Leaderboard

Popular Content

Showing content with the highest reputation on 01/03/24 in all areas

-

I agree, I purchased a Robour press from them and it siezed half way down on the first use, I was unable to move it up or down. All they asked for was a video showing the problem and once they reviewed it they (CousinsUK) agreed to replace it. They initially asked for me to return the damaged tool (also at their expense), but as shipping out of (but not into?!?!) the UAE is so expensive they agreed to let me keep the damaged one and just shipped a new on to me. Initially I was dreading reporting the problem, but pleasantly surprised by the level of customer service and the whole process was resolved in under 1 week - now I'm a loyal customer. Also, I have constantly compared their prices to the likes of eBay and Ali Express and found them to be extremely competitive and often cheaper. Technically contract of sale is made in the UK, i.e. you offer to buy the product from wherever you are located in the world and they then accept your offer, as the acceptance of your offer and, therefore, the creation of the contract is made by CousinsUK in the UK, hence, UK law (technically English law) applies no matter where you are in the world. Thus, the UK Consumer Rights Act 2015 applies which states that your contract is with CousinsUK not with the original manufacturer (they have a contract with the manufacturer, not you) and they (CousinsUK) have a duty to replace or refund (at your discretion, not theirs) if the goods are not of "satisfactory quality" - See section 20 ss 7 of the act. There are some caveats for perishable goods, sanitary items and time limits etc. Unfortunately, Many retailers will try it on and fob you off to the manufacturer hence avoiding any liability/risk/cost, but they are relying on your (and probably also their) ignorance of the law, once you remind them of this they will usually back down and do what they are required to do, or you can take your complaint to the Trading Standards office (free of charge) and they will force them to comply. Basically, you just don't accept any nonsense about sending to the manufacturer, or "store policy states we only issue store credit..." or any other BS and insist on your consumer rights as per the law...the law trumps their "store policy" every time. Also, the principal still applies that 'you cannot contract out of the law', so any comments they try on about you accepting the stores return policy when you bought the goods is just nonsense. However, I fully agree with @VWatchie that the carrot gets you much further than the stick and a nice polite conversation will often get you what you need much quicker and nicer without having to argue the technicalities of the Consumer Rights Act. Disclaimer: I'm not a lawyer, but I have studied the Consumer Rights Act as part of my DBA, so please treat the above as friendly advice only.7 points

