Leaderboard

Popular Content

Showing content with the highest reputation on 01/17/16 in all areas

-

Thanks to Mark for the Vid and everyone else for the additional info. I have been able to do a half decent job on my first re-lume and I am well pleased. First I researched for colour and got the lume that I hoped would be close to a match. It changed colour on drying but that was to my advantage, I would love to claim skill but it was pure luck. It has some luminescence but I don't really care about that part. This is the before image it looks more orange in this photo than it actually is. Got the stuff together Hands have been cleaned with soap solution in the ultrasonic and all the old lume came off, then given a good bath in isopropanol to get rid of any soap or grease. Following Marks advice, it seems to go on quite thick but on drying the thickness disappears, I ended up giving it two coats as it was a bit translucent with just the one It even glows a bit Last pic I have rested the hands on the dial which as yet is uncleaned, probably will just be given a gentle wipe down with cotton buds and mild fairy liquid solution. Not too shabby, and I would never even have tried it if it was not for help given on this forum - Thanks to all2 points

-

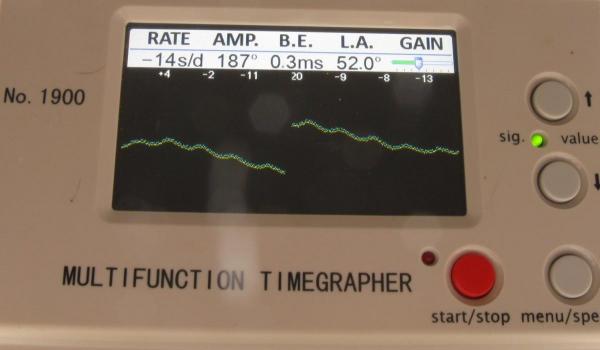

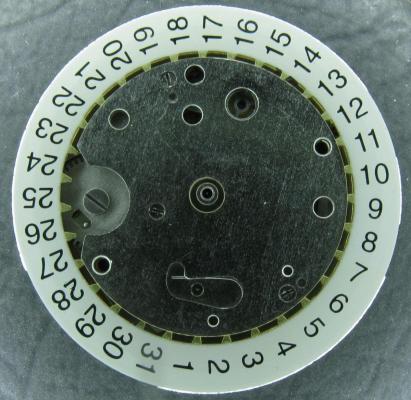

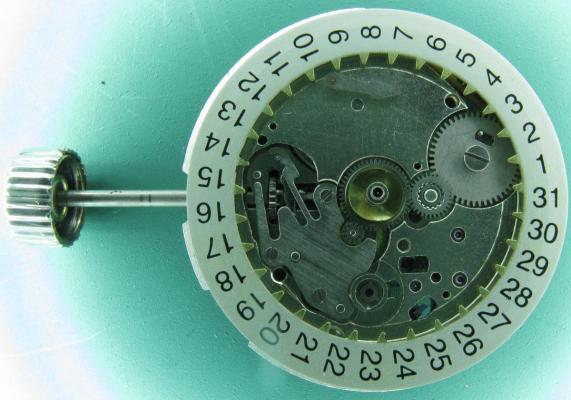

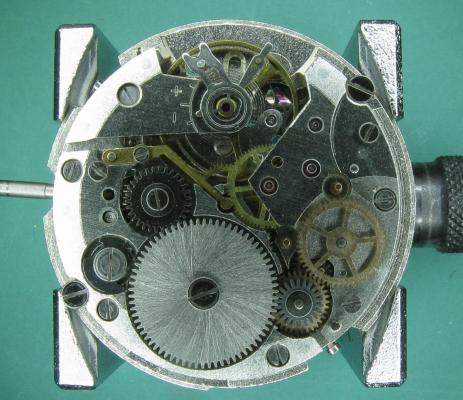

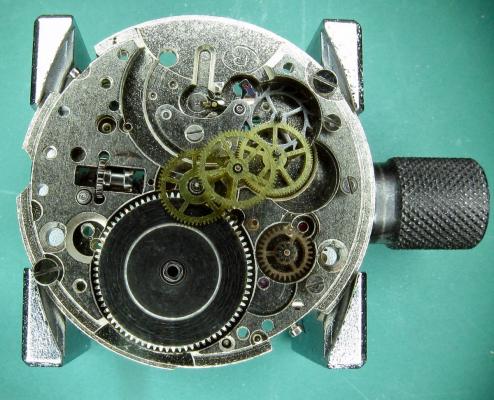

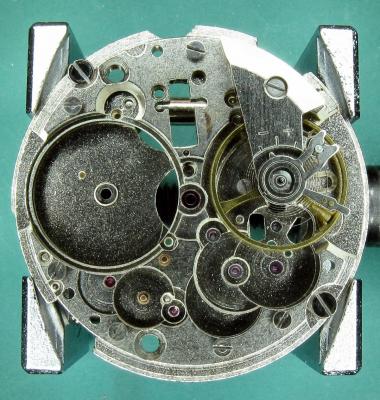

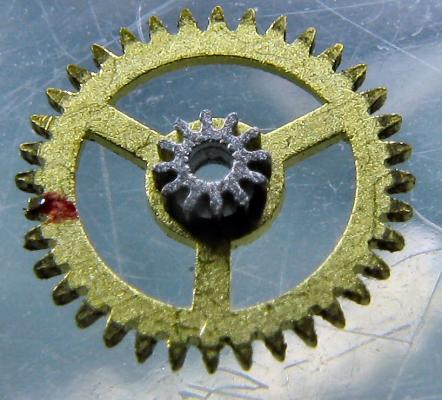

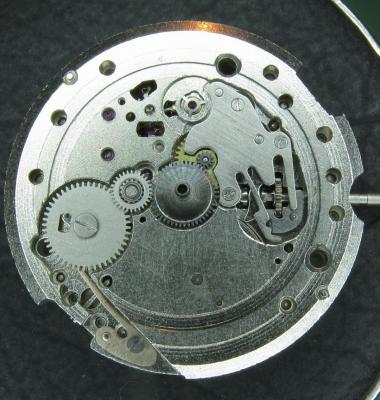

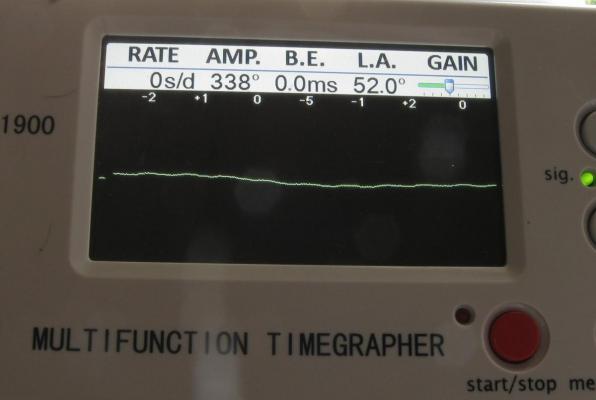

This is a bit of a departure for me as I usually like to play with stuff a little more vintage and a little more Swiss. That being said I have done a few vintage Russians in the past and this is a watch that I had been curious about for some time. I picked this one up at a car boot sale last summer for just £3 in a less than wonderful state. As you can see, the seconds hand was off and it was described a not running. It turned out that it did run, just not too well and the hour and minute hands didn't move. Canon pinion anyone? First impression with the back off is pretty encouraging. Still looking good with the rotor off. This is a 31 jewel movement, 10 of the jewels are inside those reverser wheels. Somewhat minimalist under the dial. With the calendar wheel retaining plate off you can access the motion works, the calendar works, and the keyless works. Flipped back over and with the auto-wind bridge out of the way. This is an indirect driven centre seconds hand which has a tension spring to hold the seconds hand pinion in place. This has