Leaderboard

Popular Content

Showing content with the highest reputation on 12/22/23 in all areas

-

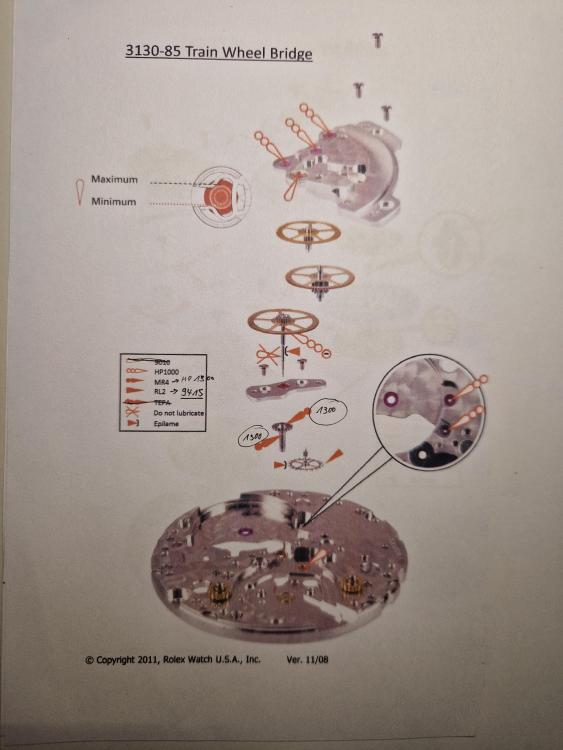

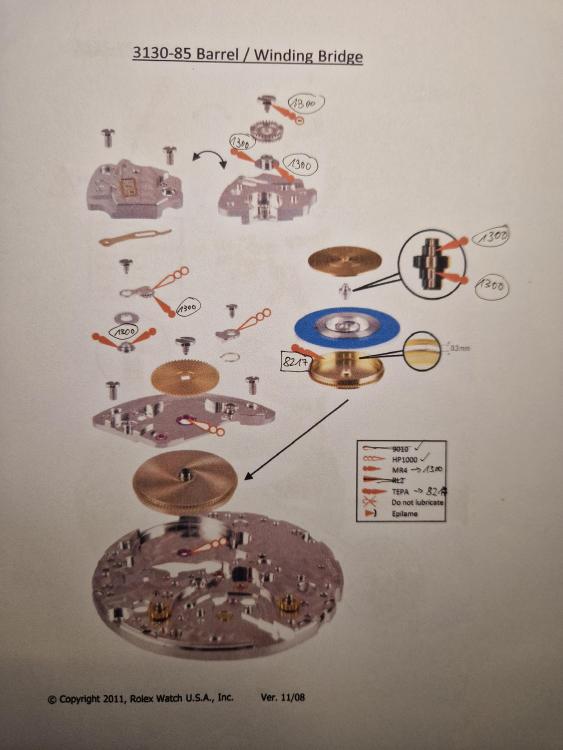

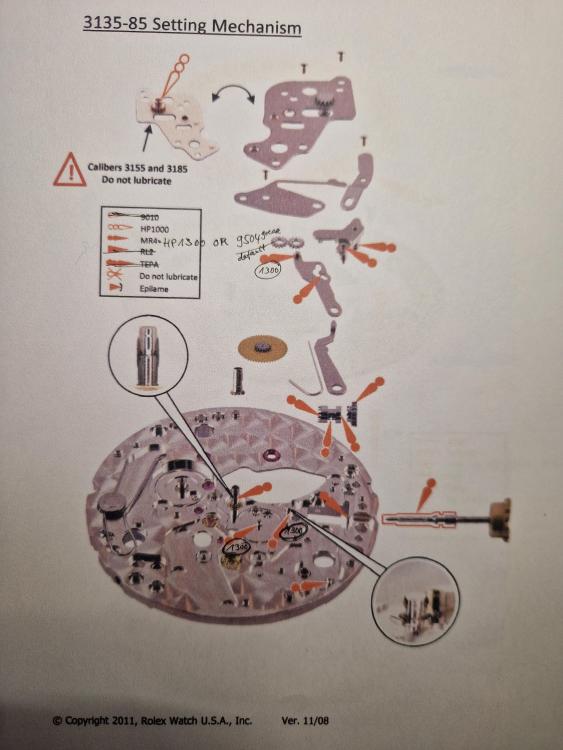

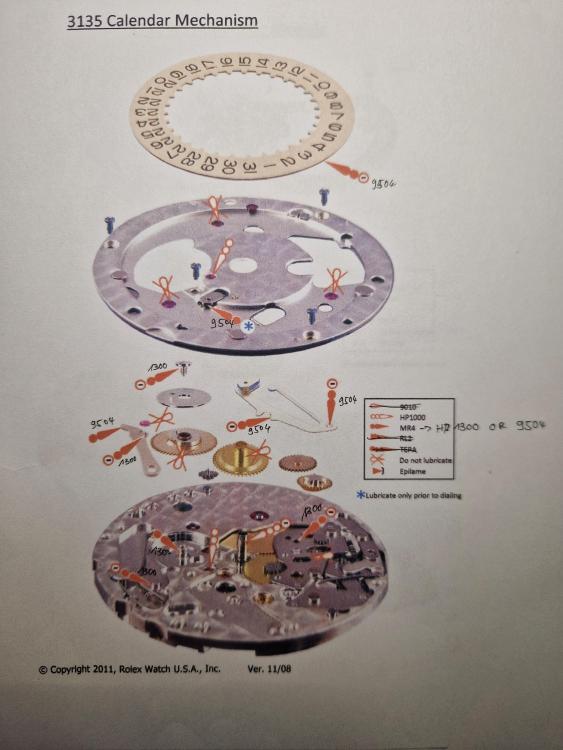

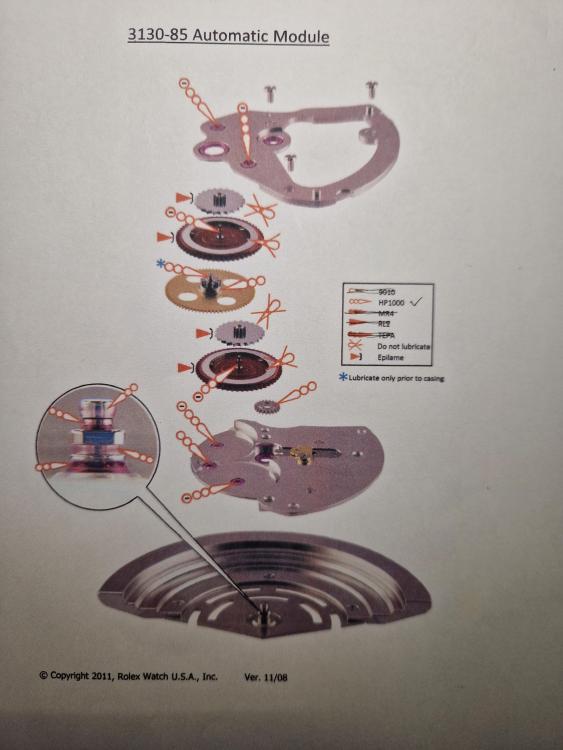

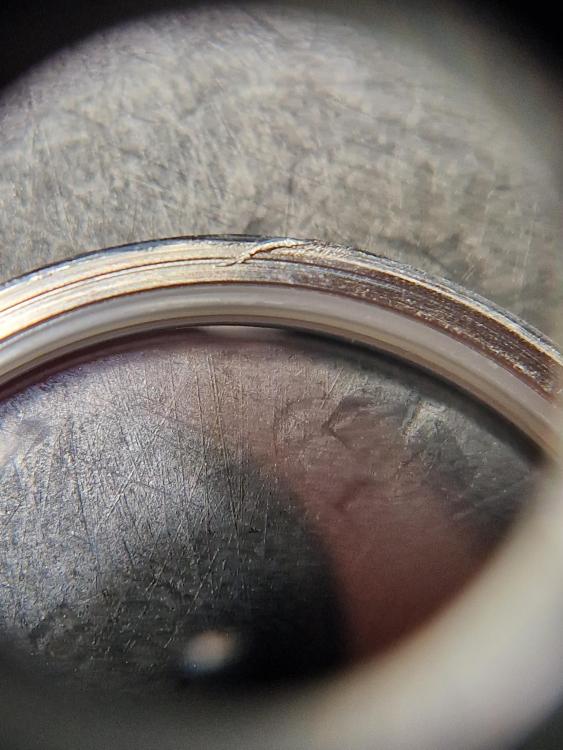

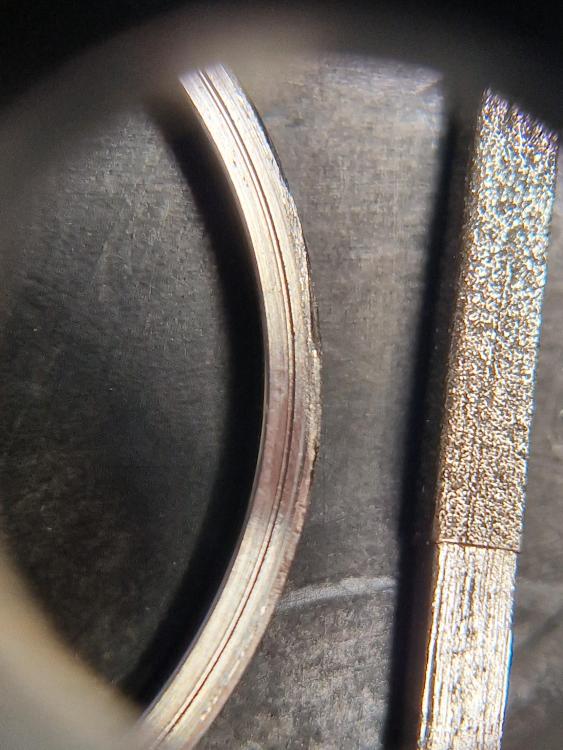

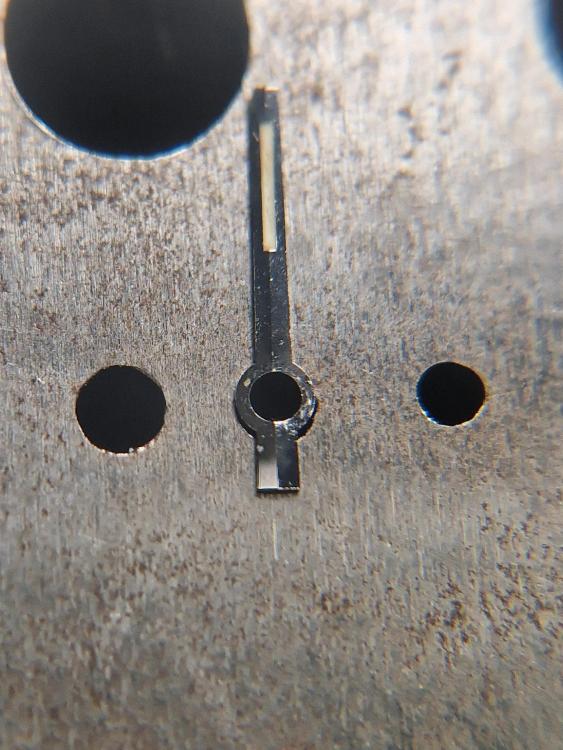

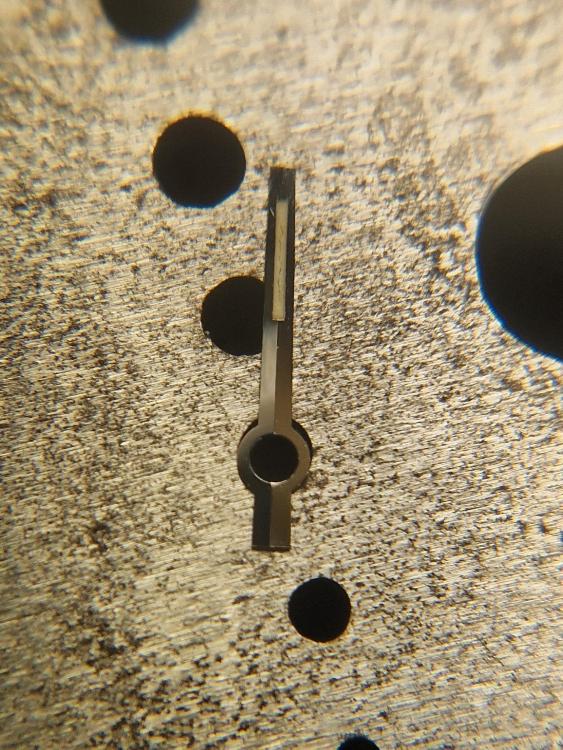

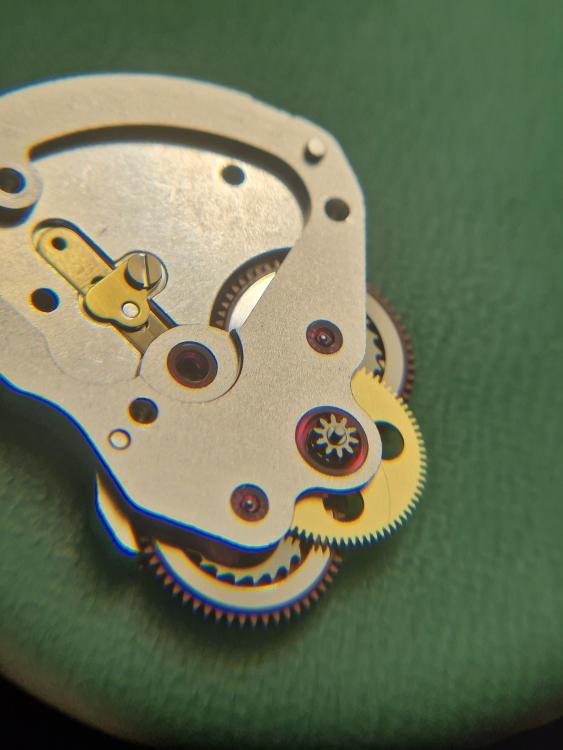

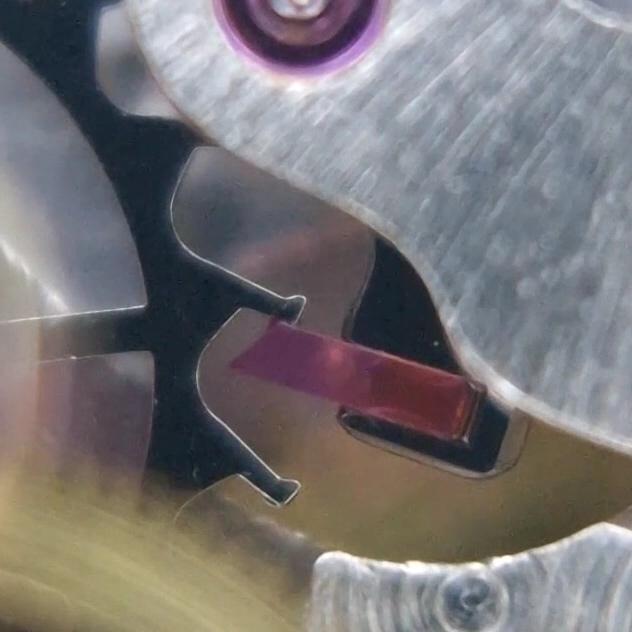

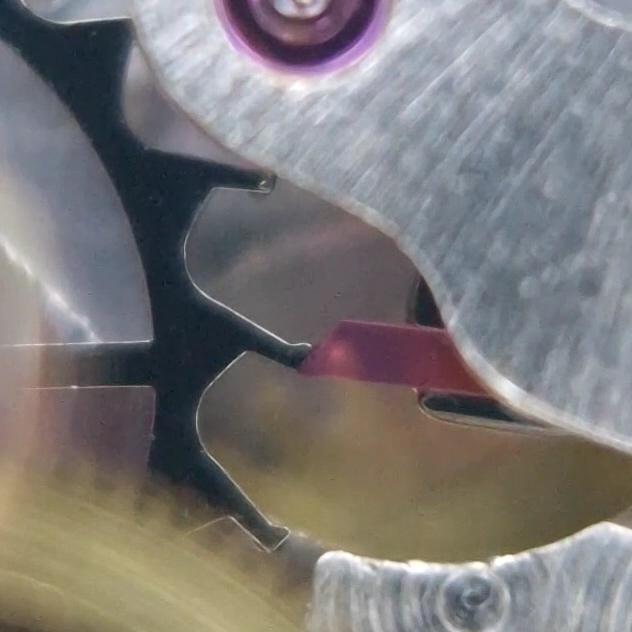

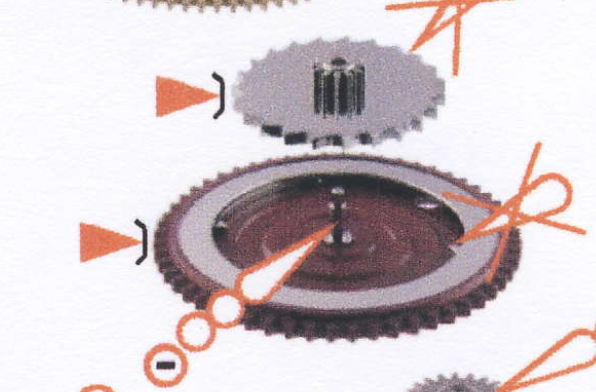

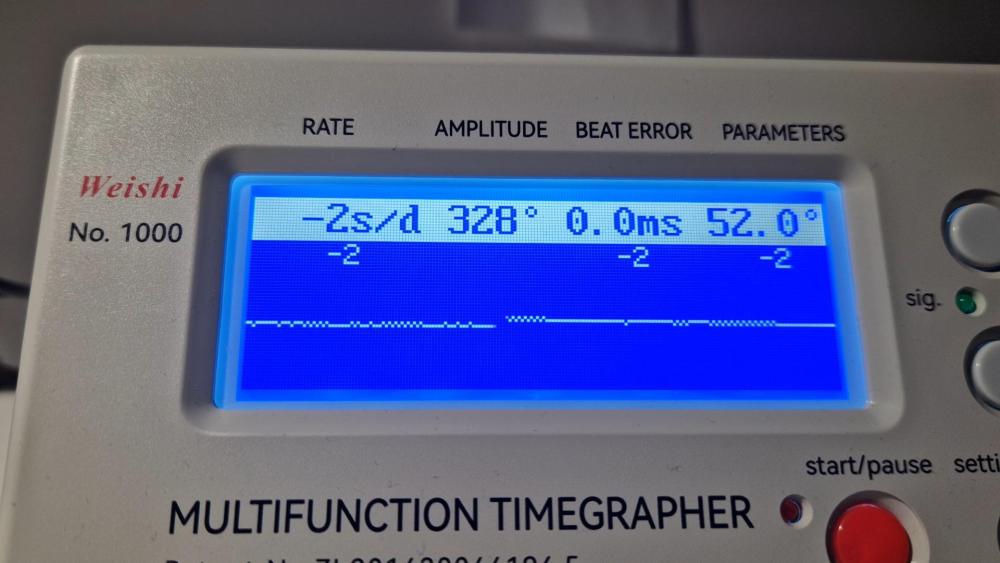

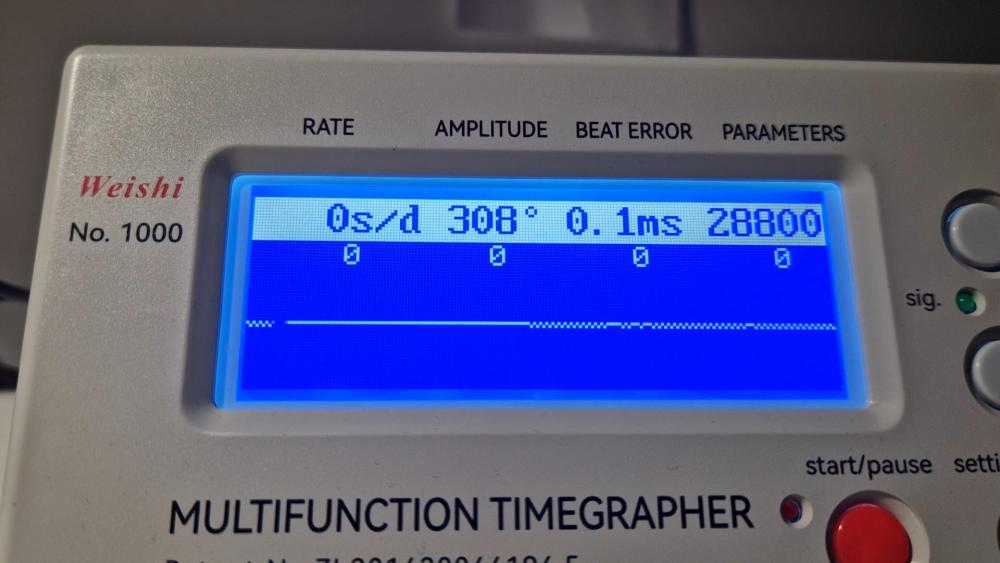

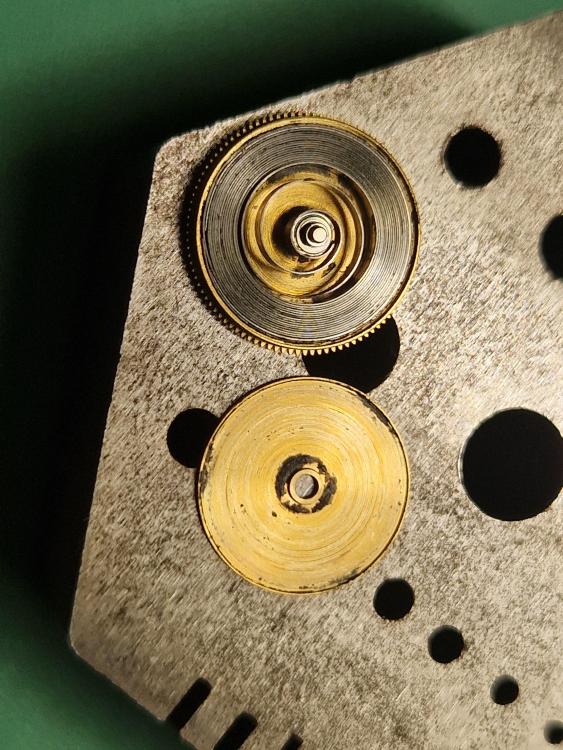

