Leaderboard

Popular Content

Showing content with the highest reputation on 10/04/24 in all areas

-

Replacing this BALANCE COMPLETE with a new one is your best bet.3 points

-

2 points

-

You can also get plenty of cheap movements to work on from eBay, as long as you're prepare to work on something other than Omega.2 points

-

Hello everyone! This is my first post here on WatchRepairTalk, and I wanted to share a project I've been working on—a DIY Watch Cleaning Machine that I designed and built myself. Since it's difficult to find a good-quality machine at a reasonable price, I decided to use my engineering skills and create one. Why not, right? Look at a demonstration video on my instagram page. You can follow this page if you are interested in my watchmaking journey! Demonstration video of Akrid the Watch Cleaning Machine I named this machine after my alias from the Dutch watch forum, Akrid (which is also my alias here). It features three stations: one for cleaning and two for rinsing. The final cycle is for drying the watch parts, allowing the movement to be reassembled immediately after the cleaning process. I've been using it for two months now, and it's been working flawlessly! The cleaning results are far superior to what I used to get with my ultrasonic cleaner. See the cleaning results here: Cleaning results of Akrid I'd love to hear your thoughts on the design!1 point

-

1971 Bulova Oceanographer 'R'. The friction pinion was rusted to the large driving wheel arbor and after cleaning off the rust it was a little loose, so I tightened it but after assembly the hands didn't move. I stripped it down again, tightened the $#!! out of it, re-cleaned and still had the same issue. I think maybe the rust just ate enough away that tightening wasn't gonna do the trick. A donor part saved the day (along with a NOS dial, crystal and minute hand).1 point

-

Not seen anyone using a hundredweight as a measure for ever such a long time Rich, thanks for the memory Tom1 point

-

In the professional world I guess you have to ask if an item is to be restored, as this was, or conserved as a museum or serious collector would want. I don’t see an issue with either approach as long as historical pieces are conserved, do what you like to anything else as you see fit. Tom1 point

-

Guys, if we talk about the situation when the watch has stopped with the impulse jewel outside the fork notch in zero position and it is needed to take the balance out and put it back correctly for making the watch work again, then it has nothing to do with the mainspring. The strong mainspring may be provoking the fault more frequently, but if it is able to happen, then it will happen again and again, until the real reason is rectified. And, the real reason is that the guard mechanism of the balance, which consists of the guard roller and the guard pin, for some reason and in some situation, doesn't work.1 point

-

the banking pins are safety feature of the watch adjusting of them for other reasons will probably have other consequences. I don't suppose you remember the mainspring number? Then it would be preferred to replace the mainspring was something slightly lighter rather than modifying the watch to work with your overpowered mainspring. but it would be nice to have the mainspring number so I can know the actual spring to compare what I perceive the watch is supposed to have.1 point

-

Finally got my hands on a non-working Atmos clock. Paid about $600. I have a few stalled projects on my bench at the moment, a Schatz Elexacta clock and a Citizen 8110A. Both projects need some repivoting work but the belt on my lathe keeps breaking. Have any of you guys experienced problem polyurethane belts? The polyurethane just doesn't weld properly. It welded fine when it was new but now the welded part just becomes brittle. Even the spare stock I have in my cupboard seems to have deteriorated. This is my second lot with this problem. They just last about 2 years. I've ordered an old fashioned sewing machine leather belt and nitrile rubber belts. China seems to be on some kind of national holiday week and nobody seems to be working. So my Aliexpress orders are all backed up. I'll probably leave the Atmos until I've cleared my bench of all my half completed projects. Too much on my plate at the moment.1 point

-

How i clean and dry watch parts... cheapy cheap diy fashion, spinning inside a US. Speed controlled CW + CCW... DC motor and mini US machine, a lab stand, some bean tins, a modded make up lid,a bit of door panel plastic and a few nuts and bolts, the wing nut acts as a small impeller...it will when i bend the wings over. How rather very simple of me1 point

-

1 point

-

Yes, it was clear: You are happy. My new one looks like yours. I'm also happy with the new one1 point

-

If it was just a bit of scratching and wear, I would have left the case. But as it was so badly pitted, I would have restored it. It was never meant to look like that. It's like arguing that you should never restore old paintings, just let the lacquer get darker and darker until you can't see anything. I don't know what he was doing with the stripping - I only strip nickel, but the current looked too high. I would have copper plated to help fill the pitting. He looked a bit heavy handed with the dial - but it looked good in the end. I would have stripped the radium with water and buds.1 point

