Leaderboard

Popular Content

Showing content with the highest reputation on 12/09/23 in all areas

-

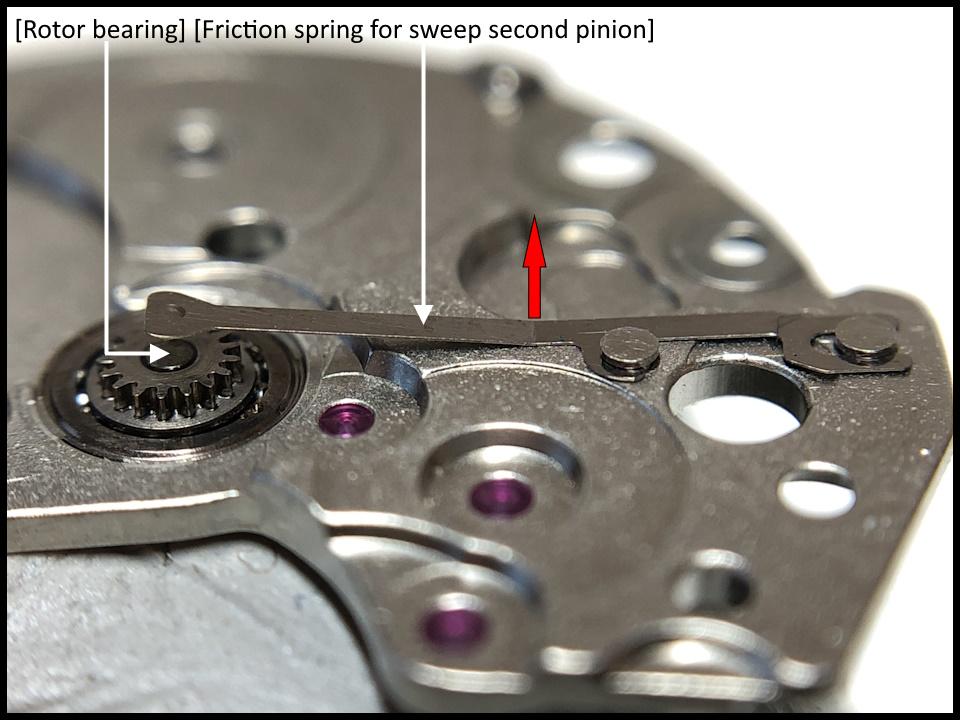

Disassembly pictures here (Please sort the pictures by name in ascending order) Assembly pictures here (Please sort the pictures by name in ascending order) Introduction To make a long story short, I've got about 100 Indian Citizen watches in my possession. It is one of these 100 watches shown in the pictures above. There is no major fault with them other than that none of them work. We all know that Citizen is a Japanese brand, but these watches are manufactured by HMT in India under license, probably sometime in the 1980s or 1990s. So, what do you do if you have 100 fine new old stock Indian Citizen watches that don't work? Well, you service and repair them, and then you sell them for a reasonable amount of money. How hard can it be!? Selling them, once they work, has happily proved quite easy, but repairing them has proved more challenging. So far, every movement has been full of gremlins to defeat. As usual, I want to remind those of you who have no previous watch service experience that this service walkthrough should not be seen as a tutorial on how to service a movement. It takes a lot of tools, consumables, training and know-how to succeed. Fortunately, there are several excellent resources, like WRT, and watchmaking schools online, and believe me, after six years I still find it insanely interesting and fun! About the assembly and disassembly pictures Unlike the disassembly pictures, the assembly pictures document screws, lubrication, and tips and tricks. Regarding the lubrication, I have not found any specific documentation for this movement. Instead, I have used my judgment and experience. It took some experimenting with the lubrication of the date and day change mechanics to get to work smoothly, so I feel a little extra proud of that. About the Citizen 8200A / Miyota 8205 movement The movements in these watches are designated Citizen 8200A on the rotor. In practice, they are identical to Miyota's calibre 8205, and if I'm not misinformed the watch manufacturer Citizen owns the movement manufacturer Miyota so there's a natural explanation. I have previously created a service walkthrough for Miyota's calibre 9015 which is often found in more expensive micro brands. Miyota's 82XX series of movements, such as the 8205 are instead found in more affordable micro brands, but there is no doubt that it is fundamentally an excellent and reliable movement. So, what do you find when you open an Indian Citizen like this? You find a well-constructed, well-functioning, albeit simple movement. In my opinion, it has a minor construction flaw, but I will report back on that. I have no idea how Indian HMT operated, but my impression is that these movements were assembled in an unsuitable environment, to say the least, by people with low-quality tools and a lack of knowledge of what a movement is and how it works. However, the movement parts themselves generally seem to be of decent quality, but when you take the movements apart you find fingerprints, hair, fibres from clothing, glue, and sometimes what I guess could be food residue. I.e. you find everything found in a typical home, so maybe that's where they were put together. As for the lubrication, sometimes it's OK, sometimes it's missing, sometimes it's in the wrong places, and sometimes there's way too much. However, once repaired, serviced, demagnetized, and adjusted these Indian movements work very well, so well that I don't think you can tell them apart from their siblings that are manufactured and assembled in Miyota's factories in Japan. Following are some tips and tricks that I hope will be useful. Stuttering second hand As in many other movements, the second hand is driven indirectly via the teeth of the third wheel, and to prevent the second hand from stuttering around the dial in a jerky fashion, a friction spring is pressed against the short side of the sweep second pinion. If the friction spring is not tensioned enough, it will not do its job. If this is the case, which is quite common, then the