Leaderboard

Popular Content

Showing content with the highest reputation on 12/08/19 in all areas

-

As mentioned, brand new GR mainsprings do not usually require lubrication. You have observed my videos on YT where I apply a little grease to automatic watches to the barrel wall. As has been mentioned above, this is braking grease. The mainspring also has an extremely light (and I mean extremely light) application of 8200 along it's length also. I do not film every aspect of what I do as some tasks are a royal pain in the rear to film. This is one of those tasks. Although I do cover this in the video course. The videos on YT are usually a 30 minute give or take condensing of a job that may last hours I cannot film everything. If you look hard enough you may notice many places seemingly not lubricated - this doesnt mean those friction points were not dealt with. My YT videos are there for entertainment purposes and whilst many find them extremely useful as a learning aid, they are not comprehensive breakdowns of a full service, that would make them hours long each., my course on the other hand is a full breakdown of all steps required to effectively service a watch. I hope this clears things up4 points

-

I picked this little Russian up and was enamored by the dial. When it arrived I discovered it had the stout Vostok 2209 movement. I found it was a very clean movement and only needed to be adjust for timing just a bit. The dial that had my attention looked to be silver plated copper with a rather dirty looking patina. The dial isn't engraved as I had hoped, but was stamped with the pattern formed during that process. I wanted to make that pattern pop so I painted the entire dial flat black and used thinner to remove paint only from the top surfaces. Was a bit tricky to accomplish but I think it came out great. Next I turned my attention to the hands. Somene had put a shiny black varnish on the hands as contrast, no lume was present. So I cleaned that of and since I didn't have any white paint, I used liquid white out. I know this is probably blasphemous, but it's a totally temporary solution until I get some lume I like. Placing the hands back on was a bit tricky as the fit was incredibly tight and tough to accomplish with my huge sausage fingers. I have a black leather strap on order for it. Very pleased with the results. Thank you for reading this.3 points

-

2 points

-

May I suggest that you are extremely careful in handling the piece, like zero forcing of anything ever, no free runs of the train under MS power, etc. Chinese mov'ts are especially delicate, they tend to break by themselves easily and do not resist any mistreatment. Very recently I have broken a Shangai one in three different parts, that before counting the rotor that had split in two and the anti-shock spring that left on a shock. A Segull can be just $60 but a Sellita 200 for GBP at 140+VAT is not that far way in terms of price, but deliver much better reliability, and the parts are actually available.2 points

-

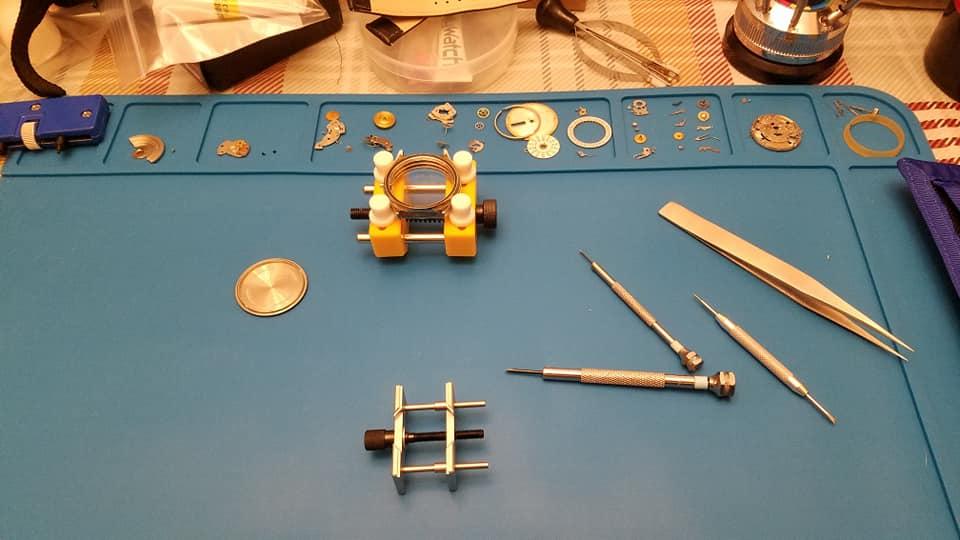

Here we go. My first tear down and repair. 1978 Caravelle 2879 movement. I think I found a problem though. Picture 3 the screw won't come out and the gear moves back and forth. I found this little piece under it. I think someone cross-threaded the screw and messed up the threads. The screw is still in it so i don't know if that gear moving is normal or if i need to repair this somehow? Are there any Movements that are close to this one that there might be a tutorial on just in case i have problems with reassembly?1 point

