Leaderboard

Popular Content

Showing content with the highest reputation on 02/06/23 in all areas

-

This is my first time trying to restore and fix up a mystery watch from ebay. If anybody who's worked on these old 70's seikos wants to follow this thread your wisdom would be appreciated! Picked up this guy for a song on ebay specifically because it's one of the nicest condition ones i've seen with an original dial. THe hands are a little patina'd but the dial seems perfect other than two missing lume pips. I love this dial. THere's no real deep scratches or gouges in the case just a MESS of desk dive scratches that should polish out real easy. It's non running, the date and day roll over with the hands but the day does not roll over if you use the second crown position. The crystal would polish up nicely but there is sadly a small crack at 12 oclock so that will have to be replaced. Opening it up the movement looks pretty good. The balance will move with some pretty strong blows from the bellows but things seemed pretty gummed up and there is what looks like either really old solidified grease or oil or maybe glue under the reduction/ratchet wheel screw. Not sure what is up with that. I'm unsure what is going on with the hairspring as i dont' know what a good one in this movement should look like but it looks a little strange inbetween the stud and the regulator arm. I hope it's not shot but if it is i got a parts movement that does barely run so if i have to scavenge one then hopefully that one works well. The movement looks pretty clean other than some light powder rust. Guess i'll pick up some evaporust unless other people have a better method for de-rusting. Under the caseback is what looks like the signature of a watchmaker and v-9-24-87 Amazing to think this thing hasn't been serviced in almost 40 years. Here's hoping that's all it needs now! I'll be diving into this next weekend probably. Real excited to give this boy some new life as i just love this funky 70's design on it.3 points

-

Hello all you watchmaking peeps, i trust you are happy and in good health. Well I'm back, missed me ? Please don't all sigh at once. Work commitments has kept me busy and my watch repair interest had to take a temporary back seat. But its now time to return to it with a vengeance. Starting with my latest acquisition of vintage tools. Nothing spectacular but some food for thought for beginners on a budget and maybe some interest and a question or two for the more advanced and pros if they would indulge me. So lets start with a source and a figure of cost. My favourite buying site Ebay, this can be a waiting game for the right tool at the right price. Which can payoff if you are like me, I'm never in a rush to buy anything in particular. But always keep an eye out for something i like and might use for when my skill set improves. I never get into a bidding war, i decide what i want to pay long before the auction ends and submit that figure around 6 seconds before the auction ends ( known as sniping, unethical ? As has been discussed before, you have to play the game same as everone else). These are actually two ebay purchases, one at 6 quid and one at 14 quid so including postage came to around 24 as they were the same seller and he combined the postage for me. The majority of the two buys are cutting broaches and files. A lot of large sized broaches probably for clocks and some smaller ones for watches. Some nice part making files, names include stubbs, favourite and one the oldtimers may know Gantoine Glardon. A graver and a few homemade gravers from square files handles i think . Something of particular interest to me is a pivot burnisher with the name David Borlo A. Vallorbe. Also in the bundle is a solid ss one piece case knive, love this as it has a cracking Marvin logo on it. An unusual staking block with v slots at each end. Three agate oil cups that i am keen to replace the plastic ones i have been using, since reading some discussion regarding some plastic components can leach into the oils placed in them. And lastly the quiz tool that has 3 accessories slid onto the handle shaft. Happy reading and any input would be welcomed and appreciated thank you.3 points