Hello all and merry Christmas (in advance)! I just finished a service on a Rolex 3135 in a lovely Datejust 16220. First, here are some overview pictures of the movement: The watch was in overall good condition, but it was running a bit fast and inconsistent (across positions) and amplitude did not reach 250 even fully wound and dial up. Upon disassembly, I did notice some a bit of dirt and some jewels/pivots had run almost dry. The barrels shocked me again (similar to the Rolex 2035 that I recently serviced): Thanks to @JohnR725, I had access to detailed oiling charts and service training guide: https://www.watchrepairtalk.com/topic/3626-rolex-3135-beat-error-adjustment/?do=findComment&comment=234180 After some good pre- and final cleaning, I assembled exactly as prescribed by the Rolex training guide that I followed the service guide in detail. For lubrication, I followed the Rolex oil chart, also posted in the link above. One particular issue is the Rolex lubricant "MR4". It seems to be somewhere between a very thick oil (like HP 1300) and a grease (like 9504). I used either HP 1300 or 9504 as a replacement and depending on the particular locations. My final "interpretation" of the oiling (with Moebious oils) is as in the pictures below. Regarding the pallet fork, the Rolex training guide seems to suggest a rather large quantity of 9415. Consequently, I put more than I usually would (but still less than the suggested amount by Rolex). See pictures below. What are your thoughts? For the automatic module, as show in the Rolex oiling chart, I treaded the reversers with Epliame and was VERY light on the lubrication of the "internal pivot" (see screenshot). As prescribed, I did not oil the internal ratchet/click mechanism of the reversers. Case: The previous watchmaker left me a present under the bezel. I noticed that it was not sitting perfectly even on the case. He (or she) must have removed the bezel in a way that damaged it a bit. I filed the damaged metal away with a diamond micro file. Bezel back on with my trusty Robur (with 3D printed adaptors for "standard" M4 dies). The dial and hands also got a bit of cleaning : Before: After: Casing: 1. align the case clamps on the movement with the matching groves in the case. That's how that looks. Turn everything around and slide the movement into position. Insert the stem. Done. At full wind/dial up. Vertical positions are running a bit faster (+8-10 seconds). I may look into regulating that further. I'll eventually post more results. To conclude, my usual "artwork": Merry Christmas to everyone!!!6 points

