Leaderboard

Popular Content

Showing content with the highest reputation on 01/07/22 in all areas

-

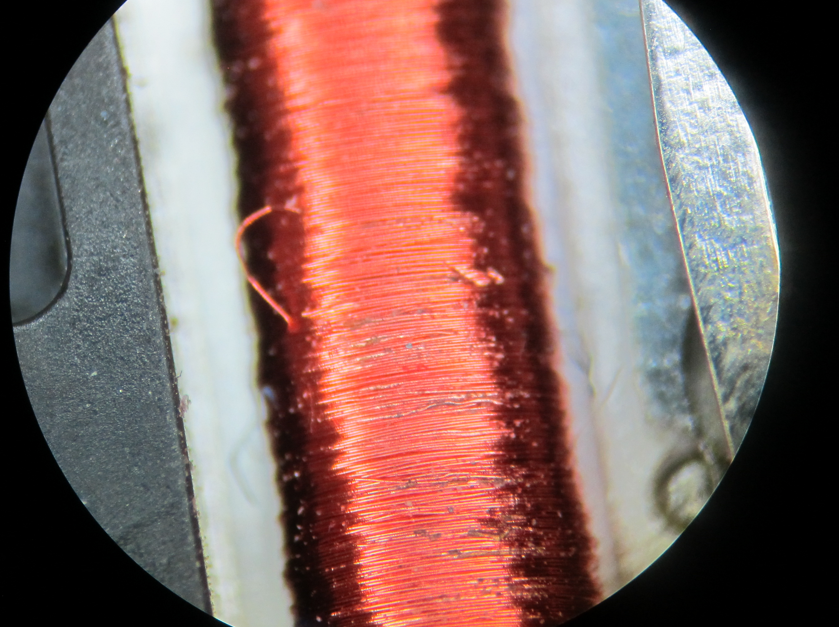

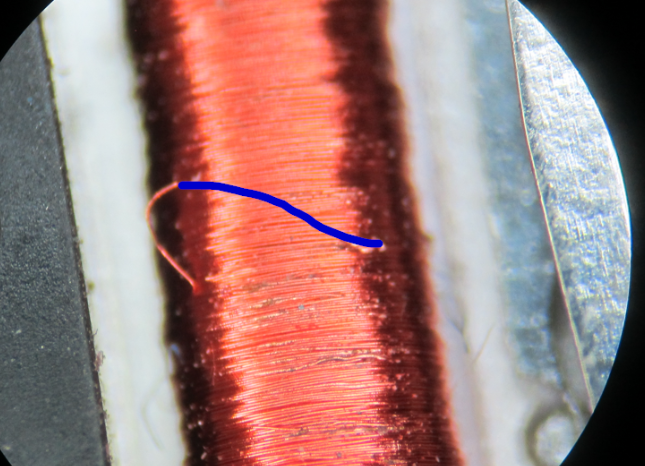

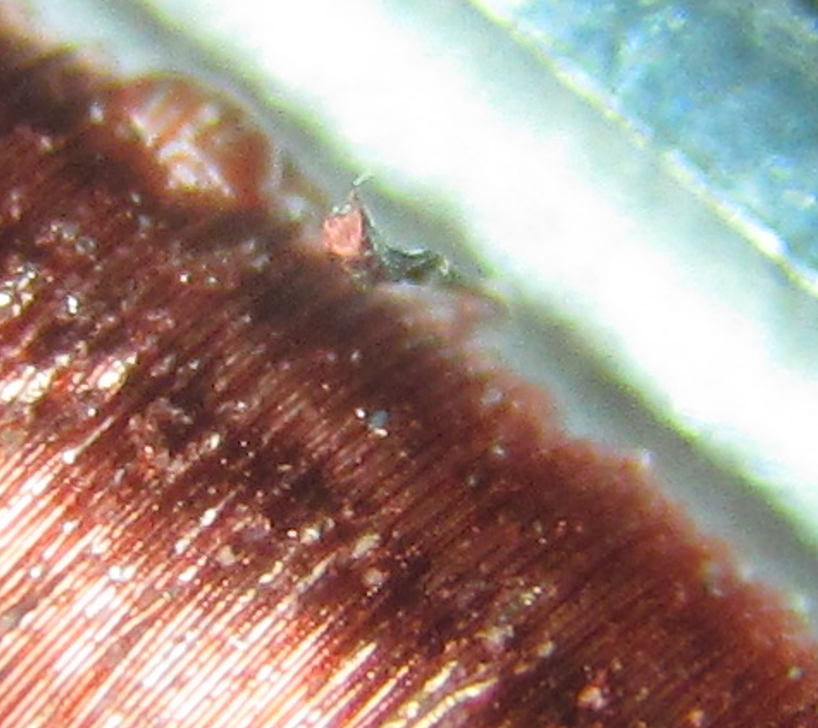

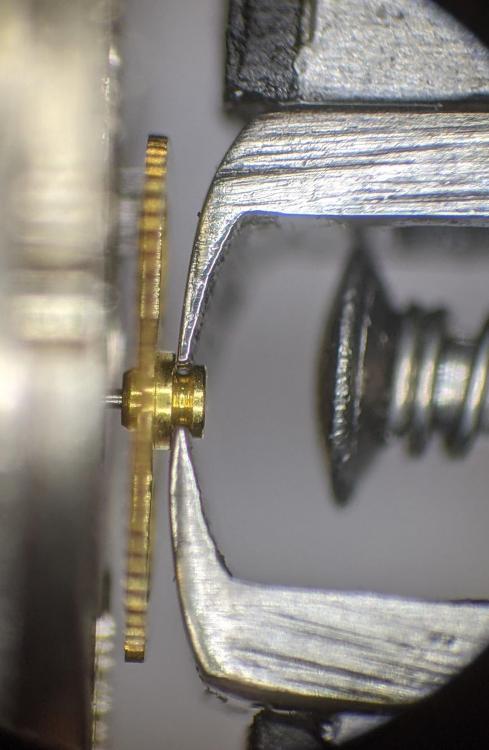

This came to me recently as part of a "Merry Christmas, I will fix your watch for free" box of watches. This thing is "Walmart" class cheap quartz watch, but the guy wanted it fixed to some level. Clearly, past battery replacements took their toll on the watch and damaged the coil. This is a Ronda movement and I would have replaced it outright except I could not find it anywhere. So I decided to apply my uber electrical engineering skills along with my amateur watchmaking abilities. You can see the broken wire in the picture and I have drawn in the desired connection in blue. I unwrapped the coil one turn from both broken ends. Had plenty of material to work with. Then I soldered them together--trick with this fine wire. Not shown in these pictures, is the repair I did to the negative-contact terminal. It was broken due to battery acid. I soldered a 30 gauge wire to the terminal and flattened it out on a bench block with a brass hammer. Not sure where to go with the missing part of the case, but I am going to look around for something. The whole point of this exercise is to learn and improve my skills.2 points

-

In general its worn/dirty balance pivot or jewels of cock/ mainplate or impulse also excessive balance pivot end shake. I check the end shake before taking anything apart. I don't think you are dealing with hairspring intermitent sticking or any part rubbing. Regs2 points

-

