Leaderboard

Popular Content

Showing content with the highest reputation on 03/09/22 in Posts

-

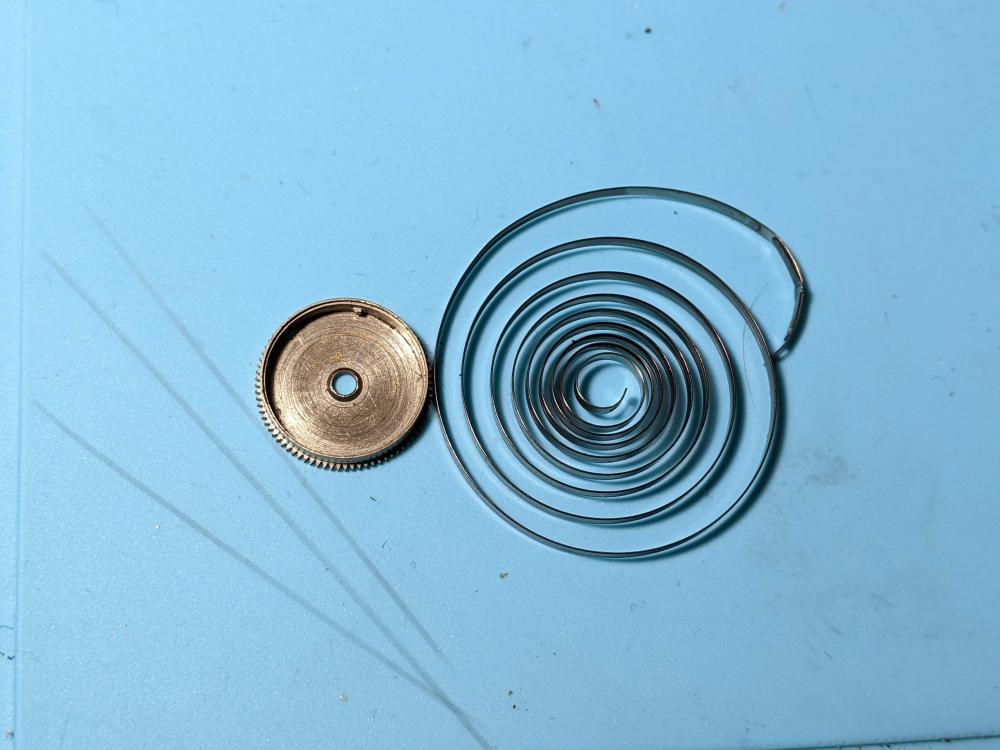

I was on the fence here, to start. Without the spring in front of me, it's a tough thing to really diagnose well. As Nickelsilber stated, in the picture it doesn't *look* too bad. I think it could have expanded a bit larger in the unwound state, judging by its barrel next to it, but it doesn't seem all that tired. Yet, as we all know, how the spring makes the watch *perform* is the important issue, not how it looks. Not knowing what its performance was before makes me want to give my default advice: if you can get an alloy replacement, I'd go for it. An NOS alloy replacement is probably the ideal situation here. Fewer worries for the future, and the performance of the watch will likely improve.2 points

-

Alloy springs are less likely to break, and generally (not always) have a very slight increase in power for the same thickness. If you find an old stock Elgin alloy spring that's great- they pretty much invented the alloy and it's still produced and used for high tech stuff: Elgiloy. To be honest that spring looks ok to me. An old rule of thumb is if it opens up bigger than twice the size of the barrel when taken out it's ok. But an alloy spring will be safer; if a mainspring breaks at full wind it can damage other parts of the gearing.2 points

-

That spring needs to be replaced. If I could imagine myself as a mainspring that is me at the end of each day bloody knackered and ready for bed.2 points

-

I agree with klassiker, even if broken the remainder of the hairspring looks long enough to oscilate to the beat it should specially that its screw balance. The outer coil is easy to streighten. Your android should give us a decent close up of the coil. Even if not successful and it will be another spring you haven't lost anything, but we will learn quite a lot as you try fixing this. Regards2 points

-

Do what John asked and remove the movement from the case, the hands and dial from the movement, and post a good picture of the movement, dial-side. Measure the diameter. The hairspring looks find to me.2 points

-

Pop off the bezel by prying a knife in the gap as mentioned by Hector. The two screws that retain the movement will give you the biggest clue as to how the movement comes out. If they are just two screws braced against the case it is more than likely the watch movement will come out the front. If the two screws hold a little plate which is trapped under a lip in the case then the movement will probably come out the back. There are other methods to retain the movement but observing the screws and what they are doing will help. Eg if the two screws just screw out, you need to ask yourself what good are they if the movement comes out the back? HTH Anilv2 points

-

First the easy questions the questions? Can the balance spring be replaced no. Yes but it's not going to happen so the answer is no. Can you purchase another balance wheel and swap hairsprings definitely not they come together typically. We would have to identify the movement and see if anyone carries old stock parts unlikely for balance complete the third question is more interesting? We need better pictures and a better description? Common practice back then was that they hairspring will stick out beyond Where it is pinned. If the protruding part isn't touching anything it's probably just fine. Then as far as a terminal curve goes a lot of these watches never had A terminal curve. We really need better pictures but it looks like there's not even space for terminal curve. Basically it's really important to ascertain the situation understand exactly what you're looking at for this watch before attempting to fix things otherwise you going to have to fix whatever you thought you were fixing.2 points

