Leaderboard

Popular Content

Showing content with the highest reputation on 12/08/21 in all areas

-

hey Thanks guys. It seems to be working fine now after i dropped it on the floor. cheers gary3 points

-

It would definitely dissolve the arbor is at steel. Whether or not you have a pallet fork that's going to be questionable probably another idea needs to be worked out.2 points

-

Hi It is easier with a staking tool but can be done with punches and a staking block, you will need hollow domed punches and hollow flat punches to complete the "rivit" its more than like;y a press fit on to a tapered pinion shaft. Both parts look ok as the pivots are intact. Care needs to be taken on not getting the wheel out of flat and will need checking with its adjacent wheel before re assembly, dont use too nuck pressure when re filling. Keep us informed on your progress. good luck2 points

-

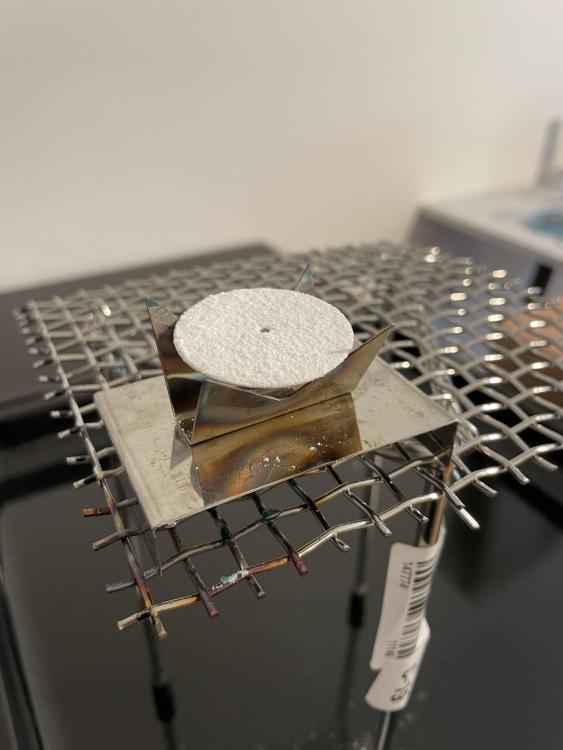

Been restoring another cricket and discovered that the pusher stem seems to be damaged, so I decided to turn a new one. Notice that I made the each end a little longer than the reference piece. I can shave it down if necessary. I made the narrow end on the right a little bit larger in diameter than the sample because I noticed that the pusher button was not seating well (still loose).1 point

-

1 point

-

1 point

-

To work on clocks you will need decent screwdrivers, decent pliers and tweezers. I also have some small BA/Metric spanners a small adjustable and a few others bits gathered over the years such as brushes etc . Initially for cleaning use some hi grade petroleum for primary cleaning dirty clocks, I use some of the PRIORY polishes clock cleaner concentrate dilutes to 7:1 do a 500ml bottle goes a long way preferably use distilled water. Drying is the key. Peg wood for the pivot holes and some Windle's clock oil. With all the above you will manage to clean most clocks. Bushing plates and re pivoting is a long way in the future but read the books watch the videos, when I started with clocks there was only books and I STILL read them. You may want a volt meter for the odd electric job and battery testing but take small steps don't dive in to three train chiming clocks untill you understand the single train and striking clocks (two trains) remember small steps, and don't over complicate things it just fogs the mind all the best1 point

-

If a cheap plexiglass was fitted then it is highly likely it does nor have a tension ring. As Joe says the size is important but after a quick search the Omega hologrammed Crystals are available online for approx £30.1 point

-

I have seen original Omega hologrammed ones for sale on Omega forums. Sternkreuz is a good too. Sizes are in .02mm increments, you should make sure to have the right size for this beauty.1 point

-

In similar situations I have made a well around the screw with Rodico or blue tack to contain the alum solution. If dipping part of the main plate - don't forget the dial screws, like I did !1 point

-

Looks like watchweasol has answered your question. It would help you if you watched a few videos on Youtube to understand which each part plays in the chiming and striking. It would also have been better if the diagram had the parts in order instead of all over the place.1 point

-

It was normal during production to mark parts that had to go together on a given piece, because these had been selected or adjusted to be a perfect fit, giving better performances. In this case the marking is part of the serial number.1 point

