Leaderboard

Popular Content

Showing content with the highest reputation on 10/06/24 in all areas

-

Just cased up my latest watch - a Longines 12.68ZS from 1953. I'm a big fan of Longines and couldn't resist this one. The dial is gorgeous, and near perfect condition. As expected from Longines, it's running beautifully. The balance even has mean time screws. Most of the watches I buy, I do up and re-sell on ebay to fund the next one. But this one is a definite keeper.6 points

-

The belief that only Chinese clone shock springs and not genuine Incablocs come loose is a myth. I worked on a ladies Omega a few months ago and being a genuine Omega, I was a little cavalier when opening the shock springs. The upper jewel was fine but the spring of the bottom jewel took flight when I swung it open. There was a little gap between the chaton and the main plate and this was how the spring managed to slip out. Had a real hard time getting it back in, as the gap was so small. So now, regardless of whether it's a clone or genuine Incabloc, I always use a pegwood stick to prevent the spring from getting anywhere near the back of the hinge where it may slip out.3 points

-

Hello everyone! This is my first post here on WatchRepairTalk, and I wanted to share a project I've been working on—a DIY Watch Cleaning Machine that I designed and built myself. Since it's difficult to find a good-quality machine at a reasonable price, I decided to use my engineering skills and create one. Why not, right? Look at a demonstration video on my instagram page. You can follow this page if you are interested in my watchmaking journey! Demonstration video of Akrid the Watch Cleaning Machine I named this machine after my alias from the Dutch watch forum, Akrid (which is also my alias here). It features three stations: one for cleaning and two for rinsing. The final cycle is for drying the watch parts, allowing the movement to be reassembled immediately after the cleaning process. I've been using it for two months now, and it's been working flawlessly! The cleaning results are far superior to what I used to get with my ultrasonic cleaner. See the cleaning results here: Cleaning results of Akrid I'd love to hear your thoughts on the design!2 points

-

No, not possible. The gears are not moving during hand setting (with pallet fork installed).2 points

-

actually I think it's only one half of the myth. I'm pretty sure the top spring usually on a real one is not coming out but I've had the exact same experience with a different brand of Swiss watch for the bottom. I'm guessing because it's so much then there in the top maybe they changed something but yes I have had them come out the bottom never have come out the top of the Swiss though. So one half of a myth. That I was trying to remember of the one I had that was a long time ago whether I was able to sneak it in through the bottom or whether had to take the entire setting just can't quite remember2 points

-

4,7mm is a common size and probably yours is that size too. Some new Indian/Chinese punches are 5mm if I remember correctly. Cousins still sell individual punches and they are 4,7mm.2 points

-

2 points

-

Very nice , Oris one of my favourite brands. Here an old 50's tank without the bug or berry , I own 3 more O tanks including a 15 jewel Star Your berry looks very much like a common hawthorn berry, lots in my area of the world.....used as farm land hedgerows, yes they are edible but i wouldn't eat raw..... the seeds are poisonous . 17 jewels and yet they still could not legally jewel the pallets, they did a great job without them Oris.2 points

-

Following on with another Citizen, this example from 1972. I purchased this for the case from Bulgaria. I have a square custom movement and dial that have been waiting for a case for quite a while now, but when it arrived was too good to just swap out. I haven't seen many of these in the uk market. This one has the 5204 movement 25J while the square custom has the 5203 movement 27J. I was assuming the movements were pretty similar so I could use the split stem, but the stems are not the same. The other main difference is that the 5204 also has hacking. I have now got another case from Italy this time, but now I need the correct split stem for the 5203. The stem adapters available from Cousins are not an option, not enough space. Have been wearing this for the last 2 weeks and it has only lost around 30 seconds.2 points

-

A few years back, I used to use those thorns for cleaning jewels and movements, did a great job1 point

-

1) watch running normally 2) watch was stopped by a too tight cannon pinion1 point

-

OK, I am waiting for You to replace again the staff. There are problems with the balance seen from TG pictures, so don't hurry to assemble the movement before rectifying all the balance issues. Take good pictures of the balance hole jewels and cap jewels in the plate and in the cock. Do the free oscillations test to compare oscillations count DU - DD and verticals. All vertical positions must give equal result and no significant difference must be between DU-DD. Make sure the balance rim rotates true and doesn't touch anything (the 2nd wheel, the pallet fork cock)1 point

-

It does have thorns, the pictures do not show it though. It has a troubled life because it has to fight for living space and for light competing with other plants. It had to fight with us as well. We time to time cut it back.. an unpleasant surprise when U walk barefoot summertime and U step on a forgotten branch. I assume it is a revenge.1 point

