Leaderboard

Popular Content

Showing content with the highest reputation on 05/31/22 in all areas

-

This first one arrived today. It's a nice Bur Walnut case shame it has two tiny marks that need to be sorted other than that it is in all round very good condition. The second one will be with me in a few days, it also is in very good all round condition. Both bought from ebay, both under £50 each. Got this one this evening its a WESTMINSTER & WHITTINGTON chime with platform escapement for just under £200 including P/P.4 points

-

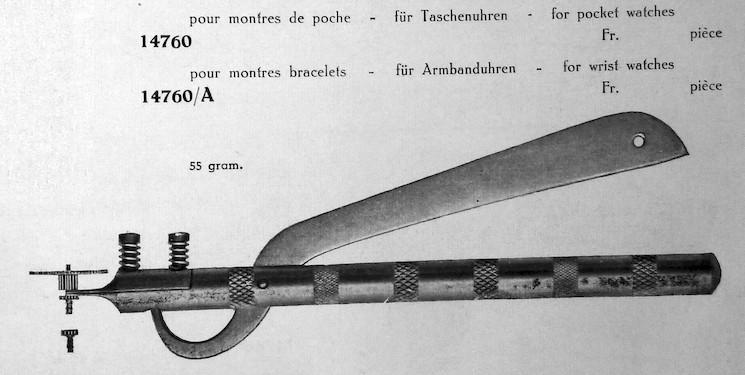

As usual, a perfect explanation by Nickelsilver! But the tool is older than offset canon pinions and aimed to a very similar, but slightly different task: Center wheels and its canon pinion came as adapted assembled units. But for mounting, they had to be separated, and this is, what the tool was initially made for. No other tool will really help, esp. with bored pinions of center seconds or chronographs. Frank4 points

-

Try an Osco 66 : http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Osco_664 points