-

After assembling few watches from readily available parts of AliExpress it was very natural to want something more of a custom thing. This is a result of my first attempts in making a custom dial and casing and all techniques involved. Original dial stripped down to bare brass, soldered movement posts to match new movement, primed and painted silver then inkjet waterslide decal and finally glossy coating. Movement holder is 3d printed. Seiko VH31 quartz movement pretending to be mechanical ticking at 4Hz. 34mm case used is from and old and broken beyond repair soviet Poljot which itself is a homage to Omega Geneve. And I twisted it further to be a homage of Explorer :)1 point

-

1 point

-

1 point

-

Welcome to the forum Ross. @rossjackson011 point

-

I very much appreciate your opinion watchweasol, and believe I completely agree with you. With a clear head brought about by a new day it’s easier to be objective. I’ve already ordered a flat crystal as well as one with a slight dome to try out. I think this will make the watch much more wearable. After measuring the height of the hand stack I reckon I could fit a flat crystal as well as removing 1.5mm from the bezel height. I think this will transform the watch. As much as it pains me to say it I agree with you regarding the seconds hand too. It just doesn’t suit the watch. I’ve actually found a case for sale in Japan that fits a 6498 and is only 40mm in diameter and 11mm thick. It’s expensive but looks top quality. I’m very tempted to give it a try. As I get older 44mm feels just too large!1 point

-

The hairspring was probably a replacement and was never shaped and trimmed. By trial and error, I was able to get the correct length for the spring and trimmed off half an inch of it. And with another half an inch through the hairspring stud, I managed the get enough space to form the endcurve. The spring moves up and down between the regulator and the 2nd coil of the spring doesn't hit the regulator when it breathes. I cleaned up the case and sprayed silver paint on the sides, top and bottom panels. I also reprinted a new dial on cardboard. Looks good for the moment but I would really like to get the case chrome plated.1 point

-

1 point

-

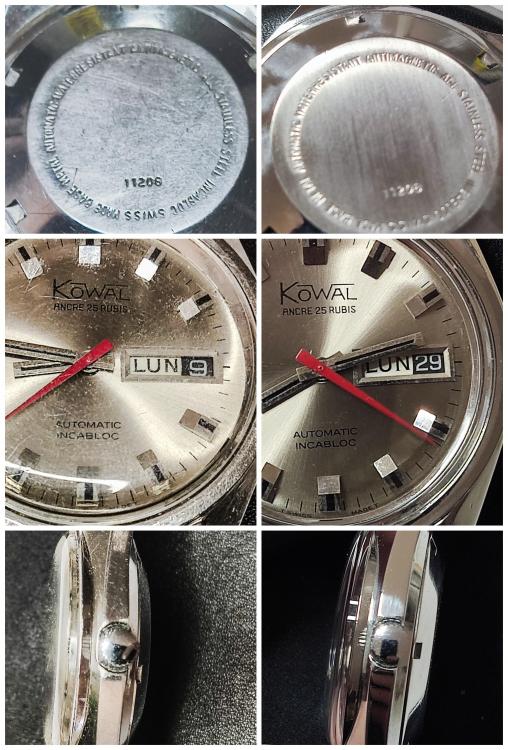

Hey friends. I'm posting this not really to show case, but to say thank you to everyone of you who gave me tips and help to finally achieve this. As I mentioned in my very first post, introducing myself, this summer I purchased 3 of watches in a jumble sale. This is one of those 3 watches, fully serviced and restored with the skills I learnt from Mark's courses and this forum. It is named Kowal Ancre, I think it was a Spanish company that bought the name from a old Swiss company, it mounts an As2066 movement. Noting more to add but some pictures. Again, thanks a lot. @Mark @jdm @Plato @Marc @HectorLooi1 point

-

I serviced this the other day. The really cool thing I discovered is that I found my Dad's mark from servicing it in 1981. I got the watch from my sister-in-law. Her Dad and mine were friends, so it is not too surprising to find that he serviced it. The crystal arrived yesterday: GS DT 305. I think it needs a 306 because it went in too easily. The picture shown of the movement is with the oscillator weight removed. Here is the info on this movement.1 point

-

A tip for when you glue the block back on; glue a piece of paper onto the block and then glue the paper side onto the case. Then leave a note in the case for the next person who repairs the clock. When you put a chisel along the paper glue-line and give a sharp tap the paper will cleave away from the case.1 point

-

1 point

-

1 point

-

I’ve just been told off for spending too much time ‘playing with silly watches’, and not enough time earning a living. Back to the grind stone.....0 points