-

You could make something, the extra base clicks into the frame and the through hole needs to be in direct line with the hole in the anvil. I wouldn't buy anything but the factory made base. Buying the stumps might be a better, i cant say I've ever seen the bases come up for sale separately, I've been looking for a base for my Star tool for years.1 point

-

Hi Hector sorry no never been rich enough to buy an Atmos but there is someone on YouTube that does and if memory serves he even does livestream so questions can be asked during the video , I think it may be this chap. Dell1 point

-

Cousins does sell them individually: https://www.cousinsuk.com/category/staking-set-individual-punches1 point

-

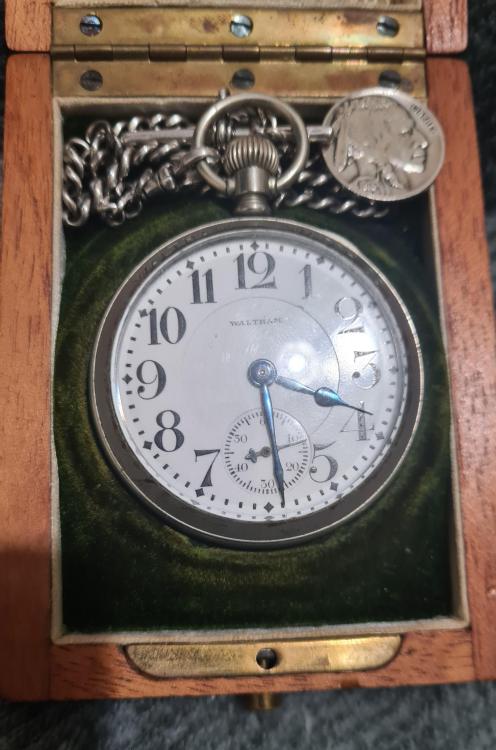

The Wizard did it I got the case back and went to take the movement out of the old case and broke the balance staff, went to 8 jewelers etc, all told me it would be a £300 service, had an old half watch (ww2 waltham) that I bought to try dial luming and put the balance wheel from that and as soon as I slid it into the palet, without even screwing down the balance plate, it started ticking all working now, with balance and case all fine. Gonna get the case plated and re-line the box now. Thanks to everyone for their help and insight. Much appreciated1 point

-

I laughed at your comment because I am a Chemical Engineer and you comments are correct. My chemistry is good compared to the general population but poor compared to a chemist. We basically let you do the chemistry and scale it up.1 point

-

I have a degree in chemistry and words like "naphtha" and "ligroin" would cause us fits in school when we were trying to figure out what they were. We used them in organic chemistry as solvents. Most things in organic chemistry are named so clearly that you would know exactly what atoms were in the compound and often how the atoms were oriented. In any case, it's my understanding that naphtha and ligroin are created by fractional distillation of petroleum. You get molecules with a specific range of carbon atoms in the distillate, and then you desulphur the distillate. The name comes from people who are making industrial fuels and solvents and are chemical engineers and not "chemists" and so the terms are a little more squishy. And historic. That's just the perspective of someone who had to deal with those solvents in chemistry lab. I liked reading through this and wondered how to see if my solvent was too dirty. I don't want to switch it out for every watch, especially since I'm working on broken watches from ebay. Just putting a drop on a mirror is much easier than the optical scattering device I was thinking of building. I really need to find a real watch cleaner though.1 point

-

If the movement is clone then the springs usually do come out without removing the chaton.... so not a genuine swiss incabloc jewel setting . You will find using rodico useful for handling the spring, attach it to a toothpick, pick it up, carry it , place it, i use a fine needle point to click in the tabs of the two sides, after dab the chaton with rodico to pick up any that remains. Another way is to weakly magnetise the spring itself.1 point

-

As suggested use a poly bag over the jewel setting. Genuine incabloc springs are usually contained in the chaton at the hinge. My advice for not losing shock springs is much harsher so i apologise in advance ........get better at removing and replacing them......practice practice practice.....and when you're done practicing.....yes you've guessed it practice some more until you're good enough not to lose them anymore. Rodico on some wood is useful to hold and move the spring, the rodico has some flex and tends to give before the spring gives.1 point

-

Hi use a large poly bag with both ends cut off so you can get your hands in each end Place the watch in the centre and work from both ends, if the clip goes AWOL. It’s captured in the bag.1 point