-

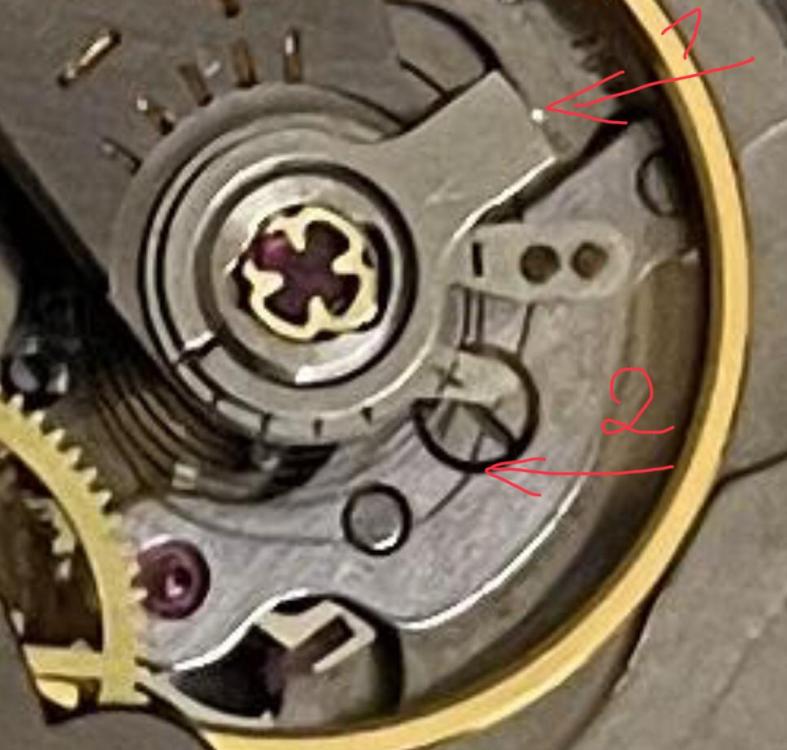

An offset canon pinion is not in the center of the watch, and doesn't carry a hand. It's seen in a number of mid 20th century calibers where the first wheel after the barrel isn't centered. Later designs like most familiar modern ETA calibers deal with the friction needed for hand setting by driving the cannon pinion through an attached wheel which is driven by the rigid offset 3rd pinion. In the pic the upper pinion is the offset cannon pinion. They are by necessity shorter than regular cannon pinions, and since they are attached directly to the center wheel with no bridge in between can't be pulled with a normal cannon pinion puller. The tool in the first post slides in between the upper cannon pinion and lower fixed pinion, and spreads, thus removing the small cannon pinion without harm. If you don't have the tool, you can often work them off by gripping them with brass or nickel tweezers and turning while pulling, or sometimes you can grip the arbor area between the two pinions with a pair of steel tweezers and slide them along the arbor (while turning the wheel), the wedge effect will pop off the cannon pinion. If you have a bench block with a V cut and that is open and thin enough on the underside you can get the assembly in it so the cannon pinion is sticking up, sitting on the V, and press down the pivot with brass tweezers. Or- a Platax tool can work well here (about the only good use for that tool in my opinion). But except for the latter technique there's always a risk of damaging the center wheel. The tool really makes it easy.3 points

-

I does look good. I want one too. Time to get your metal detector out. Hehe.2 points

-

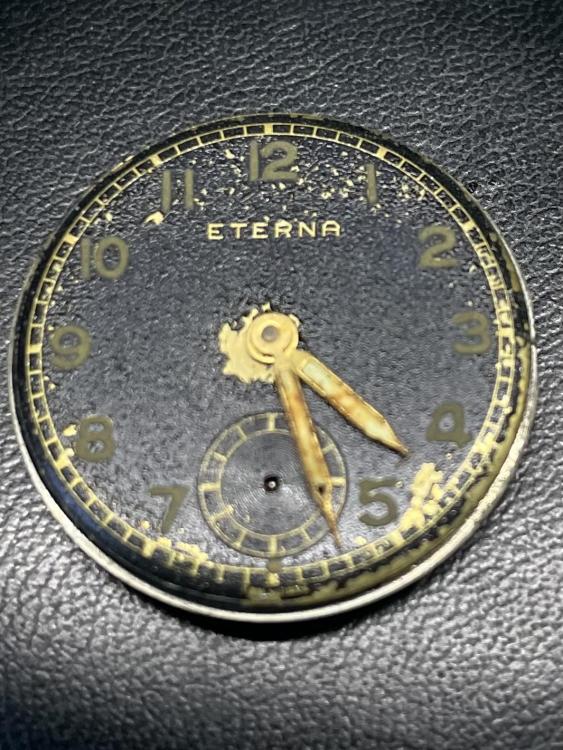

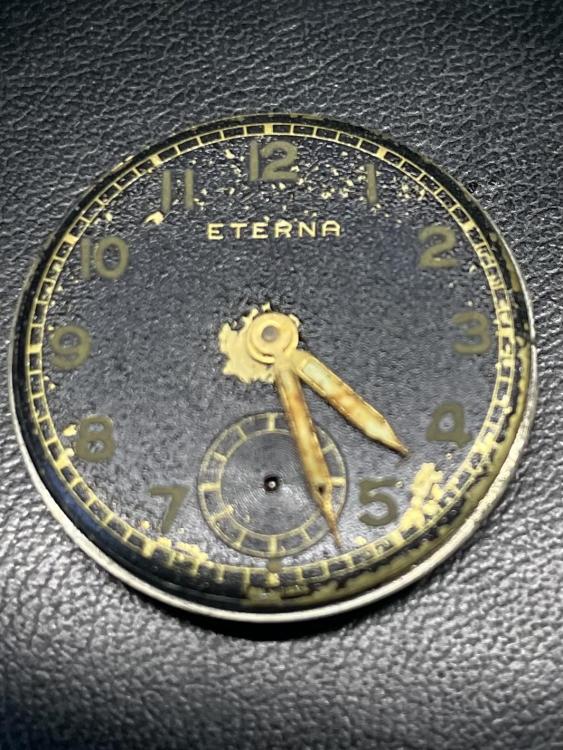

So, I thought I’d update this feed. I managed to sensitively restore the face as best I could and I’m really pleased with the result. It’s running really sweetly after a full strip down and service, strong amplitude and losing 4 seconds a day. I didn’t know what the movement was so reached out to Eterna with some pictures and they tell me it’s a 1020 movement from 1944. I attach some pictures of the before (first 3 pictures) and after (last 2 pictures) I’ll start a new feed with this also2 points

