Leaderboard

Popular Content

Showing content with the highest reputation on 07/29/22 in all areas

-

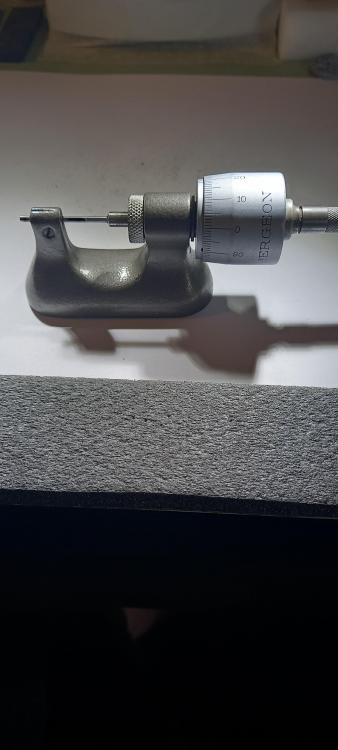

Or as Confucius said, an engineer with one measuring device always knows the correct size and an engineer with two or more measuring devices never knows the correct size4 points

-

I mostly use the 4040 or it's little brother 4039, but I also have some that are phenolic fiber in those sizes and really like them too. For "flippy" movements like chronographs a round full contact holder is best. The round bergeon can be had in any size and adapted, but I often turn them up from Delrin (I make it for a light friction fit) or brass or aluminum which I split and use a screw to tighten. The movement can be fit dial up or down. In the pic bottom left is a commercial chrono holder, the other bottom ones are shop made. Above is one of the phenolic holders and a couple more Delrin shop made and a few of the round metal Bergeons.3 points

