Leaderboard

Popular Content

Showing content with the highest reputation on 02/11/18 in all areas

-

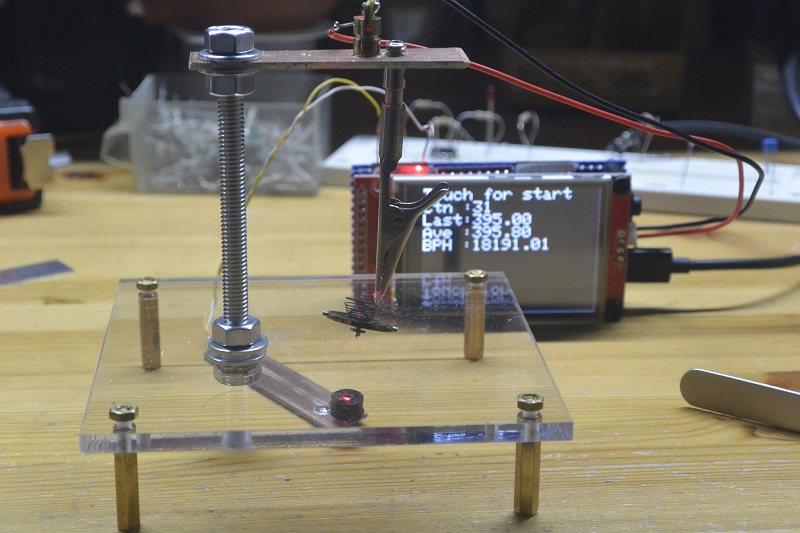

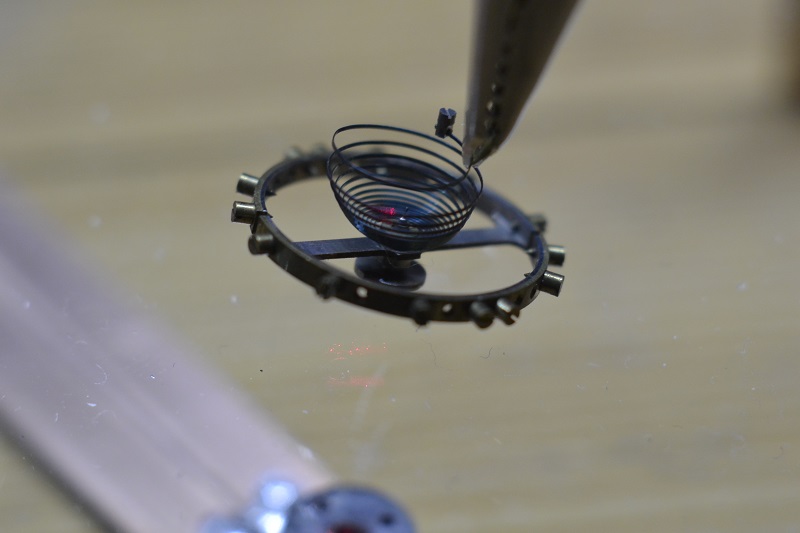

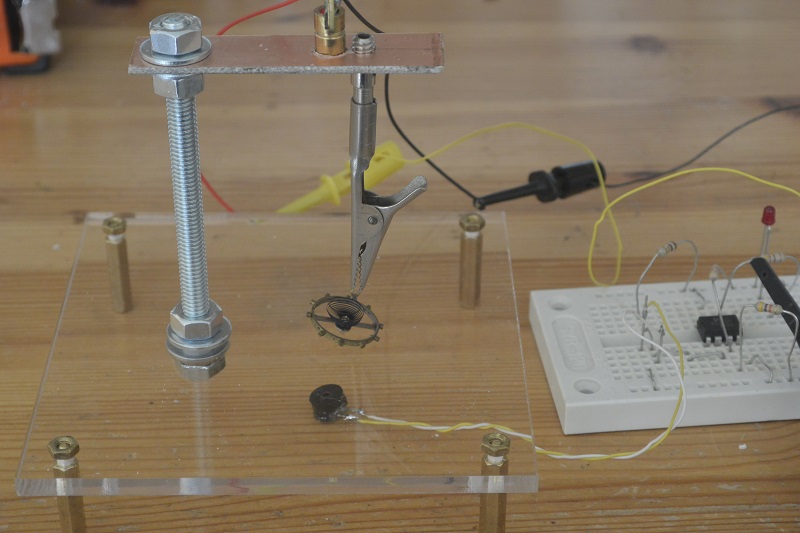

Hello guys, An attempt to make a low cost hairspring vibrating tool : Prove of concept : The hairspring (here it's a 18s balance) is clamp in a crocodile clip which has been grinded to be as fine as possible, a laser beam is set so that the beam is cut by the balance arm. The photo diode (from an old pc mouse ) is en-capsuled in a little housing to avoid parasite light (from what i thing to be an old TO3 transistor spacer found in my spare screws box). The IC is just a simple op amp acting as a comparator, the led on the output is used to visualize the that the laser beam is on the detector. First measure on scope : Doing some simple math show that an error of 0.1 ms on the measured value (which is 400 ms for 18000 bph) correspond to an error of 21.5 seconds / day. At that time base setting my scope has a resolution of 4 ms ! I switched to an Arduino based measuring system : I used an existing Arduino module based on a cheap stm32 and add a led (indispensable to adjust the beam) and the power output for the laser. The comparator is no more required as the stm32 has schmitt trigger inputs. The soft is triggered by the touch screen and accumulate a couple of measures in a circular buffer to compute an average value. This permits to eliminate aberrant measures that you can have when the balance starts to swing. Detail of the crocodile clip : In conclusion this is little tool (cost me only the plexyglass sheet, around $1.5) could be useful to match a new hairspring on an existing balance. The measures are relatively simple to do with a good consistency and surprisingly the croco clip do the job and you can get the balance swing for tens of second on the plexy. You need a resolution of 0.05 ms to be at 10 s/d and probably calibrate your measuring device. The main difficulty was to adjust the position of the laser beam. Hope this can give you some ideas. Regards3 points

-

Do you think so? To start, your "Seamaster" has a tachymeter bezel which is never used on a diver or non-chrono watch. Then lack of any thickness in the indices, poor lettering, thick date font. On the back the lettering is filled black but it shouldn't, plus no circular finishing. etc. Compare to the picture below from a current ebay listing, about which I don't guarantee authenticity either. If you want another opinion you can post on WUS in the Omega section, but I suggest you take better pictures, and with the case back removed. Also, I hope you didn't bought in the present conditions? I'm surprised that Chrono24 allowed this watch to be listed.2 points

-

Serviced it. Works good now. Seems like someone dumped a lot of oil in this movement. Re cleaned ( took it apart) properly re lubed it.2 points

-

1 point

-

1 point

-

1 point

-

1 point

-

Omega restrict parts, it would be easier to get ETA movm't or parts e.g. on Cousins UK. They report to have gilted hands, X22164. Please post pictures of your Seamaster on Watchuseek.com, let us know what people there thinks about it.1 point

-