-

2 points

-

If getting the caseback off is that difficult, getting it back on will be equally challenging. Usually for small, ladies watches, you'd need special tools for opening and closing the caseback. If you're only going to do this once in a couple of years, it'd be better to bring it to a jeweller or watchmaker.2 points

-

One picture shows the date changing though the time is only 8.30 - What's happening there ? As mentioned above, the fact that the second hand keeps moving suggests a cannon pinion problem. This movement has an unusual feature - the "Date Corrector" which changes the date when you pull the crown. If not installed correctly (I didn't the first time) it can jam the date wheel Did you install it correctly - i.e. does the date change when you pull the crown out ?2 points

-

2 points

-

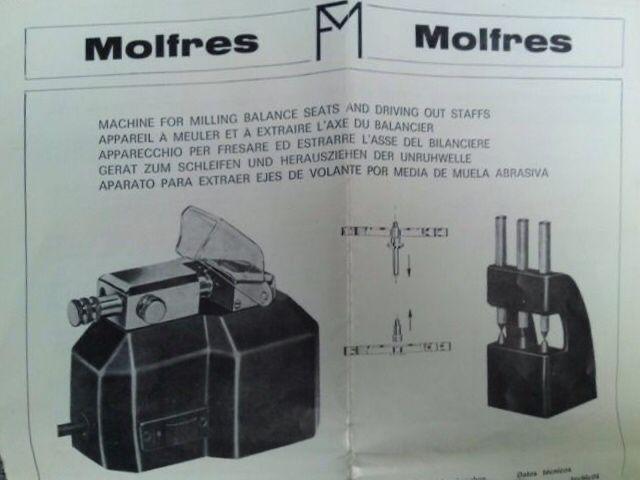

That's my personal view, either the lathe to cut the hub or the Molfres tool, which grinds away the hub (I haven't used that one but they did have it in the Swiss school I went to). I know many professional watchmakers swear up and down that they have no problem with the Platax or the similar tool used in a staking too, but I just don't feel right pushing an enlarged rivet through the balance.2 points

-

This is where the bestfit books are use full. Use the indentification section and you can check the setting leverspring design / keyless parts in the relavant section according to size and shape of the movemnt.2 points

-

Take a cell phone and do a slo-mo video. That will show if the amplitude is o.k. (should be significantly more than one full turn from stop to stop). If so the problem is not the mainspring. The observation that you can not regulate the speed points towards the hair spring. Please inspect the hair spring carefully!2 points

-

2 points

-

I can see my request for photographs went unanswered fortunately I remembered when I was at work. Then as I suspected the notch that's broken is the one that I commonly need to use for 18 size American pocket watches but I was still able to get the roller off. So we have a really nice roller remover tool. then subject hijacking? Okay I guess the subject was mystery tools and we need more photographs of one of them the tool on the left-hand side is some form of bench micrometer. As a really nice big spindle slot should be capable of a very high precision. Definitely a much better tool for measuring some things in the near calipers like the thickness of a mainspring much better. The tool on the right we really need better photos? But in the absence of anyone else guessing it's probably for truing balance wheels possibly may be perhaps. You should build a look at the ends of the tool in the middle and it should be able hold a pivot probably have the arm like thing is perhaps used to tell if your balance wheel is straight or not. At least that's my best guess.2 points

-

Nice one matey. It looks great. Now could you find me one please1 point

-

Oh well done.That looks like it's worked out really well. Nice job.1 point

-

So, I started a separate feed about this watch a few days back - discussing the state of the face and how it was literally flaking away at the touch. I thought there was no coming back for this watch but.. …some days later with some love and attention I have managed to sensitively restore the face as best I could and I’m really pleased with the result. It’s running really sweetly after a full strip down and service, with a strong amplitude and losing 4 seconds a day. I didn’t know what the movement was so I reached out to Eterna directly (with some pictures) and they tell me it’s a 1020 movement from 1944. I attach some pictures of the before (first 3 pictures) and after (last 3 pictures) Let me know what you think?1 point

