Leaderboard

Popular Content

Showing content with the highest reputation on 10/28/18 in all areas

-

Oil your balance pivots and pallet stones, it's pointless to check anything on timing machine with them dry.2 points

-

I just thought I'd share this as it may be useful for another learner. By far the most difficult thing I've come across starting out in watch repair has been correcting bends in hairsprings. I've got the right tools, the right light, a powerful eye glass and a pile of scrap watches I've been practicing on. But I found time after time I was just making the hairsprings worse. I think part of my problem is that I'm slightly dyslexic and I find looking at the spiral really confusing sometimes. But I had a bit of break through last weekend which has dramatically improved my technique. Quite simply, I hold my eye glass up to my iPhone lens and take a close up picture of the hair spring. I then make a cup of tea and sit and look at the photo, zoom right the way in and really think about what I'm going to do. This is so much more effective than hunching over the hairspring and straining my eyes for long periods and losing patience. Once I've really thought about what I'm going to do, I go back to the hairspring with a clear strategy, ie, slight bend in, fourth from the centre at 3 o'clock. I apply the bend, take another picture and repeat. I know it sounds simple, but it's been a huge help to me and I'm finally having success1 point

-

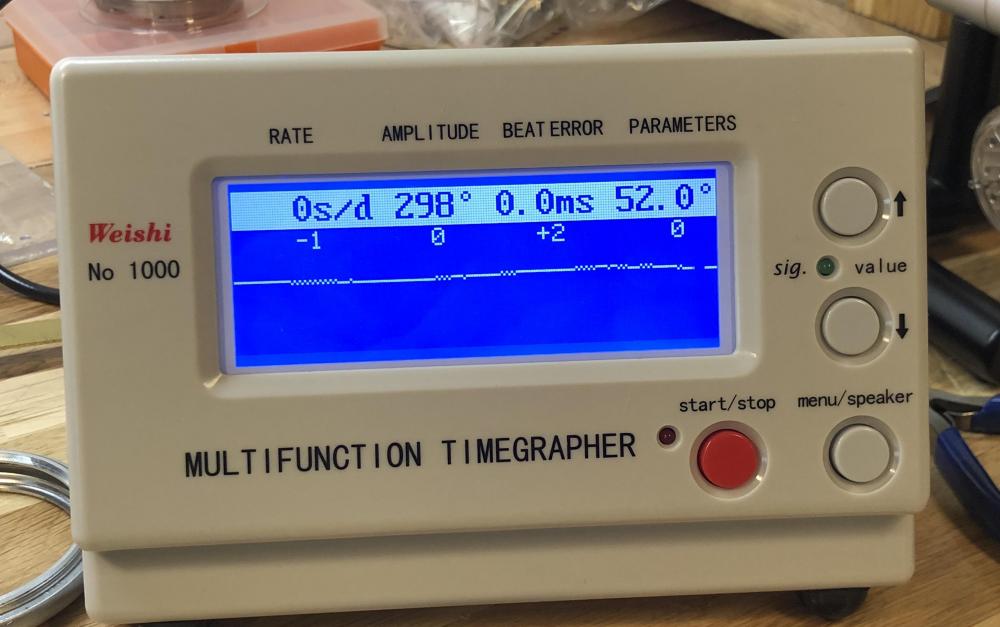

I'm curious about how you're holding the watch in the microphone? So I snipped out the way you're doing it and I have a sample of the way it's supposed to be done so is there some reason why you're doing it this way? Then I noticed the other way you're holding it where it appears to be your pushing on the crown? The jaws of the timing machine are quite strong pushing hard on your crown which is pushing on the stem isn't really a good thing to do. So many questions and so many problems. Then it's amazing how much power is lost through the gear train and escapement if it's not properly lubricated. Then totally wrong lubrication can be worse than no lubrication at all neither of which is desirable if you're trying to get your watch to run properly. The beat error? I'm attaching an image same timing machine different watch so you can see what 2.2 ms looks like. Your lines look like they're too far apart for the error they're producing? Then from the link below is references that later versions of this watch have a floating stud? If that's the case putting this watch in beat should be really really easy. Mainspring someday you'll have to put breaking grease on the barrel wall but that's not going to be an issue or problem right. Modern new mainspring are prelubricated it's an invisible lubrication unfortunately for the most part. But as you've cleaned the mainspring it now no longer is lubricated you probably should put some lubrication on it. From the list of lubricants you currently have you could use D5 on the mainspring. Then your description of it doesn't look too good? Everything you do to screw up the mainspring ripples down to the balance wheel. Besides the usual cone shape that you get from hand winding were there any kinks or bends in the mainspring? Then when timing more than one position is desirable. Your currently resting on the end of the balance pivot the least amount of friction so at least one pendant/crown position is desirable. A wristwatch crown down works fine. Cleaning fluids lighter fluid seems to be popular on this group. There are alternatives at the hardware store. It's important to remember no matter what you are using is it's not a one step process. This means that whatever you clean the watch in you now need to Rinse at least twice. Each rinse needs to be cleaner than the previous one. So the initial cleaning fluid whether it's commercial watch cleaner whatever puts things in the solution which is now coating everything in the watch. Then the next rinse reduces that concentration and the rinse after that will reduce the concentration. Then you don't have to go through a lot of cleaning fluid or rinse if you keep them in jars/Containers with tightfitting lids. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA_24511 point

