Leaderboard

Popular Content

Showing content with the highest reputation on 11/30/23 in all areas

-

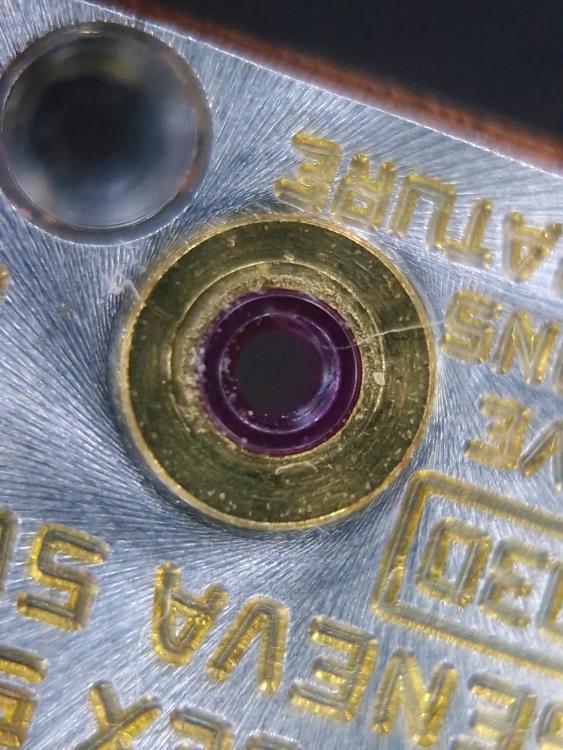

Here is how I installed one of mine. I actually found that I needed to have the jewel in the chaton or else the spring wouldn't stay level and I couldn't get it in. I use the plastic to position it and then an oiler with the force applied the long axis to snap it into place. You can see that when I first tried to apply force with the oiler perpendicular to the direction the spring needed to move, the oiler would flex. Once I came at the spring along the direction of force it snapped right in.5 points

-

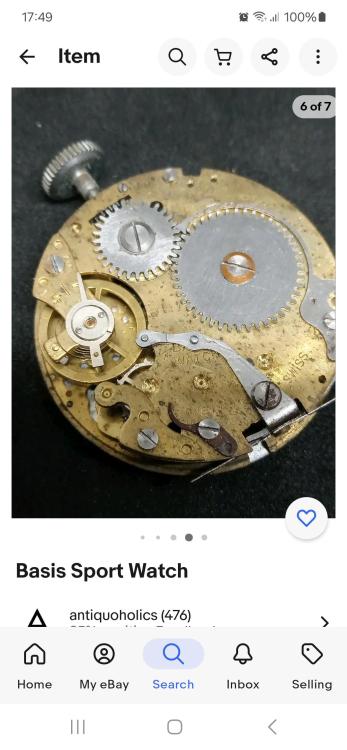

They would have to pay me to take it away (and then I'd bin it) Cheap pin pallet movement, radium dial, lots of entertainment. You could put a lot of time and effort it, and it still might not run very well. I'd go for something Swiss with at least 15 jewels, that way there's a fair chance of it running pretty well after all your effort. It's amazing what you can find for £10-£30. I recently bought two great quality ladies watches (Movado and Longines) for less than £30.3 points

-

3 points

-

Happy to report the heat plus Coca-Cola method did the trick!3 points

-

I give Guy's technique a try, little chance of parts flying, can be improved if the end of long legs are held down with a razor.2 points

-

2 points

-

Hector's got it. There's no trick, just excellent tweezers and care.2 points

-

I use an eyebrow tweezer to do it. It grips the spring so securely that you can muscle the ends in.2 points

-

At least was Seiko yet the button to push to give you a clue if you are successful with your hand motion or with whatever charging device you had. I find it's an interesting idea a mechanical watch charging a bad return run a quartz watch. But like any automatic watch especially today how much motion you actually have especially if you worked at a day job keeping the watch wound up is always going to be an issue. As always an amusing conversation in a watch shop after servicing an automatic watch. We have to explain the customer who came back because the watch still is it running that there probably not active enough to keep it running and maybe they should get an auto winder to keep it wound up at night when they're not wearing it. Where is the auto winder is probably the only thing keeping the watch wound up at all as are just not moving their arms enough or in the right movement to keep the mechanical watch wound up. Then while searching for something on the computer related to the kinetic stumble across an interesting PDF of website. Always nice to PDF for copy websites really like if you can because you never know if they will last and they have a habit of disappearing but this one has not. So here's a rather interesting website that talks about the kinetic watches good bad and whatever https://www.quartzimodo.com/the-seiko-kinetic-boon-or-bane/2 points

