Leaderboard

Popular Content

Showing content with the highest reputation on 10/11/18 in all areas

-

4 points

-

@Endeavor: -Yes, but your version takes a bit of "skill" to get to work! The versions with coils work with distance attenuation - the field gets weaker as you move the part/movement away from the coil. The automatic ones often use current attenuation, the field gets weaker around the part/movement so the part can be still. (picture from: https://www.j-ndk.co.jp/en/product/index_datsuji.html) In my version a capacitor is charged (takes abt .3s) and is then then is used in a parallel LC-circuit that takes abt. 50ms for the field to go from fully charged to zero. (depending on capacitor values, voltage and size of coil). The biggest plus is that you do not need to lift/move the movement in the coil/field and the results are equal time and time again!1 point

-

For anyone that's not sure how there supposed to be using the coil type demagnetizer this is what Omega recommends. Then even though it's in the picture I'm going to quote some text "Demagnetisation according to the three axes x, y and z is necessary when using this type of instrument. Do not release the instrument when the object is inside the tunnel as it could finish up being more magnetised than before." Then you will notice in the fine print a minimum of 50 cm away from the coil before you take your finger off the button and five seconds to get to the 50 cm.1 point

-

1 point

-

Well, the project is not over jet ...... do you have a few "minutes"? Perhaps best is to get first some drinks and the popcorn; make yourself very comfortable enjoy the following: https://www.watchrepairtalk.com/topic/9735-ive-ran-out-of-ideas-tricks-help/1 point

-

What we need is the inside measurement of the case opening and outside measurement of the case. I happen to have a box of case backs and therefore you might be lucky. PS where I got them from I just don't know, probably eBay.1 point

-

that's what I figure, it looked like Margolisd's response that he might be thinking plug with solder which would make for a very weak thread1 point

-

I would have thought it was near impossible unless it was the exact same model reference. Following this thread closely [emoji41] Sent from my iPhone using Tapatalk1 point

-

1 point

-

1 point

-

I use kerosene for dissolving the glue, diesel fuel works as well and I have not tried lighter fluid yet. Let soak for a day or more, use any wood or polymer stick to remove the soaked glue. If water has recently got to the movement, the sooner you drop the whloe movement in non water based solvent the better. Like I promissed I have all the parts you may need or brake which I will gift to you. Commercial use of the forum is disallowed possibly due to license and tax issues. 1. Release the power, you may insert the stem back in place turn towards winding ,hold the click so to free the ratchet wheel, OR unscrew ratchet wheel life the wheel , the wheel flies off violently in later case. 2. Loosen bridge screw, not to remove the screw just loosen, lift the bridge not remove, this will allow for lifting the balance pivot out of the jewel and ready to be rmoved.place the watch on surface so it can,t drop down . Remove the screw, hold the wheel and the cock in tweezer , remvove the bridge balance out. Looking forward to recieving report of your successful work. Regards The rest of disassembly is risk free, lift all pivot stright up. Use oil on hard to unscrew any screws, let soak for a day. Auto brake fluid if you got some in garage works good on rust, B12 rust killer even WD 40. Check the loc on the cabs , see how well it keeps the jewels in their housing, locs break easy ,so slide one side at a time using any needle tip tool. Open the M S barrel ,remove the MS arbor,then take the spring out ,comes out violently.wear eye protction goggles.. soak all parts excluding the H/S in your cleaning solvent. Regards1 point

-

If you do need any spares for the ST 96 dont go and buy separate components on line. I made the mistake of buying a setting lever for £12. Go on the bay and from India you can find numerous ST 96 movements all under various names Titus Oris Tissot or like yours Tressa to name a few. Bid £9.99 and there is a good chance no one else will bid. If they do, leave it and wait for the next one, probably only a few minutes. They all have of course, hideous repainted dials but nevertheless good for spares. And ermm should'nt shockproof be all one word? Not bad for a tenner post free. Heres one I purchase last week'1 point

