Leaderboard

Popular Content

Showing content with the highest reputation on 05/23/23 in all areas

-

4 points

-

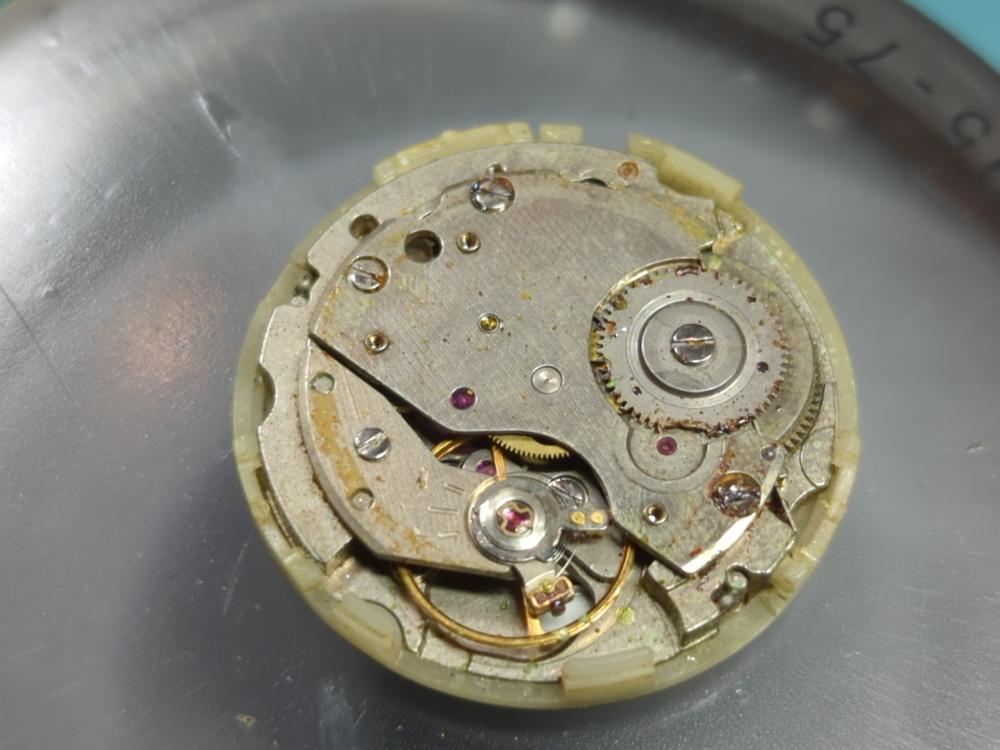

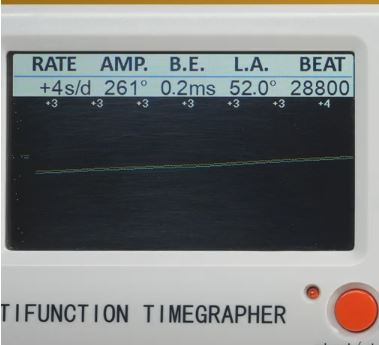

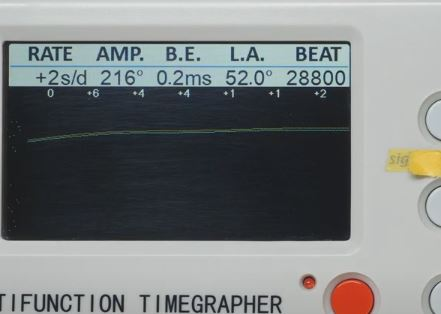

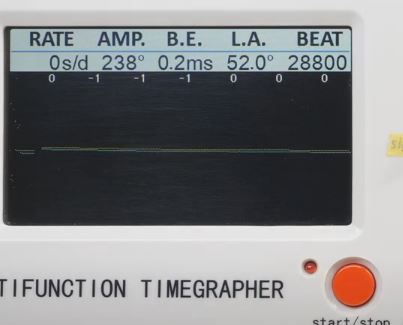

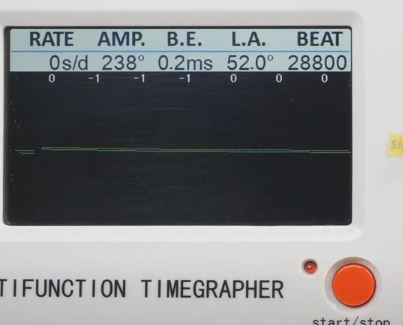

Good day everyone, I just completed a watch for my wife's uncle as a gift, its a Seiko 6309 which was in pretty poor condition and a non runner for obvious reasons. I had to replace the crystal and the ratchet wheel which was completely corroded (see pictures below) I also had to replace a screw and the cannon pinion. A quick lume on the hands and polish the case and it was good to go. Let me know what you think: Before Front: Before Movement: Corrosion damage to ratchet wheel and screw(s) Here is the finished watch along with the time graph after 24 hours:4 points