-

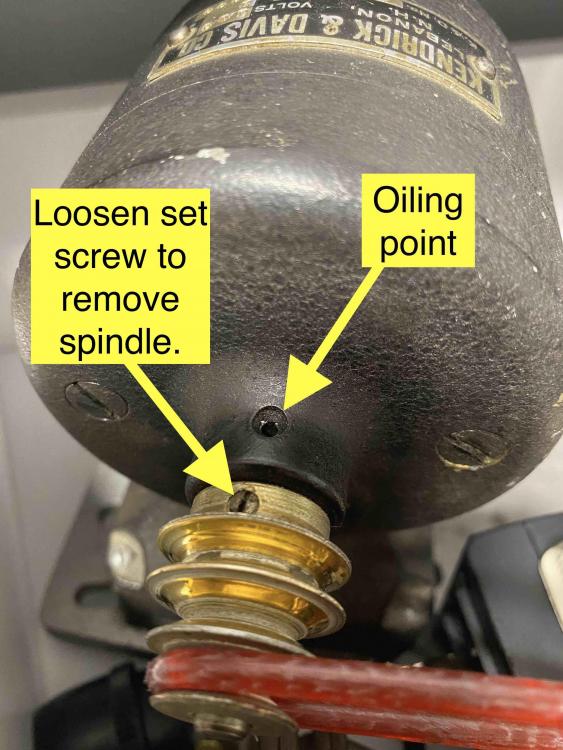

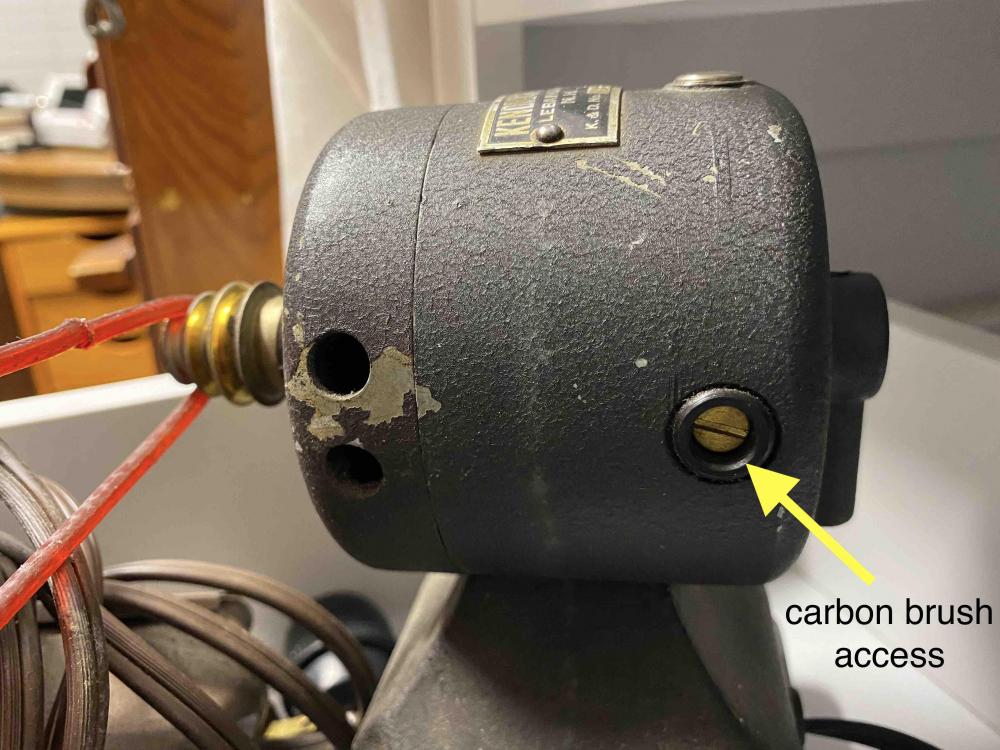

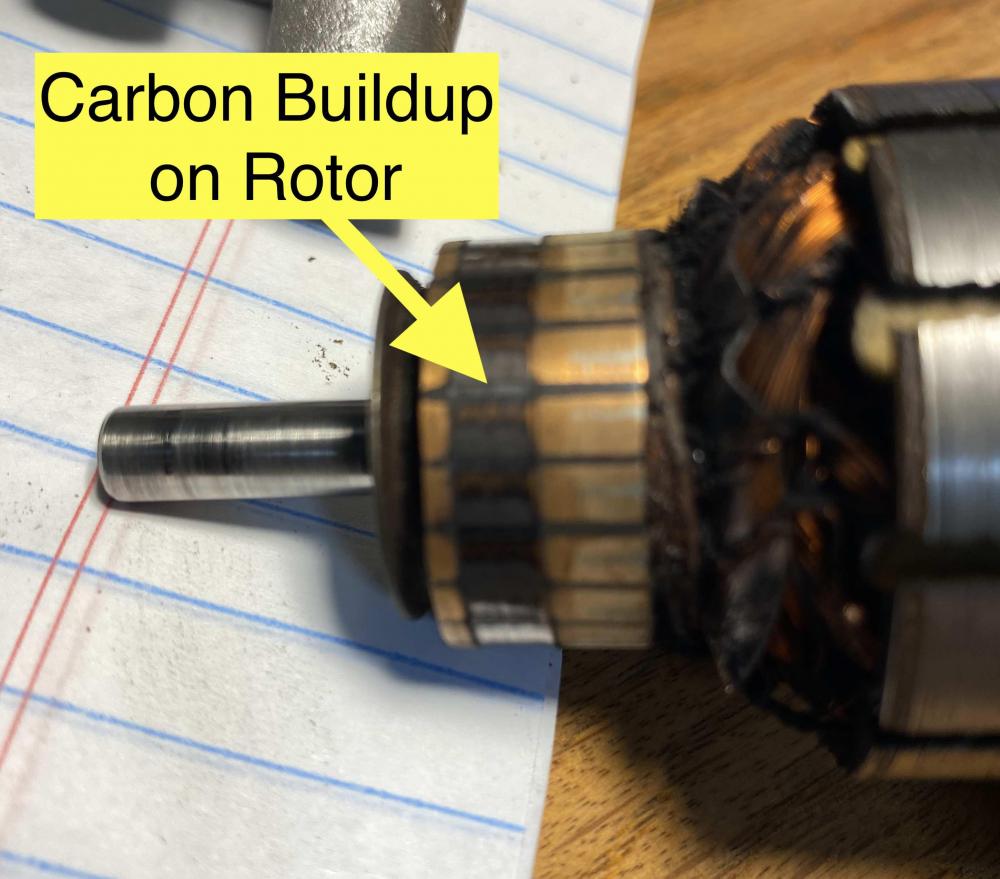

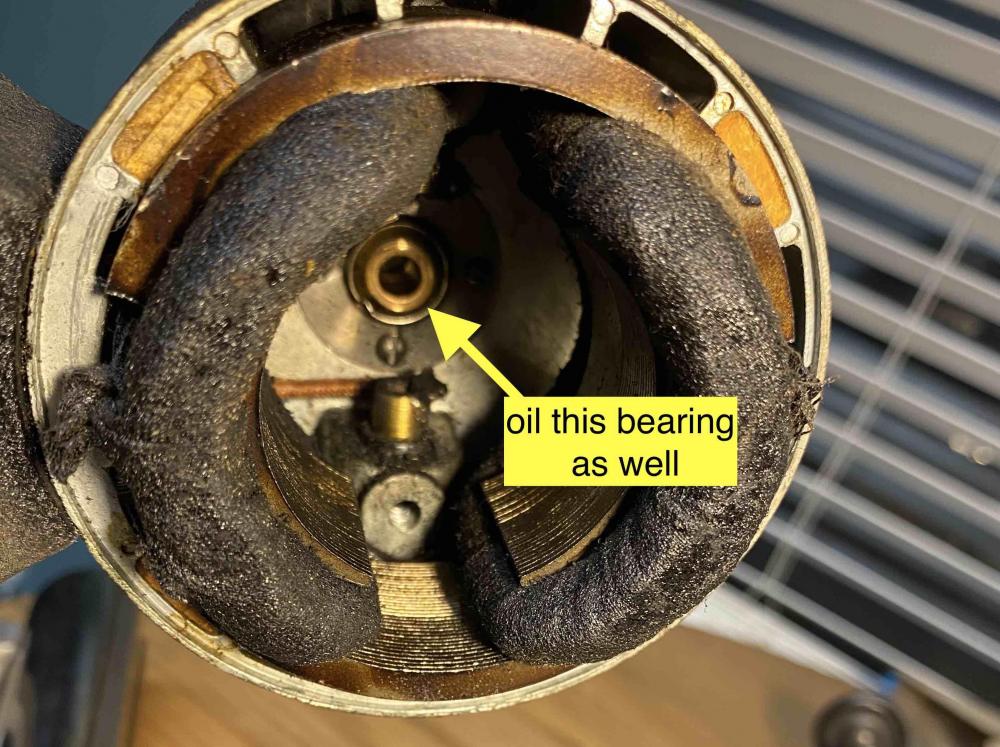

Hi Arron, sorry I am a bit late to the party. I recently serviced a very similar lathe motor for a Boley 8mm watchmakers lathe. The lathe was running not as smooth as it should so I actually serviced both the motor and the foot pedal, and a great watchmaker stripped down and serviced the lathe headstock for me when I was taking an escapement course at AWCI this summer. I am using sewing machine oil to add a couple drops to the felt pads hidden under the oiling holes you had identified earlier. You likely don't need to replace the pads, but do need to remember to oil them several times a year ( once a month) or they willl dry up. I checked the carbon brushes, by removing the two screw covers on either side of the motor. In my case the carbon piece was still fairly long but I had to replace the springs as they were mangled. I also opened the motor housing by removing the spindle attached by a couple of set screws, then the main two big screws that go through the length of the body. Once opened it revealed the carbon buildup on the rotor that needed to be cleaned using a fine emery cloth and extra extra fine steel wool so it was nicely polished brass again (be careful not to wear down the brass on the rotor by going too crazy I greased/oiled the bearing inside the housing and reassembled the motor. Now that the carbon has been cleaned off the rotor, and the carbon brushes are pushing evenly against the rotor (replaced the springs, and positioned the brushes so the worn curved ends match the rotor curve), and oiled, the motor runs very smoothly. Good luck with your lathe! Terry2 points