-

My guesses.. 1. wood chips for drying parts in after the final rinse. A bit of an archaic practice these days. 2. could be French chalk for brushing cleaned clock plates with.... or maybe diamantine powder for polishing.... could also be oilstone powder, also for polishing, although the stuff that I have got is slightly greyish. 3. Blueing pan. Fill it with brass chips, place item to be blued on the chips and hold the pan over a spirit burner. 4. & 5. Pallet warmer for softening the shellac in order to adjust the pallet stones.2 points

-

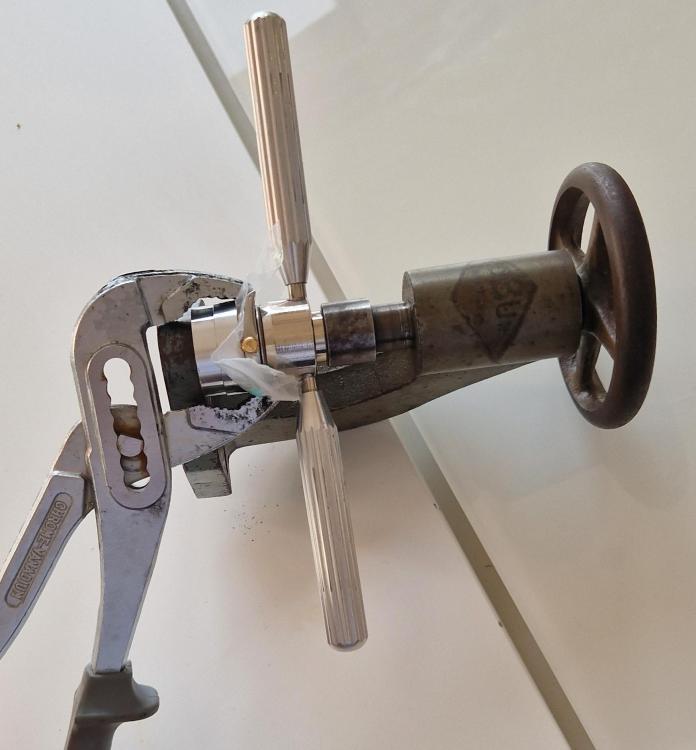

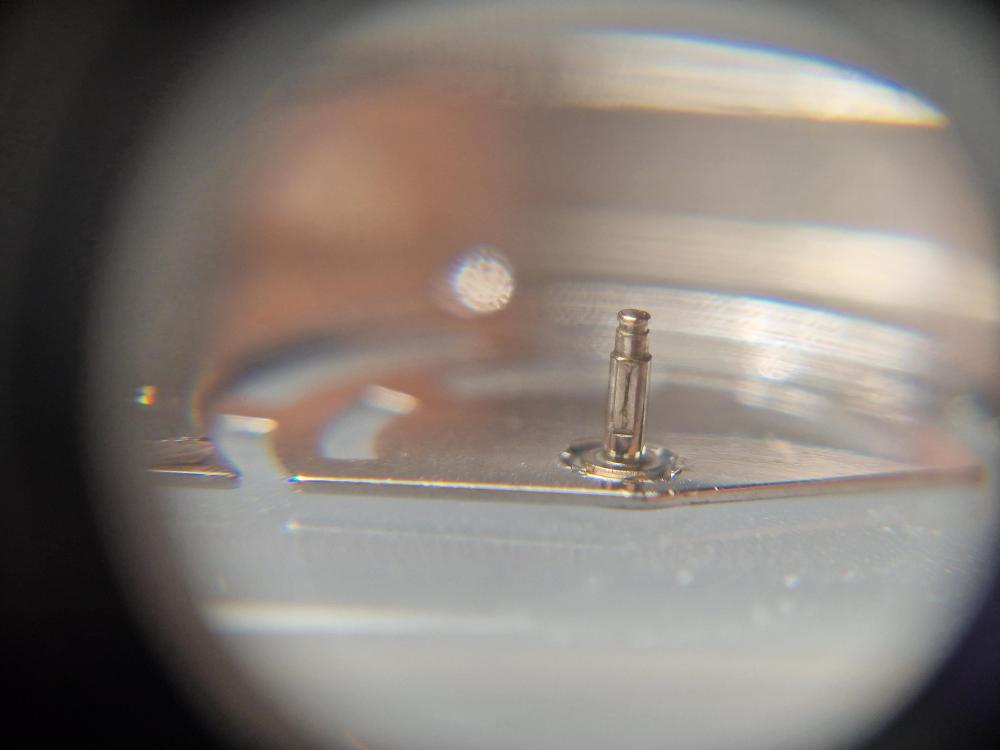

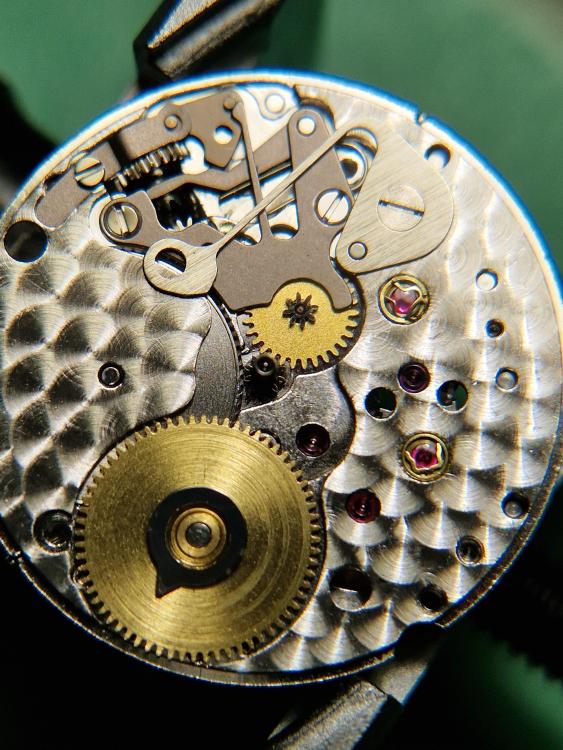

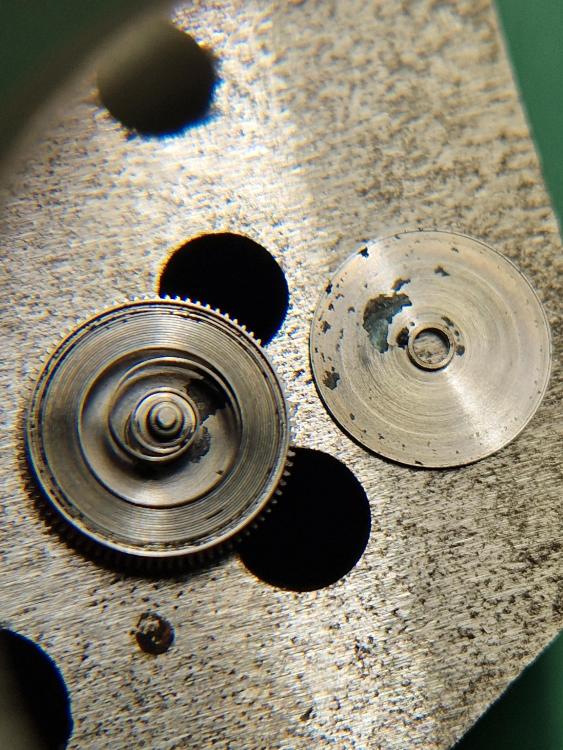

Good morning! After some back-and-forth and initial reluctance (worries about the cost of spare parts), I've accepted to service my friend's Lady Datejust ref 6917, calibre 2035. This is a first post of a potential series in this thread. Today, disassembly and assessment of wear/damage. Questions to you are marked in bold letters. Symptoms that led to service request: 10 years since last service (but done by the Swiss Rolex Service Center) manual winding clearly extremely heavy with a feeling as if it something was going to break any moment rattling noise when shaking the watch erratic timekeeping (at times minus 60s/day then plus 60s/day) low amplitude (220° at full wind, dial up), high beat error (1.4ms) I had some real trouble even opening it... the caseback was so tight. I could not open it with the 8-ball nor the wrench+dies (CousinsUK "Value"). So I had to get creative and combined the wrench with my Robur glass press and some good old pliers + plastic protection. It finally worked without scratches. Pheww. Some overall pictures of the movement (last one is after removing the date disc): 1. First observation, the rotor is a bit wobbly. I will replace the axle or the entire rotor. I am looking for the specific staking punch for calibre 2030/2035, but I couldn't yet find it in the EU (trying to avoid customs processing fees that would probably at least equal the price of the 20 USD item itself...). Any ideas? As you can see on the pictures, the wear isn't extreme, but enough to cause too much shake, IMHO. 2. Second observation, after opening, I can see how the automatic wheels are badly struggling when trying to wind manually. At first, I don't see