-

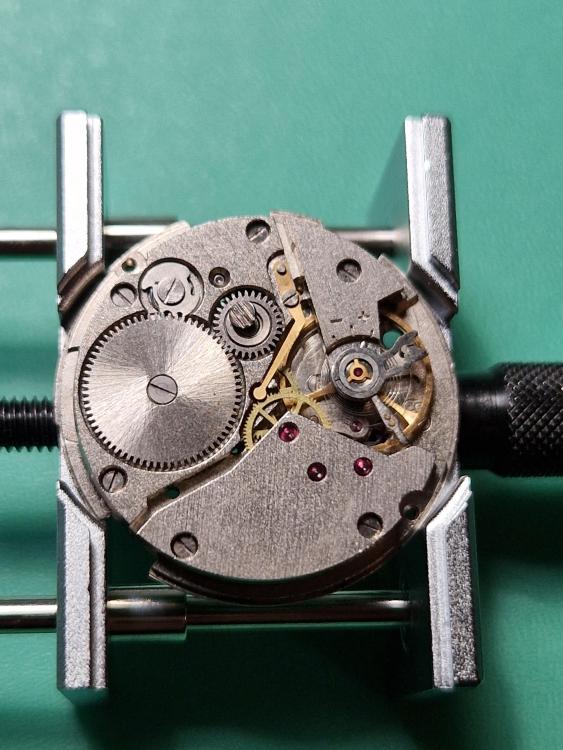

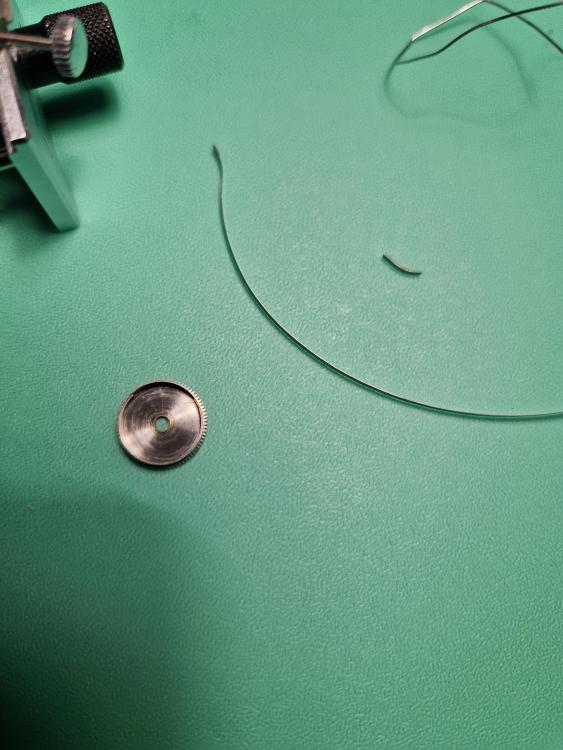

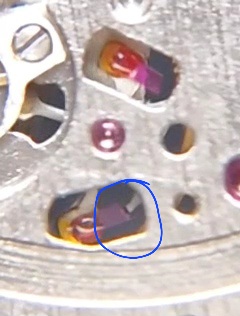

This is my Vostok 2414 from the late 1980s. It was my first ever full (and successful) service. Photos in reverse chronological order. The final product. I like how the dial colour has cracked in different levels of intensity as the shade of the paint changes. Full wind. Couldn't be happier. I'm a bit of an OCD person... note: lift angle is correctly set to 42°. Not sure if this is visible at all . But maybe you can see the small black area between the pallet (exit) stone and escape wheel tooth. That's lubricant (9415). Took me a while to get close to the recommended 60-70% of contact area (maybe I went slightly above..). And it took me the same amount of time to film it with my basic phone+loupe+slowmo technique. Oh boy, it took quite a number of attempts to get that drop of oil done well (being a first-timer). But I probably spent even more time with that bloody shock spring!!! Including 2-3 hours of searching on the floor... When I received it, the watch wouldn't wind. Upon opening the barrel and removing the mainspring, I found that the bridle had broken off... I followed a cool trick I saw somewhere (can't find the source anymore) and used a lighter to heat the spring and then bend it backwards to create a bridle. To my astonishment, it works perfectly and I get the full power reserve. Just some pics of the movement.3 points