-

OK, We see 277degr. amplitude, which may be not that real, but is not lo amplitude at all. There are some waves that need investigation. Now we need to see amplitudes in DU, DD and some vertical positions. If all with the balance/bearings/hairspring is OK or not, this will be clearly seen. It may appear that the movement doesn't lose time, but rather stops and starts again in some situations. Such behavior usually is due incorrect pallets adjustment, so escapement functions check is needed.1 point

-

Asking is learning from other people's experience. A good technique to enhance learning , ha. Rgds1 point

-

1 point

-

1 point

-

HI if it’s a Lorus it will have either a Miyota, Hattori movement once open there will be a calibre number on the plate. But as @AndyGSi said photos please.1 point

-

Just a simple check H , some experimentation to see the improvement stone lubrication makes. I use more than one oil/grease depending on the movement, keeping in mind i have an affinity for pin pallet movements.1 point

-

1 point

-

Yes, the lift angle should be 42 on this piece. Check that the regulating pins have a visible gap with the hairspring, between 1/2 to 1 hairspring thickness, and, importantly, that the spring is centered well between them. With no power on the watch, just a little movement of the balance should cause the spring to bounce from one to the other. If the spring wants to stay in contact with one pin, this can cause an increase in rate. But- once the amplitude goes above a certain amount, the spring may begin to come away from the pin. This can cause all sorts of timing issues. If all is well, and you want to reduce the overall rate, the easiest and best solution would be to add a pair of timing washers under opposing balance screws.1 point

-

1 point

-

1971 Bulova Oceanographer 'R'. The friction pinion was rusted to the large driving wheel arbor and after cleaning off the rust it was a little loose, so I tightened it but after assembly the hands didn't move. I stripped it down again, tightened the $#!! out of it, re-cleaned and still had the same issue. I think maybe the rust just ate enough away that tightening wasn't gonna do the trick. A donor part saved the day (along with a NOS dial, crystal and minute hand).1 point

-

1 point

-

Forget all this fandangled stuff, cleaning watch parts is just like cleaning your clothes. Spin them backwards and forwards in good cleaning solutions with some added agitation if required, spin off the excess fluid and hang em out to dry........ah the random shite that us penny-pinchers do to get by .1 point