any obvious damage/wear. But after disassembly of the automatic works, I can see that the pivot holes of the reversing wheels are worn. One is kinda ok, the other was bad and I could barely remove the inner wheel. See pictures of the holes below. The more damaged one definitely needs to be replaced. The less damaged one, probably too. What do you think? My feeling is that once the Teflon coating is cracked once, it will continue to break down quickly. Besides the reversing wheels, the jewels are also gummed up and dirty. One had a little fiber in it that probably sucked dry the jewel. 3. Third observation, the inside of the barrel looks horrendous! The last service was by Rolex, albeit 10 years ago... but what the f* where they using??? Thankfully, this is easy to clean. 4. Forth observation. After releasing power from the mainspring, upon removing the pallet fork, the train of wheels was spinning quite a bit more. I was surprised. The balance fork looks a bit dirty. Maybe some oil/grease travelled to the fork pivot? Ok, that's it for now. Next is cleaning. I'd be happy to hear your comments. Cheers, CK1 point

-

I have the Ruipai version and while the cap on top screws off, there isn't any room to store extra tips.1 point

-

1 point

-

The jewel collets are only good for working on the centre part of the jewel, like resizing the hole or oil sink. I've only tried resizing an endstone which was a little big and thick. I mounted the flat surface of the endstone on a brass rod with shellac. Centering the stone was a real pain. I had to warm the brass rod until the shellac softened, then spin the rod at a low speed on my lathe and used a pegwood to centre it before the shellac hardened. I reduced the diameter of the stone using a #1000 diamond file. Then worked up to #2000, then #3000. Similarly, I thinned the convex surface using diamond files. Polishing the adjusted surfaces was another pain. I used diamond paste on a popsicle stick to polish the rough surface. It took a really long time. Maybe using the diamond paste on a harder surface like brass might have been more effective. I gave up when the stone reached a semi glossy finish. I figured that the finish of the edge and convex surface of the endstone doesn't really affect the performance. That was the first and last time I adjusted a jewel. I don't even remember which watch it was. For hole jewels, I