-

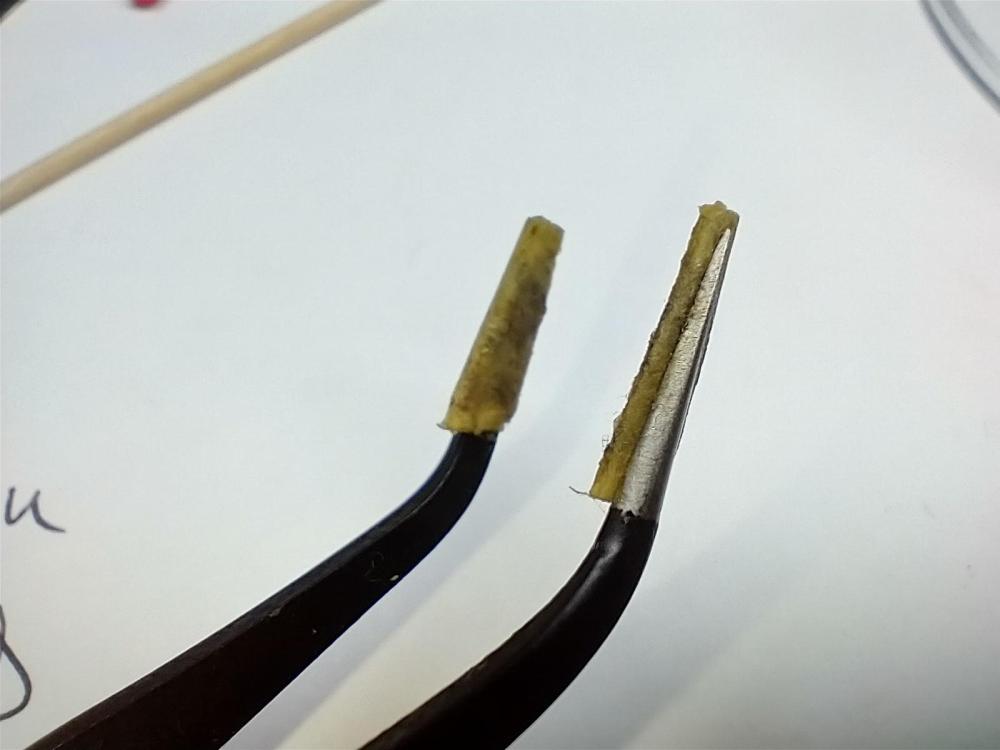

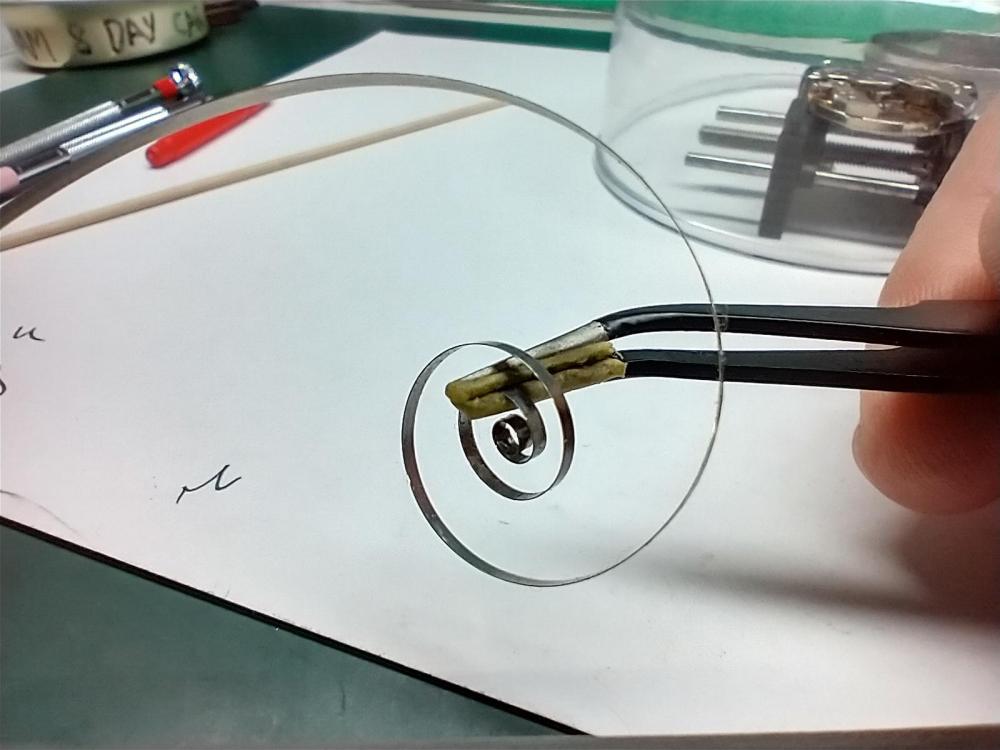

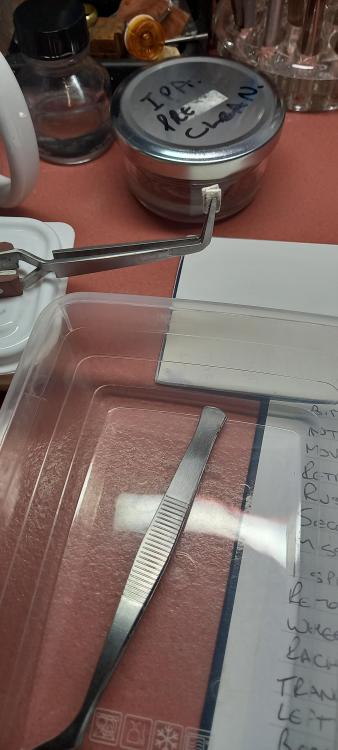

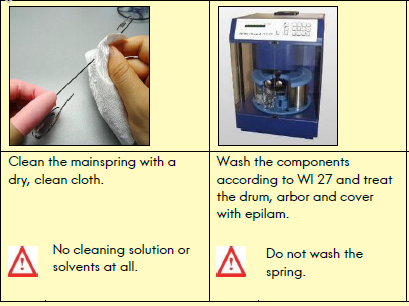

I make a pair of greasing tweezers with chamois leather on the inside. The chamois is greased with 8200 or 8300 is best in hot climates and the entire length of the spring is lightly greased. You know when enough has been applied as it is the feel of the grease on the spring and how easily those greasing tweezers slide over the spring. If you have greased the spring too much you'll see excess on top of the spring when you use your winder and it is within the barrel. If you haven't greased the spring enough then put a few small drops of grease on the top of the spring like Kalle Slappe does. There are many ways to skin a cat here. I can only say what works best for me. After you've greased a few mainsprings you'll get a feel for what the right amount is on the spring. If it is too much and you see pools of grease on the spring when in the barrel, then mop up the excess with some rodico. The great thing about making these greasing tweezers is you can get into the innermost part of the spring without risk of damage! Moebius 8201 contains Molybdenum bisulfide which improves its lubricity and improves its resistance to pressure well. It is similar in function to graphite and it has a black appearance. Some watch manufacturers use this as standard mainspring grease. When you open a barrel and the remnants of the grease is black then it was probably used. This grease is used only for the mainspring, not braking grease4 points

-

I got this from CousinsUK just after I started watches, for £63.75 you can't go wrong, link here, and I still use it on almost every watch I do and it's still going strong, I use the 4" (100mm) wheels without any issue. Adjustable speed too. I rigged up an enclosure for it (more about protecting the paintwork behind it) from an IKEA storage box and stuck in a shop vac hose in the back (hidden by the paper towel roll!) and a cheap LED USB light strip above it:3 points