-

Just adding my 2 cents here, and apologies if I seem to be stating the obvious, but I think the important thing is the difference in amplitude from before I touched it and after I worked on the watch, rather than an absolute number. As everyone has pointed out above there are so many variables on an old(er) watch; age, damage, moisture, service (in)frequency, under/over lubrication, wear and tare etc... that it is almost impossible to meet an ideal amplitude number. Therefore, I resign myself to being happy if I can bump up the amplitude, then I deem that I have done a good job, if there is no change or it is worse then I have to do better.3 points

-

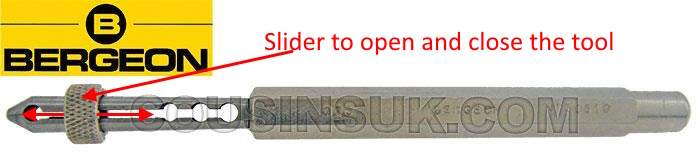

I have a Ø1.50mm Bergeon arbor holder and I absolutely love it. The 1.5mm size seems to be a decent fit for most normally-sized movements, but would probably be too large for a lady's movement and too small for a large pocket watch. I asked Alex at the Watch Repair Tutorials YT channel what size he would recommend and he replied: "The size I use almost at the time is the 150.", so that's why I decided to get the same size. Here's the video where he's using it and you'll find Alexs' reply if you look for it in the comments section. The arbor holder is much easier to clamp onto and release from the arbor (look at the picture). Also, it dramatically improves seeing what you're actually doing while removing and fitting the arbor from and into the inner coil of the mainspring. The head of the pin vice is most of the time so large it covers the entire arbor - and more - making it quite difficult to see what's going on. Absolutely not! It's just a whole lot less convenient in my opinion. None that I'm aware of I'm afraid, but we have some experts on Chinese watch tools on the forum so hopefully they can shim in!?3 points

-

2 points

-

You might have been better off searching *my* floor. I'm pretty certain there is more than one hiding there somewhere. Neat trick with the lighter and the mainspring. I may try that sometime when I can't find a suitable replacement.2 points

-

This is for measuring the fork slot to find an appropriate roller jewel. It's tapered, you find the step that just fits in the fork slot, then choose a jewel about 0.02mm (for pocket watch) smaller.2 points

-

I always used to worry about that before I got my arbor holder. With the arbor holder, I never saw the slightest dent och scratch on the arbor even after having pinched it very hard.2 points

-

Stopping at just before 60 indicates something with the minute counter. The minute counter wheel needs to be absolutely free, and unlubricated; you should be able to nudge it forward or backward until a tooth just comes over the jumper tip and it should snap into place cleanly under the jumper tension. The jumper itself- clean, totally free, and the jumper spring should be nice and straight with the jumper removed. The sliding gear should be set so that a tooth on its wheel points directly at the center of the chonograph runner. If it's off a little bit counter clockwise the finger on the runner can jam (though hard to happen on this caliber). One thing I've encountered on this caliber is someone in the past screwed down the chronograph bridge without checking that the intermediate minute counter wheel has its pivot in its hole. That wheel is unjeweled; if you screw the bridge down in that condition (and don't break the pivot) it can make a divot in the bushing, sometimes slightly closing the hole. This can cause enough friction to to cause the minute counter wheel to not snap cleanly tooth to tooth with the jumper, or, even stop the watch with the chronograph running. Have a look through, and try to post some clean close up pics of the chrono mechanism.2 points

-

Cylinderhöhenmasse, it's for measuring the cylinder height in the watch for cylinder escapements. Never seen one before.2 points

-

Er what was the question again ? . Ah yes the importance of amplitude. The short answer, it is and it isn't Oh wow pivots just fall off, on their own like ? Thats a bummer, this hobby is definitely not for me then. Anyone want to buy some watch stuff ?1 point

-

I've unfortunately sain something like this before. Notice the wording unfortunately this was really not to be a watch to be serviced. That's why when you went to remove the case back it really didn't want to come off because it wasn't supposed to ever come off again. I'm not seeing the outside of the case back but if you're trying to push in the wrong place it will never go on. I'm going to assume you're pushing in the middle of the case back? You might try pushing only on the outer edges. Often times if you push in the middle of the case back that supposed you pushed on the edges the case back will bend the edges will actually go out and it will never work at all.1 point