would choose a jewel that has the correct size hole but if it is slightly larger, I would ream the setting hole to fit the jewel rather than try adjusting the diameter of the jewel to fit the setting. I still have a few watches with cracked or broken balance jewels. But working with jewels is such a pain that I would rather root canal at tooth. Good luck with resizing your jewels.1 point

-

1 point

-

No jewel moving in this kind of watches and jewels, no jeweling tool needed here. First of all, the endshake must be checked and if no endshake but the balance is almost free. then the balance cock can be lifted alittle. To do so, the balance must be taken off the cock, the cock in place and the screw tightened. Then, lift alittle the cock wit proper tool in ordet ro slightly deform it and thus increase the distance between jewels. Then, put the balance for test (hairspring attaching is not needed at this point) and check the free play, if to much, correct by pressing the cock down (balance out!)1 point

-

5 min/day when amplitude is 280 degr is not sticky hairspring. Can we see good picture of the hairspring? What is the regulator position? Is the hairspring original to the balance, or replaced from another one?1 point

-

1 point

-

OK, for some reason that previous post messed up. I have done it. I used tweezers AND rodico so that the spring stayed with me. Not much force was applied to get the spring in. Now that I am done and have seen Guy's solution, I wish I had waited for his post, because that looks like a brilliant method. Whew!! What a pain.1 point

-

Give it a blow with a puffer and see if it runs freely. If not remove the pallet, reinstall the balance and give it a blow again. It should oscillate from about 30s.1 point

-

1 point

-

1 point

-

Excellent tweezers may be the challenge for me. I have tons of tweezers including some crappy eyebrow tweezers. Maybe I need to modify one of my dumont vintage tweezers (eeek!!). I will ponder.1 point

-

1 point

-

First, DO NOT ATTEMPT INSTALLING WITH CHATON AND END STONE IN THE HOUSING. All above must be taken out before you attempt. Second all you need is to examine the image here, https://calibercorner.com/kif/ The two short legs just slide in with ease, no need to force/ twist/ bend or anything of the like, JUST SLIDE THE SHORT LEGS IN. Good you asked, most anyone breaks first asks later.1 point

