Leaderboard

Popular Content

Showing content with the highest reputation on 11/08/15 in all areas

-

The short answer unless you try extremely hard oiling the pallet fork pivots is not the source your problems. Although you didn't tell us what lubrication you are using? I once saw in a classroom situation one of the watches the student worked on, on the timing machine could not be timed. It resemble a watch that hadn't been cleaned and lubricated in 100 years. In other words it had the symptoms of incredibly sticky gum oil preventing the train from moving in a proper fashion and it produced is really interesting waveform on the machine. So if you try really hard like grease instead of oil or something else inappropriate it will be a problem. The problem we have for diagnosis of your watch is we need to see it. So we rely on your description and as a beginner you're not going to see what we see you're not going to see the problem more than likely. So we can guess lots of guesses and the guesses are all correct in some situations perhaps in your situation but we still can't see the watch. It's why asked for a photograph which might help us. Then yes I know trying to get a decent picture of the hairspring balance wheel is an issue. So the simple is to make a watch go fast shorten the hairspring. You don't have to physically cut the hairspring off to make it short. As mentioned the other way to shorten the hairspring is something sticky on the coils they stick together. Magnetism on the modern watches it's different what it does it will be a problem but the coils usually don't stick together after the magnets removed. If this was a blued steel spring they can get magnetized and stick together. The most likely scenario is no matter how careful you were you probably have bent the hairspring. Then the other thing is what was the condition of this watch before you took it apart? In other words did the problem exist before or after you worked on it. So now we have the nifty new color tech sheet they're lots of pictures of the balance wheel on the hairspring to look at. Much much nicer than the old black and white. Then regarding timing machines depending upon who made them they do have another feature which is amplification of the sound. A lot of times when listening to a watch if the hairspring is bumping into inappropriate things or rubbing it makes really interesting sounds sometimes. Then for other ideas of how your hairspring is supposed to look a similar discussion probably not the same problem but he has some nice pictures the balance in the hairspring so you can compare. http://www.watchrepairtalk.com/topic/2914-seiko-5-gaining-suggestions/2 points