-

Thanks for responding! Funny you say "if you are really concerned about over oiling"... While I really wasn't concerned by it, I had this random/nagging feeling that I may have forgotten to lubricate the mainplate jewel for the mainspring barrel. Conveniently, it's possible to take out the barrel by only removing the automatic works, ratchet wheel and barrel bridge. The movement can even stay in the case. So I did that and, well, found that there was oil. So I didn't forget. However, I noticed that the upper jewel (in the bridge) was barely lubricated. Funny how my mind led me to that issue.. Anyway, so I lubricated the bridge jewel properly now and... amplitude is now through the roof! When I took it off my wrist after a few hours of wearing (and it was fully wound when I put it on), the timegrapher went up to 330°. Now I'm actually a bit concerned that I risk knocking. But it calms down after just 1-2 minutes and goes to 300-310°. So I think that the risk of knocking is low as you never really wear the watch in a perfectly horizontal position. Wound to the limit, straight off the wrist and onto the timegrapher (dial up): After just 1min:2 points

-

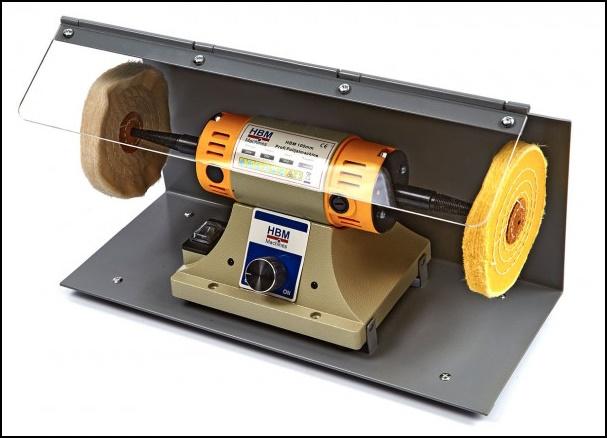

I just ordered this polishing machine from Holland (ToolsIdee) including the protective hood. The wheels are 100 mm in diameter and I think and hope that will suffice. The wait begins... (again). I will soon have to kick out my soon-to-be 18-year-old daughter from her room to get my workshop. She's studying in Tokyo right now and I'm itching. Need to make room for a lathe too2 points

-

Exactly. The majority of work can be done with tools only (tweezers, movement holder, pegwood...). I personally work without cots about 60% of the time (I could push it to 90%). BUT when I work without, I do NOT touch the movement at all -- absolutely nowhere and never. For assembly, I tend to wear cots just to be safe, but I tend to not touch the movement with them either. Some people (Youtubers..) use cots that seem to have been used a 100 times, are filthy and may equally spread dirt and oils. Work surfaces also need to be clean (the video that started the thread is a great example of how it shouldn't be). I also dip my tweezers and other tools into Rodico regularly.2 points

-

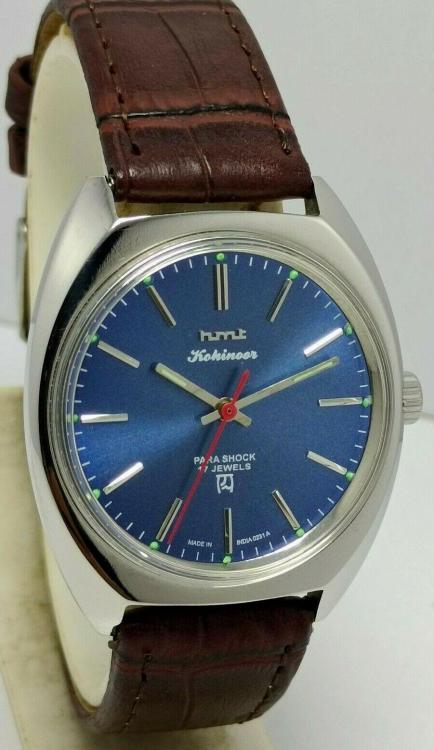

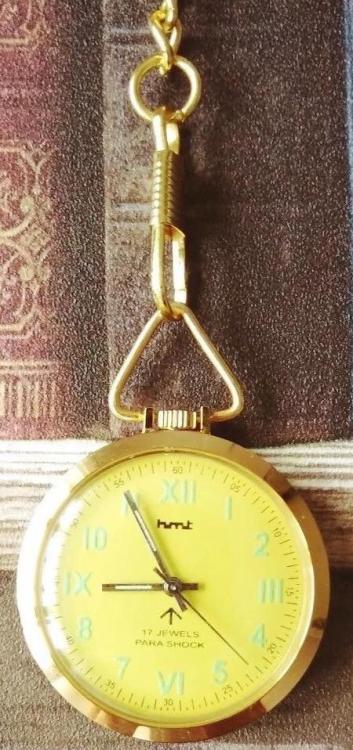

HMT watches were made entirely in India. The movements were produced under license from Citizen Japan and the one you have is an HMT 02X movement, a licensed copy of the Citizen 0201 series of movements. Parts movements are easy to come by, and they also seem to be interchangeable with their Citizen equivalents. HMT 6906 Automatic, "as purchased" and in need of some TLC including a stem and crown. HMT also produced a number of automatic watches based on the HMT 6906 which is a licensed copy of the Citizen 650x series. By and large, original condition watches are well made, but due to the large numbers produced, there are quite a number of bodged together bitsa-this and bitsa-that watches with weird "reconditioned" outlandish dials, which are the so called "Mumbai specials", some of which are quite amusing. Others are frighteningly badly put together, and at least one of the ones I encountered had half a sack of potatoes worth of dirt in it, despite being described by the seller as "recently serviced". Interesting watches, with an easily serviced movement, with a relatively large balance. The movements are almost indestructible, and, if serviced and cleaned correctly they can perform very well. I've included a couple of the "several" that I have collected over the years. I have a bit of a soft spot for them.2 points

-

Most of the reading I've done about Rolex suggests they created their untouchable reputation a long time ago, not exactly honestly either,somewhat economic with what is true Mr Wilsdorf was an extremely shrewd businessman. I believe they dont need to further their reputation, exactly as you have said everybody now does it for them.2 points

