Leaderboard

Popular Content

Showing content with the highest reputation on 05/22/15 in all areas

-

Yeah... that was on a VW bus/van... the transmission kept jumping out of 4th gear.. not fun when you're doing 50mph (laugh not..that was max!). What I did was get a transmission from a breakers and install it. At that time I did not realise that there was a fundamental difference between transmission on beetles and busses in that there was an additional reduction gear at the end of the driveshaft (behind the driving wheel) and this required the driveshafts to spin in the opposite direction. This was in the BI era (before internet :D ). Installation went fine and as the bus was parked nose up against the wall reverse was the first gear selected.. It went into gear fine and when the clutch was released it was quite a shock to find the bus going forwards. A bit of messing around with gear linkage and as everything looked ok we pushed the bus out and proceeded in first gear...the bus moved backwards...WTF? A few days followed as I was convinced something was wrong with the way we hooked up the linkages... a lot of faffing around and getting intimate with the innards of the gearbox selectors (hockey sticks in volkspeak) comparing the old and new and nothing seemed amiss. One fine day one of my buddies decided to try second gear.. still backwards!! .. third and fourth...also the same. Mucho head scratching and back to the breakers we went. There the hairy breaker bloke (actually a skinny chinaman in string vest) told us we had wanted a volkswagen transmission.. no one mentioned anything about a bus..didnt we know that they spin in different directions, You'll end up with 4 reverse and one forward gear! yeahh right .. of course... well I actually need one for a bus.... be right back with the transmission.. Lesson learnt... just because it looks the same and will fit the same doesn't mean it is the same..! Anil3 points

-

I would go further, it's impossible! On your other subject "four reverse gears", was that so yo could go back to the future without using a flux capacitor? :)2 points

-

1 point

-

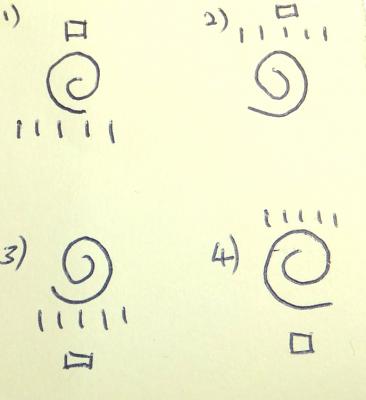

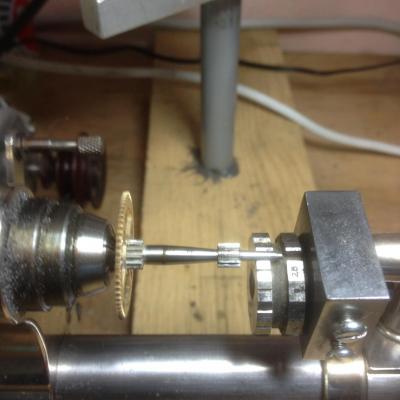

Well a follow on from my post yesterday regarding a bodged hands. You sometimes just get that gut feeling that all is not well especially when a watch/clock repairer had returned it with "to knackered to fix". I had added some pics of the service & poor workmanship I put right. The hand issue is on my previous post. The minute wheel is attached to most carriage clocks with a screw/post. When I opened the case the wheel was at an acute angle. It was fitted with this. The shaft that supports the wheel was very loose the screw/post was bent at the tip the head was also bent & whoever made this one had calculated the length incorrectly so made it fit with a brass bushing.Also the thread had been stripped on the screw & also on the case plate. So I had to make another. I also had to re-tap the plate. Sorry guys but did not take pics while making the part also some of the pics are out of focus but here are a few after making the screw/post. I tapped the case with a 1.4mm thread which was worry because I only had a cheap die so very very gently when cutting the thread. Drilling Tapping Cutting screw head slot Finished Part Testing all fits & runs smooth Some pics of polishing & burnishing the pivots Job done> The job is not perfect the balance wheel is kinked but to risky to fix. It has been up and running for the last hour keeping good time . I have made a small vid1 point

-

Hi Daniel. Oil thickness, or flowability, is indicated by viscosity (typically at 20 deg C). M8000 = 95, M9010 = 150, M9020 = 270 and M9000 (Quartz) = 100. So nearest to M8000 is in fact M9000 but M9101 is the standard for watch balances etc. The 8xxx series are mineral oils (ie natural hydrocarbon oils) and the 9xxx series are based on PAO synthesised oil. The latter has much better operating range, greater stability, oxidation resistance, and has an added anti-wear component, so will last longer and perform better. There is a 'viscosity change' test (but will not go into details) and for comparison 8xxx have +18% compared with 9xxx +2% (ie less thickening over time). Thinner oils will offer less viscous drag and the faster a part rotates the lower the viscosity requirement, hence a thin oil for the balance end and thicker oils towards the mainspring end. I would always go for the synthetic types despite their initial costs.(My earlier posts 'Lubrication Basics' gives more info and there are plenty of other posts to help you). Trust this helps a little.1 point

