corresponding LH and one RH arbor. Still eye wateringly expensive, but the £10 is better in your pocket! PS I got a half set, but I would say that 90+% of the time I end up using the 5, 6 and 7 sizes (mainly 6) for mens watches so I would start your collection there.3 points

-

3 points

-

Hi. Regarding the case, if it’s glued with resin glue it is possible to soften it up using steam to allow you to dismantle it for clean up. It’s a method I have used successfully. I borrowed the wife’s hand held steamer, worked a treat.2 points

-

Hello all, I'm writing this message after a couple of sleepless nights. I am servicing a Rolex cal 2135 and everything seemed fine until I put the balance in and put the movement on the timegrapher. Only 180° amplitude dial down and 220° dial up. As the gear train was spinning nice and freely and no issue visible on the pallet fork, my main focus of attention was on the balance itself. In fact, I observed an ever so slightly wobble. I was petrified because a NOS balance for this calibre costs around 400-500usd. I devised this assessment plan: 1. check shock protected escape wheel jewels with 2. (Release power from mainspring) Remove Pallet fork, check pivots and check backspin in wheels 3. Balance jewels re-oil 4. Remove balance/hairspring - inspect pivots visually and with truing tool - inspect hairspring for flatn9and concentricity As you can see, I put the risky business of hairspring work at the end. First wanted to exclude other possibilities. Now, fortunately, I only had to go to point 3 to solve the problem! But why am I writing this post? ..because I almost missed the issue. And I want to remind others, especially beginners, to be thorough in the inspection process. So, what happened? I took out the balance jewels, rinsed them in Essence Renata (like One Dip), re-oiled and was about to put the hole jewel on the cap jewel. But then I spotted the TINYEST bit of grime on the edge of the hole jewel (where jewel and metal setting meet). I almost dismissed it and thought it was just a dark reflection of the brass setting. I couldn't remove it with my No5 tweezers. So small. Rodico finally did the trick. All back together and boom amplitude up to 250 in both dial up and dial down (still searching for more..). That's 70° more than previously in the dial down position. No more wobble in the balance (the dirt must have caused the cap jewel to sit uneven and consequently the balance pivot would go up and down the slope created by the cap jewel). I think I was over-reliant on my standard cleaning procedure (one L&R cleaning and two rinsing cycles in my ultrasonic cleaner) without double checking every part. So, remember to check every part! Tiny details matter!2 points

-

I'd remove the HS from the balance wheel to get a good look at it. Then methodically follow it and adjust as needed from the collet to the stud. There are several decent videos about HS-manipulation on YT. If you're new to it I'd recommend these videos from Chronoglide.2 points