to be supported when installing the seconds hand otherwise the hand simply pushes the pinion against the spring and won't install. Balance cock removed with the shim that the soviets are so fond of for adjusting end shake. Hair spring is in good shape. With the train and barrel bridges out of the way the going train is revealed in all its glory. Flipped over again to strip out the bottom plate and a problem comes to light. There is some damage to the minute wheel (marked in red ink). Maybe the canon pinion isn't the problem after all? In close up you can see the damaged minute wheel tooth. This I didn't think would be a problem, just replace it..... I thought. Not so easy as it turned out as I couldn't find anyone that could supply a new wheel, and a donor movement proved elusive unless I wanted to spend a fortune on a complete, working watch, which I didn't, so I had to wait for eBay to come up with a spares or repair victim at the right price, which it eventually did. The stripped out main plate with the balance and cock, minus jewels, ready for the cleaning machine. The bottom plate back together again after a good wash cycle in the Elma. At this point I did check the canon pinion anyway and it was as well that I did. There was virtually no transfer of power through to the hands at all so a suitable adjustment was made and a tighter fit achieved. Back in the case and ticking like a champ. The rotor and massive case back gasket back in place. And a much improved trace on the timer. This is with the original mainspring which turned out to be in very good shape requiring just a clean and relube. The trace isn't perfect by any means, but compared with other Russian watches that I have played with (and with it's starting trace), it's pretty good. There is still a hint of a periodic variation that I may investigate at some point but for now I shall just wear it and enjoy it. And here it is on the wrist after a bit of a cosmetic brush up. These are available with many different dial designs, apparently this one is referred to as a "SCUBA Dude". I have worn it for two days now and it has gained about 5 seconds a day so there is a little fine tuning to do to get it right "on the wrist". All in all I'm very pleased with this one. I had been curious about the Amphibia for some time having read a couple of articles detailing its history and design. It also has quite a large following of avid enthusiasts who rate it for both value and robustness. On the value front I can't complain with this one as the total cost to me was just £11 (including the donor). As for ruggedness only time will tell, but the performance so far is very impressive.1 point

-