-

My head hurts trying to read it and that's WITH the accompanying instructions. Http://m.wimp.com/stylish-clock/ Reminds me of the hair gel I used to use when I was a tad younger [emoji1]1 point

-

Fascinating mathematically but I believe it may be quicker to go next door and ask your neighbour the time! Or get the bus into town and queue in the Post Office and ask the person at the first available window!1 point

-

Hi everyone, Thought I would share a recent ebay purchase with you all. I've been after a Cyma for the collection for a while mainly because all I have read on various forums say they are typically under valued good quality watches. So whilst busy at work on a night shift I had a quick look on Ebay to see what was on offer and was drawn to a listing for a 9ct gold cased Cyma Watersport. The listing description was as follows, A very rare original 1950s cyma swiss watersport, has subsidiary dial sold as spares or repairs works but winder has seized as has been unused for some time,9 karat gold,classic Gentlemans timepiece,will make a very nice watch ,strap in good condition. SOLD AS SPARES REPAIRS Looking at the pictures the dial looked to be pristine and in far better condition than most watches of this period, the case looked very clean and tidy too. The watch was on at £100.00 buy it now, so far so good I thought the only worry in the description was the seized winder, waying it up I thought okay buy it if it turns out to be a dud I will recoup most of the money on the gold content of the case. So I went ahead and took a chance. So this is what arrived yesterday in the post The watch on first inspection is in excellent condition, out of the package it was ticking away nicely, first thing to check the winder, which to my surprise functioned as it should it wound freely and clicked outwards and set the hands as it should, I am though pretty certain the crown is not the original, but it does look good on the watch, how the seller had come to the conclusion it was seized I don't know. The case itself is of very high quality with a srcrew in caseback free from marks or scratches the watch has the appearance of having a separate bezel but is in fact a two piece case. I then decided to have a look at the movement, at this stage I suspected from the overall condition of the case and dial it would be in a good state of repair,but on removing the case back another surprise was waiting to be discovered, The listing had stated the watch case as being 9ct gold and on one of the lugs of the watch there is a hallmark which is too small to see clearly with a loupe, so the seller must have just assumed it to be 9ct. So the swiss 14ct hallmarks where a pleasant surprise the hallmarks also indicate that the watch case was manufactured by C.R.Spillman a quite notable case maker who manufacture the early oyster cases for Rolex, this explained the overall quality of the case.T The watch head without strap weighs 29 grams so I would guess that half that weight will be gold content. The movement was protected by a gilt metal dust cover and just as I thought is in a excellent state of repair, I think its a cal 414 KA but I could be wrong as the calibre numbers are obscured by the balance wheel. It is in very good condition with a scratch where someone as removed the dust cover a little carelessly in the past , I would also add I think this dates the watch to the mid 40's. Over the last 24hr it has lost about 15mins so a service is in order, so I will send it off to my usual watchmaker for a service, I don't know enough yet to have ago myself and its too nice a watch to get my clumsy hand on. So overall this item was not as described but all in a good way, I also received another surprise in the package the seller also sent me another watch as a freebie, he had sold it a few weeks ago and the buyer had failed to pay for it and he didn't want to list it again. Its a Ebel with a eta 2824 auto movement, it is something I don't want so I will offer it as a project ( It has a Broken stem ) on the parts page for the cost of postage later today. Wayne1 point

-

1 point

-

If it is out by several milliseconds you may be able to hear it, but if it is only out by a hairs width then you might not hear it but a timing machine will.1 point

-

It,s always looking up this web site http://pennyfarthingtools.co.uk. I have used him a few times very knowledgeable but does not keep his web site up to date so worth giving him a call to see what he has got. Also not cheap but what he sells works.1 point

-

:-) who isn't Don ;-) Like Stu said, the pocket hole jig on its own will not be enough to hold your desk together, at the very least combine it with dowels, which you glue in. Once full of tools this is going to be heavy, you don't want to be stood in a puddle of splinters and tools with two side panels and handles in your hands! When you come to route your dados a jig like this is fantastic dadojig if its new to you shout and I'll dig my similar one out and mock up some pics on the theory of it working. You can do loads without a tablesaw, using a circular saw instead, but try and make it easier on yourself, when you get your ply, get as much of the cutting done on the big wall saw in the place you buy it, it should be cut to dimension and with nice straight square edges. Also build yourself a couple of jigs, first a cutting deck, to put sheet material on when sawing and routing, mine is a lattice of strips of ply wood that slot together (I realise that doesn't mean much without a picture sorry) and a straight edge guide to run the saw along, that way you can have a setup similar to the track system (festool hmmmmmmmm) used by many of the newer plunge saws. If you want ideas for jigs have a look at the dvd's available from Steve Maskery, he's a woodworking legend! and one of the UK woodwork magazines refers to him as The Jig, he covers all the ones I've mentioned and many many more besides. Handles - the type that spring to mind are cargo luggage handles, they fold flat but only open to 90 degrees when lifting, saves the hands getting crushed. Good luck and enjoy :-) Sean1 point

