Leaderboard

Popular Content

Showing content with the highest reputation on 11/06/21 in Posts

-

When I was in high school, I began my pursuit of electronics training. As a sophomore I took a Basic Electronics class and later took two years of vocational radio and TV repair. On day in the basics class, the teacher was out having a smoke and we had a contest: who could hold the two leads of a suicide chord plugged into a variac for the highest voltage. One kid would grab the leads and another would crank the knob. This was absolutely stupid. I am sure we all look back at our teen years and wonder how we survived.3 points

-

One of the underlying problems is the mindset of the watch buying public implying that a watch part made on a Japanese machine in Switzerland is better than a watch part made on a Japanese machine in China, USA, England, Australia, France, Germany or anywhere else in the world that has the machinery. The major watch factories in Switzerland offer a public perception that their watches are made by Swiss watchmakers who, by virtue of birth, are better suited to make quality watches. This is great salesmanship on their part but, in truth, their watches are designed with Cad/Cam software, made with stamping presses, CNC lathes, milling machines and wire EDM machines. Watch factories require designers, engineers, CNC programmers, set up technicitions, tool and die makers, assemblers and polishers. The one thing watch factories have the least need for are watchmakers. The point is, watch parts can be made almost anywhere to precise dimensions and tolerances. There is a video on YouTube showing a technician at the Patek Phillippe factory making a watch pivot on a WW Watchmaker lathe. They want the public to believe that this guy can crank out 65,000 plus watch pivots a year using a graver. This is sales fluff. Watch pivots are made on CNC lathes fed by a huge roll of pivot wire. The pivots are designed by engineers, the CNC machine is programmed by a CNC programmer and the lathe is set up by a CNC set up technician. In the end a watch gear, a lever, stem, pivot or any other part on a watch can be made in Switzerland or outside of Switzerland. If the watch buying public could realize this the Swiss watch factories would choke on their own greed. david2 points

-

Are you turning the screw the right way? Ratchet wheel screws can be left or right handed, and not all manufacturers are considerate enough to mark their left handed screws so that you know which way to turn it. You may have to try some careful experimentation to work it out. On the other hand if you can identify the movement, and maybe post some pics, somebody here may have already worked it out on another watch and can pass that info on.2 points

-

Hmm, OK, I'll get out the Simpson and check again. I guess I'll touch it too? It's only 60 volts... Edit- Simpson is at home, I'm at the shop, touched the frame and ground with one hand and nada, not a whiff of anything shocking. Thanks guys!2 points

-

The easiest way to get the necessary parts for this would be to purchase another practice movement. Fortunately there relatively cheap which is why there used for practice movements. Another minor issue with cloned watches are technically it's not a 6497? Yes I know on eBay were currently I'm looking at the prices Ralph $40 each which is a bargain for what they are and yes it says there 6497's but in real life they are 6497-2. That little bit of a difference at the end of the number changes some of the parts. If you look at the advertisements will tell you the frequency is 21,600 this is a higher frequency version of the 6497. One of the things to try when your new is tried putting the plates on without the wheels and get a feel for that. It would be nice if the plates would fall in place but they don't always. For instance I find sometimes with American pocket watches the plate requires way too much force just because of manufacturing tolerances back then. The problem is if you're trying to force a plate on the chance of breaking Pivots increases. Just try putting the plates on first see how they feel. Then When you get a feel for that then you can start putting the wheels underneath the make it easier to notice if your pushing on something you shouldn't unless it's escape wheel pivot or the pallet fork pivots are really easy to break off and you probably won't even notice at all if you've done it until afterwards.2 points

-

Good you have the old one or through as it has plastic ends its not that old. Just order a replacement of the same length, my preference is for brass ends as the original would be brass but its up to you.2 points

-

Just wanted to introduce myself. My name is John. I live just outside of Boston, Mass, USA. I've owned a Rolex Datejust since the early 90's and never got much more into watches. The watch hasn't been working for about 10 years so it's been sitting in a drawer. I finally decided to send it in for repair which got me thinking about nice watches. I'm now getting into watch repair and have my first project in the works. Hope everyone is well.1 point

-

Hello, My name is Alan Griffiths and I have just discovered this site. As an 83 year old Clockie in West Wales I am not very competent at digital matters. So please accept my apologies if I get things wrong. Today for instance , my lap top collapsed halfway through my first communication. I was taught by my father who was a watch maker and I took up clocking 14/15 years ago and am still learning so any help that you can give me would be appreciated. I have posted a set of questions concerning bushing of large barrels on a grandfather longcase. So far I haven’t worked out how to get any responses but I will in time. Please bear with me. Kind regards. Griff1 point