That 6s is a perfect size for a dress watch. I have a Illonois 4s that would also be a good candidate...the dial is 33mm and the movement if I'm not mistaken is 31mm. I will definitely have to some how find a case or have one made specifically for it being it is lever set.Sent from my SM-N920T using Tapatalk1 point

-

You'll have noticed that my Vostok Komandirskie watch came with a faux leather strap. This didn't look right so I decide that a brushed SS bracelet was called for. The one in the pictures cost £15 inc post from China. It came supplied with spare links and a pin pusher with a spare screw-in pin. It's heavy and beautifully echoes the bezel. Chuffed!1 point

-

1 point

-

I found that different heights are needed. IE when putting a clock together i found that for aligning the pivots it,s best done by looking up into the movement & this method works for me but for watch assembly I like to look down on the watch. My work around was I found in a used furniture shop a draft mans chair which is adjustable in height. Although there a very large range of height adjustments for the clocks I still put them on a storage box to gain extra height & lowering the chair to it,s lowest setting is perfect for me. Not my chair but this is the style. They are also designed for comfort which important.1 point

-

Thank you Lawson! Too bad that you're not allowed to edit, so I hope people read on...... or if & when inexperienced people like me, encounter the same mishaps, then read my post and get the German "Aha erlebnis" (Aha experience :-)))). I hope I can do the barrel and main spring. It's has to be done by hand as I haven't got the tools........ a test to see if my nerves and heart are strong enough........ BTW; our dog seems to be very happy with the additional walks........... ;-) Thanks again; Roland.1 point

-

I've been working on a circuit to automate the forward and reverse motor movement of the L&R machine. Last week I noticed that the motor hesitated to turn on lower speeds. After some testing, I determined that the bearings were bad and needed to be replaced. Ordered a set of bearings from Amazon and today I started working on replacing them. I was surprised on how relatively easy they were removed. As I was getting ready to assemble the motor, I took a closer look at the motor casing, especially the upper half. And this is what I found... I am glad I found this before I went further in reassembling this motor. I will be rewiring the entire machine in the next few days. I am guessing the only reason this motor did not go up in flames is because the bare metal is not touching the clamp. By time I am done with this machine it will be practically new.1 point

