Leaderboard

Popular Content

Showing content with the highest reputation on 10/16/22 in all areas

-

I found a video and is it helpful not really. Usually the center things that are adjustable are for supporting things when you're putting the hands-on. But it would be so much more helpful in a video like this if somebody would put the watch in the holder https://youtu.be/AjtldGQyA9I2 points

-

the specifications for this watch you are not even close. Maximum a 0.8 ms beat error. Amplitude of course is way too low and timekeeping is based on average are variety of positions but I'm sure you timekeeping is off. But is definitely looking better than what you started with. it would also be nice if you time it in more than one position and show us the results. then note regarding the beat? Usually if the amplitude gets superlow everything gets magnified. I would visually check the beat with the power off the watch to make sure it looks like it's grossly out of beat before you try to make any adjustments.2 points

-

These early synchronous motor clocks were not able to start automatically. The start knob had to be given a quick turn to get the motor running, much like vintage cars with a hand crank. Your starter knob seems to be broken. I think it would be safer to use a proper connector on the wires before trying to start up the clock. And check for leakage before touching the metal parts2 points

-

2 points

-

this is the problem of people not having the service guide and not following the procedures. Rolex has all sorts of things you're supposed to be following and doing and most people never seen the guide so most people are not doing whatever it is they're supposed to do. That would also include a lot of people on YouTube as they've never read the manual either. then it's very hard to obtain manuals especially anything new but it typically available from the sellers on eBay in Italy. https://www.ebay.com/itm/195317505692 then I snipped out an image where it talks about the end shake adjustment. Notice when they are doing the adjustment tools are in place. While you can look down through with the jewels missing and get a clue that yours appears to be up way too high you have to do it with the jewels in place. Then even give you precise number your adjusting for know there are no tools for measuring.1 point