-

My only experience with a monocoque case was with an army issue watch - you're probably right about removal but perhaps they chose the tension ring as it would be less prone to failure and if it did fail they'd replace the watch rather than the part? Anyhow, glad you got it sorted.1 point

-

Haha- yes, soory. Indeed there was a lot of change- I winced at the failed chrome stripping. It was kind of over at that point, then he went on to ‘stabilize’ the dial…ooh! …I will say when I have one that condition I struggle with how much to address and how much to leave…1 point

-

Sorry to disagree but if it is the wrong mainspring and too powerful it can cause overbanking.1 point

-

Hatch things up is a term used for telling porky pies. Don't tell me you don't know what that is.1 point

-

Yes that i how its usually done, once the movement is out then you can access the dial retaining screws, tabs or however it is fixed. The hands can then also be removed safely, try not to lay the movement face down until they've been taken off or you could bend them or scratch the dial if they press up against it. Most of us use hand levers and a thin plastic film cover over the dial and hands to protect it from the levers, i prefer to use paper with a slit in it slipped under the hands, this way the hands can be picked up from the paper without fear of dial damage. But as John suggests begin a new thread regarding your watch as there are a few methods for removing movements that are specific to the case style.1 point

-

I haven't bothered lately to read all the fine print top of the message board. But I was thinking I don't know how to do it or get people to actually read it there should be a thing that says start here if your new and that could explain things like a profile if you're seeking help so we might better help you. Plus just some general procedural things for the newbie. for instance one of our newest newbies has asked a question. No idea of my answer is going to be suitable or not. https://www.watchrepairtalk.com/topic/22751-eta-2898-2-documentation/#comment-2626161 point

-

1 point

-

always best to start a new discussion as I regard each watch as unique. Then which watch the same as in this discussion or some other watch? We always need a little more information but typically not always on wristwatches you can usually remove the stem and of course the back possibly a movement ring and the movement will come out. Typically you would never take the dial and hands off to get a watch out of the case.1 point

-

What you are seeing is usually called overbanking, and it isn't a result of too much power from the mainspring. The pallet fork is jumping to the wrong position mid oscillation, without interaction with the impulse jewel, or the impulse jewel is bypassing the fork somehow, then can't get back. Most likely the guard pin on the pallet fork is bent or missing, or the balance or pallet fork has a bent pivot, or too much end shake. Here's a nice article, with a discussion of the terminology too. https://blog.pocketwatchdatabase.com/2022/08/22/overbanking-in-watches-failure-of-the-safety-action/1 point

-

1 point

-

If the last person to open the watch did that to the hairspring, who knows what else they mangled. I think you will struggle to find just a balance assembly for sale anyway, so a complete donor movement in good working order might be a better solution for you.1 point

-

The original crystal did not have a tension ring. I would think with a tension ring, you could not use a crystal lift to remove the crystal, as you experienced. I think next time, I will use the compressed air trick to remove a crystal from a monocoque case.1 point

-

No, I meant the restoration. Many people think the case and dial should of been left as is.1 point

-

I am a newby with watch maintenance. Could you tell me if it is possible to take the movement out without dissembling the watch hands and dial? Thanks. Bill. *****@*****.tld1 point

-

Hi folks. I was given a non working automatic bulova that was acquired by my partners thrifty uncle for £20 from a charity shop. I foolishly declared that I would fix this watch. A year later and the Watch has been stored beside another two non working bulovas. i realised I would have to start at the beginning and have been gathering tools and Seiko movements to practice on. I do a bit when I have some spare time. Eventually I’ll bring the Bulova back to life and my partners sister will ‘steal ‘it from me1 point

-

I've bought stumps and pushers from Cousins to fill the few spots missing in my Seitz set. Good to have that option.1 point

-

I didn't know this existed either, i filled out my profile on the day i joined , i thought that was enough to entice new recruits to join my superhero group, which currently amounts to 2 individuals......myself and my daughter's Husky...Skye. The costume repair afternoon teas make it worth all the while. I dread to think of what i can now add to the " About Me " section.........give me a day or so to come up with something spectacular. Ahhh H mate...you're just a big softy at heart, we need to meet up and write folk songs together1 point

