Leaderboard

Popular Content

Showing content with the highest reputation on 11/04/24 in all areas

-

Sorry for the question, but, do You know how to replace such jewel? It is rolled one and not pressed like modern jewels. You must not screw up the way the movement looks by deforming the stone seat or leaving any kind of marks there. This is not a movement to learn on.7 points

-

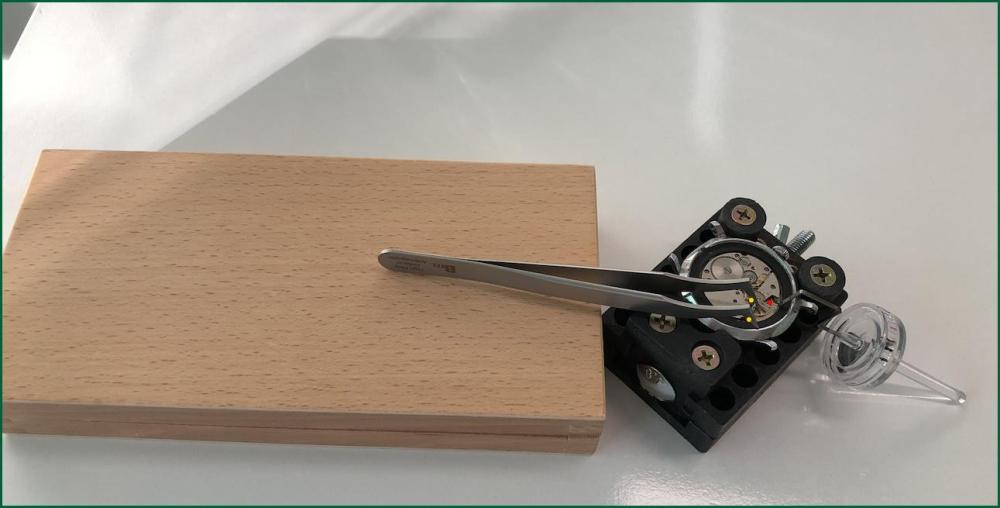

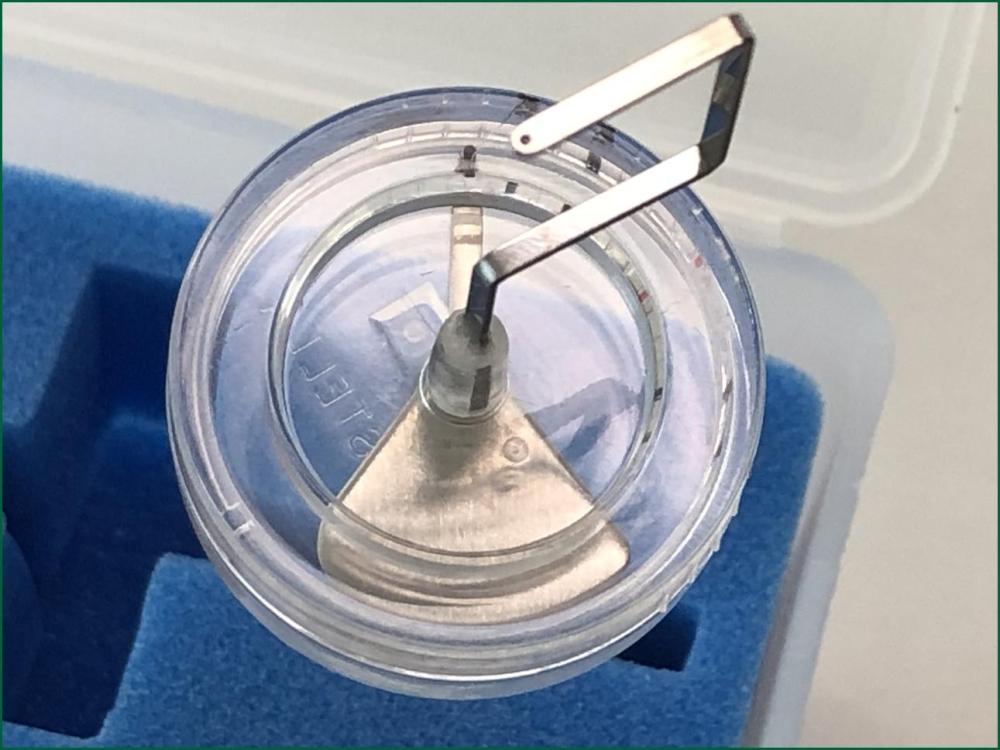

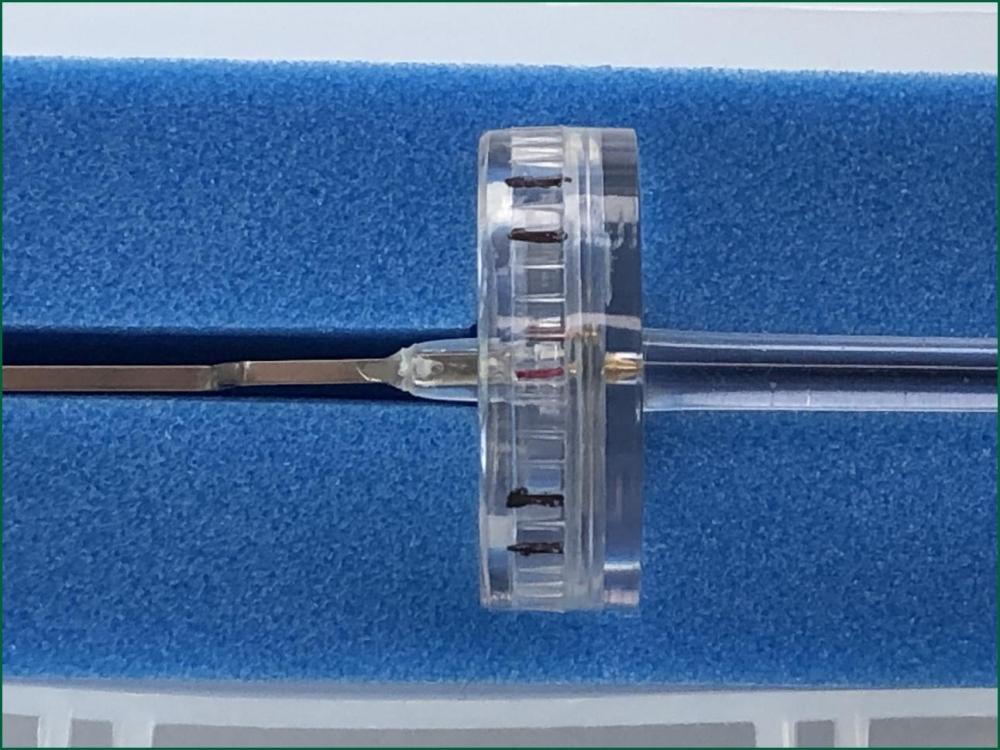

Yesterday I regulated the rate using my newly acquired Microstella tool. What I feared could become a difficult and gruelling experience turned out to be very pleasant. When I finished, I reflected on how much easier it would be if all movements were regulated similarly to this Rolex calibre 3135. It turned out to be not only quite simple but also very precise. @Jon's tips and video as well as @Endeavor's and @Mark's tips (links in previous posts) were very useful. I don't have a tripod for my phone so I can show how I held my hands but at least the picture shows my setup except for the watch itself which is a junk watch as the Rolex watch is currently spinning on my Cyklomat. I am right-handed so I held the tweezers with my left hand which could rest safely on the wooden box and handled the Microstella tool with my right hand which could rest safely on the work bench. The advantage of this type of small (and inexpensive) case holder as seen in the picture is that the Cyclops eye above the date display is in a cavity in the holder which means that the watch case wont tilt. In general, I think it's easier to regulate the rate while the movement is on a movement holder as seen in Jon's video, but I still decided to do the adjustment with the movement mounted in the case, and since Rolex advertises the Microstella tool this way I wasn't too hesitant. By letting the inside of the tweezers rest against the balance bridge (the yellow dots), as Endeavor describes, I got good stability and could grip the rim of the balance wheel without the risk of accidentally moving the tweezers sideways, lengthwise, or vertically. After that, it