Leaderboard

Popular Content

Showing content with the highest reputation on 11/04/17 in all areas

-

Just stumbled across this by pure chance. George Daniels gave a lecture at the 1990 convention of the American Watchmakers-Clockmakers Institute which was video taped and recently digitised It goes for 70 minutes, so I don't know if I will get through it all tonight, but I'm going to give it a go. https://www.hodinkee.com/articles/awci-publishes-rarely-seen-george-daniels-lecture-19904 points

-

Hello! Here is my watch collection I know it's nothing amazing for some of you but being a full-time 21 years old student I worked quite hard to have theses . Horology is really an amazing hobby and I can not wait to learn more! From left to right: -Festa pocket watch from the 50" I think. I got for 20$ from a watch market. The watch runs but my goal is to service it myself soon -Casio F-91w the legend , it is my beater watch for when I work outside or on my car. -Orient Bambino gen 2 version 2. An entry level automatic dress watch with a hacking and hand-winding movement and date complication on a leather strap. -Orient Ray II an entry level dive watch with a hacking and hand-winding movement and day-date complication. -Casio EF-527D-1AVEF, quartz chronograph with date complication.4 points

-

3 points

-

I don't think anyone is suggesting you don't get great results, not from me anyway. I don't see this content as comment on anyone's skill, only the underlying physics and engineering on what is happening and the discussion around the possibility of moving SS about with buffing. I aspire to have a scientific mind. That imposes the requirement that one should never take it personally to find out they were wrong and never dogmatically get invested in ideas and beliefs such that they cling to them contrary to evidence and science. So....if anyone can take a piece of SS, grind it perfectly flat so it reads dimension X measured everywhere over its surface by accurate measurement (ie comparator or quality mic)....and then, by buffing only, make a part of thicker, I'll will unabashedly abandon the science I think I know and be a believer. If it was possible to move SS around, I'd have thought it to be well known and appear in a variety of manufacturing and engineering instances. As there is no science or engineering I can find suggesting its at all possible, and is in fact is quite contrary to what I do know about the property of materials, its bit like asking someone to believe in ghosts.... until there is some evidence or even the good description of a plausible mechanism (a theory) its hard to accept.2 points

-

I personally prefer to have more control of refinishing a case by way of using glass paper by hand using a flat piece of wood, this way I can observe every aspect of the case in more detail, and have complete confined control of the refinishing process. The once I'm happy, then I move onto two stages of 5cm rotor wheels, and finally a light refinishing of polished areas with cape cod.2 points

-

Thanks to everyone I am just starting in this amazing hobby. This a movement I got for 3$ to practice. I managed to disassemble it then reassemble it and make it run. Now I am going to disassemble it again, clean it and oil it while putting it back! Here are some pictures so you can the movement when it's stripped and when I started to clean parts2 points

-

Just finished this the other day and had to wear it. Got the casino/poker feel and I wish I had the gold medallion and robins egg blue tracksuit to go with it. Sent from my SM-G920V using Tapatalk1 point

-

Hello, I've been lurking awhile but only recently had the time to start participating. I had a long career in IT and was able to retire early. I wanted to do something I enjoyed doing while not yet feeble. I got my Watchmaking Certification so that I had something to keep me busy and I can do as much or as little as I like. i was a watch collector for many years and realized I'd go broke getting my collection serviced so I'm my own best customer — at least for now.1 point

-

So basically all the watch houses known on earth have been doing it and getting it wrong. And the only "correct" way is your inconceivable technique.... Riiight. By the way, I thought you left this group after Mike debunked your technique? Sent from my SM-G935F using Tapatalk1 point

-

Micro welding is a viable option to repair large dents and scratches in watch cases, but I agree not for most of us. Not only for the cost of the tool but for the skill involved to use it properly too One of graduates of the watch school I attend makes his living restoring high end watches and refinishing cases. Hodinkee did an article on a case he refinished for them. The deliberately gave him a very beat up watch to restore. Have a look and see for yourself. https://www.hodinkee.com/articles/the-inside-and-outside-restoration-of-a-doxa-300t-searambler Yes I know this post is taking a bit of a tangent from what the thread is about, but it demonstrates another way to repair / restore / refinish a watch case.1 point

-

1 point

-

You are correct of course. You prompted me to dress the jaws of the cheap "presto" type tool I have - as OIi mentions above. And now they work really well !1 point