-

Yes, absolutely. But it does cover a lot. Yes, first, this if for us as watchmakers to look at our own work. If we see that we cannot reach a certain target without replacing parts, we can talk to the customer and explain. Sure, many customers won't understand or care. That's cute Well, if that's the level the movement is designed for, we should be happy with a result like that. Maybe the old timing machines couldn't measure amplitude!? Maybe they'd be able to measure the daily rate, but not amplitude. That's why they base it on visual observation. But they did care about it.1 point

-

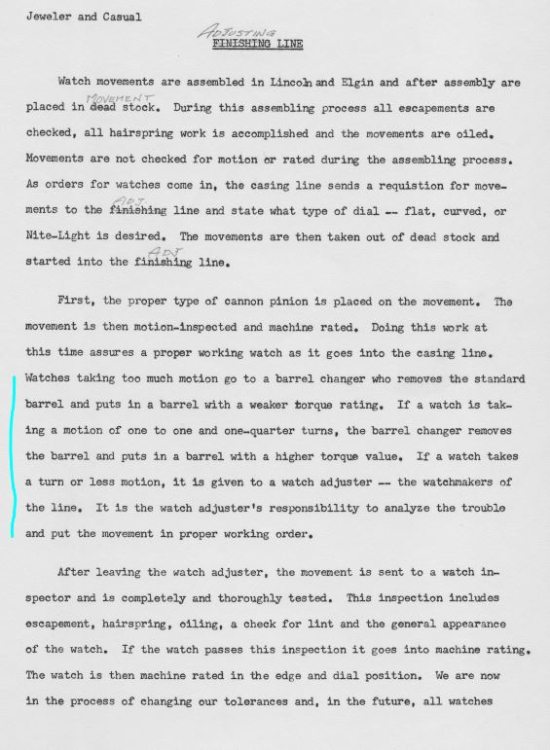

exactly you made an improvement. Or if the watch was in really good condition with modern synthetic oils you achieve the same thing as you had before. You did not make things worse. this is why I suggest newbies to start with a clone of a 6497 its large it's running and ideally they should have a timing machine. They verify the watch is running they taken apart they put together and verify that they haven't done a damage. Although if the pivots falloff hairspring gets mangled or other things they can blame gremlins that's quite common not their fault that any of those things happened. the problem is amplitude is only part of the equation. Customers can't see amplitude they know if the watch is on time. They know if the watch stops after taking it off for the evening and waking up in the morning with a watch that didn't have enough energy to run overnight. But very few have timing machines amplitude isn't important to customers at all. factory specifications can be quite amusing if you can find them. for instance Seiko from the 4006 they give you an amplitude specification to strive for. They do not give you a minimum amplitude at the end of 24 hours? typically for specifications they can be hard to find Swatch group has specifications but they're hiding behind a username and a password and account that can be really really hard to get. Which is why the best you are ever going see in this group is somebody snipping out something. unfortunately the specifications are only for newer stuff almost no vintage although Omega does have specifications for watches not covered by the specification sheet. In other words vintage but I really wouldn't call it vintage newer vintage. let's look at the past Hamilton specifications for the 992B for instance nice PDF attached. Notice the amplitude? The way the timing is specified would be similar to how they do chronometer certification today or even in the past. Chronometer certification is based on a watch running and keeping time nobody cares about the amplitude. But some people do Elgin internal documents 1955 approximately. Unfortunately they do not have a date anywhere in the thing it's based on his approximately 1955. You're right they are concerned about amplitude unfortunately they do not measured in degrees with the nifty timing machine and yes it had timing machine since the Al quite remember there is an internal booklet on timing machines stuff which is somewhere else so you can see specifications but not in degrees. It also brings up an amusing problem of if you are a service the watch today with a modern mainspring versus the original weaker Elgin spring that was needed now what are you going to do? then continuation of so we can't necessarily adjust our watches beginner watch is to keep time within factory specifications if we don't have factory specifications. Here we have from 1955+ you have to convert turns to degrees which I always find confusing. So yes amplitude is important but so is timekeeping. Brochure_technique-SW200-1_6.pdf Hamilton 992b 950 timing.pdf1 point