-

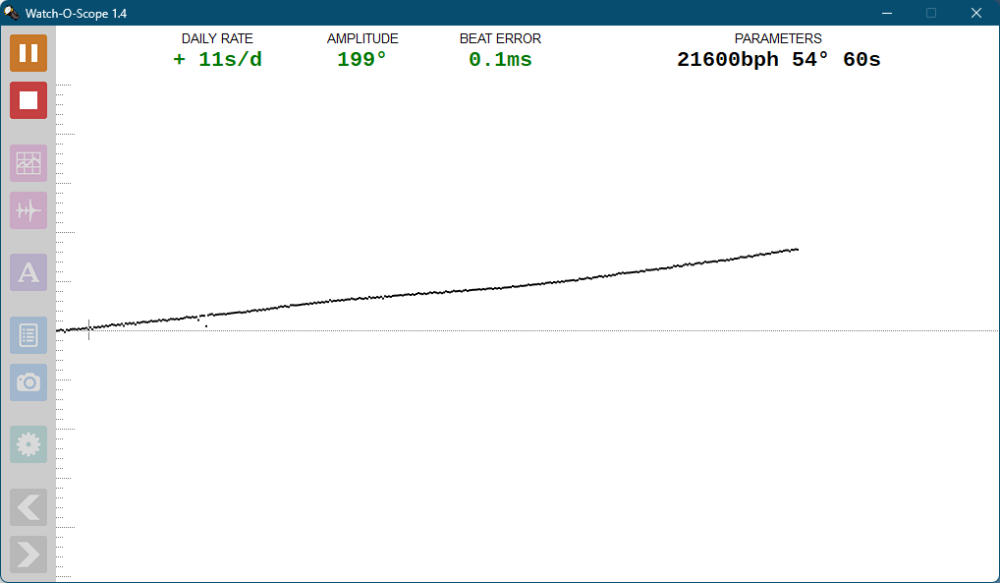

as you're just starting out sometimes baby steps are nice. Like don't worry about the balance jewels just practice taking the watch apart and putting it back together. You really need practice on disassembling and reassembling it and still having all the pivots stay in place and not fall off for unknown reasons. Then yes definitely good to examine everything in particular everything located around the balance wheel. In other words what does the balance look like as it's oscillating back and forth, what does the hairspring look like and of course what is the escapement look like. It's really nice to have a good feel for what a running watch looks like versus a watch that's having a problem where if you to take the time to study at you might not actually know what a running watches supposed to look like. Like for instance looking at the hairspring that makes triplex flat for reasons they sometimes aren't flat they get bent typically would balance wheels get removed they just magically bend themselves I'm sure they have nothing to do with how the person remove their balance wheel. And then when you have a bent hairspring it's rubbing on the balance arms of the watch doesn't work. Or it loses a heck of a lot amplitude. So yes take things slow study everything.3 points

-

I often wondered how you produce the pins that hold in the plates on old pocket watch mechanisms. Clearly they weren't cast, or turned. If you watch the early part of clicksprings latest video, then the method suddenly becomes obvious. Brass wire, a file and a small abrasive stone, and that most important of watch repairing ingredients, patience, is all you need. Now I know how to file a replacement when the carpet instantly digests a tiny, and seemingly irreplaceable 18th century tapered brass fixing component. It should work for the hairspring fixing pin on those pin lever Timexes too. I guess this is a lot simpler than trying to find a carpet with less annoying dietary requirements. Well worth watching and exploring. Thanks.3 points

-

That design of microscope is not suitable for watch repair work. 20X magnification is too high for general work. Usually we work at about 3.5X magnification. There is no tilt in the eyepieces, that means you have to look straight down, which would hurt your back and neck.2 points

-

All companies are money oriented, they have to be otherwise why be in business, i am. But i look after my customers, its paramount to me that they are happy. If they weren't then i would be affected by that in time. I can't say I've had a problem with cousins but then I've only had a couple of bulk orders with them. I know some are quite unhappy with cousins, what i was trying to say if you are going preach law and ethics to a company then really you should have your own company to top order.2 points

-

Thanks everyone for your input! Quite the funny banter here I did consider a new movement and clean up attempt but it had an inlay around the face that was broken so alas it has gone to watch heaven. Appreciate all the responses from the actual watch worthy2 points

-

My jeweler gave me the same advice. He said he'd just do the same thing I could do at home. So I put some tape on my smooth-jaw pliers and gently started bending. I got them just open enough for an 18mm strap. After some careful reshaping of the hour hand, some crystal struggles, and a little more lug tweaking, it sure looks nice on my wrist.2 points