-

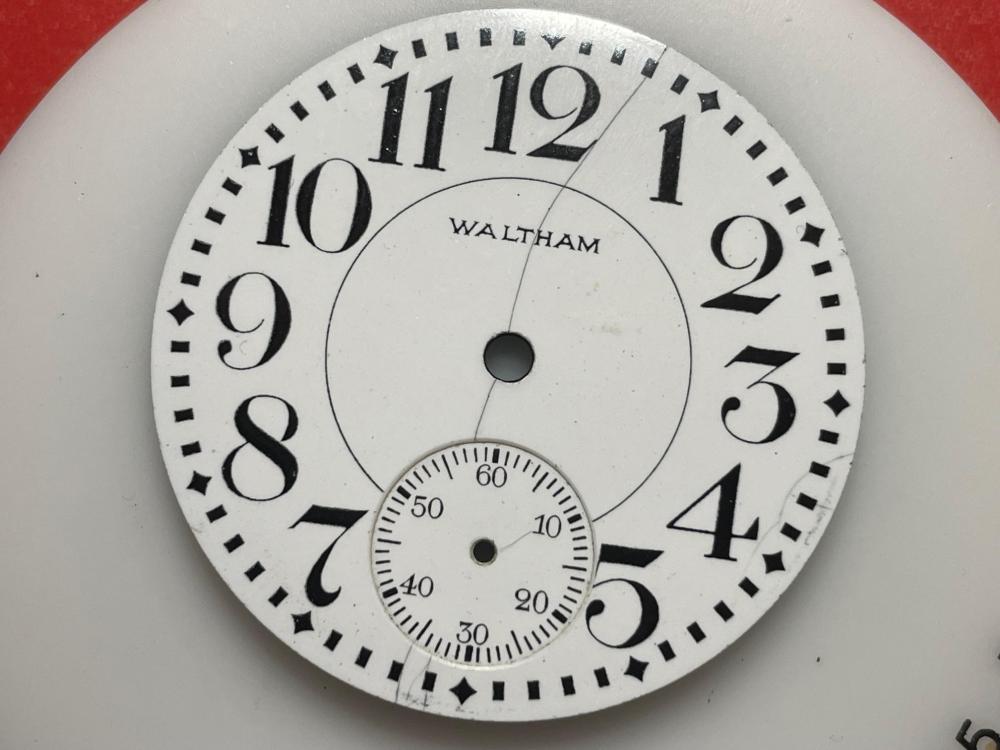

Well, I was not going to buy anything else until I got the existing ones done, but when I was searching for info on someone else's watch, I came across this one at a rather good price..... It's a lever set "Crescent Street" grade, listed as a Railroad type watch. The price was possibly due to the crack in the dial, which is rather obvious! One of the dial feet is missing - possibly someone assumed it had two and tried to pry it without loosening the third, resulting in the dial crack? The movement is generally pretty good, though it has been messed with & one part is missing! The yoke should have a spigoted washer as a cover plate; it just has a semi tightened screw from something in it instead. That part looks to be similar to a cover/retainer disc in the normal crown set movements - but the spigot in the part for those is larger than the hole in the yoke. I found a shouldered screw in a screw assortment that was a perfect fit for the yoke, though that now leaves the yoke spring reliant on friction to hold it in place. Other than that, just mismatched case screws; it looks like someone has had problems with one screw there. I got some Polydent to try and clean the dial, but that had little effect overnight. Then a few drops of bleach - still no effect. Bleach in the ultrasonic cleaner finally got the crus cleared out, then a few rinses & and ultrasonic blast in deionised water to ensure no bleach, and Renaissance wax after drying thoroughly. The result is not quite perfect, but it's no longer an eyesore!1 point

-

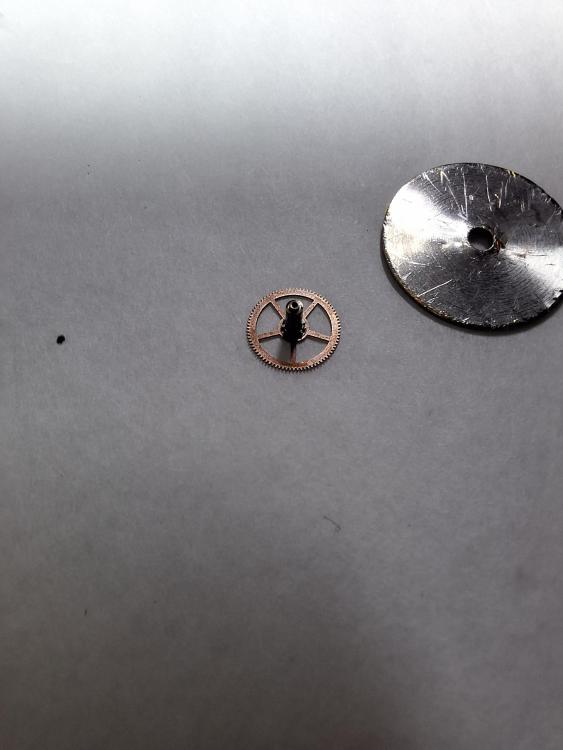

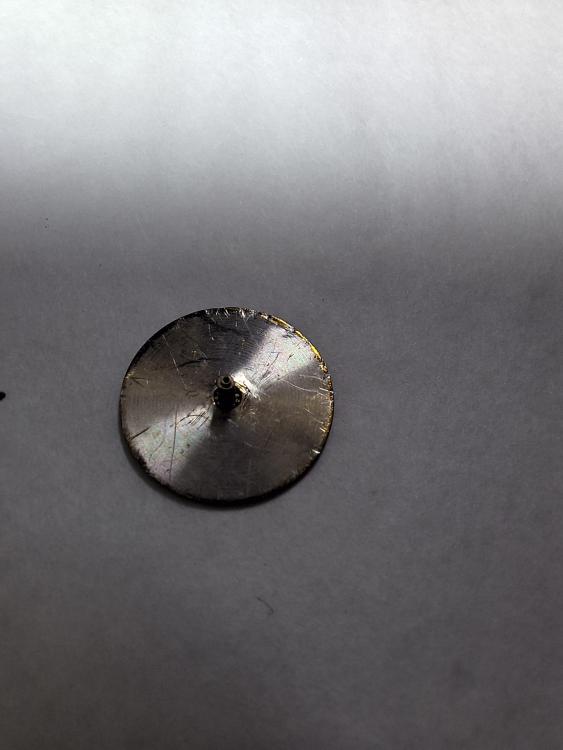

Following up on how to pull apart thr cannon pinion part # 1020-1219. I have discovered that an old mainspring barrel cover will fit perfectly over the cannon pinion and allow for its easy removal. You'll still need a cannon pinion remover, but theres no risk with bending the center wheel. The pics show a new cannon pinion which I pulled apart to lubricate-- too.much friction.1 point