Leaderboard

Popular Content

Showing content with the highest reputation on 11/20/21 in all areas

-

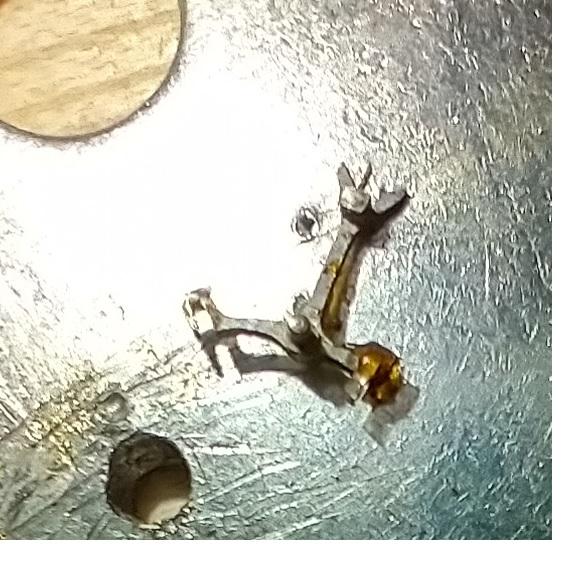

Intro A while back I successfully made my first attempt refitting and adjusting pallet stones using shellac. It was something I had dreaded doing (it seemed difficult) but in the end it wasn’t that difficult at all. Having gathered experience from a few years of handling tiny watch parts using tweezers and having developed some left-hand dexterity as well (I’m right handed) probably helped. Anyway, I thought I’d share the experience with anyone who would be interested and hopefully there’ll be some other WR-talker, now or in the future, who’ll find it useful. If you’re new to this topic you might find this page and this video on the watch repair channel a good start. As I didn't want to risk ruining my Gaston tool I melted and prepared the small pieces of shellac on a chisel tool (my improvisation) that I happened to have in my tool box. However, the chisel tool had a very tough plastic y surface but I was able to burn it away to expose the bare metal with my alcohol lamp before melting and forming small pieces of shellac on it. However, the pieces of shellac needed were much smaller than what they looked like to me in the video. My way of making even smaller pieces was simply to poke the small pieces that I had made with tweezers once they had cooled and were hard. Setting and adjusting the pallet stones was easier than I thought it would be. I didn't realize the fork slots for the stones pinch the pallet stones (Vostok calibre 2414) and actually keep them in place before the shellac is applied. So, I could replace the pallet stones and then check and adjust the locking depth to the escape wheel teeth before applying the shellac. A bit fiddly yes, and you do need to develop some dexterity with tweezers before you try this but not to the point that you break a sweat. Anyway, thank god for my stereo microscope! Anyway, it was my first attempt, and as is common when you try something for the first time, I made a mistake. Despite very consciously applying what I felt was a little too little shellac it still flooded the stones and a large portion of the fork when it melted. Also, I applied too much heat so that the shellac started boiling creating bubbles. So, I decided to start all over. Fortunately, the “industrial isopropanol” (so called on eBay) that I have is very efficient so no problem removing the shellac from the stones and the fork. The second time around I only used a minuscule amount of shellac. Also, I heated the Gaston tool holding the fork in short turns, just so that the shellac would fully melt without staring to boil. Much better! The following is what I would suggest based on my first experience: Basically, follow the video I linked to above. In the video, Mark pokes and scrapes the fork and the stones with tweezers to get rid of old shellac. I tried that, but it wasn’t very efficient. Instead I would let the pallets soak in industrial isopropanol for about 10 minutes and then use a paintbrush to brush them clean. The shellac dissolves completely in the isopropanol and the stones can then be easily removed and further brushed if required. To insert or slide a stone back into the fork slot I found holding the fork by the end of the slot (opposite side of where the pallet stone is inserted) with tweezers (left hand) was giving me the most control. I placed the pivot of the fork (guard pin up, of course) in a small hole in my staking block while inserting/sliding the stones with another pair of tweezers (right hand) into the slots. After having applied the shellac Mark suggests re-heating the shellac to adjust the stones. I was worried that it might result in a mess if I tried it, so I decided to do the adjusting before applying the shellac as shown in this video. The slots for the stones pinch the stones pretty well so if you're careful while you're testing the lock to the escape wheel teeth this method works well and won't dislocate the stones. However, to make sure, double check the positions (depth and angle) of the stones before applying the shellac. Now, the tiny piece of shellac should be placed on the rear section were the stone meets the fork. Mark is clear about this in his video but for some reason it completely passed me by when I made my first attempt. In my second attempt I followed Mark's instruction, but the piece of shellac, being very asymmetrical in shape, was difficult to place in the right spot. However, after warming the pallets to the point that it had only softened the shellac a bit, I discovered, to my surprise, that I could manipulate the shellac into the perfect spot with the tip of my tweezers, without the shellac sticking to the tweezers. Of course, as I've come to realize, every repairer must find his or her own way, but hopefully you'll find my "discoveries" useful. Above is a picture of the result. It's not perfect but still worked very well. The amount of shellac on the entry stone is a bit too little, and there is a < 1 degree tilt on the exit stone (which, of course, can’t be seen in the picture).1 point