-

Just bought this PinVice; 0 - 1.5mm. It has two bits, one with internal rounded fingers and the other bit has the edged fingers. https://www.cousinsuk.com/product/single-ended-round-with-2-collets-horotec?code=P58276 So far I've only been using it to hold a 2824-2 winding stem. Seems nicely made, works well and you get "two" for the price of £8.50 excl. VAT. Depending on your location, members Waggy suggestion seems price-wise okay. However if you live in the economic suicidal European union, by the time I get it in my hands (due to duties and registration fees) it cost me over $34 ....... That's the reason for me buying the Horrortec1 point

-

Thank you! I just searched for Jacot tool and learned about it through this thread (https://www.watchrepairtalk.com/topic/21856-jacot-tool/) and the amazing Youtube video by @jdrichard. Again, what a beauty!1 point

-

I agree that we can be a bit forgiving with very old watches. However, in principle, I think that a 100-year-old watch that has always been serviced well and regularly for its entire life can work like (almost) new and achieve amplitudes like (almost) new. Of course, this is rarely the case... so when it gets to us, we have to deal with the wear that has been caused by a lack of care over X years. But again, in principle, we could repair or replace the worn parts (i.e. more than a standard service, but rather some restauration). OR, we (or our client) make a decision to prioritize the originality of the watch and accept lower amplitudes. My point is: if amplitudes are lower than the manufacturer's specification, something IS wrong -- and if our troubleshooting concludes that it's simply wear in all parts, then that's what's wrong. How we deal with that conclusion is a second question. Accept it for the sake of originality, or repair/replace. Both are fine, but that should be a conscious decision. I recently serviced an Omega 625 from the 1970s (=50 years old) and an Omega 244 from the 1950s (=70 years old) -- these are rather comparable movements of similar size an very similar Omega factory performance specifications. The "older" watch was clearly better taken care of in the past and I'm now getting an amplitude of 295 (fully wound, dial up). The "younger" watch was in bad shape, but by replacing 1-2 parts and a thorough service, it also runs at an amplitude of 285 (fully wound, dial up). Both comply with all the factory specifications that @JohnR725 regularly posts about Omega. This is not to brag (even though, I'm immensely proud). I'm just trying to point out that the older watch runs better than the newer one because it has always been well taken care of. And again, both run "like new" (according to the Omega specs). Theoretically, and now I'm going very far... a very old watch could potentially run better than when originally produced because we can now use modern mainsprings and better lubricants. But please note that I'm always comparing with the original production performance ("what they are designed for"). I'm not comparing a 100-year-old tiny ladies watch movement with a large, modern ETA movement... Just to clarify, when I wrote "certain amplitude" I wanted to indicate that not every watch is built for the same amplitude (270 or 300 isn't always the magic number). Ideally, we would find out the factory specifications and measure our work against that. For Omega, @JohnR725 regularly posts the specs, for example here: https://www.watchrepairtalk.com/topic/3548-omega-deville-cal-625/?do=findComment&comment=215566 When it comes to the technical significance, and apart from my point above, the other Members have posted quite some remarkable insights.1 point

-

Thanks, I just use some cotton buds and water, fortunately most of the damage was loose dust/dirt and corrosion products, so more luck than skill , I finished up by using the Bergeon dial pen to get the chapters back to sparkling as well as the hands. I used rust remover fluid on the hands followed by IPA and to my surprise they came up really well so I decided to keep them after re-luming them.1 point

-

Hi, Just replaced a buzzer on my Seiko H601. The replacement piezo actually came with a Seiko quartz chronograph movement and I had saved it just in case. It was the correct size, 18mm diameter and had an array of glue dots on the back. I managed to fit it to the case back as follows. Clean old glue with metal scraper and fine abrasive (I used Scotchbrite grey). Final clean with solvent. Place disc in place and put three pound coins stacked on top for a little downward force as the glue melts. Make sure the disc doesn't change position. Put in oven directly on the rack and switch on at 200 degrees centigrade. Let oven attain temperature and then switch off to cool naturally (I opened the oven door and left for 30 minutes). When cooled the disc appears to be stuck perfectly and the piezo output is now very very good. Hope it helps. Steve1 point

-

Well done! What did you do to the dial? It looks like new! I'm sure your wife's uncle will be super thrilled!1 point

-

I managed to get it in. Very gently with a pair of parallel pliers nudged it to the left and right and it worked itself in. It's the one that had the snapped screw in the barrel arbor. the Leonidas GSTP. It's a touch long (80mm) but it's the best match there was (or I could find).1 point

-

yes definitely pictures would help because there's so many different types of cases that we can't give you advice. Because if we give you advice still probably be for the wrong case in your risk damaging or destroying this one.1 point