-

This is a real fiddly job. My tips are as follows very good magnification, the ideal is a microscope, demagnetise the spring and movement, absolutely well dressed tweezers and peg wood. If the first time experience I recommend putting the movement inside a clear bag because for sure the spring will fly off a few times before success.1 point

-

This calls for a celebration Classic vintage looks, great. Best wishes Joe1 point

-

This is one of the more fiddly tasks. It takes some practice before you can do it with tweezers. When I was struggling to do it, I put some Rodico just above where the spring goes - make a vertical surface. Then stick the spring to it, so it's just above the slot. I use some sharpened pegwood to push the bottom of the spring down in to the slot, whilst moving the top of the spring in to the correct angles using another piece of pegwood or tweezers. With the spring held in the Rodico, it's easier to manipulate without it pinging off. Cap jewel tiddly-winks is another good game !1 point

-

When slotted balances are out of poise, you should also consider bent balance halves. Your slots look as if they are of different width. Frank1 point

-

The loose/ gain is expectedly periodic. Give the period. The change is said behaviour in differnt positions? Staffs axial play, any side shake? How well cab locks keep the jewel in place? These and more, before suspecting faults due to lubrication. Regards joe.1 point

-

It needs replacing. As you say its not flat, so it has become out of shape. When a spring is out of shape and it is wound up, it will rise and rub the barrel on the inside; this can cause poor flow of power to the train and erratic time keeping. A new spring will come wound up and all you do is press the new spring in to the barrel. Just make sure before pressing in you have the spring the right way.1 point

-

As noirrac1j says, it is likely that the either the setting lever has become displaced, or more likely you may be lucky and find that the setting lever is not engaging properly in the stem. Normal advice on this movement is to remove the stem when pulled out to the time setting position, and also to depress the release pin slightly when replacing the stem. You may be lucky here and be able to get the stem to fit properly by trying to fit again with the button depressed, or it may be hands and dial off time to correct. I have also seen a thread here which describes making a tool to pull the lever outwards, but it does need you to have a spare stem to sacrifice https://forums.watchuseek.com/f6/winding-stem-postion-stem-removal-eta-2801-2-a-675689.html1 point

-

Victory! I disassembled it, washed the mainplate, fork, fork bridge, balance and it's bridge, their jewels separately in alcohol. I didn't think the fork jewels were shellac'ed on but I was watching, and sure enough, the shellac started dissolving. I pulled it out before any harm was done and finished cleaning with rodico. Reassembled and relubed everything except the fork pivots. To my surprise, I also learned that the regulator tail is a separate piece from the piece actually carrying the regulator pins, so I was able to adjust the regulation and beat nicely while keeping the tail in a reasonable position. I'm cherrypicking here obviously, but here is the final result. This movement has never ran as well as it does now, so I'm very happy. THANK YOU all for your help. Cheers Florian1 point

-

1 point