-

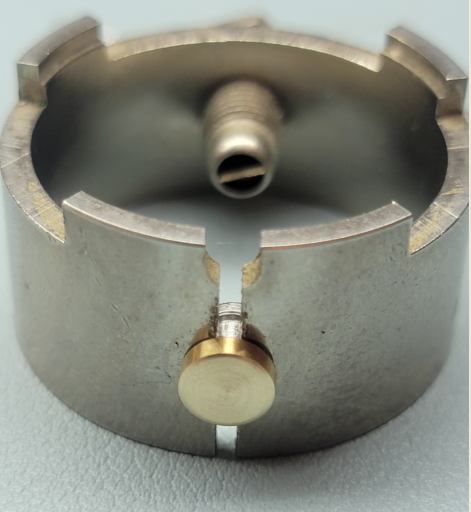

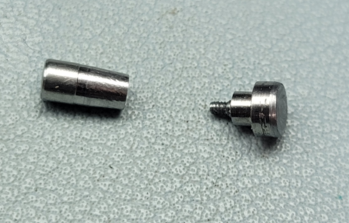

I have a couple of these movement holders for 218 Accutrons. In order to mount the movement, the holder must be splayed ever so slightly and then released when the movement is in place. I have been splaying with a screwdriver, but this morning, I made an add-on tool that does the work for me. I turned a slight conical profile with the initial diameter equal to the hole in the holder in rest position. I turned to a larger diameter enough to open the holder enough for the movement to drop in. Then I tapped the small end and made a threaded button. The tool is mounted in the holder in a semi-permanent way. When you want to insert the movement, press the pin from the inside of the holder and it splays out. Once the movement is inserted, the outside butt is pressed so that the holder collapses on the movement. I made two of these. One is mounted on the holder with a brass button. The other I show sitting alone so that the structure is obvious. The second one uses the brass button--easier to turn and thread.2 points

-

I think I am lucky with my bride. Never whinges or rolls eyes. "Parcel for you". I buy what I need when I can. I get £10 weekly spends from my bride when she has been to the ATM. Goes into my wallet. When I see an item on ebay I want, and when I have the cash equivalent, I order. I place the money from my wallet into our savings wallet. I win, we win. Not quick, but tools mount up. Been at this hobby for 2 years now. I estimate at least 1/2 is tools, the other watches and parts. Good system for me.2 points

-

1 point

-

I've just invested in an old K&D 600 series staking tool set in order to do this..... Thanks for explaining that - I've found an illustration on YT of this being done.1 point

-

1 point

-

The thing you need to be careful with and only applies if the case has a glass is the length of the center spindle make sure it isn't to long other wise the hands will rub the inside of the glass and the movement will stop. You need to sort out the hands as the ones you have might not fit so buy the hands that come with the movement normally you have a selection to pick from something near the length of the old movement and style. They all fit by a center fixing nut.1 point