distance between the tip of the friction spring and the rotor bearing can be slightly increased by prying the friction spring slightly in the direction of the red arrow away from the rotor bearing. Balance staff end-shake I have long wondered if it would be practical to increase the end-shake of a balance staff using ordinary aluminium foil of the type you usually have in your kitchen, and now I have had the opportunity to test it. I admit it's not a very elegant or perhaps even correct solution, but it seems to work unexpectedly well, at least with this calibre. The aluminium foil that I have in my kitchen is exactly 1/100mm and after I built up the balance cock with two layers the end-shake was perfect. Guard pin The metal that the pallet fork's guard pin is made of on this calibre is unusually soft and therefore easy to deform, above all in height, but therefore also easy to correct. Several of the copies I worked on had a deformed guard pin. Normally, the guard pin should run parallel to the fork horns. Why this problem seems to be so common is hard to answer, but maybe my Indian colleagues were a bit careless with their tweezers when handling the pallet fork, or it's a matter of poor QC. Who knows!? The tip of the sweep second pinion You might think that all the parts for a certain calibre would be identical, and they largely are, but one exception is the tip of the sweep second pinion whose diameter can vary between different copies of this calibre. It is therefore not certain that the second hand from one copy will fit on another. I have not discovered any more exceptions than this. The Automatic Winding The automatic winding on Miyota's movements, including their premium movements such as the 9015, is unidirectional. I've always thought that would mean it's half as efficient as bidirectional winding, but in practice, unidirectional winding seems to be about as efficient as bidirectional winding. As can be seen from the picture, which shows the underside of the barrel and train wheel bridge, not many parts are needed for the automatic winding. I think this simple and well-functioning solution is elegant! Glue or shellac? The first time I took this calibre apart I suspected that the balance spring was attached to the stud with shellac, but after cleaning the movement in my watch cleaning machine where the final rinse is 99% IPA, I no longer think so. Instead, I think it's glue that simply looks like shellac. A small construction flaw I have had a user of this movement break the winding stem and misalign the threads in the crown believing that he had to pull hard to get the movement into position to set the time. I don't blame him! This movement has what I would describe as a design flaw that makes it impossible to pull out the winding stem when it is in a certain position. When you pull out the crown, the sliding pinion moves inwards (upwards in the picture). If you are a little unlucky then the pin (lug) on the sliding pinion will be right opposite the pin on the day and date corrector (as in the picture) so that the two pins collide with each other. When this happens, it becomes impossible to pull out the winding stem to its extreme position to set the time. If you then use force to pull it out, one or a few parts of the keyless work will unfailingly break. Most likely, the stem will come off and the threads in the crown will become crooked. What one must do as a user of the watch to ensure that the pins do not collide with each other is to rotate the crown slightly while pulling out the stem. When you rotate the crown, you also rotate the sliding pinion, which means that the pin on the sliding pinion does not risk colliding with the pin on the day and date corrector. Other documentation I am attaching a couple of PDF documents for the movement and thank @JohnR725 for links to a couple of interesting articles about the collaboration between HMT and Citizen. That’s it! Thanks for reading! Citizen 8200,8210,8260,8270,8280.pdf Spare-parts-reference-for-the-Miyota-8205-8215-movement.pdf HMT Watches: The Rise and Fall of India’s Watchmaking Titan HMT Watches: A walk down the memory lane6 points

