Leaderboard

Popular Content

Showing content with the highest reputation on 01/20/16 in all areas

-

Finally I made it! Repositioning of the spring successfully completed! Thanks wrt!2 points

-

That screw loosening liquid works! I had to get a screw out of a Lockwood (local brand) deadlock which retained the lock barrel (which had become lose over the years). It had rusted solid and I could not replace the lock without removing the door jamb receiver. To do that what have ruined the door jamb and I would have copped hell from the missus! So I bought this stuff (on a friend's recommendation) from, of all places, an optical supply shop. Anyway...I placed a drop of the fluid on the rusted screw and left it for about quarter of an hour. Came back and...gently, gently the screw came out without breaking. It really works Roberto...try it.2 points

-

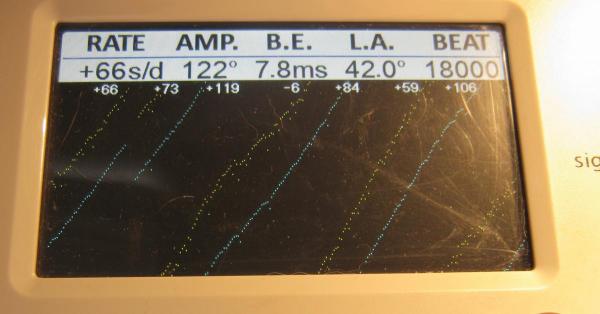

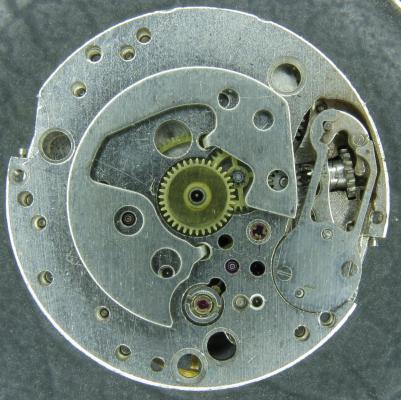

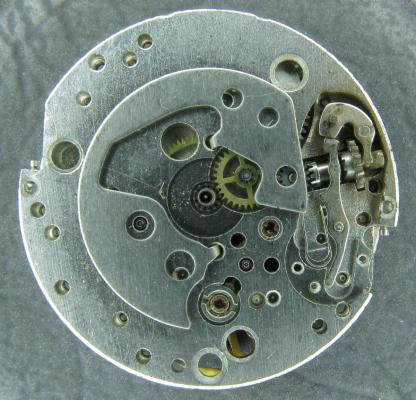

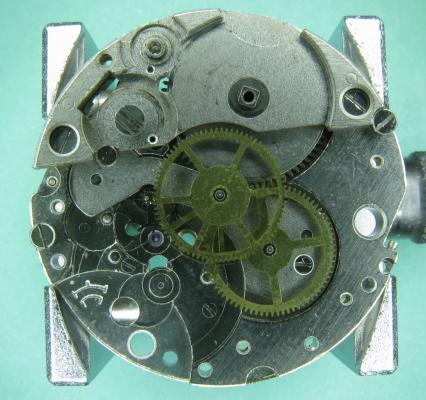

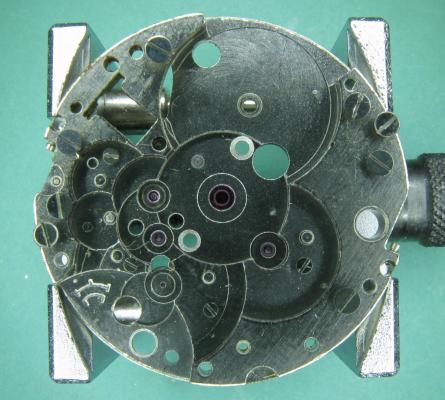

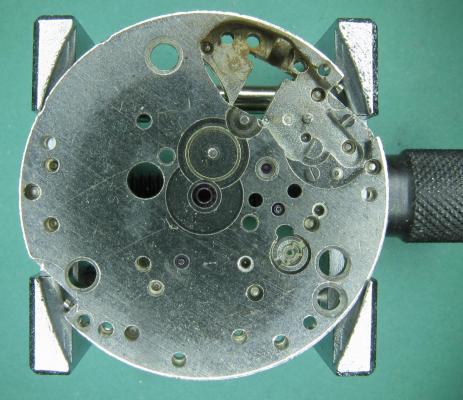

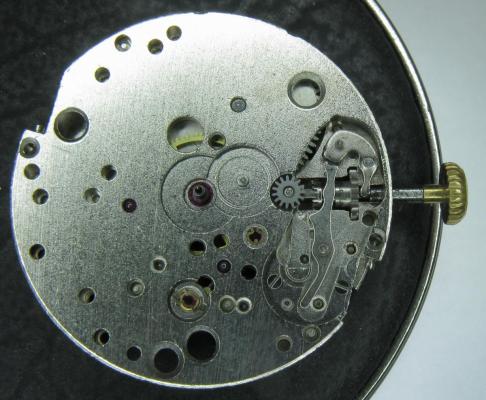

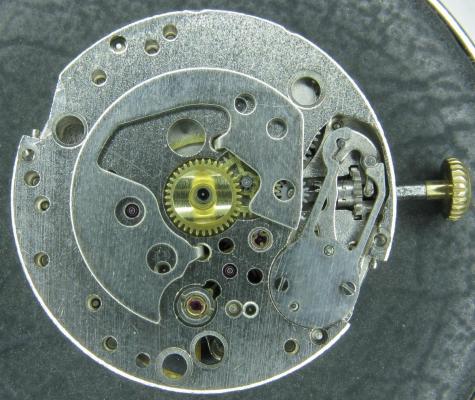

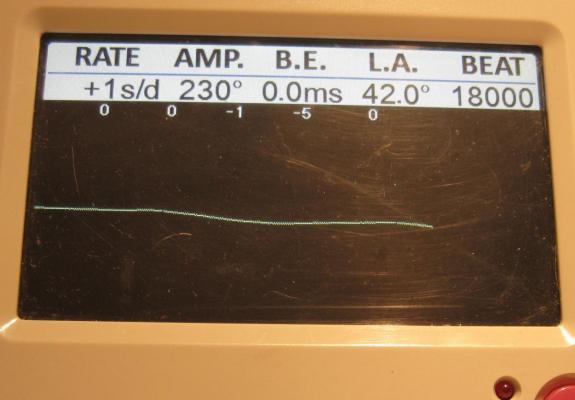

Just before Christmas I sold (through the good offices of eBay) an absolutely immaculate example of a 19 jewel Sekonda hand winder. I was a little sad to see it go as I don't think I am likely to see another in as good order for some time, and having just serviced it it was running like a champ but I couldn't justify holding on to it. Well, shortly after it had arrived with its new owner I received a message through eBay from the buyer. Huw had contacted me to say how pleased he was with his new acquisition, and did I service watches? as he had another example of one of these that was a little stiff in the winder and gained about a minute per day, and he felt that it maybe could benefit from a bit of a spruce up. I have done quite a few of these so am reasonably comfortable with them so I quoted a price and accepted the commission. A couple of weeks ago Huw's watch arrived so I thought I'd do this as a walk through. Looking well used but not abused, Huw had explained that he bought this not too long ago as a stop gap whilst his other watch (a Sekonda quartz chrono) was out of action with battery issues. First impressions are of a watch that has seen a lot of wrist time in its (probably) 40 years. The Timegrapher trace confirms the rate at roughly +60s/day, and confirms that a service is long over due. With the crystal out of the way the condition of the dial is actually rather good. The shadow to the right of the 7 is a lens fault on my camera, not the dial. With the back removed there is plenty of dirt speckled around the whole movement and everything is bone dry. The good news though is that it doesn't look like anyone has messed anything up inside. You can see the spring clip retainer on the escape wheel end stone (a bit like Seiko Diafix