-

I've read through Dewey's site pretty much since it went up (including that document), and though I haven't met him I know several folks who have and he's a clearly dedicated and capable watchmaker. But yeah, I don't agree with his views on hairsprings. I think he's referring to what's called the "Q" factor in watch engineering, which is the overall efficiency of the balance, spring, pivots, jewels, oil, and there's a formula for calculating it. Certain watches have a very high (good) Q factor, other's less good. The better the Q, the easier it is to do precision timing and the better results that can be had. A good wristwatch might have a factor of 200, a deck watch perhaps 300 or 400, and a marine chronometer over 600. I think he's got it in his head that you'll never hit the original level, and I know from experience that that is simply not true. I still like looking through his site though! It has a factor Q of at least 300.1 point

-

Basically they're saying is they need two signals and a magical lift angle number and some math and then they come up with amplitude. I snipped out where you take your lift angle and it does all the math that shows you how it's supposed to work out. Always amusing is from the image that is a perfect image of the waveform in real life you get variations for variety reasons and then of course the amplitude is off by a little bit. Or if you get really low amplitudes then the machine will end up and it doesn't really matter whether it's witschi here Chinese Chinese is much more susceptible blow if the amplitude is too low ill pick up the middle sounding part of the waveform and give you a beautiful amplitude that just isn't there. One of the reasons the Chinese may have a problem with their machine is witschi will measure of lower amplitude the window it's looking at as much bigger the Chinese machine. Witschi Training Course.pdf1 point

-

So I picked up the clocks today and then drove home. I get home and on the stairs is a pacage for me from Sydney. Yep, the pocket watch which the tracking said would be here mid next week got here today. Happy bunny and more pics tomorrow in the relevant topics.1 point

-

Shock springs are delicate for sure but only if abused do they distort. In theory they should be opened and closed every 5/6 years.1 point

-

Smaller KIF spring are particularely vulnerable. There is a tool in set of three sizes for safe removal& repalcement of KIF springs. Safer approach is; detach the Oscilator and regulator arm, put the bridge on anvil to proceed with removing the shock spring so in case the pegwood or the tool slips, oscilator isn't there and safe.1 point

-

I don't think what I made here is all that clever. It took me several tries on the lathe to get the right diameter. Once I got the tool to this stage, is was very easy to set the KIF in place. Just speculating here...but maybe wood is better than metal because you get more friction with wood. Dunno.1 point