-

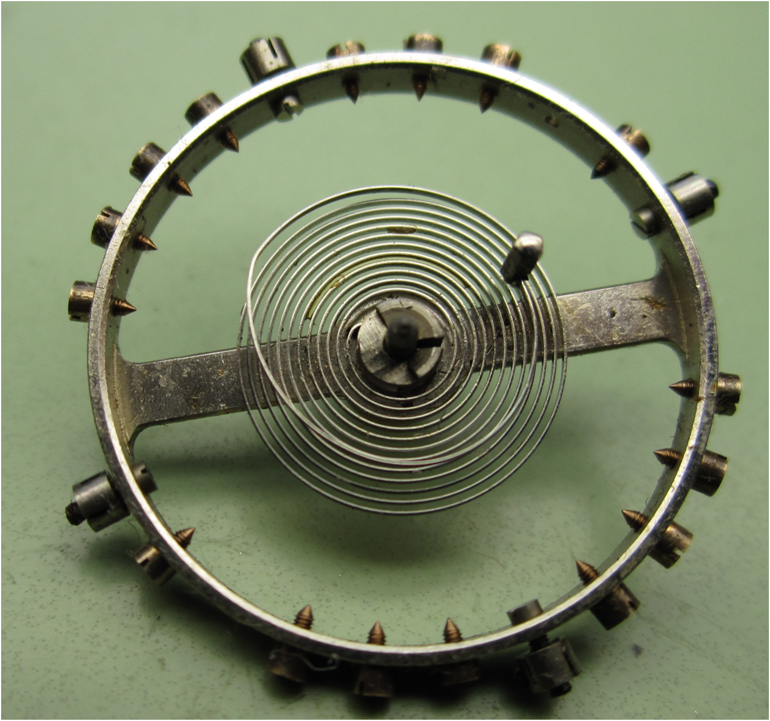

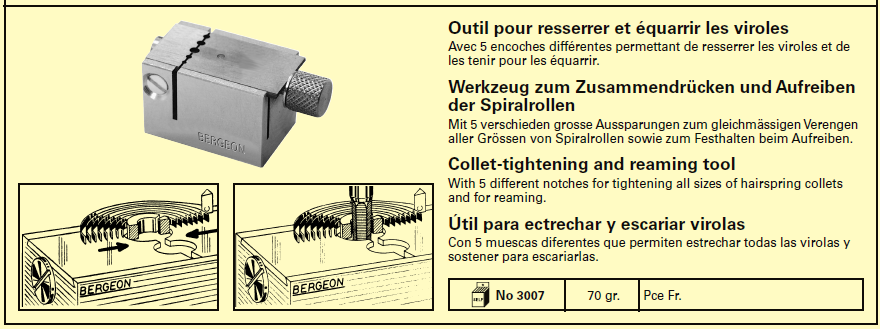

The reason why the collet is manufactured this way it's considered a poised collet. It's very common with a lot of Hamilton watches that have this for instance here's the Hamilton deck watch balance wheel Then the common way to close hairspring balance is with a tool like this normally be really expensive but it looks like the Chinese have cloned the Swiss tool as I swiped this picture off of eBay. Here's what the original one looks like From the image above you can see how the tool works and it does work quite nicely for the most part except it can have challenge with over coil type hairsprings. The reason there is a problem sometimes is standard hairsprings like in the image above are pinned in the center versus over coils which are pinned lower down to give greater heights for the hairspring. So sometimes you have to be really careful in your squeezing not to accidentally catch the hairspring and knock it out of alignment.4 points