-

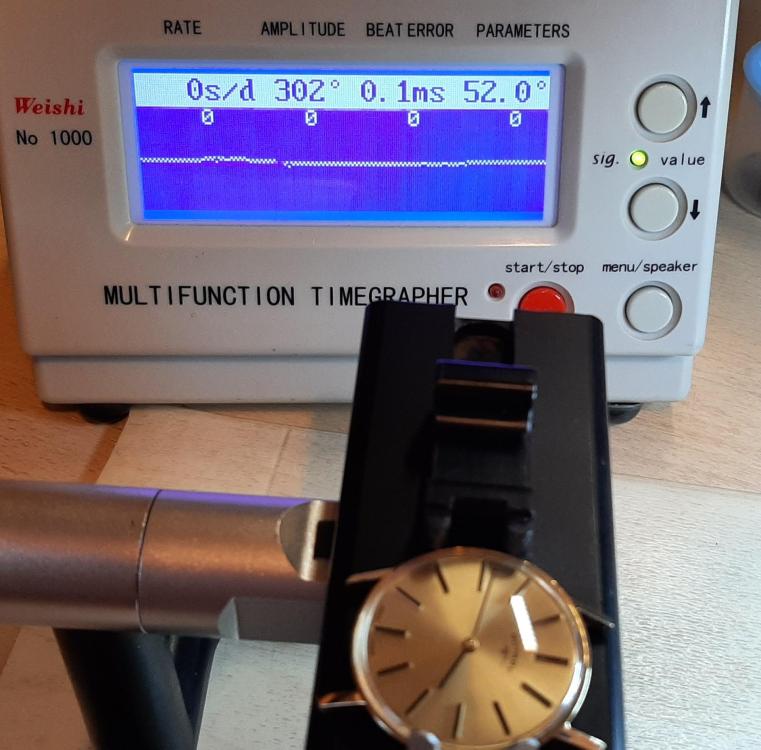

Just arrived, a Longines 30L. I've been looking for one of these for a long time. I've been a fan of Longines since I got my first, I love the quality and elegance. In the thread "looking for a simple, ultra-precise hand-wound movement - suggestions?", @nickelsilver suggested the larger Longines (30mm movements). The higher grade version of this movement (30Z) were used as observatory chronometers. So I decided I needed one. I'm expecting good performance. It's not going to just sit in one of my cases, I'm going to regularly use it. I bought it as "spares or repair", so was expecting a damaged balance. But on first look, the balance and hairspring seem perfect. It just seems to have a broken mainspring. Result BTW @nickelsilver, you also recommended Peseux as good movements. I bought a cheap Rotary with a Peseux 7050. Looked like it had been serviced by a gorrilla - the pallet fork was bent about 30°, missing pallet jewel, hairspring all out of shape. So I wasn't expecting great performance. On the timegrapher yesterday, looking good ! (I'll be buying more Peseux - good quality at a good price )2 points

-

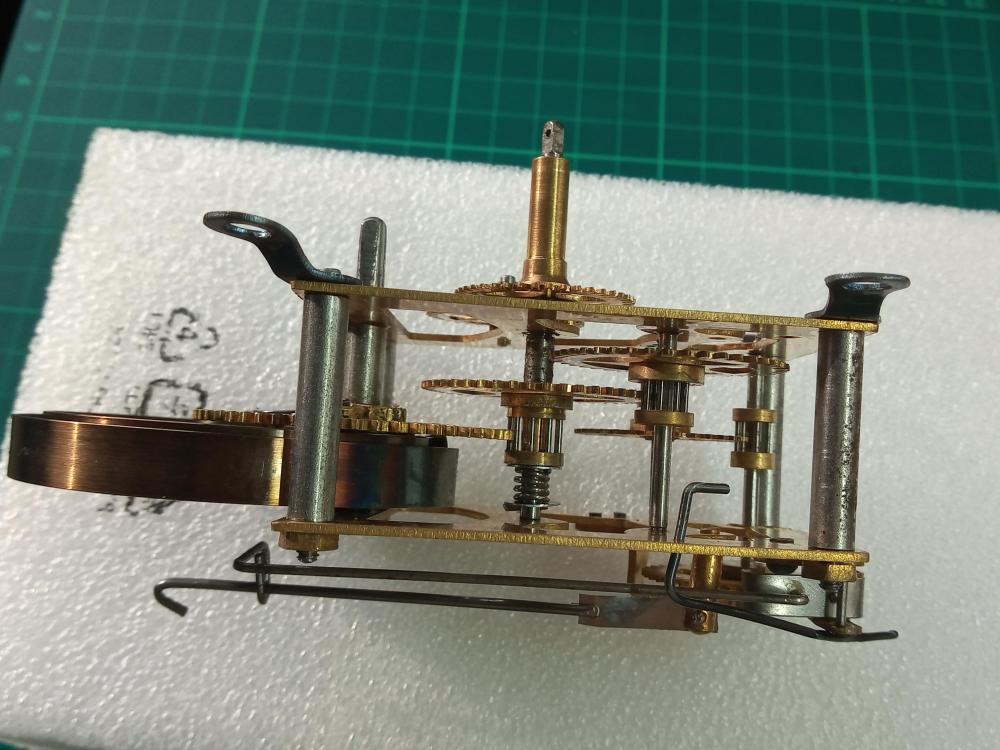

With all due respect to everyone else... this is probably the most impressive thing I've seen on this forum since I joined2 points