-

First of all, thank you very much Lawson for making this walk-through! This "I'll take you by the hand" guide has given me the confidence to tackle my first watch ever, a N.O.S. ETA 2540. As a training starter my first goal was to strip it, and directly rebuild it. No cleaning nor oiling. Stripping was pretty straight forward, but while rebuilding it, I encountered some pit-falls. I was struggling with getting the train-bridge back on. Especially the escape-wheel and the second-wheel had a mind of their own in which jewel to go. I ended up taking the train-bridge screws out and worked my way from the center to the rim. Once all the wheels were in place, I installed the screws. The other problem I had, but that may be due to my total lack of experience, that following the assembling instructions, when assembling the setting lever I found out that setting-lever-screw had to be inserted before installing the barrel-bridge. Not a big problem, I just had to disassemble until the setting-lever-screw could be inserted. I also went wrong refitting the keyless work. After installation of the setting lever, yoke, yoke-spring and setting-lever, I was left with the winding pinion, clutch wheel and winding stem. They had to go in before the keyless work, so I had to disassemble the levers & springs for another training round :-) Getting the setting lever "locked" in the winding stem, tightening the setting-lever-screw on the other side, was a hard task and took me ages. I had to take a few walks with our dog ;-) Wondering if that can be done easier? The news is, that the watch is back together and ....................... running ! :woohoo-jumping-smiley-emoticon: Next plan, disassemble the watch again, but now taking the main-spring out of the barrel, clean it all and reassemble the watch plus oiling. It's a tiny object, but a huge challenge !! If possible, and if you agree, maybe you could edit your assembly sequence with the points I encountered? Then again, it may well be that it is just my inexperience....... Thanks again for all your efforts you put in this walk-through ! Regards: Roland.1 point

-

Thanks for bringing this post to life again with this link to Unitednuclear fluorescent paints. These are really no different than the others such as Luminova or the ones sold by Ranfft. Sorry George to be so late with a reply. The only radioactivity in everything that has been mentioned in this post is the very old residual radium paint on the dial and hands of vintage watches. The radium is still active but not the fluorescent material that was destroyed long ago by the radiation.. If a thin layer of paint such as Luminova is applied over the old dial numbers or hands then it will glow because of the radium underneath, and this glow will be permanent lasting longer than the short-lived glow from exposure to light or ultra-violet rays (sunshine). This short-lived glow is phosphorescence caused by light, whereas the radium induced glow is usually called fluorescence. In Tritium fluorescent watches (marked with a T on the dial) the radioactivity is from the Tritium gas that is contained together with the fluorescent material in glass micro-spheres. The radioactivity emitted by Tritium is low energy (penetrating power) and so it does not pass through the glass. If the glass spheres are ground down by accident the Tritium gas would just fly away presenting no hazard.1 point

-

I only help out friends and acquaintances, but I still point out any blemishes and explain that there is always the slightest chance of marking the case when it is opened. I haven't marked a case yet, but saying there is the slightest possibility allows them to change there mind easily, and God forbid that I caused a slight mark, they wouldn't be surprised. The most annoying thing that has happened, was when one of my wife's friends insinuated that I had swapped watch boxes. She said that the box was in pristine condition and also had spare links in it. Needless to say I was less than chuffed and told her in no uncertain terms that it was her box, and that there were no links when I received it. I told her to send it to Tag the next time!1 point