-

I don't have one with me but the original should be 1.05 high for a 10.5 barrel.1 point

-

Hi You found the problem ok. you are probably right to go for another movement a clean start.1 point

-

Thanks for the responses. I realize that diamond is probably the best option, but I have managed to shape and polish corundum in the past without resorting to diamond polishing compounds. I would not attempt to do any shaping with the stone mounted in the fork. I was thinking more of dopping a stone (I've got a small selection to choose from) on to a stick (tooth pick) and gently working it to the proper length and angle. The movement I'm having a go at is a 1923 Elgin 16s, 7 jewel 292 cal. The escape wheel is in good condition, but one of the pallet stones on the fork is "cactus." As a last resort I can splurge on a new complete pallet with stones from Cas-KerCoy, but $50 USD is a bit much for this Aussie. Besides I kind of like the idea of seeing if I can get this thing ticking again with what I have at hand.1 point

-

The tools mentioned here so far all probably do the same job, but they are not exactly the same. Since I do not know why the differences myself I will make a summary Seitz shown above all have a (detachable) lever, and I suppose, 4mm pushers and anvils. Some use guidance is provided (attached) Chinese doesn't have a lever. Horia has various types: - No lever, 3mm or 4mm spindle (the latter is more "standard" I think), regular of fine thread, that I can probably understand. - With lever, come in two types: free or guided spindle, not sure why to chose one over the other. - With lever and bigger spindles. Their boxed sets include both first two types, as if the serious Watchmaker couldn't do without. But for the amateur and/or budget minded professional the best deal is always a basic tool on Ebay, then add the bits as needed. 2001_J31073.pdf1 point

-

I've found this old posting of mine and in hindsight I would say that 1.05 x .115 x 420 x 10.5 mm - GR2534X would be better.1 point

-

a new mainspring is always needed when doing a service/overhaul. new alloy mainsprings come with a dry lube so you may think they are not lubed but they are, . if you reusing a mainspring which i do not recommend then you have to clean off the old oil first if there is any and then use a piece of watch paper coated with oil then put it between tweezers and run the spring through it. I cant recommend an oil because i have never reused a spring but i can say it wont be 8200 since it is a natural oil and can spread and contaminate your barrel and movement. there really is NO reason to oil a mainspring except for maybe rust protection when dealing with very old NOS blue steel springs, or if the manufacturer specifies. I personally never oil automatic springs since most automatics i work on are modern and use white alloy springs, which again already come pre lubed. Some springs have a teflon coating which looks blue that will have to be removed prior to install to prevent emulsion from forming. Has anyone tested the power reserve in auto with dry spring vs one that has a lubed spring? Do that then decide for yourself1 point