-

hopefully that hairspring is on a balance wheel? Then you replacing the balance wheel with that hairspring. Typically on modern watches hairsprings do not interchange with other balance wheels because of major timing issues. Which is why typically if you need a hairspring it's a balance complete not a separate hairspring.1 point

-

I avoid talking to Cousins for anything as they’ll take the time to give a snotty reply, but can’t take the time to answer a genuine question. To answer you, I got a set of SS dauphine hands from them this week. It is white in colour but glows green.1 point

-

Hi You could try cousins for an assortment in the hope one is close enough or have a look at windingstems.com website for starters.1 point

-

As a potentially interesting aside... The Bestfit catalogue when looking for 'Osco' also has 'Parat (see Osco)' and 'Stowa (see Osco)' implying it could be worth in some circumstances looking around against these separate names should someone run into parts difficulty. In the case of the 66 however then, as @mikepilkhas pointed out, there is good parts availability so that's unnecessary. Note that Dugena 1157 = Osco 66 but Cousins deny all knowledge of the Dugena. Poor Dugena.1 point

-

I have always said that moving metal molecules to fill a scratch is BS. But I was challenged in a previous thread. I wished someone with access to a scanning electron microscope would conduct a definitive experiment and put an end to it. As a dentist, I've worked with 24K gold foil and high gold content alloys (>85% Au). With these extremely soft and malleable metals, just rubbing it with a stainless steel instrument is sufficient to physically deform and move metal. If you say buffing these metals could move molecules, I'd believe you. But when it comes to stainless steel, I really doubt so.1 point

-

1 point

-

Sometimes highly respected people tell BS. See the video I have in mind (3:30 to 4:05): https://youtu.be/YMuWrI-sCj81 point

-

always nice to give us a model number as different models conceivably can have different problems and answers conceivably could change. usually the secondhand is moving in the hour and minute hands are not Loose cannon pinion definitely a place to look except? They usually don't get loose all by themselves so how did the setting of the watch field before you put in the case? Sometimes you might have a borderline situation where it seems loose but it seems to work and then the reality is it's to use does it totally stop and then how do you started back up again? You have to set of tests this or does it just temporarily stop or what exactly do you mean? Then visit stopped twice a day or only once a day? At least one of the things with a stopping situation is it's much better than a intermediate situation that occurs seemingly randomly. You also want to look at your hands for some reason may be they 8 o'clock marker is sticking up too high is the minute hand hitting anything. It's where the quote I have up above any ideas please without proper diagnostics which you have to do we get the gas. Like hand hitting in the 8 o'clock marking position where the markers stuck up or something if there's nothing visible on the dial side that you can see is a problem you can take the movement out of the case and see if the problem goes away out of the case. Then remove the hands but make sure you note the position that there in because we need to put the hands back where you found them once the dial is off. At least you might put the hands back on otherwise you can carefully look at the dial side for any kind of damage. Does the watch have a calendar? A lot of calendars don't like to be rapidly advanced at midnight usual procedure to tell people not to advance the calendar it's always conceivable of something is broken is floating around inside their of course it would help to know which movement this is.1 point

-

Re mainspring. Was it new? I'm curious as new mainsprings come in a washer and if by "I put the main spring in the barrel by hand" you mean you pushed the spring from the washer into the barrel you should be fine. If you mean you pushed it in by hand, ie a fully unwound mainspring which you worked your way around then potentially the mainspring could be out of flat and this would affect timekeeping but usually towards the end of its power curve..ie it will run worse the closer it gets to the end (fully unwound). If you have replaced the mainspring it could be the spec is a bit far off. Do you have the old spring handy to compare? thickness, height and lenght play a part, you can have some leeway with the length but thickness and height would affect timekeeping if they are significantly different. Anilv1 point