Well, this was quite a project!! Must have been many years since it was serviced. I noticed when taking it apart, several wheels were stuck--3rd wheel in particular. After cleaning the usual way (L&R ammonia base fine watch cleaner), I noticed that the jewels had a lot of crud on them. I had to clean them under a microscope using peg wood. It was terrible. Then I noticed some junk on the third wheel bottom pivot. Frankly I wanted to just move on (the owner will were this once in a while at parties--does not have to be a time keeper). But my Dad was whispering in my ear and everyone on this forum was screaming at me!! DO IT RIGHT! So, at great risk (due to my inexperience), I chucked the wheel up in the lathe and burnished the pivot with a pivot polisher (that came with my Jacot set). I cleaned it up and nothing bad happened. Repeated on another wheel with success. No shortcuts on the balance either. I removed the hairspring, cap jewel and regulator. Cleaned and oiled and back together. Assembly was tricky with this tiny watch. The pallet fork plate fought hard. I had earlier noticed little nick marks all over the pallet plate. Now I know why! Got the dial on, set the hands and DAMN!! Cannon pinion was loose. Yet another opportunity to fail. I had bought the cannon pinion punch and stake for my Seitz jeweling tool so now was the time to use it. Two tries before it was tight. Lastly, I regulated the watch and noticed that the hairspring was never leaving the regulator pin, so I had to give it a slight nudge. That seemed to improve the beat considerably--have not tried to think that trough as to whether it makes sense. The watch is together and I am heading for the liquor cabinet!!!2 points

-

Holiday present to myself. I ordered an ETA 2824-2 elabore movement, PVD coated stainless case with sapphire crystals, dial and hands from a watch materials supplier in Switzerland. None of this stuff was cheap, but the seller guarantees that all the parts are Swiss made and I don't have any reason to believe the items are not genuine. The strap is made in China, but I don't believe in spending big money on 'designer' leather straps. So what do you folks think?2 points