-

Indeed. For cases with crisp edges, some wet n dry paper on a wood stick is excellent for control. There's always a greater level of risk with grinding burrs or those diamond impregnated rubber burrs. Very easy to over grind. Sent from my SM-G935F using Tapatalk1 point

-

You can use the "presto" type hand removing tool as a cheaper alternative to a dedicated cannon pinion remover. It will pull the cannon pinion very neatly and will be a vertical pull, no risk of damage to the centre wheel arbour. You can dress the jaws of the tool for a perfect fit, they are only a couple of pounds from China. I have a Bergeon cannon pinion removal tool, but still sometime use a presto tool as the Bergeon does not work on small cannon pinions. Whilst tweezers will work, I think they are not ideal as you risk putting some stress on the centre wheel.1 point

-

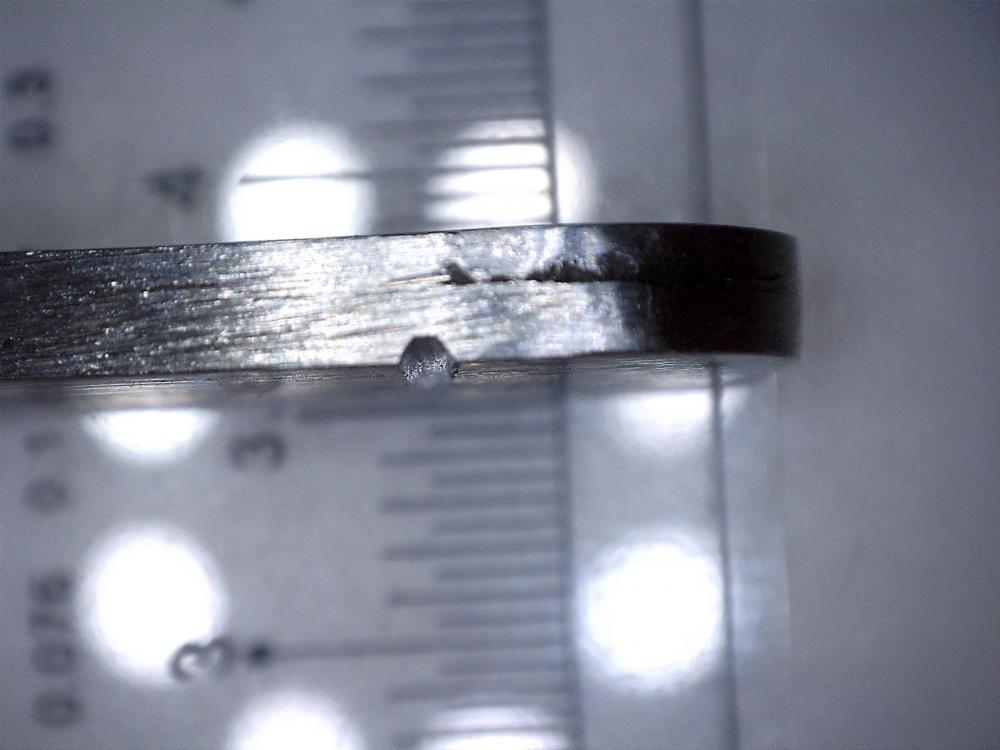

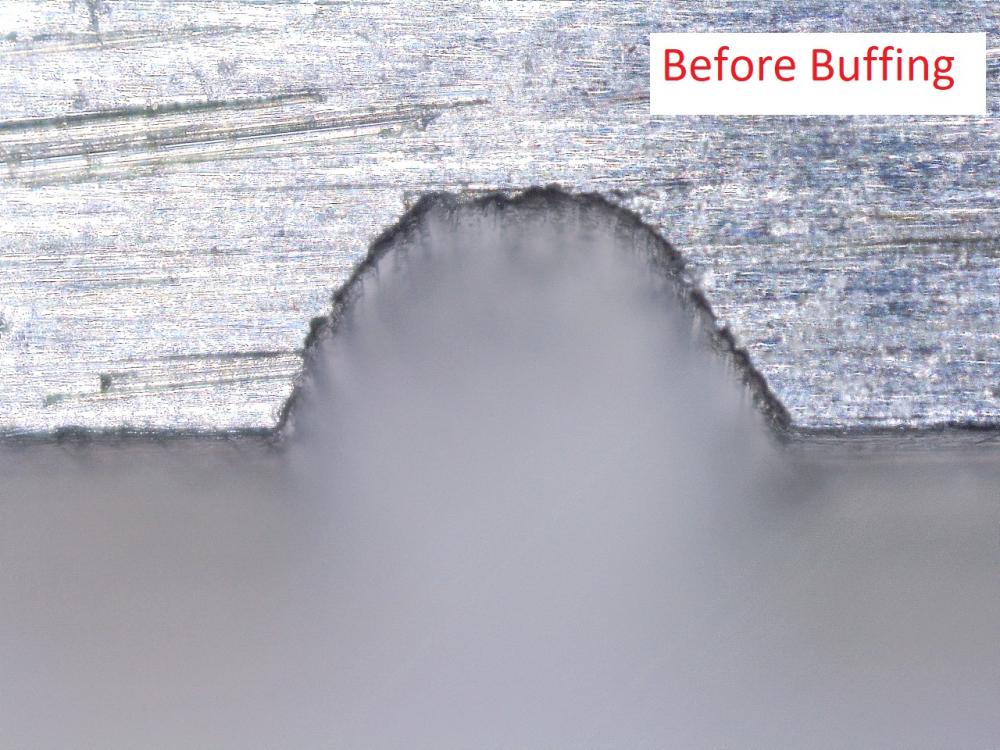

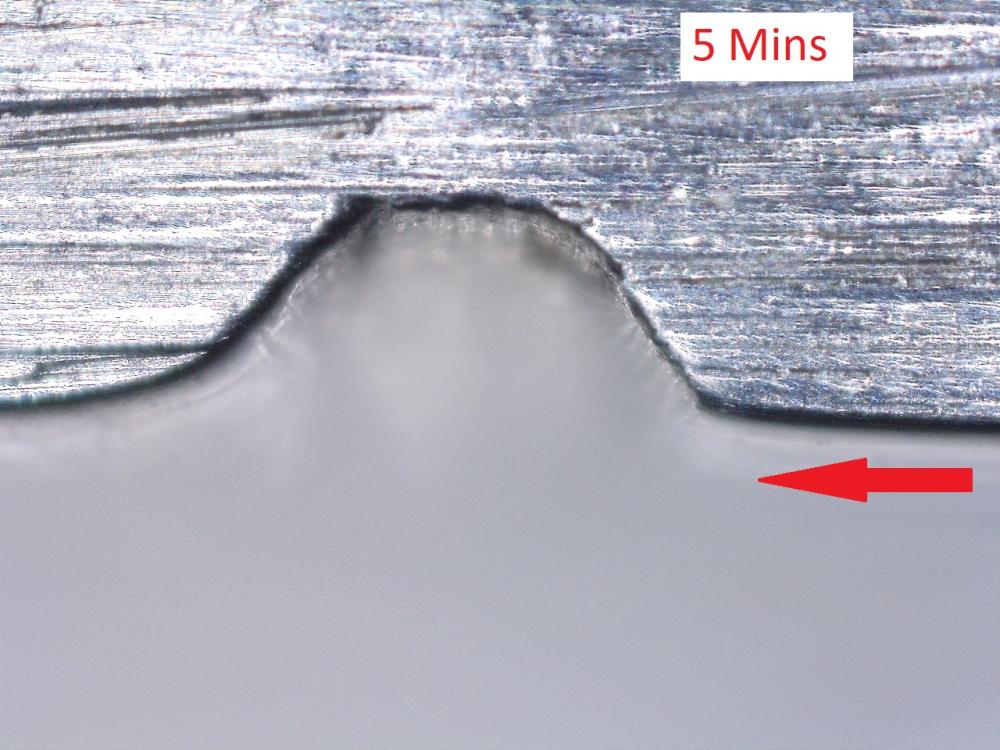

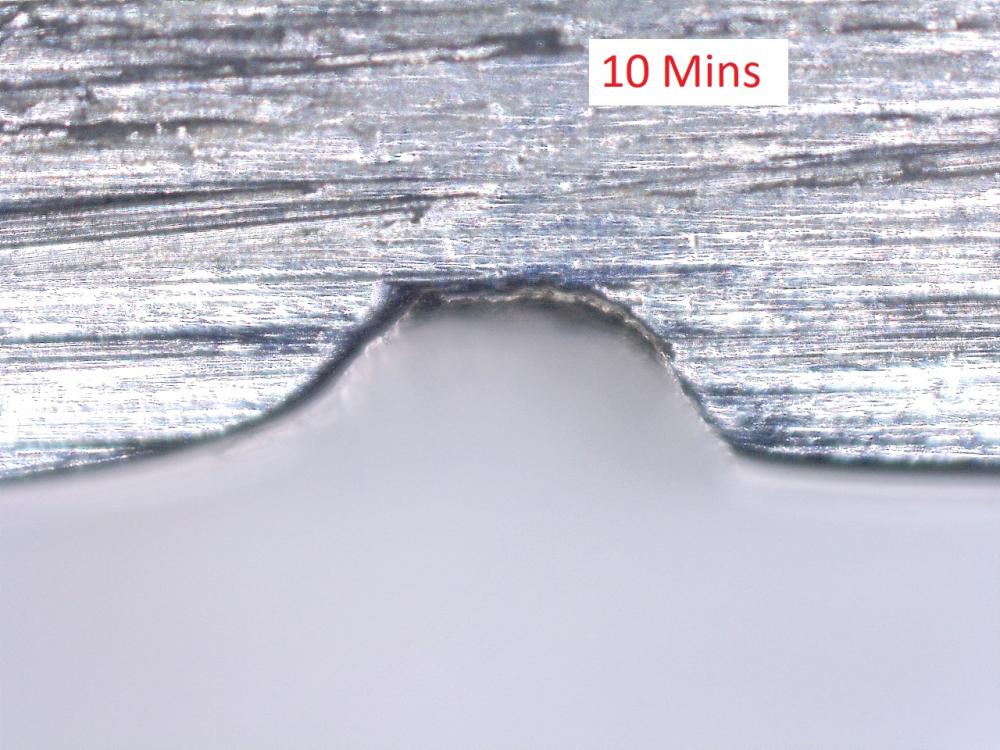