-

One half of the diashock in that picture is unhooked. It's hard to tell but it looks like the cap stone under it is partially unseated as well. I'm going to finish the dissassembly today and reset it. I wish i could take better pictures but i'm using a crappy camera phone through a cheap plastic jewelers loupe set i got for 8 dollars. Also found another example of this exact watch on ebay for 20 dollars so i ordered it for a new pallet fork. Gotta say, I'm REALLY enjoying this!2 points

-

Not a useful answer, but the truth is, it depends. As mentioned above, I use a variety of collets in my Leinen lathe without issue. A Levin I used to own was the same. The biggest issue is the thread size (considering you have a quality 8mm collet with correct body size, no burrs or dings). I have some Swiss tooling that doesn't like to fit the Leinen drawbar. It does fit other Swiss machinery. Collet wise, pretty much everything has worked except for Lorch. It's been a long time but I seem to remember using some Schaublin collets in the AWT lathe I owned. So the small difference in pitch wasn't an issue. It really depends on how closely the drawbar was made to spec. I would personally not buy Sherline collets; the body diameter is undersize and if I recall correctly they aren't hardened. I'd rather buy used Boley, Leinen, Levin, Derbyshire, or other quality collets taking the chance they may have been abused and don't run true. If they are true, they will remain that way and be reliably accurate until they are abused.1 point

-

1 point

-

1 point

-

Hello and welcome to the forum and a hobby that can empty pockets quite quickly if not controlled. there are plenty of money saving tips to be had but dont skimp on tweezers and screwdrivers buy the best you can afford, french drivers are good as are F*F and Horotec, Dumont tweezers. I use some Vetus tweezers as well and they are not half bad. 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf1 point

-

1 point

-

I was the one that sent this pm. I didn't notice he'd made a thread about it. i guess it was thread worthy after all. The guy in that video DOES seem to really know his stuff, i watch tons of his videos and the way people talk about balance springs you would think of a gnat lands on them your watch is toast. The handling in the video DID look REALLY rough so I was trying to gauge just what one can get away with. that said I'm using Mark's vids as my primary reference and he seems to do the dangle or grab the cock and wheel as a unit depending on the video. I did the sandwich it together as a single unit technique for my first balance spring removal and it went swimmingly. I definitely took my time but i think i'll try and just let it hang next time. So if you let it hang, how do you turn it over to properly rest it on the balance cock with the wheel up? that Seems like it would just cause the balance spring to bend to the side in ways it probably shouldn't with no support for the weight of the balance wheel. I really appreciate all your input and guidance people Can i see this sponge setup? Might give me ideas to jury rig something.1 point

-

For the ones I currently have they are indeed NH35/2824 compatible just remove the ones you don’t need Tom1 point

-

1 point

-

The industry standard is the Bergeon 4040. It's not very expensive, and does an excellent job.1 point

-

Interesting picture I wonder why it never brings good memories for me? Oh wait that's because that's my picture. As I'm the person at work to secure hard to obtain parts it took one year to fix the other watchmakers problem. This is why get excited whenever someone says just rip it out because on some watches the split stem's do not split when you pull the crowd out you can damage the mechanism. Then if you get really creative like the other watchmaker did he tried to tighten the part in the watch and then broke his step. By the way the stem in the watch that comes in a variety of links just to make things more fun. So yes the stem and crown it come together and everything asked to be the right size or it's not going to work.1 point