-

sometimes the English language can be a bit confusing like I'm not sure the meaning of hatch things up? but skipping over that I'm in 100% agreement with this. Typically all I really would care about is skill set and I like to know where people live but I don't need an exact address country is fine. Then yes we get a interesting problem of putting people off or maybe people just don't like to write up profiles about themselves or for that matter even doing introductions what if somebody doesn't do an introduction should they be thrown off the group? I think the last time I needed to do a profile for something somebody else had to write it up for me as I just didn't well it just isn't what I do. Or for instance introductions I don't do that either and never did one for this discussion group. Somehow stumbled across the group obviously I was not looking for help on watch repair. Stumble across the group liked what I saw jumped in and started helping with answering questions. then to be honest I didn't even know this feature existed. Well it will make you unhappy but it only sort of exists? like probably a lot of things on the message board of if people didn't know it existed then well it doesn't exist sort of. Like newbies unaware that maybe they should give a thumbs up if they liked something. Or if this isn't filled out as I just now looked at a variety of profiles including one of the moderators and if you don't fill it out there is not even a blank tab to look at. But over on the left-hand side there is a public profile that somehow can be filled out but don't worry I have done none of the as is not really my thing to do these things oh and thinking about being put off? Where I work were supposedly attempting to hire people on a continuous basis but they never show up. One day with odd timing management stepped out. Yes husband-and-wife they just go out without telling us they're just gone. A person with girlfriend came in and inquired about a job. I suspect they were in the mall and she suggested why don't you try here? So then he inquires about a job and was told management is yes it's embarrassing if we don't know where management has gone to. So typically I don't talk to these people but I asked some questions. Like did you know what a watch was? Yes we have to start at the basics and yes he did he put together his own Seiko watch. That sounds very promising. I asked about repair experience or basically where is he working now he's working in a cell phone store and he's repairing cell phones that sounds even better. Then we have the icing on the cake sales and he worked in the sales department he sounds like a perfect candidate. About that time one half of management returned and briefly talked to him. Then the other half of management came in and this is her standard profile if you come work here now she requested a two paragraph essay on usually it's a variety of subjects probably one of them is tell me about yourself and why you would like to come and join the team. Then notice I'm not mentioning names the other half of management later on asked if we got contact information and the answer was no we did not. Which was sad because this person seems very promising and of course no essay was ever seen. out of curiosity I asked Dave is a teacher at the community college teaching the Rolex watch repair program. So I asked what percentage of students in watch repair have dyslexia? Or what percentage of your students would like to write a two paragraph essay on. Yes in the technological fields you end up with a lot of people with dyslexia in various forms and asking them to write a two paragraph essay on well maybe that explains why we don't hire very many people at all. So yes sometimes writing up essays profiles whatever just isn't what some people do all we really need for the group is some sort of basic at least initially until we get to know people what their skill set is.1 point

-

I managed to get a replacement high dome crystal. Had a bit of trouble getting it in. Then noticed a piece of lint on the dial. Took the crystal back off, removed said lint and got the crystal back on. Had to use my crystal press to make sure that it was fully seated.1 point

-

Sounds good but I don't agree. Giving so much info will put people off and people at times can hatch things up.1 point

-

Yes, balance is pair with the hairspring and replacing the spring only will give working movement, but gaining or loosing time that can't be corrected by the regulator. In the case of loosing time, the spring can be shortened. If the spring is not broken, it still probably can be restored. I mean that people that are able to do it exist. But, most of the watchmakers will not do such thing.1 point