-

1 point

-

1 point

-

1 point

-

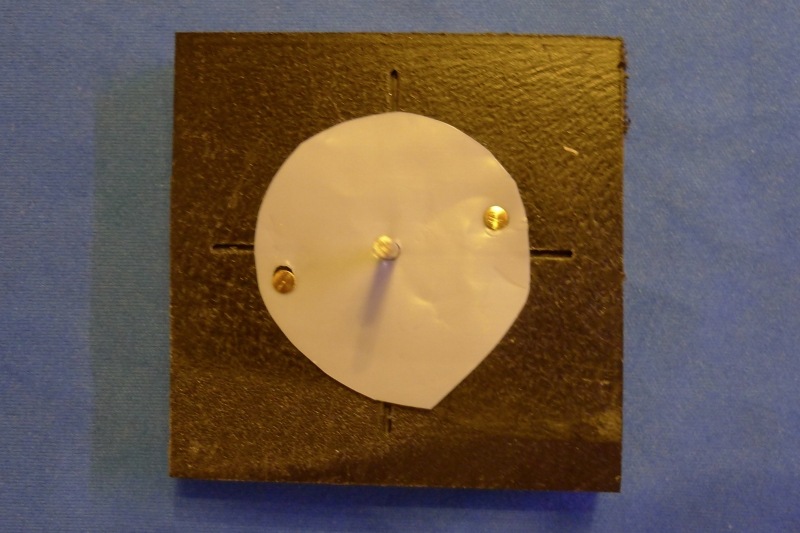

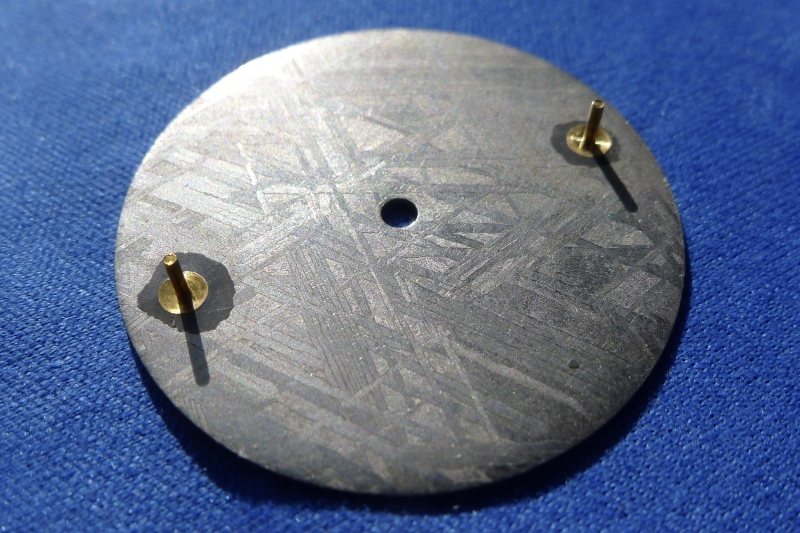

I was allways fascinated by Gems, Minerals and Meteorites. Then there was a Video on Youtube about a Watch with a Meteorite-Dial. I want that too...... luckily i could buy a Meteorite-Dial with 31mm Diameter. But the way the Guy in this Video made it was not acceptable for me, i dont want to glue the Dial to the Movement and he did not use the Screws to fix the Movement to the Holder. So i bought Dial-Feets and glued them to the Dial, for this i made a Fixture to get the exact Position for the Dial-Feets. So far so good, but the Dial was not flush with the Spacer (Werkhaltering) of the Movement and the Heigth of the Stem was not exactly in line with the Case with a Clone of 2824 / ST2130, but it did run.......for two Days. Time to do it again, but better. I had to mill Pockets for the Dial-Feets about 0.14mm deep and glued them again, now they are flush. I used a Clone 2826/ST2100 and the Stem fits now ok. And some Pictures of the Dial, the Fixture (with Teflon Sheet), the Fixture with the Parts to put Pressure to the Dial (for the Glue), the Dial with the Feets and the finished Watch, bottom and Top. I hope you like it Ernst1 point

-

one of my friends learned from his grandfather probably about the time that your father was practicing. We used to bicker over lubrication because he only used three lubricants. Basically a light oil I heavy oil and a grease and that was it. Whereas will skip over how many I have then add a nawcc chapter meeting at his house he talked about his grandfather and show the logbook. Everyone marveled at how inexpensive watch repair was back then. Until I pointed out how long was a service expected for. It is expected one year because the watches were not sealed up like they are today. Then when I got home I took the price for one year put it into one of the websites and converted it to modern dollars made the assumption that if the person was practicing today the watch would go for five years and that inexpensive price was actually considerably more money than it was today. So one year servicing you challenges are less other than to try to actually get the customer back every single year. out of curiosity can I get the exact part number of which one you purchased as there are a few variations then as I have to run out the door at this exact minute but just give is super quick answer the fixodrop/epilam is to keep your lubrication from spreading so you have to use lubricant. You only using him on the reverser wheels because you want the lubrication in the center part not to spread outward to the click parts where they would not work correctly. On the escape wheel and pallet stones is a procedure and you want it definitely lubricate not with 9010 though ideally want to use 9415. And then I think somewhere I did see you can put it on the end stone but are all of this there is a procedure it depends upon exactly which one you have. The procedure comes about because some of them the solvent the stuff is dissolved is extremely volatile and of evaporates too fast doubts the older version it would cause a chilling effect with the possibility of condensation forming. Think of an ice cold glass of water sitting somewhere and it's covered with sweat that's what will happen at your parts are on the parts and there's a possibility of rust forming which is very bad. And then there's the newer safer kind where they can be set aside someplace warm to dry and you don't have to be so aggressive on drawing fast with heat. So I get a chance I'll look up and see what the procedure is but all they epilam is for is to keep the lubrication from spreading you still have to lubricate preferably with cracked lubrication1 point