As an engineer and a skeptic, I've never been convinced by the "moving metal" theory ... so I thought I'd try a little experiment : Note that I only have a hand held "Dremel" type device. I used Dialux Orange, and a hard felt disk. I filed a groove in to the handle of some stainless steel tweezers. It looks to be about 0.5 mm wide and deep. I figured that if I applied the felt disk to one side of the groove, if metal is being moved, a lip should form on that side. After 5 mins of buffing, trying to apply enough pressure to heat the metal (it did get too hot to touch) you can see the results. The wheel is turning in the direction of the red arrow. No lip has formed, and both edges are worn. After 10 mins, still no lip, but significantly more wear. The thickness at the groove decreased from about 2.65 mm to 2.60 mm Conclusion. Metal is not being moved, it is being removed. Maybe someone with proper desk mounted wheels could repeat the experiment to generate more heat and pressure.1 point

-

French chalk is used to stop the brass work from tarnishing. You use a watch blower and blow the residue away this will clean the pivot holes.1 point

-

There is a lot dodgy stuff on ebay. I am always reporting clocks to them. If you are going to bid and hopefully win the bid make, sure ebay will cover the price.1 point

-

Yep, being new (and naïve) to the watchmaking hobby I got caught on ebay to a much lesser degree with a so-called “Oris” vintage wristwatch. I feel stupid now as this “vintage“ 1960s watch had no patina on the dial or the usual scratches/dings on the case that you would expect from a watch of this era. On opening it there was a bright new shiny “Swiss Made” 17 Jewel movement with a cheap plastic retaining ring. Definitely not an Oris movement. A less than £40 “bargain”. Amazingly it keeps brilliant time though :-) Sent from my iPad using Tapatalk1 point

-

That's fine if you have both the machinery and skill to use it! I would like to inform folk it is so easy to round sharp edges and loose the original profile..........very quickly. Using various grades of wet or dry paper, a piece of wood with metal polish and finally a silver polishing cloth will result in a black polish finish. Using this method (it does take some time) there is far less chance of damaging original profiles. More importantly, by using this method you can carefully reclaim profiles that have been damaged. I have seen more damage caused by folk using buffs that anything, and not always by amateurs.1 point

.thumb.jpg.19e73f5faacf2baf971e287c07d43e08.jpg)