was no problem to place the tool over the Microstella screw (the red dot) and rotate. Following Rolex's instructions, I stopped the balance wheel by pulling the crown out to its extreme position and then carefully rotating the balance wheel until the first of the two screws needing adjustment was aligned with the most convenient way to hold the Microstella tool in relation to the screw. What I didn't realise, which scared me a bit in retrospect, was that the impulse pin could have caught on the outside of the fork horn as I rotated the balance wheel. I guess you can probably feel if that would happen, but I think you need to be a little observant of this which is why I mention it. The tool itself I bought at Cousins. It is a rather expensive Korean clone of the original Rolex tool and works well but does not give a feeling of really high quality. What is critical is that the fit with the Microstella screws is precise and there is nothing to complain about. Something to complain about is the weight on the inside of the tool which is supposed to always hang vertically and indicate how much you have rotated the tool. On my copy, the weight rotates so slowly that it almost loses its function. Perhaps I got a Friday afternoon model but maybe it can be adjusted. To compensate, I made marks with a permanent marker on the wheel to make it easier to see how far I should rotate it. It worked well. When rotating the Microstella tool, you must try to keep an eye on both the screw and the tool. There is a risk of focusing only on the tool and slipping off the screw, thinking that you are still rotating the screw but in reality, you are only rotating the tool. The screws are seated with relatively high friction (as Jon mentioned) but because we are working in a microscopic environment, there is still a risk that you do not notice that you have slipped off the screw while rotating the tool. So, that sums up what proved to be a pleasant experience. The current rate while the watch is spinning on my Cyklomat is +1.6 seconds/day so I think I'm done, and I'm pretty sure I didn't upset the poise. I'll do some measuring on PCTM a bit later.3 points