but not quite as clever). You can also see corrosion to the back of the bezel, this watch spent a lot of time on some ones wrist. With the movement out of the case the reason for the stiff winder and all of the dusty crud in the movement is brutally apparent. The outer end of the stem has started to rust causing it to bind in the case, and the resulting rust powder is thick on the inside of the case. These cases are a bit prone to this kind of problem as there is absolutely no attempt to seal them even against dust, let alone water, so even sweat on a hot day can seed the beginnings of a corrosion problem. With the dial off the press fit retaining plate for the motion works is exposed along with the keyless works. There's that little end stone retaining clip again, and the Raketa version of Incabloc on the balance. The rust doesn't seem to have got this far. With the set bridge out of the way though there is a hint of rust in the keyless works. Ouch!!! Just in time me thinks!! Balance and cock removed and the hairspring looks to be in good shape apart from the terminal curve which is off concentric. That will need to be sorted or the regulator will distort the hair spring as it is moved. Here also is the shim that Raketa are fond of using under the balance cock to adjust the balance end shake. A bit further in and plenty of gunge under the ratchet and crown wheels. Train bridge removed to reveal the train layout and a sub-bridge for the 2nd wheel. The main plate stripped with the screws put back in their respective holes. I do this so that screws don't go missing in the cleaning machine and I always know which screw goes where. The stripped main plate dial side. And then with the balance reinstalled (minus jewels) ready for the Elma. After a thorough clean everything is ready for inspection and reassembly..... ....starting with the balance jewels. This is when I check and adjust the hair spring for flatness and concentricity, eyeball the beat, check the end and side shake on the balance, and that everything swings freely. If you leave it until later there is too much other stuff in the way. Once I'm happy with it the balance/cock assembly comes back off until later. There is still a little work to do in this pic as the coils are still not quite concentric. The main spring re-lubricated and back in the barrel. This maybe could have been replaced but it wasn't too bad so went back in to help keep the cost down. Barrel, barrel bridge, 2nd wheel sub-bridge, and train back in place. Pallet fork and bridge installed. You can see the exit pallet poised ready to receive a drop of 941 on its impulse face. Walking the pallet too and fro then distributes the oil to the escape wheel teeth. Drop in the balance and away she goes. The cleaned up and de-rusted keyless works go back in.... ...and then the motion works and cover plate. Dial and hands back on, and ready to re-case. Again, to help keep the cost down I didn't replace the crystal with a new one, however, the original