-

I'm doing a service on a very pretty 6s Elgin, and I got to taking out the mainspring, and it looks like this: It seems like it uncoiled way too small, although I haven't worked on another 6s, only larger size 12/16/18 pocket watch movements. Does that mean the spring is worn out and needs to be replaced? Edit: here's the whole movement1 point

-

Just bought some old Audemars Piguet technical guides from the 70/80s. I doubt I'll ever work on a genuine AP movement but I like to collect the documentation. Happy to upload if anyone is interested?1 point

-

I still don't see a problem with the hairspring. Can you post a picture of the dial-side?1 point

-

Pallet stones are normally only shellaced on the under side with no issues, there's no need to add more mass to the fork by adding more shellac. This regime shouldn't cause you any issues. There is some debate about u/s baths and shellac although I've never had any issues and a lot of pro-cleaning machines use a u/s stage. There is also some concern about excessive first bath durations as some cleaners can have a less than sympathetic effect on plating. Unless you're dealing with something really stubborn you should be fine with just 5 mins in the L&R111.1 point

-

I love watchmaking books, even if I haven't even read one tenth of the ones I should have. They make you a better repairer, understand the what and why. Practice does not replace the clear, reasoned approach of a Master, which tells you how to avoid ugly mistakes, and do a better job.1 point

-

Gently does it. Work on a large clean area, so if you drop anything, it doesn't fall far. Have your storage compartments open and ready nearby. Undo the screw most of the way, but don' t remove it just yet. Lever the cock off its locating pins. Now you can remove the screw completely. Use your tweezers to pick up the cock. Make sure the tips have a good grip on flat surfaces. Top and bottom is more secure than on the edges. The coil will stretch, but the balance should lift out cleanly. If it sticks or catches on anything, don' t tug. Just rest the cock back on its seat, and gently lift the balance rim until the pivot comes out of the jewel, and the roller jewel is away from the fork. Now you can lift the cock again, and the balance should follow. Put the assembly down gently on a flat clean surface. Have a breather and give yourself a pat on the back. Ideally, you should now flip the whole balance assembly over and seat the pivot into the jewel before storing it. GENTLY pinch the rim of the wheel together with the cock and turn everything over. Keep things low over the work surface and use good light and magnification, and you'll be fine!1 point

-

I picked up a badly scratched and very dirty Seiko quartz chronograph (7T94 0BS0) on Ebay for next to nothing. Idea was to practice stripping down a watch with pushers, to try a few case renovation techniques and have a general fiddle. A had a little bit of an issue with the fact the previous owner had made a dog's dinner of the battery bay (that was attended to). Mucking about - I decided to give it face-lift. A sort of a nod to speedmaster mkii...or not... Anyway....I'm pleased with it... and will wear it... leather strap? James.1 point

-

Hi Looks good, the strap looks as though it belongs with the watch, Chunky. good combo.1 point

-

I am with OH on this one Practical experience guided by books and manuals. No sybstitute for hands on. All the books in the world will tell you how to do it, but YOU have to do it in the end.1 point

-

I've said it many times on here I believe in getting your hands dirty. You can only learn so much from a book or DVD but you will not learn many of the problems that you will be confronted by books or other. It is nothing like sitting down with a repair in front of you and you working it out.1 point

-

I think what you have there is a "front loader". Could you post some photos of the front and side view so we can advise you on how to remove the crystal to get the movement out from the front?1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. We all look forward to your contributions and continued involvement.1 point

-

1 point

-

1 point

-

1 point

-

In my opinion that hairspring has been distorted by someone poking with the watch, which is (and was) actually very common. The reason of the watch not running could have been something else, and from that the supplementary damage by a total incompetent trying to "repair" it You can take it apart and check if, for example, if the mainspring or a balance pivot is broken.1 point

-

I haven't been doing much watch wise, but lots of work on watch tools. I ended up needing to make a bunch of parts for a lever action tailstock for a small Schaublin lathe. I have the factory main casting and quill (the critical parts) but all the auxiliary bits are missing. The lathe is a duplicate so fortunately I had a set of parts to copy from. First is the tailstock drawbar. Toughest part was it’s a 11.75 mm metric buttress thread. For those not familair, look at the collet; the flanks are 45 and 5 degrees vs every other thread that is symetrical. It took longer messing about grinding the tool than cutting the thread, but it worked out well – its for a W12 collets Next up, is the tailstock lever. Not particularly difficult, but man, it was a lot of whittling! Files and die grinder mostly after roughing to shape in the mill. The turned portion I did by measuring the existing one, making grooves every ½” to the right depth, then roughing and finally finishing by hand turning. I stuck the dull end of a 1” boring bar out in front of the work grabbed a large radius nose tool (maybe 1.5” radius, ½” tool bit) in a pair of vise grips and went at it as you would with a graver in a watchmakers lathe. Paint is sprayed via airbrush, with talc in it to reduce the gloss. In the last pic, I have some touch up to do….the quills were slightly different dia so I had to grind a bit out of the inside so it would fit. Its watch tool related, but for a sure little different for this site so thought you might find it interesting....now back to the salt mine!1 point