-

That's some really interesting information. One would think that such an old, tried and tested movement wouldn't have any dramatic changes, so it's very telling. Thanks for sharing! Well, it's actually quite an interesting story, at least I think so. As you may know or guess, my love started with Russian watches, especially Vostok Amphibia, and a couple of years ago there was a Swedish site that sold incredibly tasteful modifications of these watches. The prettiest I've seen without competition. I never bought any of his mods but visited the site continuously for inspiration for my own mods and for fun. So one day about half a year ago, the site was down and saddened, I contacted the owner of the site who kindly informed me that the site had gone bankrupt, which I really regretted (tragic!). It had simply become impossible to sell Russian watches with Russia's armed resistance to Western/EU/NATO expansion plans into Ukraine (just 80 years after the last attempt). It turned out that the owner of the site, before he started importing Russian watches, had imported and sold Indian Citizen, and the hundred watches or so that I now have were left over because they did not work and therefore could not be sold. So we came up with the brilliant idea that I repair and service them while the owner markets and sells them, and then we split the profits in an agreed upon way that feels good to both. So there you have it! Here are a few examples of those Vostok Amphibian mods that I mentioned. Just gorgeous!3 points

-

Thanks, Ross, and you're welcome! BTW, I just updated the pictures of the oiling of the stem and the sliding pinion in the sequence of assembly pictures. I must say, it's really convenient to store the pictures on my OneDrive instead of directly in the post as it gives me the freedom to update and improve the instructions when and if needed. I believe what we post here is locked for editing after a while depending on your privileges.3 points

-

I've had good results using automotive/car polish (T-Cut) for the final polish on acrylic crystals. It also works well as a soft final polish for metal too. Its relatively inexpensive, and a can lasts a long time.3 points

-

2 points

-

Interesting business venture with good prospects, having a business partner that already has a good reputation and marketing knowledge makes a lot of sense. I love the Amphibias i have a custom one but these are really nice.2 points

-

notice in this example the problems with charging money what if no money had exchanged hands on this? families are always very interesting with how they handle money situations. Some families are very good I'd especially when somebody dies dividing up stuff everybody's happy there's no problem in other families well the family ends and they never a talk ever again or they're unhappy for ever because of somehow they got shortchanged in the universe. At least with friends you can hopefully find new ones but losing your family over seemingly silly little things isn't necessarily a silly little thing to happen. when I was in school learning watch repair the instructor explained the importance of proper paperwork. In other words whatever is done to a customer's watches documented. Customers are interesting they remember paying money for something not always quite sure what they paid for. Like they got their crystal polished and now the watches running wonder whose fault that is? So it's very helpful if you can demonstrate that according to the document here we polished your crystal and advised you that you should get your watch repaired because it needs to be serviced as opposed to now you're servicing the watch for free because you didn't document anything. Shop that I work at all incoming items are photographed everything is documented. Quite a few times that document is really saved our whatever expressly with engraving jobs where somebody was careful to document the item was scratched or is cracked or was broken or something as opposed to did we do that? Documentations extremely important and I bet you on all these hobby fun jobs are not thinking about photographing the item writing it up maintaining books and documents after all this is a fun project are just going to help your boss out or something yes we all like this but part of this discussion is it never goes 100% that way. We explained all of our customers that everything we now touch is going to take at least six months or longer. We have a huge backlog of watches. So everything is carefully explained and do they understand 100% of the time? notice part of this discussion is well basically playing Russian roulette. Most the time things will turn out fine but that tiny percentage of somebody who doesn't understand or somebody who doesn't want to understand. Or somebody who's going to always be unhappy no matter what. We are doing these repairs for fun having lack of fun and permanent unhappy friend relative whatever not really what you want to be doing. At least we doing this commercially if they go way it's just a lost customer that's still an issue but it's not a lost spouse or maybe a spouse to now complains to every single day because her brother's watch doesn't work right or something. Even if you did explain all of it were dealing with the percentages is a tiny percentage of bad that will come of working on other people's stuff if you're not doing it as a professional. Then even if you're doing it as a professional that are still a tiny percentage of unhappy customers it set tiny percentage that ruins it for everybody and you really want to deal with them if you don't have to especially when watch repair is supposed to be a fun hobby2 points