-

Barrel lid might be pushing on main spring coil, the lid should sit flush level in the barrel and not push on the main spring . Bottom of tbe barrel should have smooth surface, polish it if its not. Are you sure the new mainspring ( replacement ) has the right strength.1 point

-

Part repairs can be a pain. It doesn't take much to upset the workings of a watch. I advise you to clean and oil the whole movement. Treat it as a new repair.1 point

-

1 point

-

But then again cheap fashion watches are often snap backed for cheapness If you look around the edge of the back with a loupe you should find where to insert the edge of a case knife. Unfortunately some don't even have that option as it's cheaper to not have the cutout for the knife and will need a more elaborate back opener, like one of these https://www.ebay.co.uk/itm/225002213763?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=3BWNpbSeRqW&sssrc=2349624&ssuid=cJqjENlHSBe&var=&widget_ver=artemis&media=COI have not yet seen a screw back wrist watch that was not obvious in some way that it was a screw back, pocket watches yes but not a wrist watch, especially a modern watch. could you post some pictures showing the back1 point

-

we got a get our terminology right otherwise it leads to confusion does the watch sound like it's galloping? Does it only sound like that one is wound up tight after its run for a few hours is still making the galloping noise? Then under the balance wheel I see some numbers it be nice to get a picture of those. This is a modern Hamilton in other words it's not really a Hamilton it's just a name Hamilton on the watch it's really a Swiss watch. The numbers under the balance rim might tell us what it is. no no no we can't have that that means I would have to retire my crystal ball. You would have to quit staring at tea leaves or whatever you used to deduce whatever the problem is having a timing machine or an app providing the app actually worked would just make things too simple for all of us that just isn't acceptable at all. terminology problem I'm not quite sure what you're getting at here? there certain problems with learning watch repair. First despite what you might've heard cleaning doesn't fix everything. Seconds knowledge is required. The problem with lacking knowledge is diagnosing problems requires knowledge of how the watch works all of the watch and if you have no experience with watches that means your diagnostic skills are going to suck. Then acting on your diagnostic skills which need perfecting usually will lead us down a path of well not necessarily the best path to be going down this is where initially when you're only running fast the timing machine or app providing it actually works a lot of them don't would've been really helpful. Now we have the initial problem and whatever you've done to try to fix the problem in which case I don't quite understand what you meant in the paragraph above that I quoted which I don't quite understand?1 point

-

Hi matey. You really need to have it giving out some running feedback on a timegrapher or an app at least. Then you can make some timing and beat adjustments. It is possible to check and set the watch for correct beat resonably accurately without a timegrapher. Its not difficult to adjust its beat by eye if you have some experience. Have you moved the beat adjuster by accident do you know ?1 point

-

Click on Resources at the top of the page then click the flag of your country and you will see many suppliers to choose from.1 point

-

Not only does the broach need to be vertical, but the mainplate/bridge also needs to be absolutely horizontal. Using a reamer with a Seitz jeweling tool is probably fine for most jobs, but some prefer to use a lathe with faceplate to ensure the hole is perpendicular in axis to the reamer just to be extra safe.1 point

-

The repairer did look a little rough with his approach to the reaming. Definitely wasnt being too careful about being perfectly square on with the jewel hole. I think id be wanting to use something more accurate as well. The best end result does require the best possible approach1 point

-

The difficulty with this is to maintain absolute centre and that requires the broach to be absolutely vertical. Achieving it by hand is not easy and no second chances with that repair. Using a reamer with a Seitz jeweling tool or similar would be my option.1 point

-

They definitely serviced it at Cartier. They sent me the receipt. This is definitely either Cartier or the ebay authenticator's fault. But a watch that is 18 months old shouldn't have issues and speaks to a subpar build.1 point

-

1 point

.thumb.jpg.f6203c1cb2a103885fbb476e4f6d3795.jpg)

.thumb.jpg.9ae9b563aec3d1ecf8d44bb880772769.jpg)

.thumb.jpg.cce6a2846dd846c0da977ccb03d5f253.jpg)