-

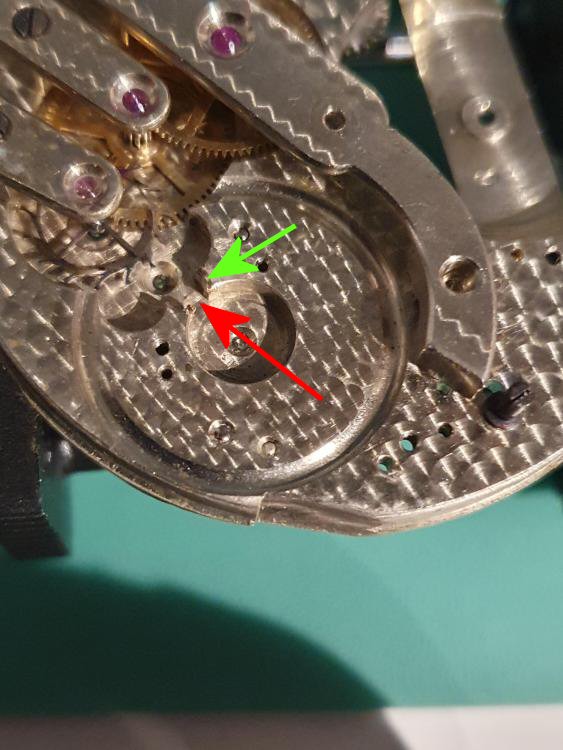

In this case, you don't. On the balance side the regulator arm comes off (two tiny screws) together with the cap jewel disc. This allows you to clean & oil the cap-jewel. That's also the moment you peg the pivot-jewel. Best / safest is to remove the complete balance wheel so you work with the bridge only. The main-plate cap-jewel sits in a disc, which can be removed by undoing 1x tiny screw. Again, clean & peg the pivot jewel, clean & oil the cap-jewel before replacing it.3 points

-

3 points

-

What you want to do is set up a search on eBay for the items you're looking for and yes you can specify a price range and then just wait and watch. Is amazing what will come up sooner or later at really good prices. True nowadays they're few and far between but it's amazing what will come up on eBay sooner or later at a good price you just have to be really really patient then it depends upon where you live in the planet. For instance in the US if you belong to the national Association of watch and clock collectors they have meetings. Their chapters all across the country when they have meetings though the a lot of them will have tools sales or a march for they sell stuff just depends on the chapter. Then blotted chapter's pool their resources and have a regional meeting that definitely has a Mart region by stuff and then once a year this a national meeting which also has a Mart for buying and selling stuff. This is where I picked up most of my tools over the years were the regional meetings before he eBay came in. People and by stuff to get whatever it is they want to then sell the rest it really bargain prices so that's where I picked up my Feintaster. Just can't quite remember the price it seemed really really good at the time though. So yes there are other things in eBay out there the problem is you have to find them. But even eBay if you just keep an eye open and your patient wonderful stuff will show up at a nice price2 points

-

@JohnR725@nickelsilver@VWatchie; the movement is back together and it runs very strong with straight lines. I've done the 180≈185 degrees amplitude test and came to a (to me the lowest I've encountered) lift angle of 36 degrees !! In the list which VWatchie referred to (above), the lowest lift-angle given among all those Omega movements is 38 degrees. Taking an operators error into account, I take over the 38 degrees lift-angle. Fully wound, with a lift angle of 38 degrees, gives me 290 degrees amplitude horizontal and 250 vertical. This corresponds (≈ish) with the slo-mo video on my iPhone. I guess, my initial assumption of a lift-angle of 50 degrees was "slightly" off2 points

-

2 points

-

I'm at it again ! The last month for me has been flogging my guts out at work doing a loft conversion. Now i want to spend all my hard graft earned looty on watch stuff. Since learning watch repair i have mostly hand wound mainsprings ( shock horror ). Yes I know its bad, some say really bad and very wrong ( badwrong / badong (if you want to understand my humour then watch movies like kung-pow ) ). I have winders but they dont always fit, and occasionally seem to want to convert a perfectly good mainspring into a mutant slinky toy while testing my very patient patience .But this afternoon while browsing one of my favourite seller's sites i came across what i think are adjustable mainspring winders made by Star. hmm yes me thinks thats just the sort of thing i would buy. Unusual, practical, versatile and gets the job done, not unlike my good self. So now i eagerly await my lovely postlady bringing me a fresh new toy to break more mainsprings with. I will post them up as soon as they arrive for approval. Are we all excited ? I am .1 point