-

I would like to second a point already made by a few others, just so it's clear. This looks like a real collector's item, and worth more than perhaps you realise. I advise you not to attempt anything yourself and to get professional help with it.3 points

-

That would be me. I am taking a risk, i know i am taking a risk with no hitory, but i am hoping that the ebay guarantee will cover me in case anything goes wrong. Will let you know once it is in my hands.2 points

-

The trouble is not knowing the condition of the movement, if it is worn and dirty adding oil will make little difference and if it is not oiled correctly you could cause more wear. With out taking it out of its case you will only be able to oil what you can see on the back plate this again is not recommended. Never just put it in some sort of fluid as the barrels will be flooded with the stuff and it will not all come out. The movement should be removed from the case, inspected, taken all to pieces including removing the springs from there barrels then appropriate work undertaken cleaned assembled oiled and tested.2 points

-

I just serviced a time and strike circa 1895. Typically when servicing these, the strike will run at some level even without any cleaning. This one, no. What I found is not atypical. It appeared that sometime in its life an attempt was made to use what was probably WD40. Anyway, the strike (and time for that matter) was gummed up. Required a complete disassembly and clean. It is running and striking great. There are rarely any shortcuts. If you do not want to do a full service, the only cheat I can offer is to pull the movement from the case and put the entire thing in an ultrasonic with coleman camp fuel for half an hour. Then remove, dry, and oil the pivots and mainspring. Maybe it will work.2 points

-

A rough work in progress/first case up... First things first I'm delighted to have an actual/real and working 6105-8000... another dream come true! There's work to do though... Got a (very good) repro bezel insert on the way from yokobies that I suspect will end up being the only non original part on this, unless I go with a repro crystal too. If not the original crystal could do with some more work... But yes, bezel isn't going to be an easy find. Dial is probably going to be switched over to another 'proof' I have - I'll want the crystal nicer for that one. Crown is a stop gap 6105-8110 repro - while not original it is nice enough to have me considering whether to use it on my 8110 if I find another, as it's clearly sealing much better than the almost 50 year old one I have on that. I might attempt a crown rebuild using the washer trick in time... Dial ring, while almost not visible without really looking, will get switched out... It was a decent effort but ultimately will ruin the look of what I hope will end up being a really good looking slim. So yes, early days but it's coming together...2 points

-

On this watch I don't think it's marvellous but I do know you'll get at least 26 hours. I'll give it a full wind in the morning and post the result. They are small barrels, and on this movement, one is a manual wind mainspring and the other is an automatic 'slipping' mainspring which would make sense. Neither spring has been replaced in this watch, just the standard clean up and lubrication. Let's see ...1 point

-

1 point

-

From memory, there's a load on the dial side, I think there's five or six used as guide rollers for the date wheel.... I know Edit: some further remembering, possibily a couple of window jewels that do nothing but fill a hole, but they managed to get a jewel in the second pinion tube (not sure of correct name) just as it comes out dial side. Not easy to clean behind it with any rust damage.1 point

-

No need to apologise, as stated your intentions are good. I've tried to give unused items away.1 point