-

Hey Scott. As I want to ensure that the inner chapter ring engages with the chapter indicator wheel properly, I would need to get a 357612 stem. This would mean I also need a threaded crown as mine is a push fit. As the current friction fit set up works, I will use that. I just wanted to see if anyone had come across this type of crown/stem before or is it an early "beta" type anomaly as Alexei suggested. Cheers, John1 point

-

Thanks for all the above - you delivered in trumps1 point

-

Lolly sticks with self adhesived emery cloth or chamois for buffing, sanding and sharpening. Can also charge them with cutting paste and compound to make flat plate laps for polishing parts. Acupuncture and sewing needles for fine oilers, collet removers, hairspring tweekers, disassembling tools etc. flatten the tip with a flat stake and then shape and sharpen for its use. Cut up pieces of yoga or click together sponge floor mat to make polish pads or fit into varoius jar lids to make watch cushions. Foam insulation used for underfloor heating or kingspan, celotex wall insulation as an alternative to pithwood. A piece of bluetack on your desk to jab your screwdrivers into to remove fibres, hairs etc. Dessert glass ramekins for keeping dust off project movements. Ebay jewellers vice converted to movement and part holders ( actually beats any movement holder i have, and i have a few ), it can fit steel, brass or wooden pins for grips. Dried flower glass holders for holding tweezers, screwdrivers, pliers, brushes pinvices etc. Contact lens cases lined with rodico for safe keeping of project shock jewels and all springs ( put them in there as soon as removed before you cough, burp, sneeze or fart ). .5 copper wire stripped from electrical cable to make dial feet, hangers for watch parts. Hanging tea infusers and strainers to hold parts for cleaning. Cheap as chips mini dc motors to spin parts while electro plating, can be slowed down to 0.5 rpm. Wow all this and I'm not even out of bed yet1 point

-

It would be helpful, at least to me, to rewrite your question and naming the components by their names as in the Omega service manual, which I included. Omega 861 service manual.pdf1 point

-

1 point

-

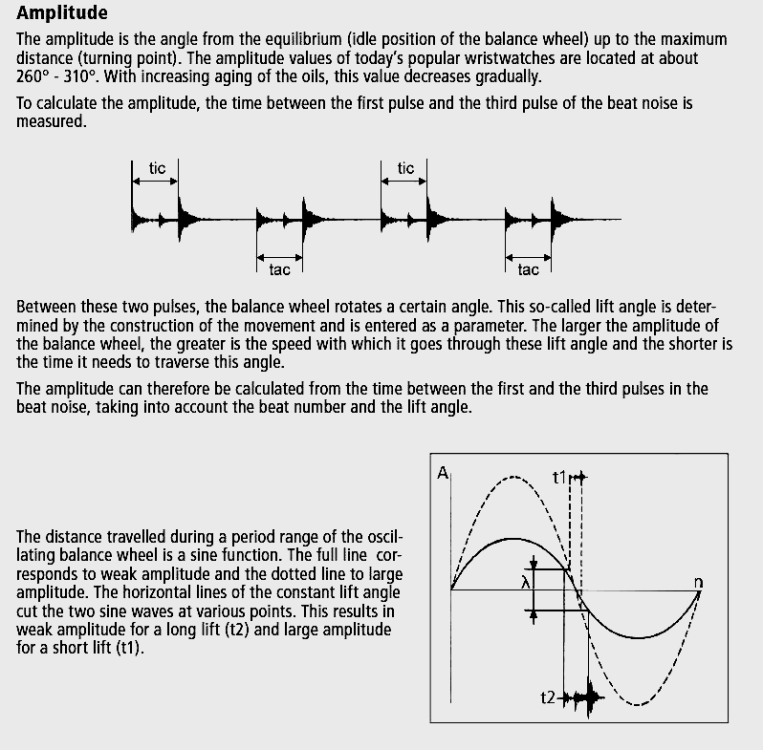

this almost sounds like a sine wave? a Sine wave that's affected by lift angle. lift angle becomes interesting because typically a modern watches it's really close to 52° but deal with older watches like American pocket watches then begin a much bigger span. Anywhere from 38 to 62° I've seen. Then another way you look at lift angle is the amount of time that the escapement is screwing up our sine wave.1 point

-

No idea, but i want one because i dont have one. Its some kind of spring loaded cutty choppy thingy.1 point