-

1 point

-

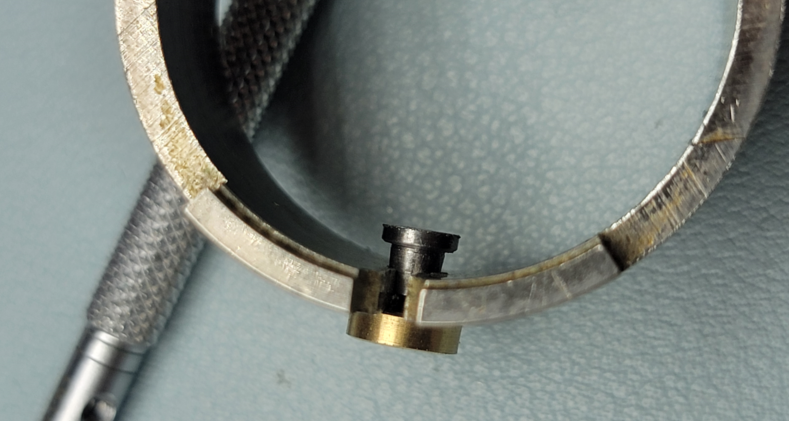

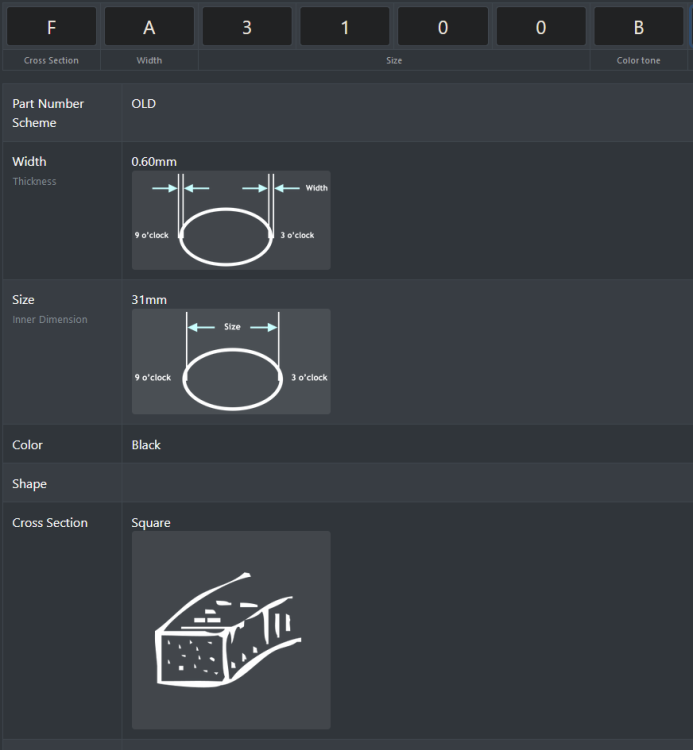

Edit for anyone coming here looking for gasket part numbers for their 6106-5549: Caseback: FA3100B: square profile, 0.6mm width, 31mm inner diameter. Crown&stem: DJ0060B: D-shaped profile, 0.8mm thick, 0.6mm ID. Crystal: OB3005B: O-ring profile, 0.75mm thick, 30.05mm ID. Found it at Seikoworldtime.com! Wow what a tremendous resource.1 point

-

Hi all, I started on this hobby this time last year. I went a little crazy on Ebay and now have a drawer full of “projects”. My latest is restoring a 1954 L&R Master watch cleaning machine. This site has been invaluable, especially with the wiring. Thanks, MichaelK1 point

-

Amazon sell a lot of products and regardless how happy the majority of the costumers are with that product, there are always some "one"-stars. One can look at the happy crowd and make up you mind, or you can purely focus on the "one"-stars. It doesn't matter what Cousins incentives are, the fact that they stand up and are willing to spend all that time & money to fight the Swatch-group is in my opinion highly praiseworthy. I'm concentrating on the good, which, IMHO, outweighs the "one"-stars by miles.1 point

-

Thanks! These are cool because they're so thin, too. This one has an 11AF movement. More info and pictures at this thread here. I also have a 1956 President "P", which I love. It's got a 10BU movement. The face is a repaint, but it's so handsome I don't care much. My thread on it here.1 point

-

I’ve always been really impressed by the lapping machines that are used to achieve flat faces and crisp on cases. Although I don’t do enough case refinishing to warrant the price of a machine, I though maybe I could achieve a similar result with something home built. The impetus to try came when I bought an Omega Chronostop. The case came with a sunburst case finish that was long gone and would require precise brushing. I figured I could replicate the multi-axis adjustment by using a telescope head. Found one on eBay for $125. Then added a 3 jaw Chuck for $50. My only issue was that I needed to adapt the two together. Because the stress won’t be so high I figured I could just 3D print some adapters and it worked perfectly! The great thing about the resin printer is that the resolution allowed me to actually print the threading! Because the case is a top loader, there was no good way to hold it properly so I printed an adapter to screw on the back. All ready to go: I am really happy with the results! The case has some dings that I wish I could laser weld but alas I can’t built one of those on the cheap. Lol. My next step is to find a way to fasten everything down so I get more consistent engagement with the sander and recreate the angles consistently between checking my work. - Craig1 point

-

I don't think that they necessarily are inseparable. Of course they are money oriented as are most companies and people who work for a living. While it's not completely mercenary for most, money is the compensation for work. I'm not saying Cousin's is the Mother Theresa of suppliers either, but deliberately irritating your customers is not a good business model and definitely affects the bottom line. That said, I do think there is a huge difference between a company selling something for a profit and one company telling another they are not allowed to -- and they do everything possible to prevent it.1 point

-

I know you always recommend a new spring Jon, but what about pulling a helixed spring back through itself. I have tried it a few times on scrap springs and it will reduce even sometimes remove it altogether depending on the type of spring. You're probably not going to get a good even film of grease over the full length and profile of the spring that way, maybe in time but that might be leaving it to chance. Oil maybe would, but back to the basic principle of # if it revolves oil it, if it slides grease it #. Might also be a reason why folk complain of issues with mainspring winders, a pre greased spring is going to slip out of the winder barrel and into the mainspring barrel much easier than a dry one, adding a touch to winder wall also helps. Keep winders boxed and brush out before using them. I use greased watch paper in a pair of tension and tip adjusted reverse lock tweezers. Makes life a little easier and gives you an extra hand to control the spring. Same tweezers i use to clean the spring with a small strip of chamois after ipa soaking the spring. Clean and grease in one operation. no i don't get that at all. Oil could spread, could excess oil make its way out of the barrel if the base or lid has a cut out ? A fully greased spring seems a better option imo. Seen it suggested many times breaking grease described as anti slippage grease. I feel there needs to be some clarification on this as that makes no sense to me whatsoever. Thats almost exactly what i have cept my tweezers are locking, just frees up a hand. Either greased watchpaper or chamois.1 point

-

I understand Cousins involvement and they themselves are heavily affected by the parts restrictions and a complete withdrawal. But i just cant help thinking though after recent discussions in the forum regarding cousins attitudes towards customers that they are just as money oriented and uncaring as Swatch.1 point