http://www.britishprecisionsprings.co.uk/html/stock_spring_list.html The above company manufacture hair springs and if there isn’t a standard one very close to the one you need they can manufacture custom springs. Expect long lead times I’m afraid. Sent from my iPhone using Tapatalk1 point

-

I don't think you're likely to come across a watch movement that hasn't been lubricated, and the oil once applied theoretically doesn't evaporate. What does usually happen is the oil thickens or otherwise loses its properties. It's a safe assumption that some sort of oil in some sort of condition is present. As far as I'm aware there's no trick to knowing the condition of the lubrication other than general inspection, testing how well the winder functions and looking for low amplitude on your timegrapher (which i like to stress is only an indication and might mean something else or might mean nothing at all)1 point

-

A silver oxide cell is what is needed for this movement. I don't know where you're seeing something about a lithium cell? I'm pretty sure there's none in the size of a 341 and the voltage would be too high besides. It might just be a dodgy cell, it happens sometimes even with the good brands, for no rhyme or reason. The second possibility is friction caused by over-oiling since I believe these are one of those temperamental ETAs that likely operate best on a very finite amount of oil on the gear-train/motion work. Maybe the hands are simply touching as they pass, or perhaps some other fault has occurred since you last worked on it.1 point

-

I managed to come up with my own solution and I saved the bracelet and spring bars which are in good shape. I decided to try and run some dental floss through the spring bar shoulder and case and it worked a bit. I was then able to barely insert the tool and pry it off. It took a few tries but it eventually worked on both sides. When I ran the dental floss through the spring bar and case I also tried making a knot but it didn't get all the way in, still it worked.1 point

-

You're wrong there. These books are not outdated at all, because proper techniques never change. My take. if you have a repair issue with a fake watch, post strictly limited to the needed detail. Otherwise post only to show others what are the details revealing counterfeiting. Having an intelligent discussion on <anything> is one thing, encouraging parading illegal items is another.1 point

-

For those who think this is a pipe dream have a read. http://wornandwound.com/the-240-year-old-pendulum-clock-thats-more-accurate-than-your-watch/ @watson1 I admire you ambitions and wish you the very best of luck. I hope that you might document your progress here.1 point

-

1 point

-

Interesting thread this is. I love (well hate) these mysteries in watch repair. Love them because they are challenging, hate them if it's a watch I want to wear (it can take forever to find those uncommon gremlins). My guess is that the watch is losing all of it's amplitude dial up. The result is the balance barely moves, but there is enough potential energy in the gear train to release the escape wheel when the impulse jewel touches the pallet. I would check the pivots and jewels for the pallet and escape wheel, paying particular attention to top pivots and jewels.1 point

-

0 points

-

0 points

-

Welcome here. The first information you need is that the watch is counterfeit, and very poorly.0 points

.jpg.4e47860354e83a20180dc2672649a6c3.jpg)