-

I thought it might be useful to share this reference of watchmaking threads. It includes the modern threads you would get from Bergeon/Wiru/Horotec sets as well as from the old mysterious thread plates labeled Martin Fils/Perrelet/Latard/Bourgeaux All values in mm. 0.30x0.075 no.1 Bergeon tap, drill 0.24mm 0.35x0.075 no.2 Bergeon tap, drill 0.28mm 0.40x0.100 no.3 Bergeon tap, drill 0.32mm; 0.45x0.100 no.4 Bergeon tap, drill 0.37mm; 0.50x0.125 no.5 Bergeon tap, drill 0.40mm; 0.55x0.125 no.6 Bergeon tap, drill 0.45mm; 0.60x0.150 no.7 Bergeon tap, drill 0.48mm; 0.65x0.150 no.8 Bergeon tap, drill 0.53mm; 0.70x0.175 no.9 Bergeon tap, drill 0.56mm; 0.75x0.175 no.10 Bergeon tap, drill 0.61mm; 0.80x0.200 no.11 Bergeon tap, drill 0.64mm; 0.85x0.200 no.12 Bergeon tap, drill 0.69mm; 0.90x0.225 no.13 Bergeon tap, drill 0.72mm; 0.95x0.225 no.14 Bergeon tap, drill 0.77mm; 1.00x0.250 no.15 Bergeon tap, drill 0.80mm; 1.05x0.250 no.16 Bergeon tap, drill 0.85mm; 1.10x0.250 no.17 Bergeon tap, drill 0.90mm; 1.20x0.250 no.18 Bergeon tap, drill 1.00mm; 1.30x0.300 no.19 Bergeon tap, drill 1.06mm; 1.40x0.300 no.20 Bergeon tap, drill 1.16mm; 1.50x0.350 no.21 Bergeon tap, drill 1.26mm 1.60x0.350 no.22 Bergeon tap, drill 1.32mm; 1.70x0.350 no.23 Bergeon tap, drill 1.42mm; 1.80x0.350 no.24 Bergeon tap, drill 1.52mm; 2.00x0.400 no.25 Bergeon tap, drill 1.68mm; 2.2x0.45 2.3x0.40 in Wiru No.1 tap/die set, 2.6x0.45 in Wiru No.1 tap/die set, 3.0x0.50 in Wiru No.1 tap/die set, 0.213x0.086 Bourgeaux thread no.24, on Martin Fils/Perrelet et Martin 'B' 0.267x0.088 Bourgeaux thread no.23, on Martin Fils/Perrelet et Martin 'B' 0.291x0.091 Bourgeaux thread no.22, on Martin Fils/Perrelet et Martin 'B' 0.312x0.093 Bourgeaux thread no.21, on Martin Fils/Perrelet et Martin 'B' 0.344x0.094 Bourgeaux thread no.20, on Martin Fils/Perrelet et Martin 'B' 0.376x0.096 Bourgeaux thread no.19, on Martin Fils/Perrelet et Martin 'B' 0.414x0.101 Bourgeaux thread no.18, on Martin Fils/Perrelet et Martin 'B' 0.452x0.111 Bourgeaux thread no.17, on Martin Fils/Perrelet et Martin 'B' 0.496x0.120 Bourgeaux thread no.16, on Martin Fils/Perrelet et Martin 'B' 0.563x0.133 Bourgeaux thread no.15, on Martin Fils/Perrelet et Martin 'B' 0.640x0.150 Bourgeaux thread no.14, on Martin Fils/Perrelet et Martin 'B' 0.713x0.159 Bourgeaux thread no.13, on Martin Fils/Perrelet et Martin 'B' 0.782x0.167 Bourgeaux thread no.12, on Martin Fils/Perrelet et Martin 'B' 0.858x0.181 Bourgeaux thread no.11, on Martin Fils/Perrelet et Martin 'B' 0.936x0.200 Bourgeaux thread no.10, on Martin Fils/Perrelet et Martin 'B' 1.008x0.219 Bourgeaux thread no.9, on Martin Fils/Perrelet et Martin 'B' 1.097x0.239 Bourgeaux thread no.8, on Martin Fils/Perrelet et Martin 'B' 1.203x0.261 Bourgeaux thread no.7, on Martin Fils/Perrelet et Martin 'B' 1.299x0.271 Bourgeaux thread no.6, on Martin Fils/Perrelet et Martin 'B' 1.404x0.274 Bourgeaux thread no.5, on Martin Fils/Perrelet et Martin 'B' 1.523x0.289 Bourgeaux thread no.4, on Martin Fils/Perrelet et Martin 'B' 1.641x0.298 Bourgeaux thread no.3, on Martin Fils/Perrelet et Martin 'B' 1.797x0.320 Bourgeaux thread no.2, on Martin Fils/Perrelet et Martin 'B' 1.984x0.359 Bourgeaux thread no.1, on Martin Fils/Perrelet et Martin 'B' 2.169x0.388 Bourgeaux thread no.0, on Martin Fils/Perrelet et Martin 'B' 2.363x0.420 Bourgeaux thread no.00, on Martin Fils/Perrelet et Martin 'B' 0.367x0.087 Latard thread no.20, on Martin Fils/Perrelet et Martin 'L' 0.395x0.094 Latard thread no.19, on Martin Fils/Perrelet et Martin 'L' 0.432x0.102 Latard thread no.18, on Martin Fils/Perrelet et Martin 'L' 0.479x0.109 Latard thread no.17, on Martin Fils/Perrelet et Martin 'L' 0.529x0.115 Latard thread no.16, on Martin Fils/Perrelet et Martin 'L' 0.591x0.126 Latard thread no.15, on Martin Fils/Perrelet et Martin 'L' 0.665x0.138 Latard thread no.14, on Martin Fils/Perrelet et Martin 'L' 0.736x0.149 Latard thread no.13, on Martin Fils/Perrelet et Martin 'L' 0.798x0.164 Latard thread no.12, on Martin Fils/Perrelet et Martin 'L' 0.870x0.180 Latard thread no.11, on Martin Fils/Perrelet et Martin 'L' 0.956x0.196 Latard thread no.10, on Martin Fils/Perrelet et Martin 'L' 1.036x0.209 Latard thread no.9, on Martin Fils/Perrelet et Martin 'L' 1.106x0.219 Latard thread no.8, on Martin Fils/Perrelet et Martin 'L' 1.181x0.233 Latard thread no.7, on Martin Fils/Perrelet et Martin 'L' 1.269x0.246 Latard thread no.6, on Martin Fils/Perrelet et Martin 'L' 1.363x0.262 Latard thread no.5, on Martin Fils/Perrelet et Martin 'L' 1.464x0.284 Latard thread no.4, on Martin Fils/Perrelet et Martin 'L' 1.568x0.304 Latard thread no.3, on Martin Fils/Perrelet et Martin 'L' 1.703x0.325 Latard thread no.2, on Martin Fils/Perrelet et Martin 'L' 1.869x0.342 Latard thread no.1, on Martin Fils/Perrelet et Martin 'L' 2.029x0.352 Latard thread no.0, on Martin Fils/Perrelet et Martin 'L' I extracted these from https://www.improwis.com/tables/threads2.webt1 point