-

In any system, there is noise. Some random, and some systematic. I will call the point where the balance crosses zero, in John's figure, the trip point. The faster the rate as the balance crosses the trip point the less susceptible it is to noise. So, higher amplitude (faster rate or slope) would seem to be better for at least that reason. I am somewhat amazed at low amplitude pin lever watches that keep pretty good time.1 point

-

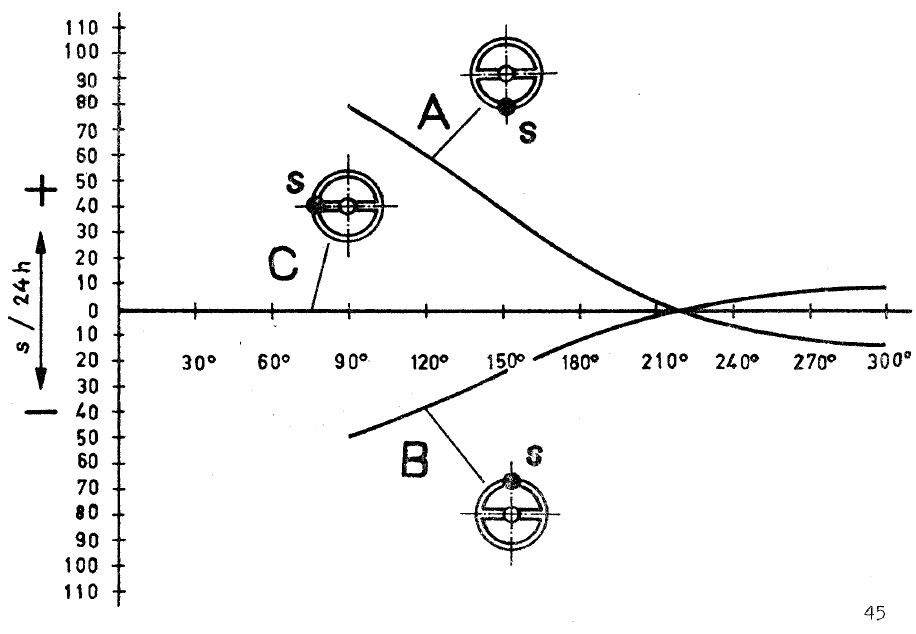

one of the places were amplitude would be more interesting and useful is. New watch you got it for the first time you run a timing cycle six positions you record all the amplitudes and rates. His service the watch you should see better amplitude. if you look at technical specifications from the Swiss for instance you will see that they typically do not tell you what a good amplitude is they've only tell you what a unacceptable yes. They usually have a maximum because of you go over 300 depending upon the watch that is undesirable but other than that they don't care about a high amplitude they only care about a low amplitude typically at 24 hours sometimes they'll specify which crown position it is other times it's more generic. Then it depends upon the watch watches can vary as to what is good and bad I think the lowest I've ever seen Omega have some other movements would go 260°. so how about an example this is a Rolex it was incoming know of valuation was done on the inside yet. We know for 3035 Rolex that and attends you little variation here currently it seems to be 200° at 24 hours is unacceptable some other tech sheets had 190. so first image dial-up fully wound up looks pretty good next we have crown down now here we can see the amplitude has dropped by quite a bit 24 hours later dial up and by the way this shows why when looking at a watch you should look at more than one positions the person who gave me the images actually had all of the images I only snipped out a couple of them because they were too many. crown down at 24 hours is looking below the 200 that we typically see but above the 190 that some of the tech sheets have all the other interesting thing with the obsession with amplitude on this group is often times people don't look at does the watch keep time? Then yes amplitude is a measure of performance but unfortunately each watch can be different. This means spending lots and lots of time trying to get something to do 300° conceivably is almost a waste of time because the factory never designed it that way. Look at Seiko watches typically lay have pathetic amplitude and they oil the pallet fork pivots which makes it worse. oh and the Rolex watch above a 3035 as an issue can you tell me what it is? all we know is the current owner wears it occasionally. Oh and this is where amplitude also has a problem if it's a watch you serviced if you documented your watch properly especially when you're learning. Example incoming watch check it in six positions write all the numbers down when it's fully wound up just for the fun of it wait 24 hours do it again service the watch see if you have an improvement. A year from now another year another year keep checking see how your watches doing. But is a minor problem to this? oh and is amplitude a problem on hundred-year-old watches what about out of beat? One of the watch keeps time are those other things important well they are where I work my boss gets annoyed if the beat is too extreme or the amplitude looks low I tenderly worry about if it runs overnight keeps time. one of the problems is what exactly was the amplitude when these watches were new? The theories of horology have changed with time for a variety of reasons things basically today more efficient. Back then there were more concerned about keeping time than amplitude. they didn't have a timing machine to please. then there is a problem of all the people who worked on the watch over time. All the strange things that have happened to certain degree it's a miracle if you gave it to get these watches running again. maybe a picture would help. if you look at the image below you'll notice something interesting poise of the balance wheel. the purpose the chart is it shows what happens when you have a heavy spot on the balance wheel. At various amplitudes depending upon where the heavy spot is the watch with a run fast or slow its how we do dynamic poising for instance. But as the amplitude increases hitting approximately 220° you no longer will observe any poising errors at all. Then as you go faster in noticed that the errors aren't as big. Which is why dynamic poising is easier at a low amplitude as it's much much more noticeable. So this is what makes 220° kind of a magical number as no poising errors suggest think if you watch could run a perfect 220° no poising errors.1 point