was just a little too deeply scored to easily polish out and there was what looked like a very small fracture. So a quick scout through my spares box and I found a second hand replacement which has cleaned up nicely. And the proof of the pudding ... as they say!! At 230 degrees the amplitude isn't anything to write home about but it is a significant improvement on the starting point. A new mainspring would almost certainly help this up into the high 200's (on the watch Huw bought from me I seem to remember it was 300+), but 230 is certainly usable. It is otherwise a nice clean trace with minimal beat error. It has been running for a week now in which it has gained just under a minute, so after a final tweak to the regulator it will be ready to return to Huw. I like these movements a lot. They are well designed and well executed, and capable of excellent results if looked after. They also seem to turn up quite frequently at the boot fairs. Unfortunately though, the lack of any attempt to keep moisture out of the case does mean that they quite often suffer from corrosion issues, and the relatively low cost (both when they were new, and when they turn up second hand) means that they are often used as a beginner watch smiths practice or learning watch, with the resultant butchery that many of us have dealt out as part of our learning curve. It's a shame in many respects, but then we all have to learn somehow. When you do find one that has survived unmolested though they are very well worth looking after. My thanks to Huw firstly for buying my watch, secondly for asking me to help this one to keep going for a few more years, and finally for allowing me to post his watch on here.1 point

-

Well after absconding to a friends beach house on 23 of December, and not getting back until this weekend I've been devoid of watch talk and only a wardrobe of three watches. My Suunto Core Black, the Citizen Airwave and my Junkers "Iron Annie". I still haven't got my other 50 or so out of the safe yet, it takes longer to unpack and get re-organised from a holiday than it does to get ready for it! I have a couple of projects I need to tackle, one is a simple little mechanical based on an AS movement, the next is "The Pogue". I have the replacement bits for that but being my first chrono I'm going to tread very carefully. Good to see we are all enjoying this fascinating/frustrating little hobby and I'll be back with some input soon. Cheers Jim (A pic from the holiday)1 point

-

I use one drop of washing liquid in a cup of lukewarm water and a cotton bud. Dip the cotton bud in the water then remove excess water leaving the bud damp. Now very gently wipe the dial with it to remove the staining. Finish off with a clean cotton bud using fresh water, again making sure that the bud is only damp. Finally use a clean piece of rodico to remove any tiny specs of dust or strands of cotton from the bud, if there are any. I don't recommend using any type of solvent on the dial.1 point