-

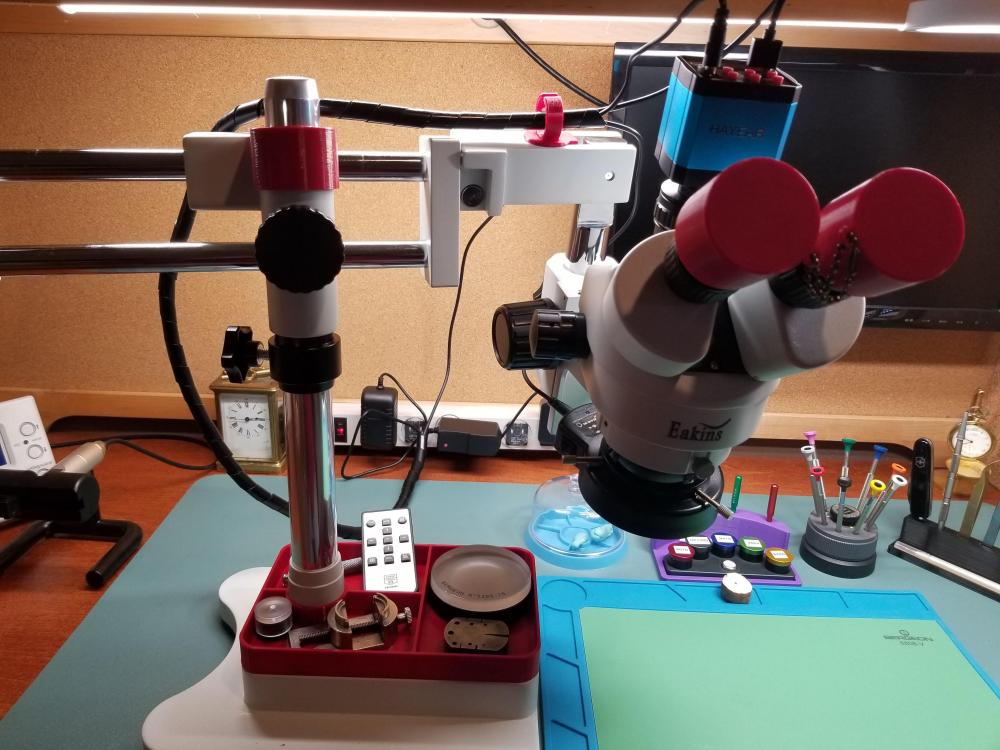

I've been adding some 3D printed accessories to my microscope. Found the STL files online and tweaked them to my liking. Though, I might do a bit more tweaking of the cable guides. I like the extra storage that the tray provides to make some of my commonly used tools handy instead of having to dig them out of a drawer. I happened to have a length of cable sleeve tube handy to also help tame the cords. I traded out the old thick and stiff HDMI cable for a new slim and flexible one.2 points

-

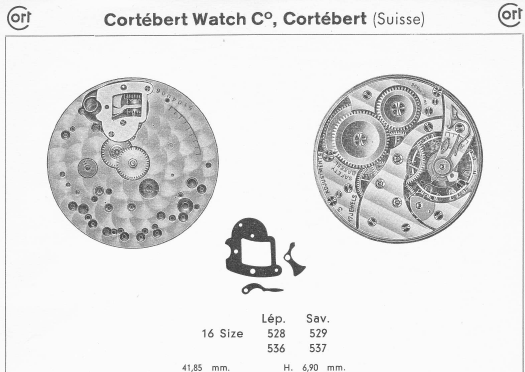

Hi All, I had some free time to work on a Pocket Watch I picked up a while ago. It wasn't running but it looked nice and appeared to be intact so I took a gamble. It came in a tidy Dennison Star case and the movement says cal. 529 although I could not find much information about it. I think it is a Cortebert but Im not an expert. Disassembly was straightforward and everything appeared intact (apart from a missing adjustment screw on the balance). Nothing seemed worn or damaged and a couple of runs through the watch cleaner to clear the congealed gunk and it came out nice and clean. Now I have this thing up and running Im not actually sure what Im going to do with it, Im not much of a waistcoat guy! Not terribly dirty but a lot of gunk on the pivots. And finally all clean and running!!1 point

-

I carefully wipe off the surface I have been working on with a certain grit before I go to the next but I don't really wash it. However, I continually keep the sandpaper moist and clean by dipping it into clean water which I do several times while working with the same grit.1 point

-

When I was in school basically the Rolex recommendation is what we had. Small blob on the impulse plane of the exit jewel and then you move the pallet fork back and forth so one third of the teeth go by another small blob another third and then one more. But at the time I was taught we were using 9010 on the escapement now of course it's 9415. The catch the 9415 is in some situations if you get too much you will lose amplitude which is why Swatch group goes to the insane lengths of an electron microscope and putting extremely tiny quantities on the stone letting it run etc. etc. I'm joking about how obsessed they are on the other hand they usually recommend replacing the escape wheel and the pallet fork because there is another lubrication which is applied at the factory that we can't do. I'm attaching the Swatch group recommendation for lubrication if you are really concerned about over oiling I would do the method like Rolex or I just suggested let it run for a while take the pallet fork out rinse it off and put it back in again and you should be fine. But your amplitudes look fine anyway so I just wouldn't worry about it. Often find on the group of people sometimes go to minimalistic I think in a recent discussions somebody said they put one drop and somehow expect that the magically spread all around the escape wheel and conveniently I just looked the other way and ignore the whole thing because that's not enough lubrication. 8645_WI_40_rules for lubrication cousins.pdf1 point

-

I've converted a bench grinder, works well but no speed control. Are you washing between different grits and polishing?1 point

-

I wear finger cots for nearly the entire duration of working on a watch, but I've recently realized (albeit it a bit late) that I need to replace the cots at more regular intervals. I do not have the luxury of working in a perfectly clean environment (but I try my best to keep my workspace clean), and my finger cots can gather some bits of dust, etc. during the process. It is something I'll be more conscious of moving forward.1 point

-

1 point

-

I am definately a newbie. That said, I watch YouTube videos for 3 main reasons. The first is for learning such as Mark's videos or Alex Hamilton's or others with tutorials on specific topics. The second is to look for a specific caliber that I may be servicing or have in my collection. The third is for the ASMR effect where it relaxes me to view servicing of a watch. However, it sounds like in this case none of those 3 reasons would have me watching the video _ YouTube r mentioned in this thread. As an aside to the finger cot discussion, my understanding they are only for the thumb, index and middle fingers of the non dominant hand and the dominant hand is for tools and should not need to touch the movement. No matter what the profession you learn standard practices and always implement them, otherwise you are lazy, have no attention to detail and won't be working on my project.1 point