-

That's exactly how I just ended up buying a vintage Seitz yesterday. Locally, good price, good condition, 98% complete set. The opportunity overruled the comparisons with other tools I must say that I'm just blown away by the beauty of the tool. And adjusting in 0.01mm increments is so impressive. I'm just in awe. I hope with practice, one day, I can be like you1 point

-

You can also use a sewing needle. Grind the tip in the length (axial) sharp with a medium size (#200-#300) grit emery paper, so the scores in the needle tip will remove some material, and slowly start to open up. Keep checking your progress. For example fine drills do snap off easy, rendering the seconds hand instantly useless.1 point

-

Just a heads up that even the premium brands discussed above can have their issues, I'm sure this was just an unlucky 'one-off', but 2 or 3 weeks ago I recently purchased a new Robur press from a popular UK online retailer, and on its maiden use the thing completely locked up having barely contacted the crystal, it felt like the internal threads were cross-threaded?? Now it will not open or close at all and is now a very expensive paper weight. Kudos to the retailer who was very responsive, but the solution from their supplier that they have proposed is to supply a replacement shaft which I have to fit myself. I'm glad that my press may become useable again, but a little disgruntled that I purchased a new press, but I will be left with a repaired press. If I hadn't invested in the Robur dies I think I would walk away and go for the Bergeon type or a good clone as this has left a bad taste in my mouth.1 point

-

Can you imagine hanging a 1 day clock off your balcony on the 8th floor with 8 days worth of chains? I never got back to the seller.1 point

-

I never repaired those horrid quartz watches. From what you have said I find that quite silly.1 point

-

it would be helpful to see picture of your testing device just so I can see what you're working with. I don't suppose you have any other test equipment like a DVM for instance? the problem with a quartz watch is it has a electronic component and a mechanical components. The electronic really needs better test equipment even without seeing the picture of what you have. This is were even having a digital volt meter would be nice but additional test equipment that you don't have would be even better but that's going to cost some money. Then the mechanical component by the way in case you didn't have it I've attached the service guide there seems to be two of them I don't know why the second one looks more like a parts list but there's two of them. You'll notice this is also a mechanical watch mechanical components. Quartz watches like any other watch need to be serviced especially if there at all dirty or bad lubrication or the battery leaks and get some things quartz watches require almost 0 power to run and things that wouldn't even affect the mechanical watch could stop it. Then yes the thing the spin the train doesn't necessarily mean the watches going to run. Probably all the watch needs is to be taken apart cleaned and there is a special oil for quartz watches I believe it's 9000 which I found works really well on quartz watches but if you're only going to do one well that's a problem because sometimes the wrong oils can be an issue on a quartz watch. So without proper testing equipment it's hard to go much further other then it probably just needs to be cleaned. You could try a taking of the plate off that's holding the wheels in place and take the gears out except the rotor and put that back in and see if that will turn when the watches running and that if that works in you can put the next gear in but it's probably just a cleaning issue. Seiko 6923A.pdf Seiko 6922A&6923A.pdf1 point

-

Not a watch, but a screw-head polishing tool. Offered on eBay as an auction, but the seemingly incomplete Lorch & Schmidt polishing set with a below mid-starting price got no bids, apart from my one in the last 5 seconds. However, only when enlarging the other sellers pictures, it seemed as if there were more collets hiding underneath the polishing disks and the polishing tool. This turned out to be the case. After quite some TLC of the parts and the wooden box, the set turned out to be like this; Less than 1/2 price than what these (be it fully complete) set are currently going for on eBay Three parts, for polishing screw-thread-ends, are missing ...... I can easily live with that1 point

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)