-

Welcome to the forum. What experience have you got with watch repair?1 point

-

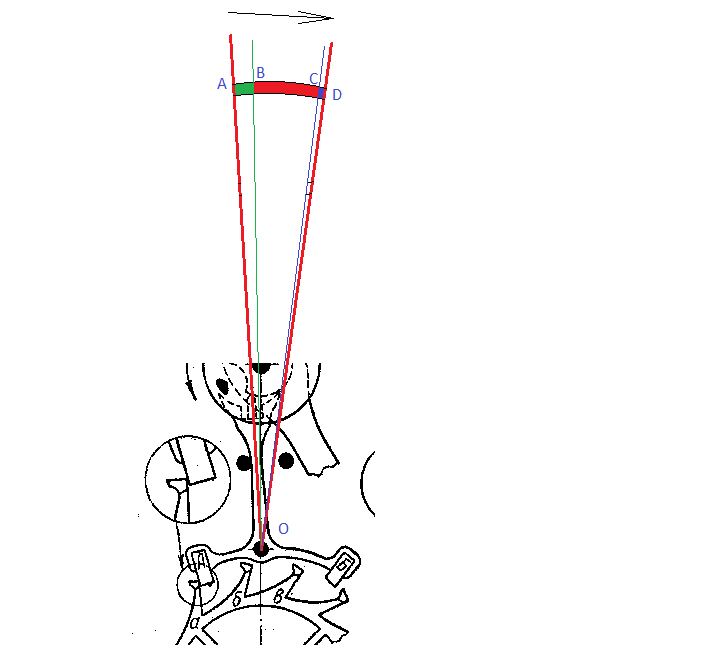

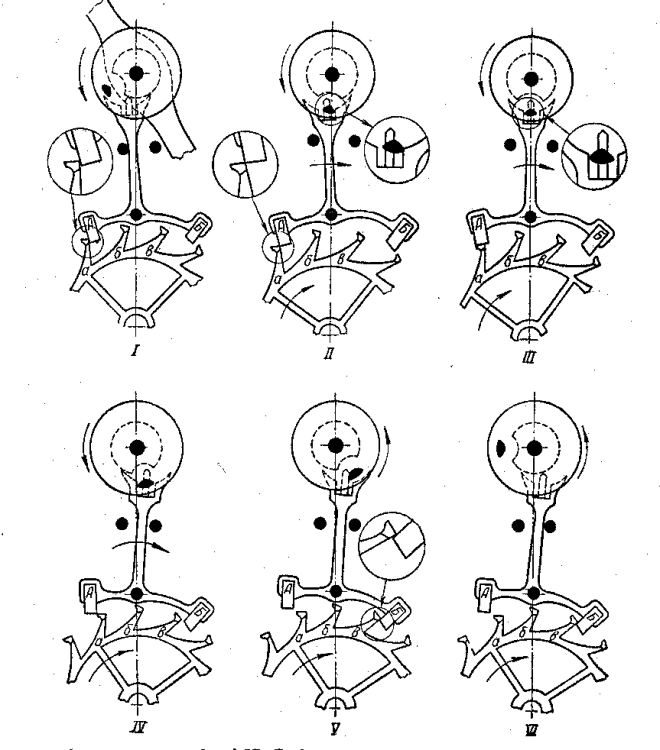

Hi Dmitry, First, a little theory needed here. I will try to present the theory in a little different way, hoping this way is easier to understand it. Look at this drawings: The angle AOD on the first one represents the whole angular movement of pallet fork tail from one banking pin to the other. In the beginning, the tail is in point A, which is shown as "I" on the second drawing. Angle AOB is the rest angle. If moved to the green area, before point B, and then released, the tail will return to A by itself. If the tail is moved past point B to the red area (point B is corresponding to "II" in second drawing) and released, it will snap to the other banking pin by itself. The red area (angle BOC) is impulse angle. The important moment here now is the point C, corresponding to "IV". You will see on "IV" that the tail is not touching the banking pin. This is very important. In the moment when the tail leaves point C and enters the thinny blue area, the tooth "a" leaves the pallet "A" and the tooth "в" falls on pallet "Б" as shown in "V". The movement of the tail from points C to D is RUN TO THE BANKING. Movement C-D and the thinny blue area MUST exist and this is very important. What happens in You case is that 'Run to the banking' in the exit pallet is close to 0. If we look at the second drawing, this is like IV and VI to coincider and in the first drawing - the blue area to not exist. The tail to be already rested on the banking pin, but the tip of the tooth а can't leave the edge of pallet A and there for tooth в can't fall on pallet Б. Of course, this happens only on one or two teeth of the escape wheel, which are higher than the others. And, the drawing is for the entrance pallet, but the problem in You case is with the exit pallet. As I already said, the easiest way to make the watch work is to open a little the banking pin as to allow some healthful 'run to the banking'. I understand that You don't want to bodge with the escapement, but You have to understand that this is what is needed here. What i saw on the last video... See, You show actually nothing helpful. Just endless jerking the brass table of the escape wheel with steel tweezers. This can only hurt the escape wheel teeth, which is something not wanted. The correct and simple way to look for wear of a bearing is to give some force to the wheels repeatedly in forward/reverse direction and see if the pivot moves. Then, the bearing that is actually interesting is not seen in the video, this is the main plate bearing.1 point