-

You may know Mike at that point in time but only because she wants you to know. Any other time you are unlikely to have the faintest idea . How long have you been married ?1 point

-

1 point

-

It may be to do with autism and all round Neurofunkiness, but I hate seeing tatty cases and dials. i get it that most folk seem to like the effect of age showing as it adds character and gives a feeling of having had a life, but if its mine, it gets the shiny. Just one of my many quirks, but I like to see it as its was made and intended to be. I understand that sometimes gold is used for more than aesthetic reasons, but its a very lustrous material and I think its lustre should be celebrated and not covered up by years of sweaty fingerprints and sebum. Tarnished or dirty gold just "gies me the wullies". Frankie I've had a Parkside wired one since Moses was a lad. The actual tool is connected to a plug in power supply by a three pronged micro plug, pretty weird set up, but I've had it for years and still works flawlessly. Wifey can always tell when I've been polishing something as the inside of the shed looks like its been roughcasted. One thing I don't like about the von haus is the collets, i'd rather have a jacobs chuck type holder. As far as I'm aware they are readily available. I do have a special birthday on Saturday, so..... One thing that I really do like is the extension cable. It lets you keep everything else out of the way and lets you concentrate on the job in hand. Quite a bit of thought went into that cheap orange lump of very useful plastic. Frankie1 point

-

For hand motor I have a basic level Proxxon that's seen hourly daily use for 16 years, still running strong. Dremel doesn't hold a candle to it (owned those too). The boutique watchmaker Christophe Claret issues each watchmaker in his employ with a Proxxon, they're 10x cheaper than the real hand motors and they just work. A high end hand motor can cost from 1.5k to almost sky the limit. A bench polishing machine is a very different animal and there are plenty of YT vids of serious case restorers showing how they build back up a case with laser or brazing and then bring it back to original shape. Back in the day you'd lean in and get "everything shiny". Now most vintage watch owners opt out of case polishing . But on your own watch, a combination of perhaps filing and abrasive paper finishing with a hand motor polish can look very good.1 point

-

Eyup matey. I use a cheap cordless dremmel type tool by the make name of parkside, supposedly German from a supermarket here in the Uk called Lidl. They also sold a bench mounted jig to hold it so it has the use of hand held and bench mounted. Variable speed and even though it is battery run it does last for hours between charges. It takes different sized collets that hold all manner of accessories, the 25mm felf buffing wheels are perfect for polishing cases. Both the tool and jig came to £20 . Vonhaus gear is ok. I have a big cordless stapler which is great for tacking plywood and a slotting tool for joining worktops also not bad.1 point

-

Looks like mine minus speed control, which I recommend to get. For a little more costly alternative look at Proxxon, which is collets only, that can be boring at times.1 point

-

1 point

-

The Dremel you linked is 300% overpriced. You can buy a no name rotary tool with same or better quality, full accessories, for less than one half. If possible get an accessory to fix it on a small vise (Proxxon has it) or the like, for light polishing it will do almost the same work than a bench one.1 point

-

If you happen to have a UV flashlight, they can help, too. The little buggers will glow when they are hit with UV. Helped me several times.1 point

-

It's rare for a pivot to get damaged with shock protected jewels (though it does happen). More likely on this caliber is the hairspring got shifted and/or possibly bent; it can happen in a way that would give your symptoms, and seem to be relieved with the added balance freedom of loosening the jewel spring. Some pics would help. If you have a phone made in the last 5 years it will probably suffice for this, no need for ultra close-ups at this point.1 point