-

Hi Richard you are right using metal tweezers and shorting pos to neg equals battery knackered.1 point

-

1 point

-

I don't work on quartz movements but don't you have to be careful not to short the battery?1 point

-

Hi anything of this nature either requires re plating or metal spraying best evaluated by a working jeweler. If the bracele5 is an alloy there may be processes it undergoes to be able re plate.t1 point

-

Just had the same problem with my Seiko 7S26-0480F. I tried my special tool with 4 blades that inserted into the bezel gap. No matter much pressure I made, I could not remove it. I then used the hand press tool. Large plastic part underneath to support the case base and a smaller disc on inside the case and onto the crystal. Increase in pressure. A loud 'crack'. Top press to bottom. Bezel and crystal removed. Phew! So much for the specialised remover. Back to basics for me.1 point

-

I would say it will comes off like a Rolex bezel. Don't use a four jaw bezel removing tool. as they are crap and I don't know any decent watchmaker who uses them. They use a Stanley knife and brass hammer for really awkward bezels. A lot of the time a Stanley knife going slow along the circumference of the bezel will do it. Here's a link to my cloud storage where a video of removing a Rolex bezel. I'm not saying it is the same, as I haven't got the case in my hand, so on on your head be it. Use really thick plastic sheet for protection. Not jiffy bag stuff that you use to remove hands! https://drive.google.com/file/d/1dEmHz_9pLCPeMukfk1IMFL8J0Ymju7S2/view?usp=sharing1 point

-

What sort of watch is this ? Modern quartz fashion type of watch ? Might be my imagination as well there looks like a filed in notch next to the lugs. You will know for sure watchie, i would try a sticky ball on the glass first to see if you can get some rotation either way, very unlikely you will damage with that amount of force. Place a piece of masking tape over the edge of the bezel onto the case as an indication of movement, the tape will wrinkle or tear if anything is budging.1 point