-

Hi folks, in response to Vich, D5 is mineral oil based and HP1300 is PAO (polyalphaoelfin) based. PAO is basically synthesised mineral oil, which means most of the undesirable elements of a mineral oil are removed by reforming molecules into an oil rather than cleaning-up what you get naturally from the refining process. Typical Properties are as follows D5 HP1300 HP1000 Viscosity at 0c, Cst 7300 5900 4700 Viscosity at 20c, Cst 1200 1267 1013 Viscosity at 40c, Cst 175 307 295 Pour Point degC -18 -41 -39 Evap loss test, % 0.83 0.59 0.56 Baader Ageing Test % +2% after 12 days +7% after 50 days +7% after 50 days I have also included HP1000 as some use this instead of D5 HP1300 has similar viscosity (runnyness) at 20c (an industry standard temp and near a typical average daytime temp) to D5 with HP1000 a little thinner. At higher and lower temps the viscosity change with D5 is significantly more than HP1300 and HP1000. Loss of viscosity at higher temps can mean that the oil film can be broken and lead to more wear. Increase in viscosity at low temps means the oil film is more viscous and so the mainspring has to work harder and the watch may slow. Therefore the HP series will have less effect where temps vary greatly. The pour point is the temp at which the oil ceases to flow and so the lower the better, especially in winter conditions. The Evaporative Loss test is measured after exposing a fixed volume of oil to 100C for 5 days, and again D5 is inferior to HP. This is basically a measure of how quickly the oil will 'dry out'. It can also indicate what gummy residues are formed as the oil thickens. This could be important in high temp environments. The viscosity change (Baader) test measures the change in viscosity over a period of time at a constant temp. Unfortunately the Moebius figures are for different time periods, this test has check points for stopping testing. Effectively the HP are again superior in this aspect. What this means is that HP will hold their viscosity better (confirming long term viscosity stability at various temps as discussed above). Therefore the HP series are certainly better than D5 based on above. One other factor is the lubricity (slipperiness) of the oil and D5 needs an additive to enhance this to HP's natural levels. This additive will be 'consumed' in normal service and therefore the D5 oil will be less effective over time. Only downside is cost, but shelf life is longer for HP and small quantities are available and will last a long time if used carefully. I myself would always go for the synthetic oils over natural oils whenever possible. HP series also contain a dye (red for HP1300) which may not be desirable in high end watches and/or where the movement is visible through a crystal case-back. I believe undyed versions are available but maybe not in the very small volume packs. Hope this helps and not too deep!1 point

-

Hello Roger, Welcome to the forum from the sound of it you will fit right in ! Grab an old watch and rip it apart clean and lube it and watch in awe as it comes to life or perhaps there will be a problem in which case there will be help from the forum as to which whisky to use to stop the sobbing before sorting the b****r out with the chisels hammers and cutting tools, mounting them on a board, call them steampunk and sell it for thousands of ££££. Cheers, Vic1 point

-

1 point

-

1 point

-

i just looked on ebay and saw that an ETA 6498 movement is 36.6 mm. this would get you very close to using any watch case that parnis makes. you could use that speedi-fit compound to make up the difference.1 point

-

what case are you looking for? anything that will hold your movement? you are very close to what would be a nice dress watch with the size of your waltham. what i would do is look in some of the specification literature for a popular movement that is the same size as yours and than see what case is available. in other words, say that (hypothetically) an ETA 6497 was that same size as yours. you can find plenty of cases on fleabay that house an ETA 6497. that might be a good starting place.1 point

-

When I first saw your response, I was thinking, "people don't know how to use apostrophes any more; should be 'George Daniels' was pretty'". Then I looked at the picture. :-)1 point

-

I've created a Google sheet that lists the part numbers for all versions, including 7S25, with the differences highlighted and annotated. Hope it can be useful to someone. If you notice any mistake or addition to make please let me know. https://docs.google.com/spreadsheets/d/1sYt_mI9c4tAPiKN3IM8lQx3NEEOyz2DMjVHx5I1_Mqw/edit?usp=sharing1 point

-

Today I'm wearing a 1959 Omega Constellation Calendar (first offering of calendar from Omega). This one has the chronometer grade 504 calibre of which about 25,000 were made. The arrow head markers are in pink gold as is the sweep hand. The hour and minute I replaced with genuine omega dagger hands but they don't make pink gold hands anymore so I used regular gold. The strange thing about the watch besides the pie-pan dial is that the case is stainless steel. I've seen other examples with the stainless steel/pink gold combination in Desmond Guilfoyles comprehensive review of the constellation line. I wonder about the patina at the 8,9,10,and 11 hour markers, but I know it has NOT been repainted--this is the original dial. I have two examples of these chronometers, and am thinking of selling this one. In any case, hope you like it. JC1 point