-

Due to my location (and I'm a cheapskate) it takes around 2-3 weeks to get a new crystal, hence I have had to develop my acrylic crystal refurbishment skills to revive the original crystals that come with vintage watches and I thought I would share how I do this as I now have pretty good results, assuming the crystal has only scratches and no cracks or chunks missing here is my process: Use 320 grit wet-dry paper over the entire surface of the crystal evenly to remove the deepest scratches - hold your nerve, this will look terrible after this step Use 600 grit wet-dry paper over the entire surface of the crystal evenly to smooth out the results of the step above Use 5000 grit wet-dry paper over the entire surface of the crystal evenly to further smooth out the results of the step above Use Autosol metal polish (see below) in small circular motions over the entire surface of the crystal evenly with a cloth until the paste disappears, may need to repeat this step 2 or 3 times, this will get you 95% of the way there Use Autosol acrylic polish (see below) in small circular motions over the entire surface of the crystal evenly with a cloth until the paste disappears, rarely have to do more than one application, this will finish the job Side note: I have tried the Autosol acrylic polish side by side with Polywatch and there is no difference in the performance or how it looks/feels - I even got my son to decant some of each into containers in a double blind test and the results were indistinguishable. Hence, in my experience, the only difference is that gram-for-gram the autosol acrylic costs 3.7% the price of the polywatch. Here is a quick example of before and after using the above process:1 point

-

Good the members aren't they?1 point

-

Just a quick reply to let everyone know that I managed to get a used 2846 balance and finally finished rebuilding the watch yesterday. Seems to be running pretty perfectly at the moment. I still need to measure it properly and maybe make some minor adjustment, but it was still on the correct minute after running for a day or more. On to the next one! Thanks for all your help! Lee1 point

-

That sounds like a great idea! Given the global nature of this forum, having two people (especially two active people) as close as we are seems like a relative rarity. A side by side comparison of the name brand-ish AmScope and the relative no name ostensibly from the same factory might be quite revealing and a rare opportunity. You're going to make me clean my office up enough to be able to take photos... Given the basement-splosion situation, that's going to be quite a challenge...1 point

-

I got a replacement sleeve from Daveswatchparts.com. Ill be checking the fit later this weekend.1 point

-

can be seen in many adverts of the time. also can be found in the dealer catalogs. but mainly the water proof casing.1 point

-

You can count on it. I run a GP forum and I'm a bit of a GP neo-vintage nut. I appreciate the importance on being involved and contributing back to the community.1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

I think I am at about 50 watches. At least 10 are working well. I think I have enough donors to complete a few more. 2 years of collecting donors and gaining experience. Watches of Switzerland - Seafarer - ETA 2989-1 Sekonda 2427 and a 2428 Seiko Bellmatic 4006, Seiko 7009, Seiko 7S26 Bulova Caravelle - AS1721/13 Enicar 167 Citizen 8200a1 point

-

Good well documented read as always watchie. I have a wonder of how aquired 100 nos watches.1 point

-

I haven't tried it, even though I have worked with chemicals and in a lab, wouldn't want to try this at home. https://www.china-machining.com/blog/how-to-remove-chrome-plating/1 point

-

1 point

-

1 point

-

Could you provide a picture of the movement? Others claim that 32 means the jear 1923: Junghans-b32-movement1 point

-

1 point

-

Show the movement for calib identification , cuz variaty of calibs were put in this brand. Swiss brand mainly made in India, sold fifteen million pieces mostly in Asia and still going strong. Sowar means " rider" , made for cavalry division of the army. The watch itself is a work horse too, and the brand was the first to adopt incabloc shock system, for more on its history go on to wikipedia, you get an idea of the price on ebay. Welcome to the WRT forum.1 point

-

No manuals, but B32 on Junfgans Wurtemberg movement means that the movement was made in second half of 1932. And it is the same for all alarm or wall clocks and everything made in Wurtemberg factory1 point

-

1 point

-

Great post. Doesn't show that I have downloaded your .pdf's But I have. Oooh! It does now. Thank you1 point

-

The only way to get round your problem is to use an ER collet adapter and ER collets because they have a better clamping range, if you use the wrong size collet ,if to big it will only clamp the stock at the front of the collet conversely if stock to big for collet it will only grip at back of collet both will cause runout and possibly damage the collet. Dell1 point

-

I have the same one, and yes the reamer spindle fits in the side of the wooden tray. The stump posts on mine are 3mm whereas on the more modern lighter version i have they are 4mm, so just be aware when ordering replacements. The reamers and spindle size is the same on both.1 point