-

Sometimes there is a small "lip" in the case where you can use a case tool to open. It almost looks like I see one in your last photo. (It could be the camera angle.) I can understand being careful with this watch.1 point

-

Thanks again both. I have ordered what looks like a #68 on eBay so we'll see how that goes. The rear door is very warped so I am going to try using a steam wallpaper stripper to straighten it out - might not work but it beats decorating the house.1 point

-

When I run up against this kind of situation, I use a razor blade and gently pry up to see if there is any movement. If not, I assume it is screwed on. I realize this may not help you, but when I have something like this that is hard to unscrew, I will often design a tool and print it in PLA on my 3D printer. PLA will not damage the watch. You may also consider the superglue/nut technique. Glue the nut on the glass and see if you can unscrew it. These situations are always tricky...and sometimes scary.1 point

-

1 point

-

I don't know for sure but on a similar looking watch, the bezel unscrewed. I believe a custom made die was made to remove it.1 point

-

Thank you everyone for your responses. Regarding the pendulum, I had assumed I needed to get the correct weight pendulum bob, so it seems I have some reading to do. Thank you oldhippy, the date is nice to know. I hadn't noticed the hands were odd, again some reading required. The case needs to be completely dismantled and reglued as it isn't square and there is surplus glue oozing from every joint. I have seen a few pendulums that would fit but wanted to find an original if possible. The bezel has defeated me so far but if I can find a picture of a complete clock it would improve my chances. I'll post the pictures as requested by watchweasol in case that helps.1 point

-

For sure your eyesight is better than mine, I'm pleased that you sorted it and a good reminder to check and double check everything.1 point

-

one of things you want to do with hairspring is is to as others have mentioned take it very very slow. I was looking at it and I'm not seeing any Ben's some wondering if you're just overlapping coils?1 point

-

Thanks! Yes, "easier said than done". I was just thinking and thinking about the possible causes and the strategy of fault-finding. And the potential costs of a bent balance pivot (which was my main fear). I did indeed only return to the "bench" after 5 days -- precisely because I was never rested enough before that (I usually tinker in the evenings, after work and after my 3-year-old sons goes to sleep -- not ideal). On pegging jewels, I did that (it does indeed make a big difference!). But the pegwood doesn't usually go to that corner between jewel and metal setting. But it could & should. Oh, PS: unfortunately, I didn't take picture of the speck of grime. BUT I just found an interesting picture of the assembled jewel setting (that I took before finding the dirt). If you look closely, you'll notice that the pivot isn't properly centered with respect to the oil circle. Can you see it? In retrospect, this could have been an indication that the cap jewel isn't laying straight. Might be useful for others when inspecting!!1 point