-

1 point

-

Sounds like you found and fixed the original fault. I don't think we've been allowed to use variacs where I work for donkeys years - no isolation, they're regarded as dangerous! My guess is that you're just picking up noise on your meter. It's picking up induced voltage like a radio antenna... someone will explain it better than me.1 point

-

OH NO! Thou doth besmirch the mighty Simpson 260?? In this case the Simpson which (as I recall) 10k ohms/volt will give a much lower impedance to the leads when measuring a voltage and you will likely not experience what @Platodescribed (essentially you are measuring electrostatic potential). Also use the Simpson to measure the resistance from each lead to case so you dont have to deal with the autoranging meter bouncing about. I trust the digital meter...dont get me wrong.1 point

-

I assume when you're looking for coil continuity you have the resistance range relatively low? Like if you're using a digital meter on the 2K range and the resistance here is really high you're not going to see it. So put the meter on the highest resistance range and see if it detects anything.1 point

-

The clock isn't earthed is it? It's just the two wires going to the stator. Your high impedance meter might just be picking up mains hum. I'm assuming you're on the ac setting on the meter. Connect one end of your meter to earth and the other touching your finger and you'll get a reading even though there's no real voltage.1 point

-

Hello and welcome to the forum, As you are just starting the journey the attached may be of assistance. 1612608791_ToolsfortheHobbyist (2) (1).pdf TZIllustratedGlossary.pdf1 point

-

Hi Not got much on the Helios but have the attached which may be of some use for reference. 1575713002_KDstakingtoolcatalogue.pdf Cross-over-punches.pdf Boley staking tools.pdf1 point

-

Wilst we were all debating the state of the industry Swatch as producing this type of watch that is according to Christian "Total Crap", well stuck in a case that you have to go tho those lengths to open and the some what peculiar design ie Non removal stem, balance non adjustable, use of plastic in escape wheel and pallet,bascically means non serviceable / disposable which to my mind is a waste of materials (not very green credentials there). Plastic case by all means, even plastic parts but make the thing repairable. we are trying to save the planet not bury it under duff Swatch watches.1 point