-

1 point

-

If you were me... I would consider going ahead and spend a reasonable level of money on parts the watch needs. To me, sourcing parts correctly is another skill/knowledge we need to learn in this hobby. It doesn't matter if the parts cost more than the watch in my opinion. Reaching the finish line with a working watch is both the goal and an attitude boost. Chalk the parts cost up to "tuition".1 point

-

I use a bench micrometre; JKA Feintaster. Although, they are going for silly money these days. Five years ago, you could pick them up for less then £100. Now they are triple that! A jewel gauge is useful too, as someone has already said, it's handy to check the pivots 'feels' free in the jewel.1 point

-

Thanks Mark. I have taken up to 15 reams over 30 minutes and when it does fit it slips over. As you say. More delicate touch needed. I'll give in another go. Down to my last sizes set.1 point

-

I measure VERY carefully with a micrometer, or I use some of the spare Incabloc chatons I have - you can look up the hole size, and find one that just fits with a little play.1 point

-

It appears he's using standard silvering powder, and the link looks like standard silvering powder. The silvering powder is a combination of silver nitrate, salt, (or silver chloride, which is what you get when mixing silver nitrate and salt), with cream of tartar and sometimes a little alum. There are many recipes. Having mixed up quite a few, I will say it's far less trouble and with more consistent results to buy the ready made mix like in your link. The finishing powder they list is just cream of tartar. You do have to lacquer the surface or it will tarnish.1 point

-

I don't suppose the pin in the fusee was copper color? Then the fruit of the brass pins in the plate I use a 15 a or something equivalent cutting tweezers. I'm not trying to cut the Pin but you can reach in with cutting type tweezers and grab the Pin as long as you're careful you can usually pull the pin out because otherwise as you found trying to pry it out from the backside is very difficult if not impossible sometimes.1 point

-

Another thing that makes the Seitz gage useful (essential in my mind) is with small pivots it's very easy to form micro flats on the pivot with a regular micrometer that uses a screw. The JKA is different in that it uses a light spring to close, but it's not as accurate as a screw mic. If a jewel is slightly loose you can (usually) close the hole a bit so that it holds, but it doesn't always work. Sometimes you have to ream up to the next outside diameter, if you have a jewel that size. Or you can ream up, or preferably bore in a faceplate, perhaps 0.6mm oversize and make a bushing to take the correct jewel.1 point

-

Are we talking about a plate jewel or some other jewel? Then for plate jewels usually what you do is put it in and check for end shake. If you don't have enough because the jeweling tool has micrometer adjustments you adjusted a hair and push the jewel a little more easily get proper end shake. Then at the link below Is all sorts of interesting things to download. But for this discussion scroll down to the section titled Joseph School of Watch Making. You'll notice there's a section on putting in jewels but rather than just download the section you can download the entire book. Sooner or later you're going to need other information in the book anyway. https://www.mybulova.com/vintage-bulova-catalogs1 point

-

1 point

-

My drawing skills suck but you should bill a see where the stem comes in and you look for the balance wheel jewel because it's unique and then it goes to the pallet fork escape wheel and the fourth wheel which carries the small secondhand. Then what happens with the Chinese watches there will be a whole bunch of variation of plate styles but the gear trains have to follow the same path because they're all meshing together1 point

-

Hello and welcome to the forum, there are several possibilities already mentioned dirt etc. take out the fork and re fit the balance and give it a puff or a light brush to start it moving , should run for a while on its own if free and also check out the spring coils for being stuck together or out of flat.1 point

-

Welcome to the forum. Enjoy. The mistake you have probably made is when you assembled you did not test after ever section is put together.. nothing is more annoying than after final assembly it does not run.1 point

