Leaderboard

Popular Content

Showing content with the highest reputation on 05/30/18 in all areas

-

When I joined the site I had only a passing interest in clocks but I have over the last couple of years started to buy more and more they are starting to take over every shelf window ledge and free space I have here are just a few of the clocks I have picked up over the last 6 months. The first one is a Walnut Lenzkirch ting tang clock bought off the bay of evil, I paid £70.00 and had to go to Hull to collect it, the clock had suffered quite a bit of neglect over its 100 plus years and had been stored somewhere damp it had areas of lifting veneer. all the varnish had deep scratches and the movement suffered from a fair bit of rust in fact when I picked it up my heart sank here are a few picks before I started working on the clock. I have cleaned the movement, I use brasso cotton wadding and clean by hand, and brasso and a medium brush to clean the wheels and small parts I then wash in nothing more than warm soapy water and clean out the pivot holes using pipe cleaners soaked in alcohol for the larger holes, and cotton thread or peg wood for the smaller holes I then dry and brush with french chalk pivots are burnished on my lathe I usually replace all taper pins on a clock of this age as most are pretty chewed up the springs are removed inspected, replaced if needed and oiled. The bulk of the work on this clock was on the case the lifting veneer was glued and clamped in place, there was a crack running down the middle of the clock front I have filled this with filler, I use a white filler and paint the surface once dry and sanded with watercolour paints to match the colour of the wood there are various coloured fillers available but I find these a waste of time. The back door panel was broken into four parts, it had been glued at some point in it's life but was a bit of a mess, I removed the old glue then re glued and clamped until dry, I have replaced the cloth on the back door the old cloth had rotted, having no knowledge of what the cloth was I have replaced it with a red satin cloth I have no idea if this is the correct cloth to use. The vast majority of clocks of this age are varnished with shellac based varnishes it was in such poor state the only option was complete removal, this I do with very fine steel wool 0000 grade soaked in methylated spirits I would never use sandpaper on a clock case other than on small filled areas, the steel wool breaks the surface of the varnish and allows the spirits to do the work after a bit of light rubbing the varnish turns to a sludge that can be wiped of with a cloth, again soaked in spirits the advantage of steel wool is it kinder to the wood surface and can be easily worked into corners and detailed areas. I then french polish the case leaving a hour between coats after every 5th coat i rub down again with very fine wire wool and start again applying coats it is a time consuming process and there is no easy way to do it. French polish will darken quite quickly with age but you can add spirit dyes to it if you wish to change the colour or if the colour is not to your liking. The dial and bezel where cleaned and polished then re laquered and the inner bezel cleaned re silvered and laquered This clock has a plaque on the front it was a gift to the Rev T. Salusbury Jones from the congregation of his first pastorate in 1901, I can never resist looking up the people on these plaques. Clocks where a very popular gift to vicars in the 1900's and I have three such clocks, the Rev Salusbury Jones had three sons whilst at Sutton Valence church sadly two lost their lives in the trenches of the great war and there is a local Sutton Valence history web site that tells the story of how his sons where killed in the war. I still have a little work to do on the clock the gongs where rusty so I have cleaned them with fine wire wool but I need to blue them but they are quite large so im thinking of buying a electric hotplate so I can blue them and any others I may have to do in future. I also need to clean the decorative band around the top it just needs cleaning with a cotton bud and spirits as it has residue from rubbing with the wire wool and looks a bit dirty. The next two clocks are french striking clocks with slate cases the Brocot is a 14 day duration by Samuel Marti the other is a 8 day by Richard and co. Both are rack striking movements and are very easy to work on I think they are more prone to wear on the striking train but are generally very robust movements. Both these clocks where very grey in appearance when bought, the easiest way to restore these cases rather than buying the various potions available is to rub the case with baby oil, Literally 2 drops on a duster and a bit of elbow grease and all the grey areas return to black you really do not need to use a lot once the case is back to black use a wax polish and case comes up like new. I also love carriage clocks and when ever I see them cheap on Ebay I buy them three of the clocks in the next picture cost no more than 30 pounds with the cheapest being £22.00 bought from a antiques centre the same day I picked the Lenzkirch up from hull I try where possible to buy with original platform escapements but where they have been replaced with modern ones I replace as soon as I can, as is the case with the next clock Two things attracted me to the above clock the shape of the case and the buy it now price of £30.00 free postage it was listed as not working, but the only thing wrong is it hadnt been cleaned in a very long time, the clock had a new platform fitted I would guess in the 60's 70's so I have replaced it with one from the late Victorian period that is correct for the period this clock was made I have re laquered the case with a mid gold Horolaq laquer. I source platforms from antique centres and ebay there are many unloved clocks hanging around antique centres and if it's cheap and has a platform I buy it and use it for parts the platform I used in this clock came from a clock with a case beyond repair and missing its back but the platform was good it cost me £8.00. I haven't really gone into detail on how I clean a clock in this post and the light has been against me today as far as photography has gone but I have a clock hopefully coming next week so will do a full walk through of how I clean a clock and hopefully any one who spots any thing wrong in what I do will tell me.2 points

-

While browsing the internet I have come across this. Here is a photo of a clock mainspring winder. This is the same as I had. It has different size arbors to fit the size spring that you need to remove or fit. Come in a nice case to keep it safe and altogether. Look after it and it will last you a liftime.2 points

-

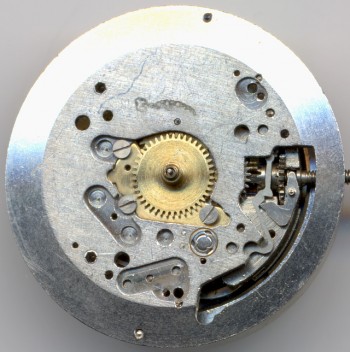

This was made by Unitas search instead in the Unitas section they have a setting lever and screw at £5.962 points

-

2 points

-

Recent EBay purchase of 1970 Timex Electric diver turned out to require more work than I thought. In this case the stem retention clip was cracked in two and I noticed the fixed magnet had come on done. What I did not count on was the magnet being lose damaged coil on the balance. So I went to a parts donor and with little effort 2 became 1 again. here we have the original seller pic and followed by the repaired watch along side it's new friends.2 points

-

1 point

-

1 point

-

Found an old Ebosa movement in my parts drawer. It had a pretty good second. I had to straighten it and paint it. But works fine. It was a very odd size on this second pivot. Think it was something like 1,3 mm .1 point

-

1 point

-

Getting back to the original question I have found shims in a few vintage watches and in the occasional pocket watch. I think some Russian watches have them fitted as standard. For others it is where a new staff has been fitted and it is a bit tight. The correct method is to hone the staff to the correct length but some revert to the shim method to save time1 point

-

1 point

.thumb.jpg.78e33c741e0a637584cb6bd2b0ef1424.jpg)

.thumb.jpg.a70fa2d75a48765154b73032e5db4667.jpg)

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)