-

2000 grit should be fine enough to start polishing/buffing (for me the terms are interchangeable ). But it can be quite challenging to polish with such small buffs. Even doubling the diameter would help.1 point

-

1 point

-

I'm not sure how this affects us because how exactly will we purchase these parts from Rolex anyway? There are ways of purchasing new Rolex parts but typically in the US it's very complicated. If you are outside of the US there are opportunities at least there were at one time my understanding is Rolex is trying to close the parts availability issue were basically there are no parts for anyone that Rolex hasn't blessed which is basically all of us.1 point

-

Thanks. I thought it looked very familiar. The one I purchased hasn't arrived yet, but I'm pretty sure you have nailed the identification of the movement. Better still, I have some parts movements, so if there are any problems with it, I should have the parts. Its interesting that a high end French jewellery chain should go for a USSR produced movement and not, for example a Lip or similar. I guess they used them for the same reason that Sekonda in the UK did. They were relatively inexpensive but also relatively well made. Speaking of Lip, the Chaika 1601/1601a and the Zim 2602 and the Bostok all appear to be derived from the Lip R-26 There is a discussion about this here -> https://www.watchuseek.com/threads/lip-r26-vs-pobeda.12673/1 point

-

1 point

-

1 point

-

Just the way of the world John, its about control, enormously wealthy companies controlling what and when people can have and cannot have as and when THEY decide. Look at computers and technology, its for sure way more advanced than WE are led to believe, stacked high,kept in storage and on hold. But releasing it all in one go or as its developed doesn't benefit the ones that have it, so its handed out in small bite sized pieces. Then its a nice consistant high income each year for the ones that have it. The same obviously happens in the pharmaceutical industry, who knows what THEY can actually cure ? WE dont ! Its about THEM and US or am i just a conspiracy theorists , dont even get me started on Covid.1 point

-

Remove the balance wheel => block the escape wheel carefully => remove the pallet fork => let go the escape wheel1 point

-

That is probably not an electrolytic capacitor. It's most likely to be a paper in oil type, which is the best kind of capacitor in my opinion.1 point

-

All of your mylar and paper capacitors are probably okay it's this one that I would be concerned about Especially since something has leaked out from somewhere unless it had leaked in from the top through the cracks in the case leaked from somewhere it's probably This is this looks like electrolytic capacitor. This should be markings on it some place just not visible in the photograph1 point

-

Unfortunately on the message board sometimes things get confusing I sometimes get confused and my dictation software definitely gets confused so often times we have lots of confusion. Is not just social media it's Rolex currently and possibly even Rolex policies amongst Rolex New York and Rolex Geneva. They should be identical or the same company but I believe they're actually separate companies in a way. They have different policies of how things work in the world. Like parts distribution in the US it's basically impossible to purchase new Rolex parts. Because we are not worthy of Rolex parts and the places that are worthy have to jump through a lot of hoops into a lot of crap to get their parts then for instance we know Rolex watches are valuable because they cost money and their scarce. How do we know their scarce well if you go to the stores authorized to sell Rolex watches and I don't know if this is changed but about the time we went into lockdown everything got scarce Rolex watches got scarce. So if you wanted a Rolex watch you had the place your name on a waiting list. You had to sign paperwork promising not to sell your Rolex watch after you purchased it because you could ask he sell it for more than you paid for because somebody might want the Rolex watch he doesn't want to wait a whole year for your Rolex watch to be made. But maybe the Rolex watches are just sitting in a warehouse someplace because it looks nice on paper that you had the weight a whole year for your precious watch. So it isn't just social media it's Rolex playing games. My favorite was when I went to my class reunion in Switzerland I believe in the mid-80s. We can pick the various factories to go visit so I went to visit Rolex because I want to see them mass-producing high grade watches and we saw all kinds of stuff but no making a Rolex watches I was very disappointed. Of course how was I to realize they don't make Rolex watches in Geneva where the headquarters are. Then at the time of the USA there was a shortage of I believe the chronographs and we asked and the person showing us the factory showed us a whole room full of chronographs there was no shortage? Oh and I've attached a PDF it's a section out of a much longer PDF. Something you typically don't see every day and all later versions of this yearly report conveniently are missing these pages. One of the reasons obviously Rolex is visually out there more is when you look at the chronometer certification numbers who gets more certifications that anybody else? So love or hate Rolex visually there's more of them out there because they get more certified than anyone else. Oh and of course the reason why we never see these production numbers ever again is that we probably weren't supposed to see these in the first place. Because now we know how many watches Rolex was making at least at one particular time because I believe all of their watches are certified. I might be wrong maybe they sell something does not certified but we do get amusing numbers. COSC 2015 page 12 to 14 RANN2015 Chronometer.pdf1 point

-

So, what kind of dough did you make? Plain flour and water? Any olive oil, salt or baking soda? Plain flour, bread flour, wholemeal or low GI! With all the silliness going on, I can't tell if you are serious or just being silly. Now poor Ross will be in his kitchen making up a batch of dough. Just another tip, cockroaches and rats love raw dough. So you'll need to keep your homemade Rodico in an airtight container.1 point

-

Maybe this is a better way to use your rodico or dry cleaning dough. Pegwood in a retractable pencil, drill a 1mm hole in the end of the pegwood and push in your dough. After you've wiped off the excess the pocket of air pressure built up in the hole slightly pushes out a bump of dough,great for picking up jewels . Thats exactly what ive been doing for the last 18 months, i hate cots for the same reason and only wear them when i cant find a way not to. I even sandwich the dial and movement between two pieces of sponge when putting the dial screws in.1 point

-

I guess I'm another old bugger. I must have gorilla hands; all the cots I've tried were so tight as to be almost painful. I've invested in good tweezers, good screwdrivers, good pin vices and tool holders, and good movement holders. Even before cleaning, I touch the parts as little as possible, and after cleaning - not at all. I will put on cots if I cannot do something without finger-manipulation, but I've been practicing with my tweezers and I believe I'm getting pretty good. Learning to dress them right helps also. But I do have a K&D winder that I like very much. And I always have the Rodico close by. And I know how to oil these things. So I am hoping for a measure of absolution too.1 point