-

Sounds about right Andy, you now have to get Evri to admit they left you parcel in an unsafe place, i hope yours wasn't valuable. I think ive made some headway today, 4 sarcastic emails to Martijn De- Lange has possibly p.issed him off and the threat of asking Martin Lewis to dedicate one of his programmes to rogue delivery companies with Evri as public enemy no. 1 has put some frighteners on someone at Evri, they are now contacting my seller directly, which is what i asked for 2 months ago. Give em hell Andy. Paypal are coughing up for my losses, something in me just wont let it go, I'm an absolute bugger when I'm riled up . Your seller can clearly see where they left it. This isn't classed as a safe delivery, so it is deemed as lost, if it was delivered into your hands then it would be you that lost it.1 point

-

I had a similar issue recently with Ali-X's shipper... I haven't had my coffee yet today, so I can't remember their name... A seller had sent me a replacement part for something that had previously arrived missing a piece. In the however many weeks it took to ride the slow boat, a wildfire broke out below us in the canyon, and we were evacuated for a week. It was a nationwide news story, you could see the smoke for miles all across the Denver area. The asshole delivery driver marked it as a wrong address and sent it back to China. Ali-X said it was being held by the post office (USPS), which has zero affiliation whatsoever, and since I couldn't prove a negative and whomever was on the receiving end of the dispute didn't seem to understand that USPS and... Whatever they're called have no relation whatsoever, and denied the claim. Ended up having to go through PayPal or my CC to get my money back, and had to return the tool that was missing the part in the first place. The poor seller took a long time to respond for some reason or another, and it sounds like he ended up getting dinged somehow. Everyone lost in that transaction except the shitty shipper.1 point

-

Get yourself a sewing machine motor and foot control it is ideal for a watchmakers lathe. That is what I had.1 point

-

During covid couriers started doing this "leave the package, ring the doorbell and flee" thing. With the exception that UPS doesn't even try to deliver the package, they take it straight to the access point and claim that no one was home.1 point

-

I think you'll be ok Andy, my Chinese seller wants me to jump through hoops.... to get something that the delivery company wont provide. Ive emailed the ceo 3 times today....woth one automated reply to say hes out of his office till weds. Martin Lewis is my next turn in this viscous circle.1 point

-

Ernest Tope would be the man down there, he does very nice work.1 point

-

Another method but similar to LWS is imersion in white spirit (turpentine) with added oil leave overnight . Remove any excess and run the clock , best to remove the power from the springs first. No substitute for a complete service but may get you out of the hole. Good luck1 point

-

Have a look at this video. Mark shows how to use a truing tool to check for true and how to straighten and true the wheel. Many Seikos seem to have distorted balance wheels. I always check them. I had to straighten two of them recently.1 point

-

Back to basics Glen......function groups.....if you suspect the balance has the problem....then just install the balance, inspect and work that area.1 point

-

There is good Stephen Pahlow video about decoration https://www.youtube.com/watch?v=S_S8oA9HdlY&t=168s1 point

-

If you are looking for someone in the U.S. who can make the minute wheel and replace the jewel, Matt Henning is excellent. For more info on the movement, post it over at the NAWCC forum on complicated watches. Rjenkins has narrowed it to a Patek related movement, but someone made the base (LeCoultre, etc.).1 point

-

So no resolution has been reached between Evri and the seller. The seller did not accept the explanation in the email from Evri.....the seller wants an official proof document that is stamped signed etc etc.....so basically bullshit that you'll get from a chinese seller to totally avoid dealing with the situation. I have been told that Evri dont supply documents like these, so a stalemate has been reached....However i brought paypal into this as my transaction card is linked with PayPal and i use PayPal wherever i can. Paypal protection has stepped up and refunded me..........However.....I will continue to be a total basta.d with Evri until they do something that I'm happy about.....so its going to be a very long year, i never give in....and I never back down from a situation.....my mum used to say " son..your like a mad dog with a bone " Bye for now chaps .....I have emails to send Another email to evri's ceo, my new morning routine has been set1 point

-

You need tool steel with carbon content 0.7-1% or so called 'silver steel'. I am not much familiar with american and european steels, I have and use some USSR steels, for important things - some 115CrV3. Sometimes tool steel can be got out of ... tools. Chinese hex wrenches, cutting disks like when steel sheet is needed. The steel of this kind of disks is soft enough for machining and only hardening and annealing after the part is cut is needed. O1 was commented as good for balance staffs, this means it is good for everything else. But, the best steel for someone will be the one that He is familiar with it's hardening regime, feels comfortable with it and every time gets good results. If the steel is new, then He would try to harden some example, try it with file, then anneal to desired hardness and break it to see the crystal structure. For making the ratchet wheel, I would use piece from middle of the disk shown. Then would make the square hole by forcing in smaller hole a square tool, shaped like 4 side broach. Next will be turning of the piece fixed with shellac on the face of a rod, centered by the hole - first one side, then another, in order to roughly thin it to size and to exact diameter, then cut the teeth, harden, anneal. Then final turning the sides to the thickness needed, form the recess for the screw head, and finally - the decoration1 point