-

1 point

-

Thank you for all the replies John. A little embarrassment on my part but the pivot was actually fine, i added an update after my original post. Working at 3am is not a good idea for watchrepair, tired brain and tired eyes. Later that day fresh eyes saw a different scene and a dab with pithwood revealed a perfect pivot. A little jewel jiggling was still required to improve the endshake but the train runs well now. Still all the ideas suggested will be relevant at some point, all good knowledge gained is useful one day.1 point

-

1 point

-

@Jon i like your tweezer idea, ideal use for worn or crappy tweezers we al likely have kicking about in our toolbox. Tom1 point

-

Lovely watch @ManSkirtBrew. My favourite style - plain white dial, gold hands and sub-seconds. What's the movement ? - I'd like to find one1 point

-

I placed my first order with CousinsUK in 2017. Since then I have had two problematic products delivered. The first was the Bergeon cannon pinion remover, advertised as able to extract cannon pinions of any size, but in reality only cannon pinions with a diameter >= 1mm. Cousins contacted Bergeon about it, changed the description on their site and refunded me my money. The other situation was a pallet fork for an ETA movement. The package was opened and the exit jewel was missing. This time they sent me a new pallet fork stamped "chronometer" which was not even listed on their site. Through the years I have learned that the most efficient way to resolve a situation is to ask for help even if you're entitled to demand help. So, so far I have only praise for CousinsUK and through the years I've probably spent an amount close to a Rolex submariner on them. No worries John, we all are, the only difference most of us are fortunate to get over it1 point

-

1 point

-

when the problem is when people asked questions on the message board in order to really get a proper answer you should give us pictures otherwise we will give you generic answers not necessarily helpful for your particular situation so if you still have some of the pivot left yes you could shorten a little bit providing you can actually move the jewels. Sometimes the jewels are flush with the plate and you can't move them in any farther they will fall out other times there recessed and they have a lot of room to move around. All things that conceivably would change our answer. Now as I migrate up the messages I see your picture and what exactly is wrong with that pivot now? In other words it looks like you have quite a bit of the pivot left so much so that did you just move the jewel now? I thought we were talking about no pivot or very tiny pivot but that's quite a bit of pivot left? often times you have to soften the steel. It also be very careful with drills not to burnish the hole you're trying to drill as it will make it basically impossible to drill. typically all carbide drills are bristle. The general rule is if you drop one on the floor there's no point in picking it up basically cause it's going to be broke. Carbide drills work really well if you do not twist or bend them. As long as they're running at the right speed and they go straight into the work they do a beautiful job. actually that's something my father used to do depending upon the carbide drill some of them only have the carbide drill part others basically the whole thing is carbide. So he would silver solder that into something and grind it and make it into a cutting tool for the lathe. Oh and just to clarify not a watchmaker's lathe but a machinists lathe1 point

-

1 point

-

1 point

-

I always try to stay one step ahead of the game in family life. Tbh it never bothered me at the time if they were happy then so was i . I'm quite lucky now, all mine are grown up with great jobs, even the missus earns more than me these days, so I've been let out of my cage.1 point

-

From what I’ve seen Scott it varies depending on who you watch, some it’s no grease, some 8200 and some maybe 3 drops of HP 1300 on top of the coiled spring. I don’t know if any of it is best practice except don’t have to oil a brand new spring. It does make sense to me that a spring that has been through a watch cleaning machine would need lubrication. I suspect that it would also help when using bergeon style spring winders to ease friction. Maybe one of our esteemed pros could help us out with their experience. Tom1 point

-

How I see it is 8200 can be used to grease the spring, not the barrel using a piece of watchmakers tissue lightly loaded with the grease, folded over the spring and drawn along the length to give a very light smear of grease. The wall of the barrel should be greased with braking grease separately with something like 8217. Tom1 point

-

If it is a fake they faked a Must and not a Cartier? You may have been innit just for the treasure hunting but If you like the idea of improving this tis true you could replace the movement without much expense and cleanup the case and band. The dial is in good shape… I have no suggestions on the..bezel thing? What is that? Could that have been plated or painted at one time? Ugh…sorry, now I vote bin…1 point

-

Thats well cool, i love the inset tray for the small mesh baskets. How does the filament hold up to the cleaning solutions , elma wf pro plays havoc with some plastics.1 point

-

I have made some changes to my DIY machine over time and thought that I should do an update of this thread. Outer wash basket has been redesigned with larger openings. Prints a bit faster and uses less filament. Also added a bottom impeller to encourage fluid flow through the basket layers. Added a basket layer that holds 4 of the mini mesh baskets. I still have one for holding 3 of those baskets. Drying shroud was made a bit larger. Less chance of the basket rubbing against the sides. Bottom jar baffles replaced with stainless steel mesh along the sides of the jars. The bottom baffles looked to be reacting with the wash and rinse chemicals. The stainless steel mesh has not had that issue. Testing with and without the baffles does show some reduction in the swirling of the fluid. https://www.amazon.com/gp/product/B0BMTY6KH4/ I extended the stirring rod for the basket. My 3D printed extension ended up breaking. I used a coupler and a length of stainless steel rod instead. I did grind some flats on the ends for the basket and the coupler to tighten to. https://www.amazon.com/gp/product/B07P5YZKY5/ The STL files have been updated for the 3D printed items. https://www.thingiverse.com/thing:59051661 point