-

I put in one end first then persuade the other end in.1 point

-

1 point

-

The earlier models can't take a lithium battery as there isn't a charge controller in the circuit. Putting a lithium battery in place of a cap is what kills the pcb.1 point

-

I love my Horia clone. Have used it twice already. I have two Seitz but now prefer the clone1 point

-

I always thought it was anodized aluminum but that's just what I thought It's always interesting what I find lurking in my computer vintage service guide just in case you don't have one. Then you Need to be careful about a standard operating procedure of demagnetizing as there is a magnet found somewhere in this watch. You'll see is a reference to used for the breaking of the sweep second hand. 2030-2035 rolex tech.pdf1 point

-

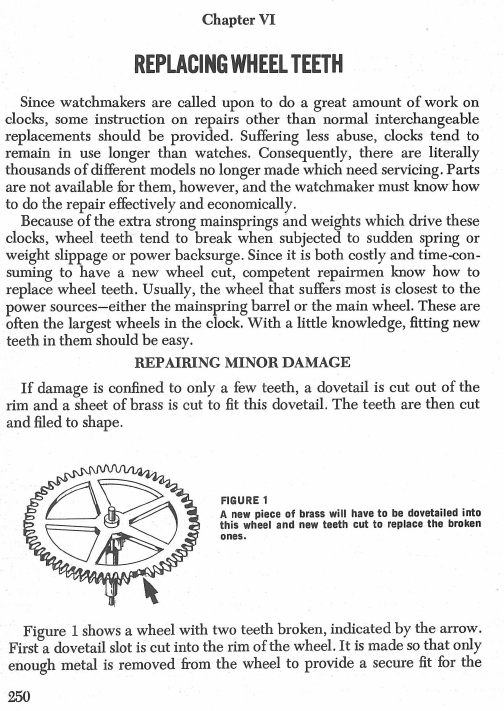

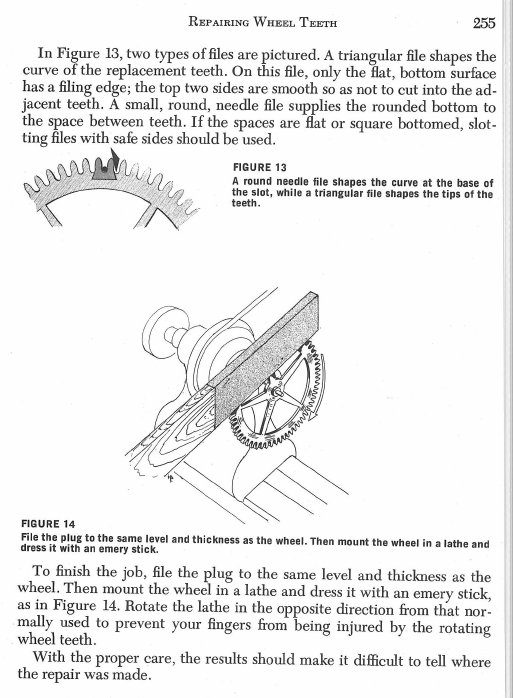

Now that we've grasped the subtle difference in titles one book excludes clockmakers and my copy embraces clockmaking? I do tend to think of replacing teeth as much more common in clock repair which in the first page he explains why So years the first page showing the problem. Then the last page Showing the outcome all done by hand. Much nicer if you have access to the gear cutting set up but it's amazing what you can do with the file in a saw if you're careful.1 point

-

@JohnR725 got it thanks. I thought about this, but doesn't react to my UV light and isn't radioactive (I have a radiation monitor) - I think the consensus is that it's some kind of polishing compound, which makes sense. I'll post more crazy tools from the job lot tonight1 point

-

They also come in slightly different shapes like this one resembles the one that I use Unfortunately I don't have a good picture of it in use so you'll have to use your imagination and hopefully word this correctly. First you turn your pallet fork upside down like in this image Now is where you have to use your imagination. Slide the black locking ring back to release the part that holds the pallet fork in place. Grab the pallet fork in the image above movement up and drop it onto the tool. You want the pallet stones facing outward. Then when you slide the ring forward you'll see the slot on the locking part will come down onto the pallet fork arbor holding the pallet fork in place. Now you can take the alcohol amp preferred and heat up the pallet fork on each side so you can play with your shellac.1 point