-

1 point

-

I think i have nothing errrrrmm nope nothing. Welcome to the forum1 point

-

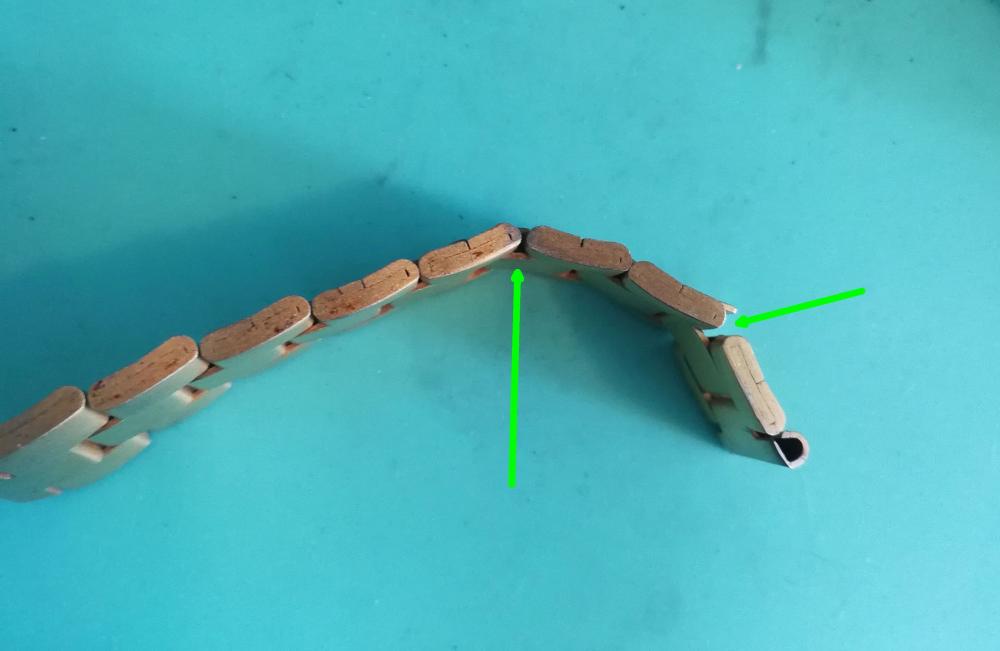

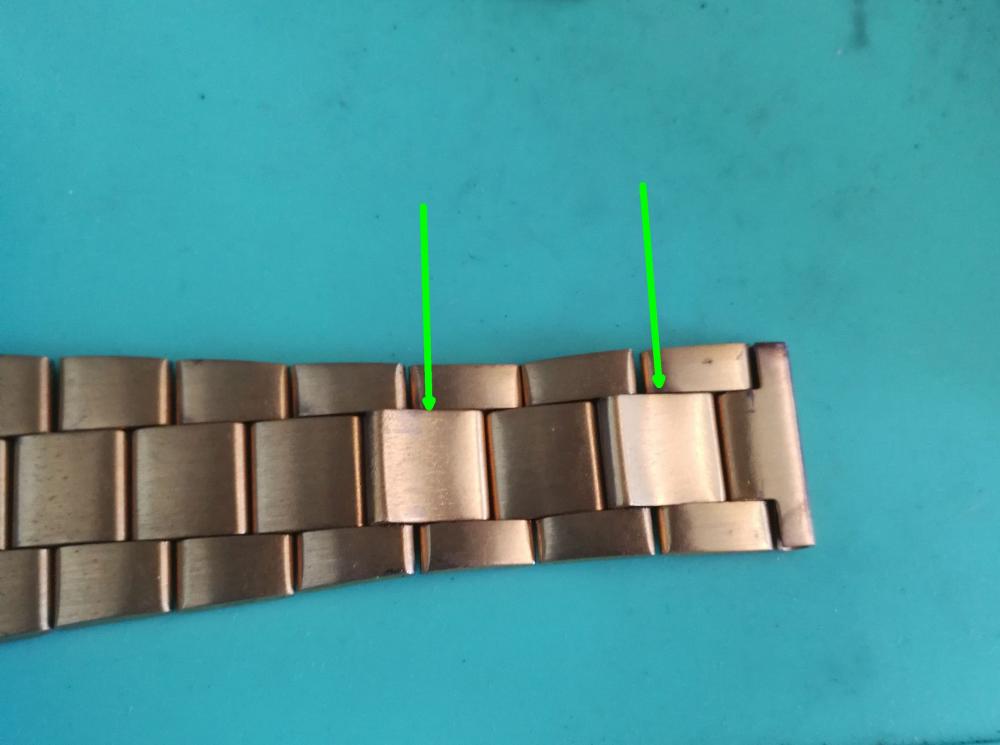

Well, I had no other choice than to go destructive. The links are too tight to put any tool inside to push out the joining pieces. My focus was to do as little damage as possible. The band naturally will only bend backwards a limited amount. Either with my hands, or with one end of the bracelet held in a vise with nylon jaws, I bent the bracelet backwards, which opens up the links on the inside. To the right you can see a link that is fully opened (after prying open; bending backward doesn't open the links this much). With that little gap opened up, I could put a screwdriver in there and carefully open up the links further so that they could be disconnected. This opening of the links creates some reverse bending on the outside, so you don't want to open them up any more than is absolutely necessary. Here, the links are opened and the bracelet can be disassembled. After removing the extra links. I closed the links by first placing the bracelet in the vice (soft nylon jaws!) and using the vice to start closing the links. Then I did the last bit by pushing down with a blunt tool with the bracelet on a soft (silicone) surface. This mostly got rid of the reverse bends on the outside. You can see that the cheap gold plating came off from the distortion of the steel underneath. It was already starting to come off in spots anyway from nearly 50 years of oxidation. I am pleased with the results! I'm not sure yet what I think of the watch! It looks like I might be wearing it as a consequence of court-ordered monitoring!1 point

-

in the timeframe that he operated epilam did exist I think it first came into existence in about 25 roughly give or take. What would happen here is where did he learned watch repair. Did he belonged in a horological associations probably. Did the horological Association ever published anything on epilam did he read the article and did he care. And then it's back to if the technical documentation up until recently other then specialized documents were they specifically covered cleaning lubrication epilam if none of the technical documentation mentions epilam people will happily be servicing a watch is falling to recommendations with no idea that there supposed to be doing this of course the other way around this is like the keyless works is to decide that Greece would be better than super light oil with epilam or you question the sanity of why would anyone use super light oil and not know about the epilam.. In which case you use grease