-

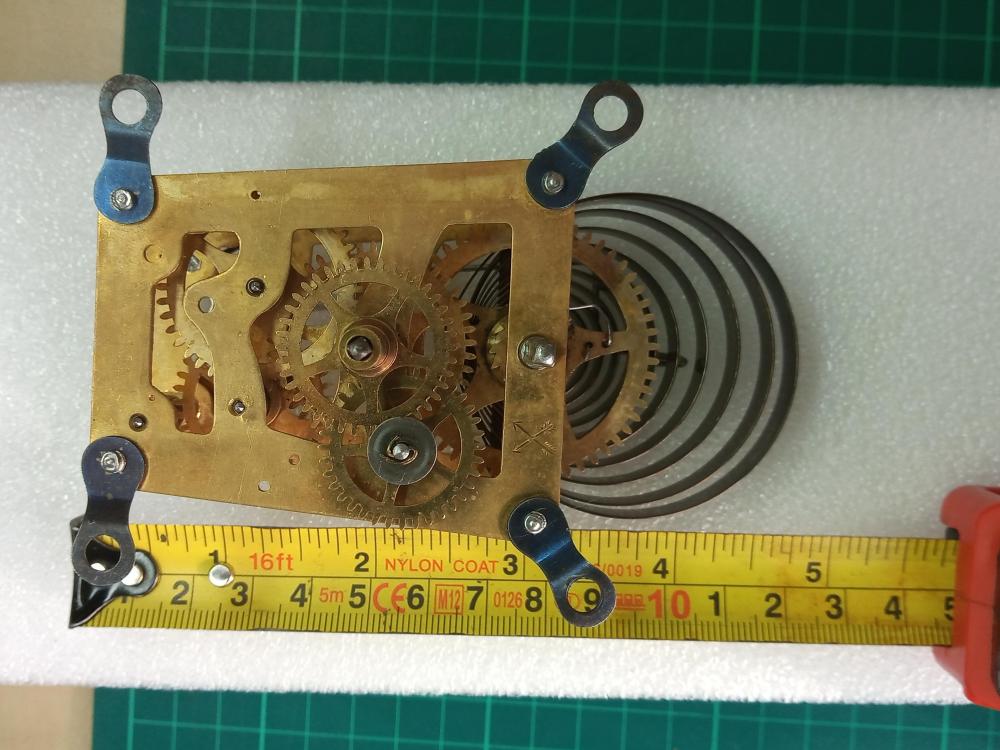

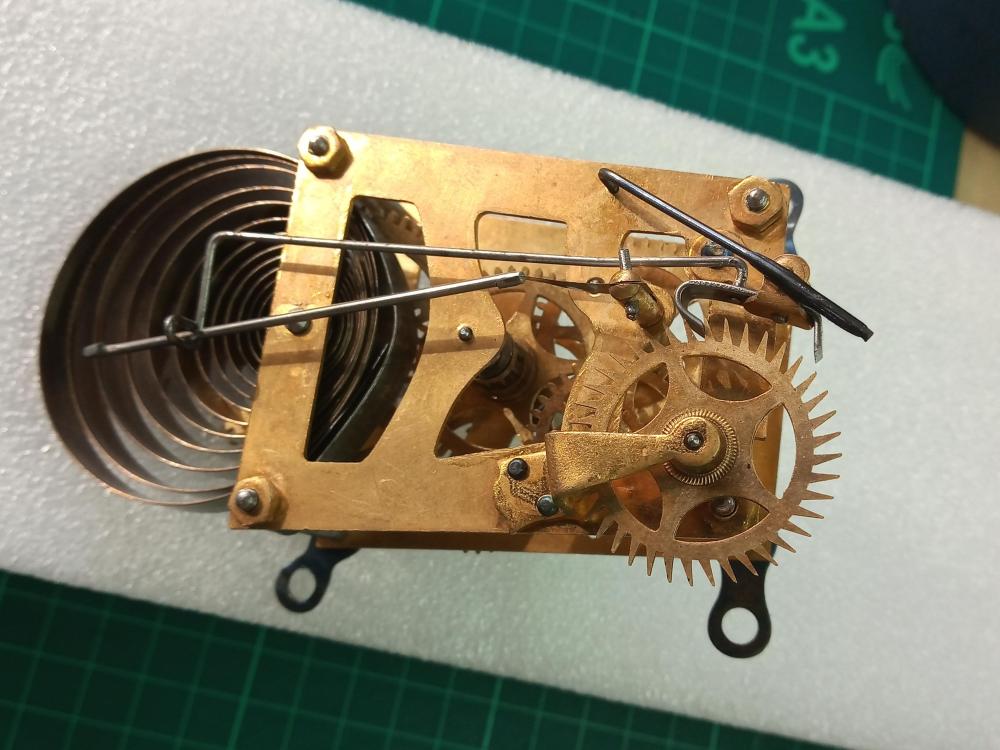

H A C stands for Hamburg American Clock Company. So it is after 1900 probably around the WW1 so 1914. Looks to be a 30 hour movement going by the spring. The hands are odd the hour is in the style of what is called moon the minute is what is called Spade. All wood case and the inside is still very rough which is what you would get. Needs a lot of T L C. With the internet you should be able to pick up a pendulum and you might be lucky with a bezel.1 point