-

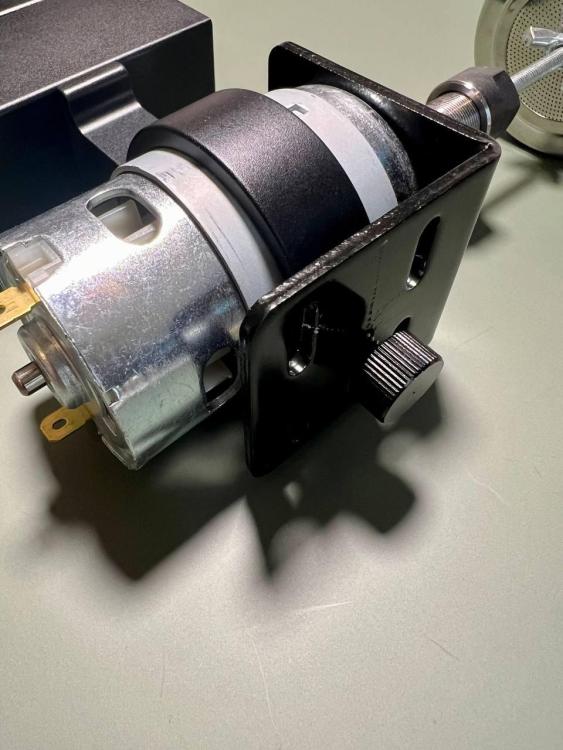

Hi everyone! Here you can find an idea on how to build your own cleaning machine for less than 150$ using some stuff from Aliexpress (or Amazon). First - the video: Second - the stuff (all the wire connections were made w/o soldering - only crimping terminals were used; also 3 additional holes were drilled): Hope it will be helpfull to someone.1 point

-

This is definitely something you do not want to do. Often times will get pictures the balance wheel and hairspring out of the watch in the problem is that's not where the problem is the problem is in the watch. You need to look in at the hairspring in the watch to see if it's flat removing it will reveal nothing in fact usually hairsprings will look perfect out of the watch. For instance if you bent at the stud which is a very commonplace to get bent out of the watch the stud is at an angle which it probably never see and they hairspring will look flat so leave the balance wheel and hairspring in the watch and look and study is there that's where the problem is not out of the watch1 point

-

Even though you checked, first thing I would check again is your balance staff pivots. I know when I was first starting, even a broken pivot looked okay to me, and it'll still assemble fine and often run (albeit poorly) with a bad pivot. Take a close look under as high magnification as you can get. The one on the right is broken, left is not: Or bent like this guy: You want to see this:1 point

-

1 point

-

Sounds to me like the balance does not oscillate free. Remove the lever and do the free oscillations test as adviced above. Look at the hairspring condition and position. Pictures are welcome1 point

-

Will you elaborate on this. Sounds as if impluse jewel is way out of beat or missing .1 point

-

A bit nerve wrecking for sure but it was interesting to watch, good job. for anyone interested here’s the video link Tom1 point