-

Yes, all this things: the end curve shape, it's position against the begining of the spring, and the beginning curve shape and distance from beginning point to center (staff axe) have special inpact on the frequency as function of amplitude. And yes, the frequency depends on amplitude and this function is complicated one. But all this needs to many writing to explain, and it is easier to point where is written in a book, as many books have already been written on the matter.1 point

-

It's something you mix into your lubrication it helps to lubricate things much better. Just let me know how shiny the pivots look after a few years A classic polishing compound usually came in several grit sizes if you would call it that they all look like white powder. Typically would be mixed with some oil used to polish your pivots. Not used anymore other than a novelty in your bench. Even in my day the only time people are using wood chips were well in school at least one of the schools the rumor was if you didn't do things right it would go into the sawdust box. Then you get to start over again. That would also explain why there are holes in the lid of the can to allow the vapors of the solvent-based products to eventually escape.1 point

-

1 point

-

The title that has the "Correcting the bent hairspring" and "Replacing wheel teeth" section is titled "Bench Practices for Watch and Clockmakers" as shown above. The other book without the two sections is titled "Bench Practices for Watch Repairers". I have both because I wanted the hairspring section. I am not sure why he had two separate books like that.1 point

-

Hi. Along with the Swiza movements these were good quality for alarm clocks. It will clean up very well. Use Windles clock oil on the rebuild is the best for clocks.1 point

-

Add a drop of oil to a small amount of the powder, mix to a paste, see if it will polish the handle of a pair of tweezers.1 point

-

Right? I'm prolly $2500 in already and I know that's nothing. Bought a poising tool cheap. Took a while to tune it parallel, the design for fine adjustment is not great. Bought a staking set cheap. Almost all the stakes are clean, just a few with too much corrosion. Looking forward to polishing them all up, getting the faces truly flat or domed as needed. Still need a jeweling rig. I understand Seitz has a lot more functionality than a Horia clone, cheap as those are. A gauge like the Feintaster would be nice, but then maybe I could make something using the Mohr Supremax I already own. I am handy with machining precision parts, so I fantasize about creating much on my own. So for example I've laid out a plan to make a set of jewel hole gauges by turning a set of them. Thought that would be good hands-on experience for making pivots. Also to make a pivot gauge plate (expensive on ebay) from a jewel assortment (cheap on ebay) in which I learn about setting jewels. Even thought that making a stack of those to sell might help alleviate the $$ for what I won't build. About the most adventurous I'm considering at the moment is to add a spindle to the milling attachment I have. I bought an ER16 on a 1/2" shank ($24, and I measure *no* runout with a tenths indicator on a surface plate! Try toolots dot com for crazy low prices on excellent parts) I'm planning to machine a bearing housing for that. I already have a set of ER16 collets. But then of course it's a short mental step to cutting teeth. But topping them? I like the idea of those cylindrical tools over the common spiral cutters. One thing that really draws me to watchmaking is the precision. It's *very* expensive to work in tolerances of some tenths on a 10x28 lathe. But a loupe and graver can handily get there. Hobby grade machining turns a surface finish of a couple thou then relies on files and sandpaper to get it clean, but good luck landing on 0.0005". My Jacot is missing some parts unfortunately. Another thing to fashion... On the actual watchmaking side, I've been studious with several YT producers, including Mark. My favorite is Kalle Slaap at Chronoglide - such love for the craft! At some point i'll drop $ for an actual course. I like being able to support the hard work they've all put in! Then Daniels' book puts the lust in me to make all the parts...1 point

-

If its cork that is used for drying. White power I would say diamantine powder, french chalk is normally in a block.1 point

-

1 point

-

Just use a cheap silicone grease applicator like the one listed below https://www.cousinsuk.com/product/gasket-grease-applicator They come preloaded with enough grease to last years before a top up is needed, and when it does here is a nice big tube that has enough to last a lifetime. https://www.cousinsuk.com/product/molykote-111-tube?code=G494951 point

-

Most o-rings will be made from nitrile (NBR) as it is cheap and has all round good properties, so unless you are using some strange o-ring material they should be chemically compatible with the grease which appears to be a mix of mineral grease and vegetable oils. You can check out the compatibility here The only other thing you need to think about is if the grease will stay where you put it and not end up somewhere you don't want it. Just spotted on the Moebius 8200 sheet that Moebius also belongs to the Swatch Group?!1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)