-

Thank you, Bob. I made the tool and I got it out. Now I'll take a break and let the coffee wear off before I put it back again and not watch the stock market...1 point

-

I would use some CRC electronic contact cleaning fluid (which you can get in a spray can). It's a type of solvent that will not damage plastic or paint and leaves no residue. You could spray some of the stuff into the lid of the spray can and use a cotton bud to soak up a little of the liquid. It dries quickly so you'll need to work quickly at wiping the stain. I'd test it on an old watch face first to see if it doesn't do any harm and then have a go with it. It's magic stuff precisely because it leaves no marks behind.1 point

-

The problem with water stains is that most of the time it won't wash away with water! And since the dials are so delicate, any other chemicals might destroy the thing you are trying to fix. There is baby oil you can try but again it might or might not work since in the end, you'll need soap and water on the dial one more time...not recommending anything, just a thought. The baby oil floats dirt and stuff and, we are not talking about floating those but the actual water stain which is a completely different animal. I wish we had a dial expert on board!1 point

-

I'm sorry it happened Bluebarb! Dials are very delicate and I don't have the expertise to give you a solution. Those dials here can probably be purchased for about US$400...maybe ebay or a refinishing business can be the solution. Maybe another member can offer a better solution. Hope all gets sorted to your advantage. Cheers, Bob1 point

-

I read somewhere that top end watch makers flush out the watch with argon gas. Doubt this is available in small amounts for the small user, but could another inert gas be equally effective?1 point

-

The problem I have with blatant fakes is it is a straight forward con. In many cases being supported by organised crime. There are thousands of these to be found in holiday resorts Spain/Greece etc. If it is a copy & sold as is then we'll ok. Sent from my iPhone using Tapatalk1 point

-

1 point

-

If you look on the cousins web site the parts you have marked as RL are listed as Ronda (Harley ,RE, RL).1 point

-

Does anyone have any foolproof method of removing/replacing Novodiac springs without paying $60 for the tool? I made a tool from pegwood and I am trying to muster up the courage to use it. It has 3 small nubs on it to fit between the spring and turn it out from under the cleats. It should work - I hope. One of the main problems I have is keeping the 18x loupe attached to my glasses focussed on the job - I pretend I'm George Daniels. Perhaps that's my main problem. ;-) Dave1 point

-

1 point

-

Thanks guys. This is most lovely watch I have. The "watch" will be faded but like a child, they don't stay little for long but they will always stay in my heart. As you said, its priceless Here is my daughter learning how use tweezers. Sent from my iPad using Tapatalk1 point

-

Trawling again! Found this interesting site which covers movement info and technical discussion, including a few oddballs. http://17jewels.info/1 point

-

Yet more trawling !!! This is an interesting site for those requiring bespoke parts etc. Based on Honk Kong. http://mpi-limited.com/aboutMPI.aspx1 point

-

1 point

-

Thanks guys- I think one of the greatest hurdles for me is where I work..... The University is in the top ten in the world- but that also means they like strange people. Like me- I'm the one that sees something broken and has to fix it e.g. microtomes, crytostats, microscopes, shakers, old fashion lab timers, etc) :D Thanks for the input, Dan B.1 point

-

I would turn the watch over, front and back - in front of them - while photographing it, also in front of them, with a compact camera. If they can't be bothered to spare the time for that, hand it straight back and walk away. If they ask why it's so important, explain the situation. It may even be advisable to open the case in front of them and do the same, but that may not always be convenient. A signed disclaimer is also useful - but then it's starting to become a business...1 point

-

George Daniels was pretty! :) I like the idea of 2 different heights although all that space is quite a luxury for me...my wife will kick me out of the house! :)1 point

-

Robert, I've been using a bulk VCR tape demagnetizer on tools for some time now with good results. Also a VCR head demagnetizer - its small and has a rubber coated, roughly 1/4" dia. tip for smaller items and I see them all over the various flea markets around our area for next to nothing and could be a source of almost ready made parts.. Starting at a distance from the coil it should work on watches and other parts. Might be worth a try?1 point