-

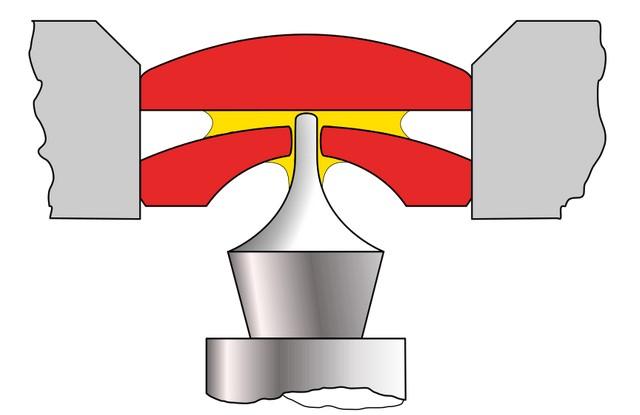

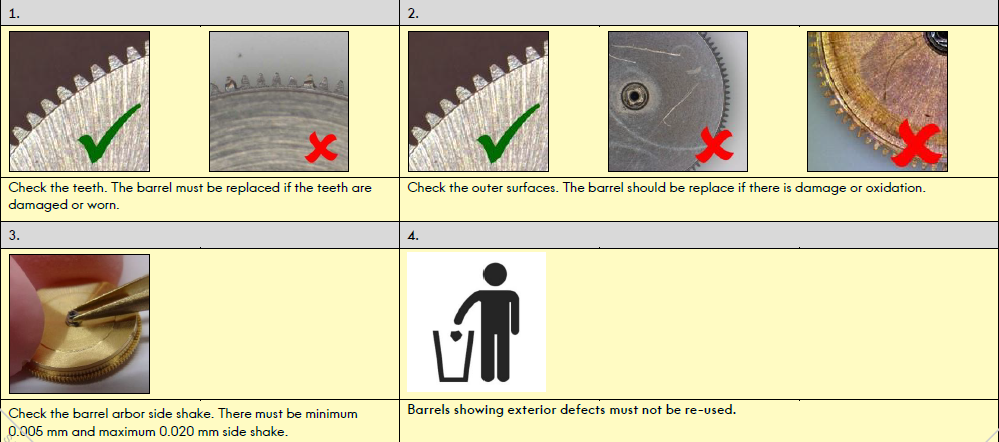

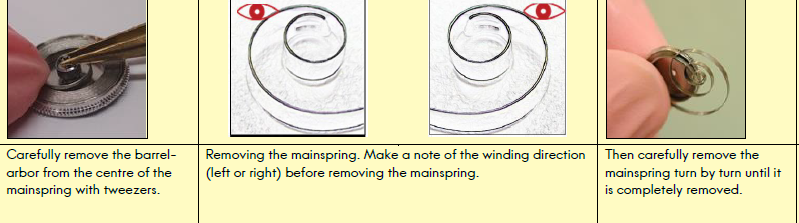

One of the minor little problems is which Grease? Thinking about Tools watch tools Aren't you in a country where they allegedly make watches? The reason I bring this up is if they make watches allegedly it stands to reason that there might be shops lurking here and there selling used horological tools? At least much more likely they are then other parts of the planet where they don't make watches? When I deal with pocket watch spring is I've seen spring is coming out of the barrel that looked beautiful. In fact I just put a spring back in Illinois that came out of the watch because it looked perfect. Versus brand-new Springs that have looked worse and the other day I regret not getting a picture a brand-new spring which I have to take out of the ring is because I have to use a mainspring winder put them in to get the end stop book. This brand-new spring basically had the curvature for the Armature and it went off basically straight it had no curvature at all and that just didn't quite seem right but it's what I had and the watch seemed to work. So yes there does seem to be a lot of variation in the curvature of new springs from beautiful back occurs which should produce a really nice long linear power to others that have no back curve at all or any other curve Then what Omega recommends in a working instruction versus the service center where they just throw everything away. Okay they don't actually throw it away they return it to the customer. One of my friends took his coaxial escapement watch in and when he got it back he showed me the picture of the parts there was a mainspring barrel had been disassembled some spring was out and you could see it. Although a friend who worked in the service center is sometimes apparently they were just randomly put mainspring barrels in when they sent them back they were entirely well the had leftover parts that they didn't use and they would return them to the customers not necessarily the right customer which I found amusing. So know we cannot go and raid the trashcan and get all this wonderful stuff. Oh and that would include the epilam I did inquire about that. Now with the modern cleaning machines that do really nice jobs of cleaning they basically epilam every single watch it's in the final rinse stage. Only a couple of components are removed everything goes through and they go through this stuff in huge quantities. Unfortunately when they dump it out it's all mixed together in other words the will cleaner the epilam and while it was a thought So you're looking for working instruction 67 which doesn't exist in the wild but let's see if I can easily snip out a few images. Easily stepping was not exactly I had to work really hard as I did not feel like taking time the airbrushed out the corners. Plus somewhere I think down below I mentioned I skipped over the section of breaking grease as I know I've snipped out images and their lurking somewhere else on the message board. Amusement in all the things you look for because based on some of these images none of the pocket watches or most of them should I be reusing the mainspring barrel. But fortunately for Omega other talking about relatively modern wristwatches the barrel should be fine. Yes I've seen the reference to not using solvents at all of course they don't say why. I will do it occasionally when I'm cleaning new old stock mainsprings that seem to have something sticky on them or reusing a new spring which was previously lubricated with something. Notice how they don't use lubrication on the spring at all. Oh and then notice on the cleaning the reference to epilam. This is one of the reasons you can use the HP oils I think any time I've seen a reference to the HP oils they do have a habit of spreading over the place despite with their technical sheet says so you have to use epilam. Oh and you will note I'm skipping several images because they're lurking somewhere else on the message board. Hours I skipped over the section of how to apply the breaking grease B is as I said it's been covered somewhere before. And then the real purpose of this was to show you that yes you really can reuse a mainspring as long as everything is reasonably perfect.1 point

-

1 point

-

I had a little time to work on the machine again and this is where I'm at. Very much still prototyping but key elements of the design is working. I've just shortened the cycles to 5 seconds each, as opposed to probably the 5 minutes that it should be - I'll have to go soil up a watch movement to get an idea how much time it needs in practice. It turns out that it's a lot more stable now at 900rpm than I initially thought it was going to be. Now I just need to work on the wavebreakers and make things a little more permanent.1 point