-

I concur with Andy, then if it ran close to its nominal power reserve, add a bit of power to the barrel manually ( use wooden tool ), if amplitude improved, we can suspect insuficient torque supply by barrel. Add power to any gear of the train that you have access to, a good test, usually indicates faulty escape between escape teeth and pallets or the escapement. Does it run slow in all positions?1 point

-

Dmitry, the other possible reason is that the bearings of the escape wheel has worn and as a result, the escape wheel has shifted towards the pallet fork - just a little, but enough to cause the problem, effectively the depth of the escapement is increased and run to the banking in exit pallet is missing. Do not search for other reasons, the problem is in escapement.1 point

-

1 point

-

I am not the one to say if You are crazy, but what You describe is common for the movements with indirect driving of minute hand pinion and 7750 is one of them. The simple explanation is that there is a free play between teeth of wheel that drive the pinion and the pinion leaves (the mesh between wheels) and this free play measured by the hand moving is about 30 sec. This is due to the construction of the movement and is fully normal. To avoid what You describe, set the time finally by moving the hand back, not forward. Wat I mean is if You need to set 12:00, then set to 12:01 and carefully turn back to :00, thus the hand will start moving immediately after pushing the crown in.1 point

-

Hi there. Your 7750 may be experiencing an issue with its friction driving mechanism. Mechanical watches have a connection between the balance and train of wheels on the back of the movement to the motion works on the dial side of the movement, in the form of a pinion or wheel that slips like a clutch when setting the hands, but grabs with friction and should not slip when the watch is running. As that part wears, it may lose sufficient friction and that has the effect of the minute and hour hand losing time even though the watch may be running normally otherwise. Sometimes it is extreme, like losing 15-20 minutes suddenly but it can also be just seconds before the minute hand "catches" and begins to turn. The 7750 has a driving wheel that should supply friction (this part in this disassembly video) and it may need to be replaced or tightened. Do you also notice that it feels easier or a little sloppy to set the time than before, like the hand setting moves too freely? In any case, if you've been using this watch for 10 years it is time to have it serviced by a professional watchmaker. When you take it in, make a note that it seems to lose a little time immediately after setting.1 point

-

There is the whole spectrum of YT channels, some are very good down to what I think are complete idiots. If you don't like what you see, move on to an other channel. From nearly every channel you may pick up some interesting information or techniques which do work good for you. There are many ways to skin a cat. There are currently methods and techniques which are touted as "the only holy way", only to find them obsolete in a few years time. The past is littered with those. Also there is no point in worrying about beginners, they have to learn to differentiate between what's good and what's less good, just as we had too. Beginners have to, just like we had to, take their own responsibilities. I'm pretty sure that my all techniques are total crap. The way I skin the cat is a combination of techniques I've learned through the years, picked up from many different sources and guess what; all my watches I've done are still working fine. Who on this planet has the total wisdom anyway ? If I see an interesting channel, I watch, learn, thank them for their efforts and move on once I'm done. To me there is no point in winding myself up about those whom I perceive as well meaning "idiots". Besides, if these people weren't there, how can you compare?1 point

-

Oh my... now you are playing with fire , I never noticed his oiling technique, but I guess I won't be able to not notice it now I am aware of it. Maybe the best strategy is to take the best bits from each youtuber to develop your own style/skills.1 point

-

I would prefer to come across as less competent than I am rather than giving bad advice or incorrect information.1 point

-

Wristwatch Revival kind of got me started and I'll concur Kalle and Alex are my favorites. Watch Repair Tutorials has some of the best videography for some topics and techniques others have difficulty capturing... I'll admit Watcheyes is...unique but I've implemented two or three techniques from the Speed King video I haven't seen others use...1 point

-

The only ones I regularly watch are Chronoglide and Nekkid Watchmaker.1 point

-

The only one I follow is Chronoglide Watchmakers.1 point

-

Elliot clocks are English I have many ranging from time pieces to Chiming all with platform escapements they are very well made clocks from the movement to the cases. The coiled spring on the escape wheel should act as a silent tick, that is if it is working correctly. You need to make sure the balance is in beat, if you stop the balance and you have power on the spring the balance should start up on its own. You need to check the balance and the depth of the contrite wheel making sure the teeth engage correctly. No matter what position the movement is in it should work, if it stops the depth will be wrong.1 point

-

I just picked this and I gave up after a few seconds because he called the leather strap a bracelet.0 points

.thumb.jpg.cb17a66989f1e796fd4217db2e9ca9df.jpg)

.thumb.jpg.19a9c4ff164d78d516aa9f05a063752b.jpg)