-

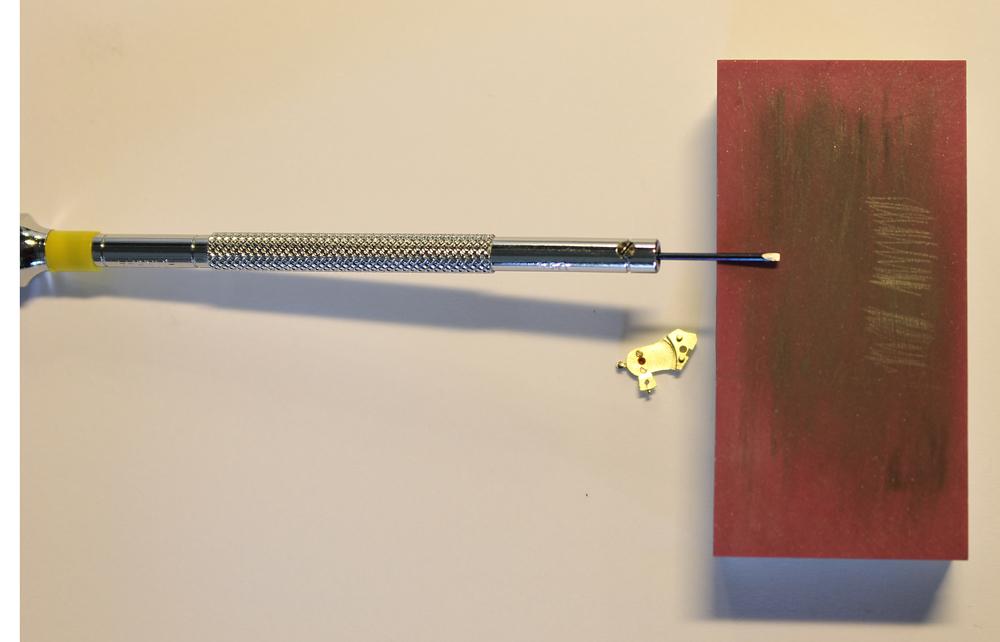

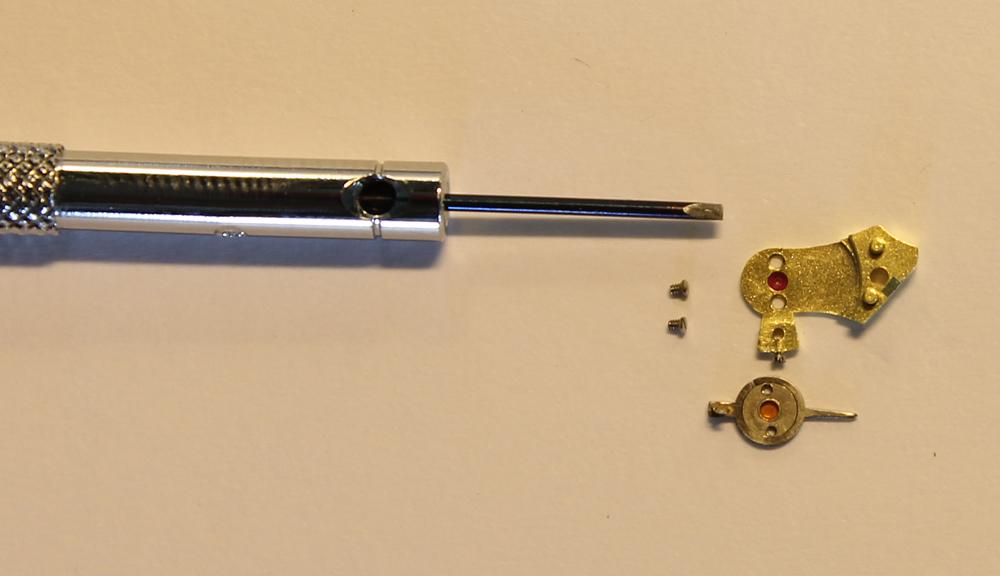

Totally dissatisfied with the results above, I decided to strip the movement again and let the parts soak in Zippo lighter fluid. Old oil seemed to be the culprit and some serious pegging had to be done. This time there was no easy "opt-out", the balance jewel in the balance bridge had to be properly pegged and oiled. I decided to get the delicate balance out of the way first. As described above, the 0.8mm screwdriver was too big, the 0.6mm screwdriver fitted, but proven to be too weak for the task. I decided to customize the 0.8mm screwdriver blade by dressing the sides down to the full length of the screw-slots (about 0.7mm) and flatten the tip of the blade until the blade had the maximum amount of "beef" and fitted the screws-slots snugly. This would give my the highest, and the final, opportunity to undo the two screws. Lo & behold; It worked !! Now I could do a proper oil job, but pegging the extreme small bore of the ladies movement balance jewel was another challenge. My experiences with these tiny holes are that if you get the tip of peg-wood in, it brakes off easily. Next to that, once you got the peg-wood in, while rotating, your fingers slide & rotate down. Once the fingers are to the end of the peg-wood, and some more pegging is required, you either have to pull the wood and try it again or; try with the peg-wood still in the jewel-bore to get your fingers back on top of the peg-wood ........ with a very high probability that the peg-wood tip will brake off; stuck in the jewel Some kind of solution had to be thought of, perhaps this has been done before, but so far I haven't seen it; the screw-peg ® ! I had a small box of toothpicks. The diameter was 1.6mm. One of my screwdrivers is 1.6mm. I removed the screwdriver steel-tip and with one of the toothpick ends cut off, the toothpick is a press fit in the handle. The toothpick-tip can be sharpened multiple times by either a knife or dressing it on a diamond stone. Now, with the peg-wood tip in the jewel, you can rotate as long as you deem required. I also found to have very high control over steadiness, direction, rotation and applied pressure. Works like a treat !! Back to the movement; Pegged & pegged again every hole till spotless. Pegged every pivot. Installed the balance to check free movement and re-check the impulse jewel line up with the center of the banking-pins. With now both cap-stones oiled, the balance rotated freely and smoothly. Same with the pallet-fork; installed the fork and it rocked backwards & forwards on its own weight. The wheel-train run with the slightest touch on the spring barrel. Sounds good !? ....... hmmm, not so........ with the movement assembled, it still doesn't run happy. An amplitude of below 120 degrees is hardly something to brag about. It also stops after a few minutes, continues again after a little shake .... perhaps pallet-fork / escape wheel area ? Still a beat error of over the 7ms, whereas the impulse jewel was spot-on the center of the banking pins ..... Hmmm ....... Being Dutch, I will say: "Luctor et Emergo" .......1 point