-

1 point

-

I agree with you about the #5, I have a Dumont steel set with the green coating for grip and once I get them in my hand it's hard to put them down until something inevitably pings away. I think the slimmer points of a #5 make them more springy (less stiff) and this is combined with the fact you have less contact surface area means the parts are then more likely to ping away than drop onto the work surface if you loose your grip. Like you, I am quite strict with myself and try my best to use them sparingly. As for material I stumbled upon the titanium tweezers from CousinsUK, their own brand, and they are now my go-to tweezers the quality is excellent and they are almost as non-scratchy (hard) as brass: titanium = 70-74 Rb, brass =60 Rb and stainless steel = 121 Rb. However they have around the same tensile strength as steel (tensile yield of titanium = 480 MPa, brass = 124-310 MPa and steel = 485 MPa) so the time between dressing and risk of deforming the tips is very similar to steel. Also, the tweezers also seem to naturally form a brushed/sand-blasted type surface finish which is good for gripping (both between the tips and finger grip). I did try some cheaper off-brand titanium, but they were thin and I had to repeatedly open-up the tips so they returned to an opening distance that was workable, they felt spongy and cheap. Finally, titanium is by nature non-magnetic so it's one headache you don't have to worry about. In short, I think I have found my 'sweet spot' in titanium, not saying they are a panacea but I would recommend that anyone should try out a good set and give them a chance. I dress the titanium with one of those M40 diamond metal plates which seems to work well. Only when working on a delicate movement (Omegas butterfly wing coatings !!) do I switch to brass, but all the time thinking in the back of my mind I can't wait to get back to my titaniums. I have a set of #7 carbon/plastic tweezers that I use for dials, and date/day rings, so they don't scratch, but find them too clumsy for anything else. In regards to size I use a #00 for most of my work as the stiff tweezers tend to be less pingy... new word! However, when working on the finer parts or on a ladies movement I swap out the #00 for a set of #3c which are smaller version of the #00 and handle the smaller parts without the fear of damaging (crushing) them. I tend to use the #5 for removing shock springs and working on hairsprings, I use my steel Dumont #5 and the Cousins titanium #5 together for hairsprings - I can get a needle like tip on the Dumonts, but find that the titanium ones sharpen to a slightly less needle like tip, but still sharp. I use a set of #7 for holding the shock jewels as the curved jaws hold the jewel/chaton on the same plane so you seem to have more contact surface area = more grip = less pingy, you are also holding the part sideways so not pushing down, so less tiddlywinks. I also use the #7 occasionally just to change things up when working on a movement. @nevenbekriev Wow, just wow, that's impressive!1 point

-

Theoretically the period should be independent of weight. But in real world, weight is a factor.1 point

-

1 point

-

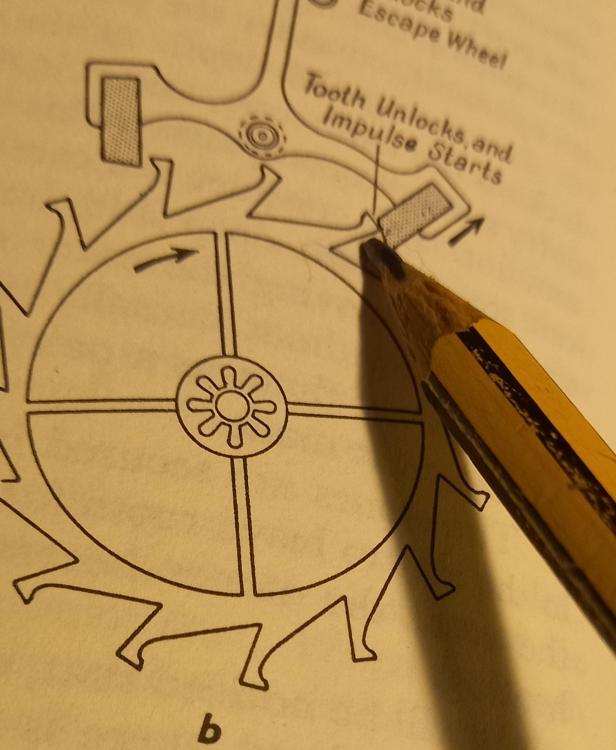

I thought it would eventually, but when you look at the direction in which the oil is being pushed its away from the locking faces of both the pallet jewel and the escape teeth. Whereas if the locking face is oiled the oil is pulled to the front corner of the jewel where it can be picked up by the impulse faces. I can see that watchie a much smaller area to oil on the jewel and a larger area on the escape wheel that might spread Thanks guys, i can also answer my own question as well, it was de carle that suggested oil the locking face of the jewel which prompted the question, maybe the old masters needed to learn a thing or two. But this picture shows that transfer should take place. As oil is pushed to the back of the jewel it should build up at the root of the escape tooth and at some point transfer to the escape wheel's locking surface. Its good to learn though.1 point