-

I have an example, might be relevant, might be not, just something i feel like sharing, I'm a very open sort of bloke . My sister's husband died this April, a heart attack and then brain damage, decision was made to turn off his life support that same day. Very, very sad day, my sister was inconsolable and is still devastated by her loss after 50 years of being together. While helping her and my nieces and nephews to sort funeral arrangements at her home she comes to me and hands my a watch. A 20 odd year old Sekonda quartz, "this was Kev's watch" she said, "he wore it every day ever since i bought him it for work, the battery has been changed a few times but its stopped again and one of the little hour thingies has fallen off, can you do anything with it, it doesn't matter if you cant, you can say no ". With tears rolling down my face i replied " of course sis no problem ", what else could I say. I have never panicked so much repairing a watch or anything else for that matter, in terms of money it was worthless, in terms of sentiment it was beyond my comprehension. I gave her the watch back the next day with a new battery fitted, but with no cleaning or polishing of it whatsoever " aw you've even put the hour thing back on " i received a big long hug. When ever i see her she tilts her right arm to show me Kev's watch " its still working, i wear it every day ". That makes me smile, however the sweatstain on my watchbench is a permanent fixture . Ah a genuine example, nowt as wierd as folk as they say. Families eh, been there many times, you can choose your friends but you can't choose the family you were born with. And a bit of knowledge is dangerous, you think you know, but really, no you dont1 point

-

I would assume, just like the hardwood I'm currently using, that the rubber gives a constant and a homogeneous / repeatable resistance. BTW, it such a good idea, my wife can't find her new toothbrush anymore Had to do the over-coil bends over again The height of the over-coil turned out to be too high. With the terminal-end being so mangled up, I adjusted the height as suggested in Henry's book; two or three times the width of the hairspring, but that was in my case too high and the spring touched the bridge. I ended up with a height of 1.5x the width of the hairspring, at most. The movement is running again but sadly with not much improvement in the amplitude; around the 170 degrees Dial Down...... Dial up and the amplitude crashes. I'll dig deeper, but that goes off-topic1 point

-

My advice and you probably wont like it. Don't touch family or friends watches or clocks. It can cause nothing but trouble not because the items aren't yours, but to save all the bickering and bad feeling that comes with it. Here is an example a member of family is charged £30 for servicing his/her watch, another has a watch serviced and is charged £45 because you had more to do. Word gets around the family,they don't see it that way and it causes ill feeling in the family. The same goes with friends.1 point

-

Morning everyone. Thanks for your help. I think Darthkram may be on to something here. Apparently yes it is a national electric watch cleaner. 2500 gives me somewhere to start. Thanks so much everyone.1 point

-

Looks like a winner, the dial and hands look in good condition, you could also probably rescue the crystal (I have my crystal technique down pretty tight and I usually do the crystal whilst waiting for the watch cleaning machine to do it's thing - link below). Then there is is the dilemma of the case, go too aggressive and you end up having to re-plate the whole thing (Doh!) or live with some marks. Looking at yours I would probably just hit the case with some Flitz or Autosol metal polish and live with the outcome, will be interesting to see how it turns out1 point

-

This waffle dialled Ingersoll Sealion is heading for the 404 club. This one has all the hands and wheels, but an unstated number of jewels. One would be my guess. Almost certainly a pin lever, perhaps a BFG 866, a Ronda 1221-21, or something similar. Despite the dirt, it looks in pretty good cosmetic condition.1 point

-

1 point

-

I, too, order from Cousins. We only have one watch/clock material supplier in Singapore but their inventory is limited.1 point

-

1 point

-

1 point

-

Hi. From your description it’s the set up of the escapement that is out of beat. Take all power off the clock and make sure the movement is level. Observe the pallet in its rest position and the positioning of it on the escape wheel with the leader and pendulum hanging straight down with no power, is the pallet even within the teeth if not avhieve that by adjusting the the leader this is a friction fit , by moving the leader far left / right you are able to move the pallet In relation to the leader. Once having achieved the balance next set the depth of the pallets locking on both faces by moving the bridge / cock. When done apply two or three turns of the key and start the clock.1 point