-

1 point

-

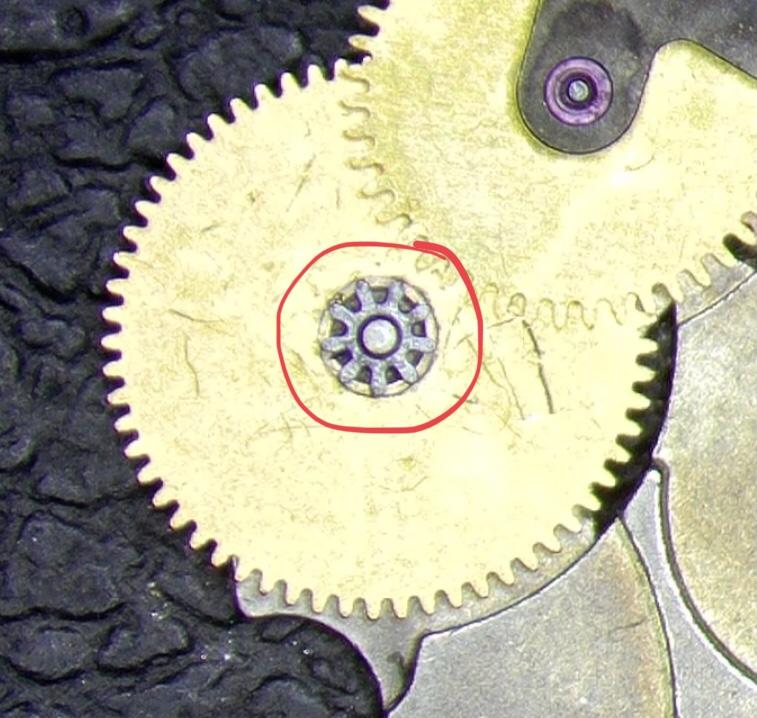

Another watch pulled from my "Dresser Drawer Auction" pile. This one is a "Black Shield", what a killer name! It's a new brand to me, anyone heard of this one? It was already a runner, and a good one at that on the timegrapher, but I was able to get it down to +5 seconds/day and 0.1 ms beat error, so I'll call that a win. It was my first time working on a UTC 29 / Seiko 66 and the Diafix springs on the escape wheel gave me fits. I may have said a bad word or two. Or three. After sending the dial side spring into the ether I learned that you don't need to remove the spring and should leave it in before replacing the capstone, and my dresser drawer coughed up a donor spring and 2nd time went much easier. I'm sure it's not a valuable watch at all but the lessons learned were, so again that's a win. And it has a SS case as well, so all that swearing was worth it1 point

-

Thanks for all your help so far guys, really, I am truly grateful for all your advice, comments and input. I've since refitted all the plate screws. I await delivery of a crystal lift which should arrive next week. I will keep you all updated.1 point

-

1 point

-

Movement comes out thru the front. And as suggested, replace the screw in the plates (apart from the ones around the rim) otherwise the whole thing may come apart! good luck Anilv1 point

-

The movement is probably in need of a total service with cleaning and lubrication since the drive train is in a dead halt. I see you got the stem out and been picking various screws away.. guess if you turn it around and take the crystal away with a crystal lift the movement will pop out through the front with a slight push on the back. Just some theories i have since one can't see the front of the watch.1 point

-

When you finally purchase you watch timing machine you might find the following vid interesting. How to determine what the watch you are working on lift angle is using a timing machine.1 point

-

Well spotted, that was exactly what the problem was A few careful hammer blows and my staking set soon tightened it up enough to now work. Did I mention this movement was cursed. Put the Auto wind bridge back on the movement and confirmed that the autowind will now work started to refit the rotor and suddenly the screw went loose first thought was (dam it) or words to that effect I have broke the screw but no if only it was that simple The screw goes into a threaded collar on the A/W bridge and that had broken off. Fortunately Cousins have them and they are not too expensive. and I will order a new wheel as well just to be safe. Don't think I will ever touch another TAG again. GRRRRRRRRRRR And to cap it all the repair I did to the second hand which popped off its tube when I removed the hands didn't hold so I have got to replace that as well and the only ones I can find are £110 a set GRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRR Did I say I am never going to touch a TAG again0 points

.thumb.jpg.cc3c8ec385b5da900d7dd199e32101a2.jpg)