-

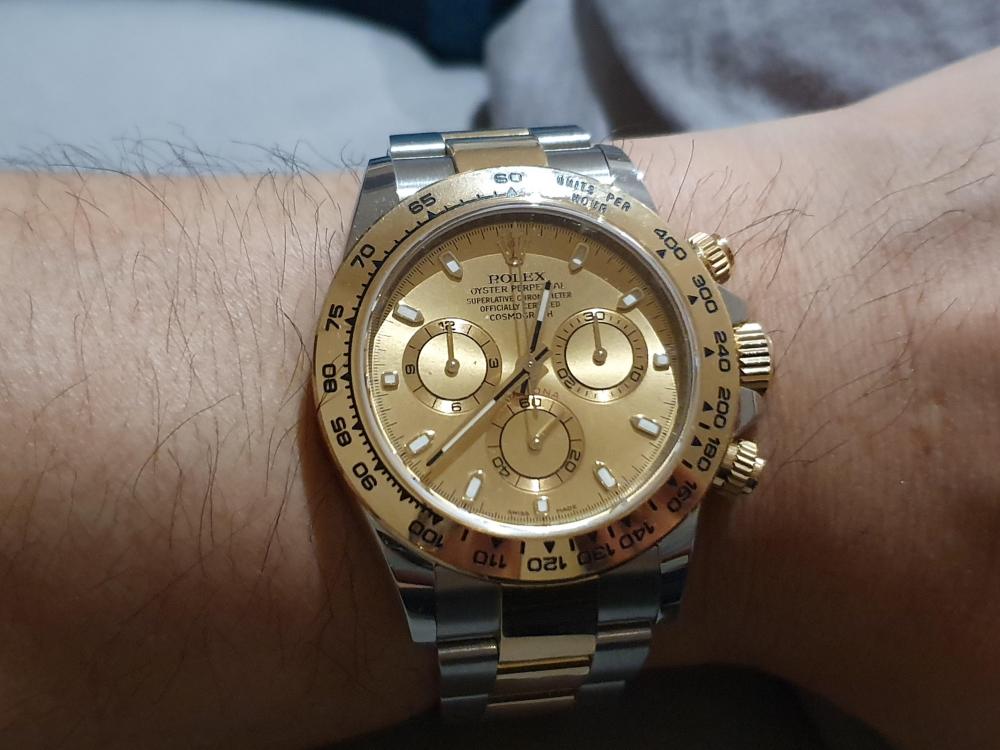

1 point

-

I'm not sure how the OP thinks he can do this, but if with the stone in the fork, assuming it would be even possible, then the stone will become too short and not have the right lock and draw. Faulty stones should be replaced.1 point

-

1 point

-

Thank you so much for posting this. I just tore down my 2879. I took pictures but my lighting is so bad that the pictures kinda Suck. Your 2824 is pretty close to my 2879 so these pictures will help me out a ton when i go to reassemble.1 point

-

Some of the stems/crowns in other movements are one piece (perhaps the majority), and the crown does not come off, but there are a few Timex movements (this being a good example) where the crown does come off. In the cases where the crown and stem are one piece however there is generally a screw or spring that holds the stem in place, so all of the mechanisms can all be removed from their cases relatively easily, one way or another, generally without removing the dial. There is quite a bit of information out there, some of it accurate, and some not. I have yet to find a site that gives complete info on all of the movements. Here is a little bit more about the various movements, incomplete, but worth a quick look. https://en.wikibooks.org/wiki/Budget_Watch_Collecting/Timex_movements#Base_Model_22 Having said that, @JerseyMo and others here would be able to answer pretty much any question you may have about vintage Timex stuff.1 point

-

Hi @jdm - with a comment like that I feel I've got to come back and defend my honour! My intention was not to imply "here's a 52 - look it's a match". What I was trying to do was help @jguitron establish that, back to the original question, it's not a Valjoux and that I'm in the Landeron camp since I'd noted specific part matches to the 52. I wasn't blind to the fact that of course there are also differences! I also wanted to make the observation that Eberhard have a history of taking an established 'base movement' and making their own alterations i.e. it might not be possible to find an exact match to a Landeron on record if indeed Eberhard have made various alterations to a Landeron of whatever calibre we hopefully establish. In that regards @wls1971 had a helpful suggestion. I just wanted to put the record straight as if you've misinterpreted the reasoning for my posting and the helpfulness I thought it could bring then other might have too.1 point

-

1 point

-

You try can source a Seiko 401615 From Cousins I think this one would work Mainspring, 1.00 x .11 x 420 x 10 Automatic - GR24571X1 point

-

I beleive u will get many answers from that video Now ! from your timegrapher i see that watch amplitude its low but decent . From the 2nd picture i see that the escapment system has problem and especially the pallet fork , anyway the watch has some serius problems and it will not work properly. You have done service on watch ? demagnetisers the watch before you check it on timegrapher ? u check all the watch systems carefully before the assembling ? and 1 lust question plz . You are a professional watchmaker or a hobbyist ?0 points