and that's going to work just fine and you don't need to epilam. The other thing that happens is? Okay epilam is used everywhere that 9010 is used at the factory level the balance jewels treated with some process balance staff. Pallet fork jewels and the teeth escape wheel so what happens if you don't and how do you know that you didn't? So which case he can service a watch it can go out and how we do know that you didn't what would be the consequence is it a spectacular consequence an answer is no because what was you would notice right away uunless you have a timing machine that measures amplitude near obsessed with amplitude and you're watching a watch year after year after year you might not see a falloff of performance and even if you did would you blame it on the lack of epilam and the lubrication on the escapement for instance running away. My place that I've ever noticed this on watches IdcService long-term and why don't use 9010 is 9010 on the and stones the balance I've noticed long time just disappears which I was that was strange I thought it was a undesirable characteristic of 9010 which it actually is. So if the end stone was treated with epilam they do not recommend the hole jewel probably because we can apply a super thin coating like the factory does but that's a guess but without the epilam on the end stone the oil would be free to spread with time. sso basically it means the lack of proper technical literature that spells out that you should be doing this than most people probably wouldn't know until relatively modern times when it's started to be mentioned literally everywhere. Bike if you look at a modern eta document it's prominently mentioned on practically every single parts where the older documents was never mentioned at all. That's why he never used it nobody ever told him that bad things would happen to the universe if he's not using it so. It's kind of like the discussion on radium hands if you don't have a Geiger counter is that going to be a problem for you?1 point

-

Hello and welcome to the forum. If you can stop chasing the wife around, read the attached pdf. TZIllustratedGlossary.pdf1 point

-

1 point

-

Thank you all for your reply's. I'm only using the lubricants on personal watches; not doing any commercial work. I wondered about the expiration date because the logic seems flawed. If a watch is to be serviced every 5 years and the lubricant used is set to expire one month after the watch has been serviced then what does that mean for the newly serviced watch (as neverenoughwatch says). "200,000 year old Himalayan salt with a 3 month expiration date". Excellent!1 point

-

1 point