-

I apologise, but an error has slipped into the assembly sequence of pictures. For detailed info, please read this post: OneDrive Disassembly pictures here (please sort by name in ascending order) OneDrive Assembly pictures here (please sort by name in ascending order) When I first started out trying to service and repair watches, I took a picture of every step, and I needed those pictures as I didn’t have the knowledge to deduce where the parts should go, how they worked, and how they interacted. Now that I’ve gained some experience, I no longer need all those pictures, but I still need some pictures. For example, it’s very convenient to have pictures of the train of wheels or certain parts of a date complication, and so on. Anyway, I enjoy taking these pictures as I go, and I organise them and keep them on my OneDrive for future use. For this project, servicing my brother’s Atira Plana housing an ETA 2472, I felt it would be fun, interesting, and perhaps even useful not only to take the pictures but to edit the pictures, adding visual and textual instructions. These pictures are made for my personal use and are not intended as a tutorial or to tell other people how to service an ETA 2472. The pictures simply document how I went about it. Nevertheless, I guess others may find my work useful, so I’m happy to share it. There are many ways to service a watch, and I’m still learning. That said, I do follow the practices taught on watchfix.com, and they work very well for me! Here's a post with links to some of my other service walkthroughs on WRT:1 point

-

1 point

-

1 point

-

I have a Bulova that is very very similar. I grabbed the lip with a presto #1. One of the feet hits a flat bit of the bridge, but it took hardly any force to remove it, I think one can just grab it and pull a bit and not use the feet. The Presto #3 doesn't fit like you say. While I've read, "leave the wheel on," I don't think it's possible on my movement. The seconds pinion has a flange on the bottom that hits this indirect 3rd wheel if you try to remove it. So you can't get the seconds pinion out. Which means one would need to remove the main bridge perfectly straight up to not bend the seconds pinion. But one can't do that, not only because that seems too hard to do anyway, but also because the captive 3rd wheel on the underside bridge will interfere with something.1 point

-

Probably something like the Bergeon 30638-3 their 5 spoke wheel remover. Not seen anything cheaper. I know Richard Perrette uses some modified tweezers to lift them off so that might be an option, check his latest YouTube video showing them in use.1 point

-

That cannot possibly be the case. I'm going to assume that you aren't ignoring the cavitation effect of ultrasonic cleaning. The abrupt changes in pressure along surfaces absolutely draws off contaminants and debris. That you are merely referring to the heat. If your ultrasonic doesn't cavitate it doesn't work. The standard test is to drape some light-duty aluminum foil over a stick or something so that it dangles in the water but does not touch the bottom of the pan. If the ultrasonic action doesn't perforate the foil, it's broken. The application of heat, just as when washing dishes with soap and water, both softens greases and other contaminants and increases the energy that the cleaning solution has available to react with contaminants.1 point

-

1 point

-

Maybe you should simply not care about these things and just enjoy the hobby. After I got parallelized I learned that it is not important at all what other people think. It is about what makes you happy and to do the things you want to do. There will always be people that will have the same interests and and help each other out. What the rest thinks o well, they have their lives.1 point

-

I bought a crystal from Esslinger that fit perfectly in my pro diver. Here are the details. Watch Crystal Flat Round Mineral Glass Crystal 3.5mm Thick (MM Size: 33.5) Sku: 201350-33.5 I did a post on the repair:1 point

-

1 point

-

Agree with Nucejoe end shake could be the culprit particularly with a big difference in performance between DU and DD. If no end shake then re clean the upper and lower cap jewels and re lubricate.1 point

-

@jdm is right. It's not a strawberry. Damn. I'm rubbish at this identification thing.1 point

-

1 point

-

As a newbie myself I would highly suggest you get a cheap, but in working order watch to work on before you start on that Omega. taking apart, cleaning and rebuilding the cheap watch and having it run again, or not run again will teach you a huge amount. I have destroyed several cheap watches on this journey with the most simple of mistakes. All that aside, good luck and have fun! Sorry, I don’t have an answer about the mainspring.1 point

-

Nice! That's a sawtooth gravity clock. And did they use an actual bandsaw blade? I've only seen small table top versions. Never anything quite so big. Probably Oldhippy can tell you more.1 point

-

You can put a piece of Scotch tape on the bridge, the translucent one, not the clear one (it sticks just enough but no residue), to protect from scratching with the hammer spring. I put both spring and hammer before the bridge; it almost always stays put (chrono in "run" mode so the hammer isn't on the chrono wheels). I can only remember once in the last few years having one that didn't want to do that. Can't tell what grade it is. Even standard grade tends to hit chronometer level rates, or close to it, even after 30 years of being run without servicing. It's not the prettiest chrono but it's a runner.1 point