-

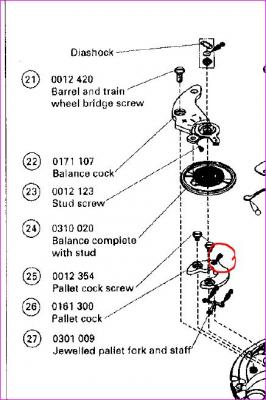

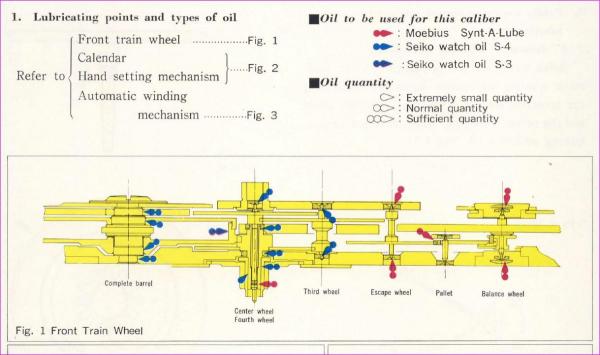

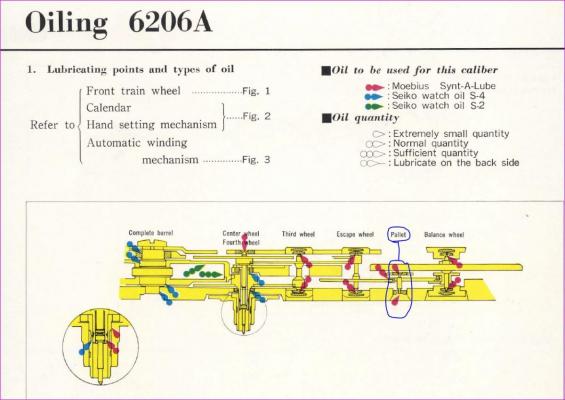

It be really nice if we could have a close-up picture of the watch specifically centered over the balance wheel. I'd like to see the position of where you put the regulator and the floating stud. If you don't understand what you're doing you can move these in really bizarre positions and the watch is never going to keep time. Then if you had access to a timing machine/timegrapher It really can help speed up diagnosing things like this. There are some things that only the timing machine will show you there is no other way to find out. Then an alternative to a self-contained timing machine can be found at the link below. http://www.watchrepairtalk.com/topic/3002-d-i-y-watch-timing-machine/ Then lubrication one of my favorite subjects especially in horological groups. So most of us know that the end of the world will come if we oil pallet fork pivots. For anyone with access to a timing machine put some oil on the pivots especially if its heavy oil the results could be quite dramatic. Except this is a Seiko watch and Seiko sometimes does things differently. In another group somewhere we were discussing the forbidden subject of lubrication I was probably pointing out the evils of oiling the pallet fork pivots and somebody pointed out that Seiko oils all of theirs. The reality when I went to the tech sheets is not all of them but most of them. So I've attached some images the black-and-white comes out of service manual for the watch in question. Then at one time Seiko produced nice colorful lubrication charts two separate ones attached 7005 and the 6206. Notice one is oil and the other is not. Then even though I pointed out Seiko does something different for someone learning watch repair your timing problem is not the lubrication of the pallet fork pivots it's probably something basic and simple it's not the obscure things that get the beginners it's the simple things that you don't understand yet.2 points

-

1 point

-

Here's the version that shows oiling points on 7s36 movement. Can't seem to attach a pdf via tapatalk. Keeps crashing the app. https://docs.google.com/viewer?a=v&pid=sites&srcid=Z2xlYXZlYW5kY28uY29tfHRlY2huaWNhbHxneDoyZWMxOGU0MTRjYjk5NWZi1 point

-

Correct. And they also oscillate (seems the right word to use in this context) in different revisions of the tech guide for the same movement. Attached two versions for the 7S26. First one indicate "extremely small quantity", second and third say "normal quantity" (!) Another confusing practice of Seiko, some guides uses the normal convention of indicating oil q.ty with a drop symbol with none, one or two additional circles, and type by color or pattern. But others (example attached) do exactly the opposite. All that even before coming the million dollar question - why Seiko greases look totally different from their generally recommended Swiss equivalents? 917_Seiko7S26A,7S36A.pdf 7S25 tech.pdf NH25.pdf1 point

-

I gotta share this .....I got my first non working 218 Accutron running today . Granted it did humm when I put in a battery , but the index and pawl fingers were both out of alignment with the index wheel and the pawl index finger was bent and twisted . I managed to straighten it out a bit and align both index fingers and jewels with the index wheel including the proper hack spacing on the pawl jewel . I did have to use my 10x loupe and my new new 7x - 45x stereo microscope to do this .....but it's running on my wrist . Step 2 is to take it apart now , clean and lube it and put it back together....YIKES !! I have some spare movements I can practice on . Baby steps at this time . The stereo microscope is attached in the link : http://www.amscope.com/stereo-microscopes/7x-45x-trinocular-stereo-microscope-with-80-led-light-1-3mp-usb-digital-camera.html1 point

-

1 point

-

This movement is pretty bullet proof and a sign of very fast running may be very low amplitude (how far the balance wheel spins from stop to stop). It could be caused by a number of factors. Check your train for smooth running by letting down the mainspring, removing the balance and pallet fork, then wind the mainspring gently and watch the train to see if it runs freely. Then refit the pallet fork and see how many turns you need to get a full wind on the mainspring which may tell you if the mainspring is broken or slipping (too much). All of this assuming your hairspring is working perfectly of course. A timegrapher is invaluable if you are going to do much tinkering.1 point

-

Few pics of what I ended up with! -/very happy, just saving up for the led lamp at cousins that you guys have verified is good. Back at the bench, very happy. Thanks all for your help! Cleaning all goes in inside the cupboard, as long as I keep the door open I'm not worried about fumes or heat Put in some LEDs too! Sent from my Nexus 5 using Tapatalk1 point

-

I believe I misspoke . I said , " I don't think that a tuning fork watch has been made since the 80's"…I meant 70's1 point

-

......after getting another nice Hamilton ETA 2846 replacement movement . It was advertised as NOS with issues . Supposed to be a customer return . I think the customer was a butcher . At first I thought it was only a loose rotor , No problem . Then I noticed it ran very fast...and found a broken inca bloc spring . Then I noticed that the calendar was haywire...missing , bent , and mangled parts plus the setting mechanism had snafu's . I put it away and looked for a replacement movement at a good price . I found a Hamilton movement that was supposed to have been in storage , Almost NOS , Just dusty ....which it was . took it apart and cleaned and serviced it . $41 for the movement . Now the watch and I are happy campers..... :stuff:1 point

-

Waaaaaay toooooo dear Micky, but then I'm a canny Scotsman! :D Pot of silicon grease :- http://www.ebay.co.uk/itm/121408713571?_trksid=p2060353.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT Silicon grease applicator for case back gaskets :- http://www.ebay.co.uk/itm/291242993254?_trksid=p2060353.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT Much cheapness, and works very well. :)1 point

-

1 point

-

1 point

-

Outstanding! Thanks for the assembly pictures. This has got to be one of the all time great saves :)1 point