-

Oh no they are worse, much much much worse, dont get me started on Evri, ill be at it all night. Thd CEO Martjin De-Lange is a complete **BLEEP**-r.1 point

-

There are producers in the US qualified and capable of making parts appropriate for a high end watch like this..1 point

-

I was there too! I met Philippe Dufour there @nickvon found out about another event in Geneva next weekend. Maybe another opportunity to meet.1 point

-

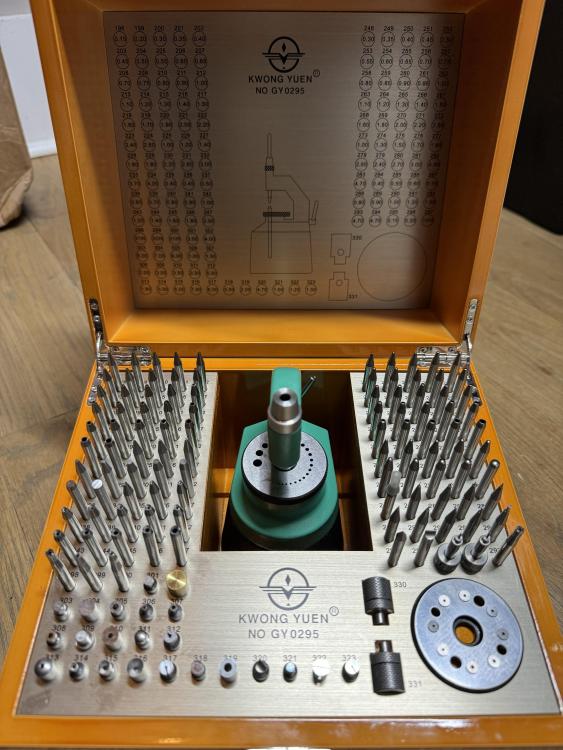

I spent some time today cleaning up the staking set (the jeweling set is in a great condition already, have used it for setting some hands). I gave everything a soak in wd40, then a rub down with some fine scotchbrite. Gave a few bits some 1000-2000 grit wet and dry, and did the stump mounted in a rotary tool. Finally ran everything through an ultrasonic clean/since/IPA, and a final coat of silicone oil. There's still some staining on a few of the punches, but it's all looking much better.1 point

-

Something to say here. The ratchet and the crown wheels are 'the face' of the movement. One expects to see perfect decoration there. Of course, it is not a problem to replace broken teeth, but hard soldering will leave at least half of the wheel soft and will make impossible hardening, as the solder will melt before hardening temperature is reached. Then, the wheel will usually bend out of flat when soldering, and thus will need a lot of grinding when decorating the wheel, the wheel will get thinner. The soft wheel will work fine, but the same reason for which hardened tooth breaks will make he soft tooth smash. This is the why I recommended to leave the original wheel 'as is' rather than replacing the broken tooth1 point

-

1 point

-

1 point

-

The 1802 is a good movement to work on. It is broadly similar to some of the Indian HMT movements which are licensed copies of it. I have a few nice examples of both the Citizen and HMT. A nice robust and elegant looking watch, and a steal at that price.1 point

-

The replacement bit is a bit clumsy (I used the width of one tooth) but a superb result! I didn‘t heat treat, imo it was still sufficient resistant. Frank1 point

-

From some very quick research, it seems the Swiss Tiffany company shared the Patek Philippe factory at one time, and used their movements. That serial fits the Patek Philippe movements, and would put it early in the 1905 - 1910 range. Info from here: https://german242.com/en/patek-phillipe-cie-geneve-serial-numbers/ The movement does appear to be similar to Patek Philippe ones from circa 1900, as this one: https://somlo.com/products/18ct-yellow-gold-hunter-case-minute-repeater-pocket-watch1 point

-

1 point

-

1 point

-

Well as expected my parcel wasn't their this morning so will have to see what the eBay seller has to say.0 points

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)