-

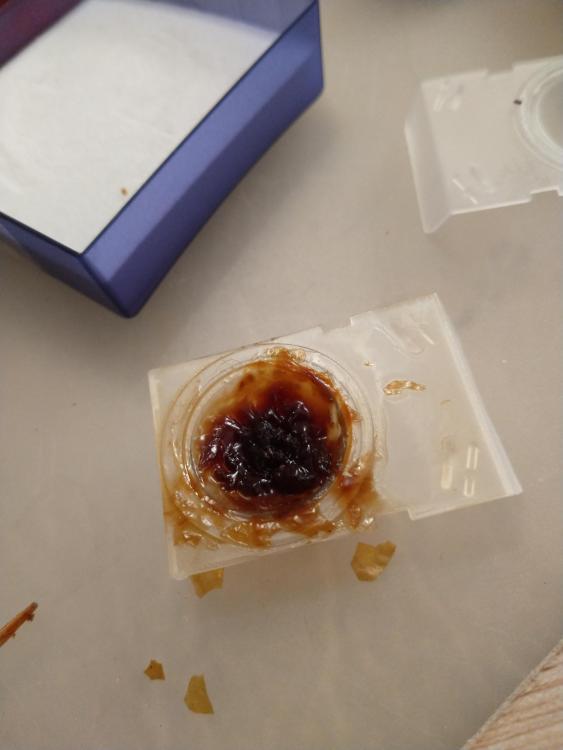

Dear all, I'm a complete beginner, so really just starting out. Having had a bit of luck in taking apart / putting together some pocket watches, I've moved onto something more challenging (ie smaller). The pallet forks on a watch needed new jewels, but having read about the fun people have had with fixing them with shellac did make me wonder what I was doing here. What I've ended up doing is something which I thought others might have opinions on: I've put a load of shellac into a small plastic container (a contact lens holder!) top the container up with isopropyl alcohol microwave it for say ten seconds It reduces the shellac to a paste, which I found useable for several minutes, before it starts to stiffen. With the jewels in place, I placed a small drop of the shellac paste on top where I wanted it. I had no illusions of it being finished at that point - what I did was to heat up a small screwdriver (using the flame of a tealight as the heat source), then apply the hot end of the screwdriver near to the jewel, with the dob of paste on top. When it bubbled a bit, I took it to be enough. Whether that's a fix, I'll find out in a bit! I've attached a few photos: 1) the shelllac paste when it came out of the microwave 2) the paste after a few minutes (you can see how it's set) 3) the pallet fork with the shellac on top. Anyway, if this is useful, hope it helps.1 point

-

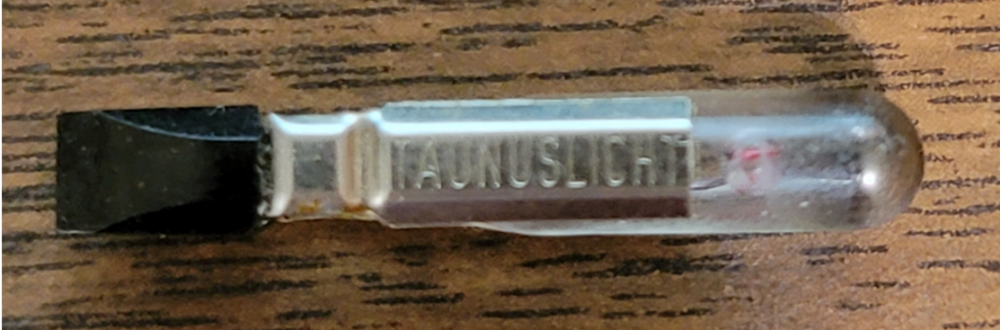

Continuing with my Vibrograf obsession (finally got off of lathes!), I noticed that the pilot lamp was dead. A quick search on the interweb did not yield a replacement, so I just modified the lamp by changing it from an incandescent bulb to an LED bulb while using the same bulb housing. Unsolder the old bulb and solder in the LED+resistor.1 point

-

Dewey has some views I don't really agree with (like it's not possible to vibrate a new hairspring and achieve original performance), but I agree with him on this one- pretty much. If I make a staff and install it, I might check on the poising tool, but even if there's a clear error I don't touch anything until I've checked it on the machine. You can end up doing a dance where you have to undo work static said was necessary after checking dynamic poise. But static poise isn't worthless. He chose a poor example of the high grade Hamilton; I'm certain that balance would check out just fine on a poising tool. I did a staff for a LeCoultre 104 for a colleague, it had something like 100s delta (which isn't unheard of on these- the official timing spec is within 1 minute on a cyclotest machine, haha), he begged me to poise it, which I did on my Levin poising tool. Ended up under 30s delta, which is unheard of on these. This is a caliber that is about 1mm bigger than the LeCoultre 101, smallest in the world. Odd thing on really small delicate calibers, the dynamic poising procedure actually reverses sometimes. Never figured out why, and other truly expert timers have observed the same, with no idea why. On that 104 I might have chased my tail for 2 days dynamic poising, where static poising gave far better than factory results. So I agree with Dewey, except for when I don't.1 point