-

1 point

-

I remember watching the George Daniels interviews, and George lost a screw on a job he was working on, and it turned up a few weeks later under his fingernail lol1 point

-

No, Don. 1/2" Finnish (like the country, Finland) birch should be fine. Finnish and/or Baltic birch ply has many many plys with no voids. It's a great base material. You can find it in smaller sheets at many supply houses. Try Pinecone Lumber over by you for a start. You won't find it at a big box like Hope Depot.1 point

-

Unless you can get someone to solder some lugs on, I would say it's only worth the movement that's inside! If you still want to wear the watch, your best bet would be to get a jeweller to solder a tube under the existing lug so that you can affix a chunky leather strap using the 'dumb-bell' type strap retainers. Anil1 point

-

Hi Don, I think in my profile says I'm a carpenter and cabinetmaker so I can speak with some experience. You are embarking on a big project with a limited skill and tooling. That said, you should look into Finnish/Baltic birch plywood for your carcass and for your drawer/door fronts and 1/4" tempered Masonite for your drawer sides and bottoms. It will take a lot of pre-layout to rabbit the corner, back, and top joints. Then you have to dado the joints separating the separation between the sections all before you put the box together. As far as the drawers go together, you can do a simple rabbit joint and dado for the drawer, Masonite being used here. To hardware. You can use a SOSS hinge which I use a lot and are great, http://www.soss.com/invisible-hinge/soss-invisible-hinge.html?invisible_hinge_mat_thickness=30 or a simple miniature butt hinge like you see on your front door. To keep the doors and drawers closed you could use a bullet or ball latch. A router is fine, using a guide to cut the dados and rabbits but a hand held circular saw will be tough to get a straight cut for all your parts. Better to buy one of those small table top table saws you can find cheap on Craigslist. You can do all your rabbit cuts with it as well. This is a great project and I wish you luck. I just found that to buy the cheap unit from the supply houses suits my needs and didn't have to put in lots of hours and money away from my business. If I was to need a full sized watchmakers bench, then I would be looking to design and make it myself. If you need any help or advice, please feel free to PM me here or PM me with you phone and I'd be glad to talk. Stu edit to add, your pocket screw jig is good for kitchen cabinets but almost useless on something this small. Think large jewelery cabinet. :)1 point

-

This is just how its designed, unless she was using the watch before and its now working differently? I can't imagine how you could assemble a watch to have it wind in the opposite direction. Off topic but I have installed a manual transmission only to find i had 1 forward and 4 reverse gears! Anil1 point

-

Greeting folks :) Now i know you've seen me in the advice section a few times ( too many times lol ), but i figured that i should share some of my recent repairs that are a success rather than a mess. I do manage to succeed 90% of the time with my restorations but no harm in asking for help when i know im stuck ;) So today i finished two watches that i had been working on, one being a nice automatic and the other a more classical manual. I can't quite put my finger on why these simple watches are such fun to work on but i do enjoy some of the more basic pieces. Both had a few issues but nothing that a good tinker would not put right. Both movements were crammed up with old oil and gunk and few small parts had seen better days, luckily i have a draw full of spares that brought new life to this pair. Casings have had a light polishing with scratches removed from case backs, new glass and a restored glass, new crown for the auto, and a nice but simple pair of straps to finish. Tissot Seastar Automatic GP ( Cal 784-2 ) & Rotary 21 Jewel Incabloc ( Cal AS 1702 ) Tissot - Has nice new gaskets, new AT Glass, and a nice new gold crown to match, the old crown was Tissot but silver ? Lord knows ? Rotary - Simple but effective timekeeper :) The poor Rotary was swimming in oil and dirt from where someone had previously tried to murder it by drowning, luckily i have two very good cleaning machines ;) I forgot entirely to take photos of the Tissot engine but im sure most of you know what an automatic looks like by now ha ha :) Anyway i figured it was time to share some success rather than my stumblings. Enjoy :D1 point

-

Not the same model but looks to have the same strap mounting system. E bay # 131512335220 Check out the photos. One has a pretty clear view.1 point

-

Thats a difficult one. I very much doubt that any strap available would be suitable as the fitting is completely non-standard.1 point