-

1 point

-

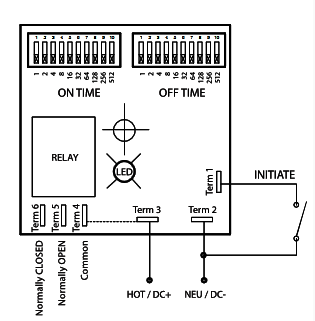

Those cycle timers are available in the same configuration by many different manufactures. They are fairly common for use in machine automation and prototyping. To your second question, are you talking about the plumbers test cap for 3" Pipe? the Janta jar lids do not seal completely, the gaskets are horrible so to prevent evaporation and odors I fitted a plumbers test cap to seal the jars and not use the Janta lids. Just insert the test cap and tighten the wing nut until sealed. Price is about $8.00 US for 1 test cap. Please post your results when you get your Janta modded, best regards Trey, James.1 point

-

Does adding little power ( manually) to the barrel , give you GOOD the amplitude? If not lets see the lock of pallet on escape teeth. Regs1 point

-

One of this forums strengths is its openness and genuine help and advice from experienced and less experienced members. Sometimes it can get a bit heated but not often. Since joining the forum (2014) the membership has grown from approx 2k to over 11.5k so we have things about right. Personally I just found this hobby fascinating and the deeper I went the more tools I needed to tackle all of the tasks. Generally it’s not the tools or lubricants that make the difference it’s the repairers experience and skill.1 point

-

I've found the whole "cheap ultrasonic at home easy peasy cleaning" conversation to be fairly divise and from all the research I've done I've only gotten more and more confused, haha. All I know is this seems to work for me using four easily obtainable ingredients; dish soap, distilled water, shellite (naptha, lighter fluid), and IPA (isopropyl alcohol). Pre-clean the heck out of your parts. Pegwood, soft brush or cotton bud and distilled water or IPA on stubborn gunk. Forget about rust, you can barely remove it let alone reverse it on parts this small. If you don't like the look of a rusty part replace it if you can or take a crack a the whole coke soak thing. If you want your parts to come out with no rust staining or marks you need to remember that you're using a cheap ultrasonic and off the shelf chemicals. Adjust your expectations accordingly. Pro Tip: no IPA near the pallet fork or balance. Warm water 60-70C and dish soap in the ultrasonic for all parts. In baskets in the tank, or baskets in jars, however you like. Like, 5 minutes tops. This is a mild degrease and clean. All parts in a warm distilled (or better yet demineralised) water in the ultrasonic. In jars or in the tank, either way. 5 minutes tops. This is an initial rinse to remove crap from the degrease/clean and remove the dish soap. Otherwise you'll risk making an emulsion from the chemical cleaners in the next step. Soak the balance and pallet fork in shellite/naptha/lighter fluid. I have shellite, so that's what I use. Don't put this in the ultrasonic, just a sealed jar or two. The point here is to displace the water and prevent rusting, and the shellite/naptha/lighter fluid will act to disintegrate any stubborn oils and grease. It doesn't need cavitation to do this, you can give it a swirl for light agitation if you feel like it. Keep a lid on it, awful stuff. Again, only needs to be a couple of minutes. Soak everything except the pallet fork and balance in IPA. Same reasons as above, only it's cheaper and less nasty than shellite. Get as close to 99% pure IPA as you can get so it dries off cleaner. If you're worried about any other jewels or parts unglueing in the IPA, you can leave them out. I'm not your dad, do what you feel like. I then like to quickly air dry those parts, then dunk them in shellite for good luck, then pull them out of there and air dry them. Because I feel like the shellite has less residue than IPA, but eh, I dunno, this is backyard science. Probably just the IPA is fine. Remove everything from everywhere and let it air dry for a second. Turn it all upside down and inside out to remove any and all moisture. You've either pulled it out of IPA or shellite, naptha, whatever, that stuff dries quick but not if there's a lake of it. Put some baking paper in a tray, sprinkle your parts in gently, and put in a fan forced oven on like 50C with the door open for 10-15 minutes or until golden brown. Or put into a food dehydrator if you have one, those apparently work great too. Do a final inspection with at least a loupe and reclean any parts that need it. If your ultrasonic cleaner lasts longer than 4 hours, consult your doctor.1 point

.thumb.png.7d7b7e6e162c1bc4c16e6ab14bd39800.png)