-

1 point

-

I picked up this little Chinese Standard movement pocket watch for a penny under four quid, as a non runner to use as spares. Sure enough, it wasn't running when it arrived, but once stripped and cleaned it goes just fine. I also assumed that the sub-dials were fake. It turns out that all of the sub-dials work. Sub seconds, 24hr hand and a day night moon/sun complication. Well arguably that is really just a sub second and two ways of displaying the same complication, but for less than four quid I 'aint complaining. It wasn't running when it arrived, but once stripped, cleaned, and lubricated with a slightly higher quality oil than it originally sported, it goes just fine. The exhibition half hunter case still had the plastic protectors attached to both of the crystals, so there isn't a single scratch on them. Its not particularly high quality as you can imagine, but none the less, a quite attractive little novelty item for the collection.1 point

-

Well... That took forever... I have very very bad internet (<.5 mbps on a good day and very unstable to boot), so I don't like to upload photos very often. We're having some work done on the house in preparation for winter, and my wife took the baby away to not be around potentially infectious strangers, so I have the whole half meg to myself! Over the last few months, I've managed to score enough 404 wins that I haven't been able to find a gap when there wasn't something en route since the last photo I posted! I obviously have a type: All stainless, fully jeweled, European movements. I've taken a stab here at a Russian and Indian movement, and will probably try to find a Chinese one just to round it out (I've got Japanese covered already). Being a little picky keeps me from drowning in the things, and hopefully gives me a shot at making a few bucks on these when and if I ever get around to putting some finished ones up for sale! Here's the whole lot since that red jump hour a month or two ago. Ignore the Slava. I thought it was 404, but I stretched for it, and the photo is already uploaded. Everything is flipped, and otherwise in the same orientation. Ditto, now open. HMT. A little corrosion on the ratchet wheel, but otherwise this is the cleanest watch I've come across superficially. Technically, I cheated a little, and won the auction at $9.50, but that included free shipping, so I'm counting it anyway. If this one regulates out OK, I may not mess with it much. If this Clinton cleans up OK, this might be a handsome enough watch to hold onto, at least for a while. I'm a sucker for cushiony cases, and I need something a bit dressier than my daily driver for those occasions. This is an interesting one... "Garuda" is the name on the dial, but it has the Seiko "5" logo. Came out of China, which may explain the pretty obvious trademark infringement. From what I was able to find while no one was outbidding me, the brand used everything from jewelless pin levers up to mid-level Swiss movements. I took a gamble on it as there were no movement photos in the listing, but 21 jewels and an all stainless case seemed promising. That said, the movement is supposed to be 21 Jewels, but it looks like the cap jewel plate is missing so I may have been ripped off for some jewels. It's possible I have another watch somewhere with the same movement that I can salvage from if need be. Also, I can't see the escape wheel, but the balance is real chintzy looking, and it might be a pin lever escapement. The crystal has some interesting faceting as well, but I'm just going to replace it and not really spend any time trying to polish it up or find a matching one. Interesting watch. I think it's the only one of the whole lot that doesn't run at least briefly. Full disclosure, this one is not technically a 404, but the photos are uploaded... I've wanted to fiddle with one of these double mainspring high jewel Russian movements for a while, but I can't stand plated brass cases that every. Russian. Watch. Ever. is cased in. This is an export model, and is either in really good shape, or all stainless. Big modern size too. This one is a Frankenwatch... The case back says it's all stainless, but upon receipt I discovered that the case is actually plated brass. Formerly plated in a number of places as well. Lame... No bid deal though, because 404 and.... This guy has a pretty rough looking movement, but is actually stainless! I might just swap the Canoe movement and dial over, and have a decent enough watch in the end after all. And, because it's 404, no sweat! Last and probably least is this guy. All stainless and fully jeweled, so it's got that going for it. Handsome enough as well. I don't think it runs for more than a few seconds, and I'm not sure what's going on with the movement/dial. The dial is loose and turned a few degrees. It was straight in the listing, but arrived askew. At least it's not glued in place or something. Also, I think the movement is also loose in the case despite the spacer. Probably another frankenwatch, but won't know until I get into it. If the dial feet are broken off, there's not much I'll be able to do immediately. I might have a movement spacer, but it might go into the parts tray. So that's what I've been up to lately. I often only have an hour or two in the evening to screw around, and trolling eBay every few days for 404 fodder is a great way to while away an evening. Almost as great as reviving them!1 point