-

Oiling the faces of the pallet jewels provides a nice defined area to place the oil. The teeth pick up the oil, and have to distribute it to the locking surface. Keep in mind how little contact there is with the locking surface- you won't notice much oil there even properly lubricated. But if you place oil there, it will 99.99999% sure creep on up to the fork body.1 point

-

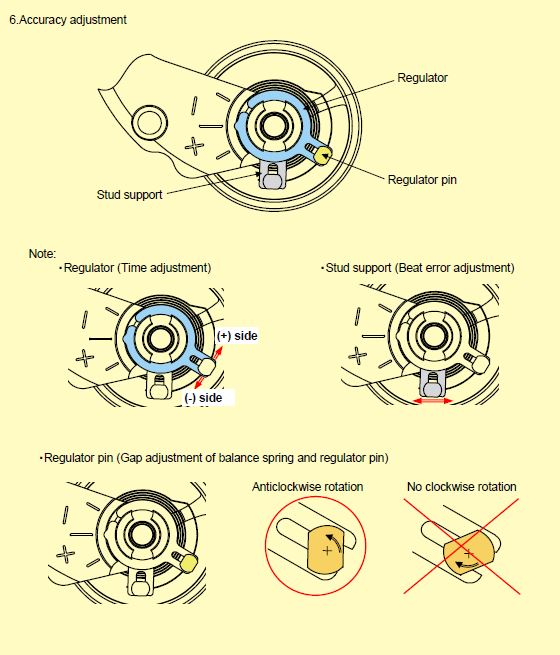

I think mangled is a bit of a harsh word here. let's interesting in the world of horology the battle of Japanese watch manufacturing with the Swiss is that sometimes they share things like the system here of the regulation on the stud commonly called a Etachron system the Swiss hold the patent for one part and the Japanese hold the patents for the other part. I'm attaching an image so you have a better idea of how things look. For now what I would do is just open the regulator up to its maximum and just move it out of the way see you can see if they hairspring got bent there. you and up with way more adjustments which of course will cause way more confusion when you're trying to figure out what you're trying to do here.1 point

-

You definitely need to reshape the endcurve and put the hairspring in the slot of the regulator. The regulator stud can be rotated to align the slot with the hairspring. Seiko uses a system similar to Etachron. To remove the hairspring stud, you can use a fine tip tweezer to carefully wedge the stud out of the clip.1 point

-

Thank you for the comprehensive technical info @JohnR725. I did not know about the new copper beryllium cannon pinion for the 1140. There's much info here to improve my level of precision. More to come! Excellent point @eccentric59. I did check the the engagement action of the yokes and levers (as well as all pivots of course)before securing the cover plate on, but it is definitely worth looking specifically at the teeth of the heart cams. Will also make sure the return hammer isn't hanging somewhere. Thank you.1 point

-

No search functions seem to work or single page loads. All i can do is to load all the pages and scroll through to find a calibre.1 point

-

Oh my word Joe what you thinking 'unpin the hairspring are you mad ? Quite possibly but maybe right as well. There comes a day in watch repair when you need to be brave and bold and say to yourself I'm going to unpin that sucker straighten it out and re-pin it. And that day Louis has come for you my friend, good luck bold one we shall see you on the other side.1 point

-

Thank you very much for all the responses, so I will try putting the hairspring out and going through the coils with an oiler. Wish me luck1 point

-

Is it a knot ? Or is it not a knot ? Ive had coils jump inside each other, you can work it up to one end, the cock stud end with a fine needle. Fried was a bloody master of hairspring untanglement. If i can find the video, i once counted the number of times he said tangled and untangle, it was a lot, yes I'm a very sad and strange individual . Hairspring 101 i think it was, let me find it and come back. No it wasn't 101 I'm talking out my arse, but this is Henry the hairspring wizard performing his mystical art . https://youtu.be/egCwtMMoOCU?si=4LDRlpfqWVXKUHET1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.ca502b3e67e1e13936648168231d15c1.jpg)

.thumb.jpg.b2036d29fafacc5dd87762d69c98ea08.jpg)