-

1 point

-

I found a slightly better image from a different Dupont watch, which looks more like what you've got there to my eye: Not sure if that's helpful--I can't read much on it beyond the serial number. Edit: ah hah! I thought that said 1601. From here, listed as a "Tchaïka 1601". And I feel like I've seen that hallmark before...yes! Here at Watchuseek forums, listed as a Soviet era Vostock And here is some more info on a Chaika 1601A movement, which looks right to me.1 point

-

One thing I found out was that I had my eyepiece diopters set all wrong. When watching this video, they note that there is a silver line that you should first adjust the diopters to just above the line. Then adjust one to get both eyes focused. That actually increased my FOV through the eyepieces and now I only need to make minor adjustments to focus as I zoom in/out. Looks like I may need to repeat my 0.5X Barlow vs 0.3X Barlow experiment to reflect the proper diopter settings for me. Of course, the diopter settings have no bearing on the FOV for the camera. They don't seem different. I believe that both will take a 28mm screw in camera adapter and if you remove the threaded ring from the port, you can use that other style of adapter that uses a grub screw to hold it from spinning. I think it depends on the camera. The sensor size and if the camera itself has optics. I know when I tried a 0.35X C mount adapter with my camera, I got an increased FOV for the camera compared to using a 0.5X C mount adapter. With zero reduction in magnification, then I would have a tiny FOV for the camera. So, I definitely need some optics in there to decrease magnification in order to maximize FOV.1 point

-

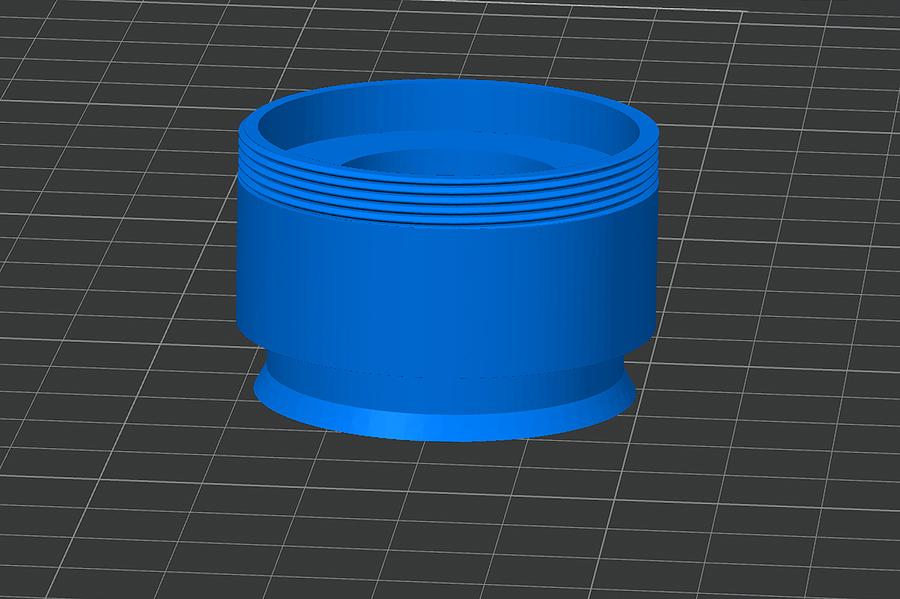

I've been looking for a way to connect one of my mirrorless cameras to my microscope since I got the scope. I've never been particularly happy with the camera that came with the scope, not just from an image quality perspective, but there are some functional issues that really bugged me as well. One of the biggest issues was that if the exposure was perfect when zoomed in, if you zoomed out it was way overexposed. So I would constantly have to adjust exposure by going into the camera menu, dig down to the exposure menu, and then adjust. Every time I zoomed in and out. Then there is the file naming issue where it will reuse the file name as soon as you delete the files from the card. So if you were working on more than one watch at a time and moving the files off of the card, you would get files with the same name when you came back to work on one of the watches. Then the camera just started to randomly stop recording for no reason so I would look up at the monitor and realize the camera had not been recording for who knows how long. So, I went down the rabbit hole looking for adapters to connect my Sony a6300 to the microscope. Most adapters seem to be for Amscope microscopes which, I believe, has a different trinocular port than the Eakins. But the reviews for the Amscope adapters are hit and miss regardless. I don't think the optics in the adapter are particularly good. But I really couldn't find anything that was as simple as, "use this adapter for the Eakins microscope and a Sony aps-c camera". I came across this video which looked very promising, although it was for a different microscope and camera. But the video does explain why adapters even use optics. Which it turns out, you really don't need. You can just project the image from the microscope directly onto the sensor and avoid subpar optics. I had a concern for the design he used as the length of the adapter needs to be perfect. If it is off even a fraction of a mm then the camera will be slightly out of focus when the image is in focus through the eyepieces. Seemed like it could entail a lot of trial and error getting the correct dimensions. I've come across M42 adapters in the past that have a helicoid focusing ability, often used in macro photography. Using one of these will move the camera (and sensor) closer to or further away from the microscope and will then let you dial in exactly where you want the sensor to be. So the adapter drops into the trinocular port on one end (and is fixed with a grub screw) and on the other end it screws into the M42 adapter which you can then focus using the helicoid. The image is parafocal between the eyepieces and the camera. It works perfectly. I actually get a slightly wider FOV in the camera compared to the eyepieces. When zoomed fully out there is some vignetting and I get a FOV of 68mm, compared to 61mm through the eyepieces. When zoomed all the way the FOV is 10mm in the camera and 8mm through the eyepieces. If anyone is interested I have freecad and stl files on Thingverse but it looks like there is a 24 hour hold until it is published so it should be available tomorrow.1 point

-

Well the watch guys database turned out to be extremely handy indeed! I filtered all GR4502 springs and noted it is also used in the ST1686 - the very movement I bought in a box of spares a couple of years back. So, I installed the ST1686 main spring into the AS1186 (much longer and now looks proportionately correct) and immediately it ran up with gusto! On the timegrapher, with no regulation Im getting 280degrees amplitude, +7s/day rate and a BE of 1.0ms This is similar in all planes except pendant down. I think after another clean and proper lubrication this will improve. [emoji106][emoji16] Sent from my iPhone using Tapatalk1 point

-

I have an Electrical Engineering degree and this would scare me. Don't like those written logic problems...If Jane has 2 dolls and Mary has 5 then when Mary gives Jane one doll, what is Jane's birthday. Sent from my GT-N5110 using Tapatalk1 point

-

0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.f0fdcb904fb94600b8d08cf1e4ea5a6b.jpg)