-

1 point

-

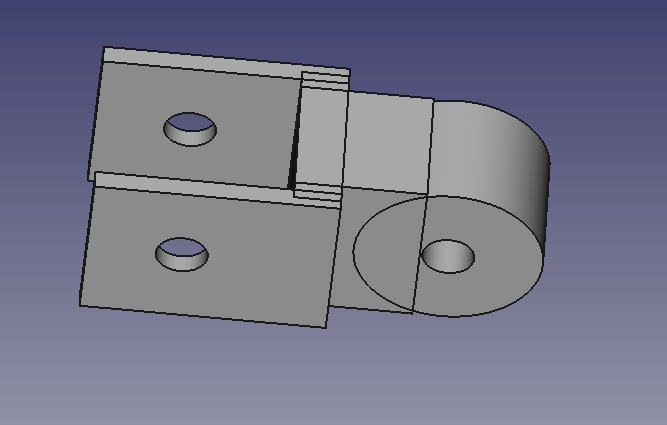

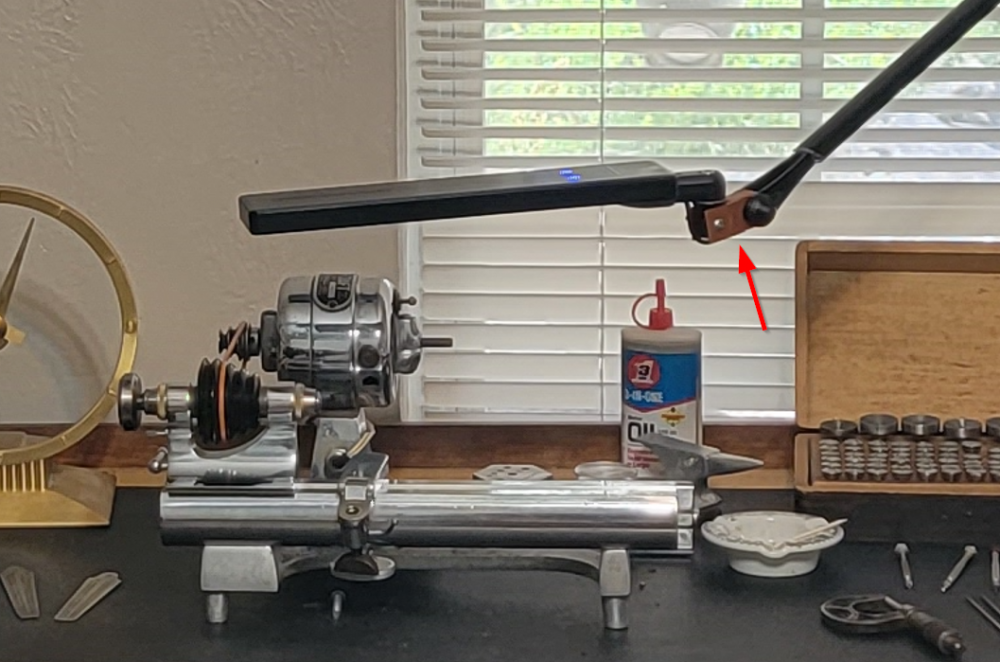

I agree 100% with this? The point I'm trying to make is as somebody's pointed out that CAD is easy and designing things Is easy and making stuff with your 3-D printer is easy. The reason I picked my particular example was you expressed a valid negative opinion of a program that supposed to be simple and easy to use. But things that are supposed to be may not actually be. As We are both trying to point out to the original person asking the question contrary to someone else's opinion that designing stuff with a computer may not be as easy as it appears. Thinking about friendly to use programs what about this one? https://studio.blender.org/training/3d-printing/ Notice it's description it's been around since 2002 so they should know what they're doing. Notice how it's description makes it sound really wonderful we should all be using it because it sounds wonderful. But I vaguely recall from my own personal experience I really thought the program sucked. It definitely does not function the way my brain does but it doesn't a nice description of how wonderful and friendly it is to use Maybe a better way for somebody get in the 3-D printing if they want to make their own stuff is find a CAD program you like. I'd recommend trying the free programs see if you find any alike. Then yes there are places out there that will make your stuff for you see a lot even need a 3-D printer. Haven't looked at their prices in a very long time though and of course it depends on where in the planet you live. But the simplistic of this paragraph is get some software try it out there knows maybe it really isn't that hard to do. But at least if you're trying free software all your spending is your time you're not buying a printer discuss sit around doing nothing. Then this video isn't exactly right for the discussion but? There is some good ideas in here learn how to make sketches on paper before you even go to the CAD. Pay attention like when he talks about the stuff he is designed he might take a whole week doing it. So if you think getting a 3-D printer is going to make you a quick tool the first time Your not paying attention to the video. But a lot of this does apply to watch repair like modify existing tools. Or adapting other tools. Which strangely enough watchmakers a been doing for a very long time. As proof of that find anyone that's been In watch repair For a long time and start looking at their tools you'll find all kinds of weird strange tools probably acquired from another watchmaker that you have zero idea why it exists, Okay maybe that's not the best example? I did notice the time watchmakers do tend to accumulate all sorts of strange and wonderful tools that hopefully they had a purpose at one time even if it appears to be a total mystery as to why it exists now in their accumulations. Because somebody acquired another tool and used in watch repair. So you don'talways have to make a new tool just find one to do whatever you need to do. https://youtu.be/a6clcMGufUo1 point

-

Hi old Hippy, long time off the forum for me, interesting view you have there, I use the bergeon graded bushes along with the bushing tool and reamers and have not had one problem. As for the OP, I’ve used those bushes on the great wheel on a Haller movement the other day, and I friction fitted them but also soldered on the inside of the great wheel ( barrel ). Obviously I never solder bushes into a plate though. You can see my work on my Instagram account where I’m logging my record of work but also my journey through the BHI DLC , “white_time_horology” is the page to search for1 point

-

OK, lets call it a tie! I have a Ph.D. in EE. I am not crowing about it, but to say that one of the most important things I got out of my studies was to not be afraid to tackle the unknown. I had my son, my one and only child, the year I earned my doctorate and I determined to instill in him the same fearlessness when it comes to discovery. Anyway...3D printers are fun. Routers are fun...screwplates are fun...lathes are fun. I love it all!!!!!! I hope I dont run out of years!1 point

-

1 point

-

Looks like 758 this is the movement number. 4 11 is the length in French inches The date is 1888 2.5 oz is the most popular weight. So I would go for that.1 point

-

Dials are made from small sheets (50mm x50mm) of sterling silver purchased from cousins. I use 0.3mm thickness so I can add paint etc without it becoming to thick. Dials are marked out and cut with a jewellers saw. I use sterling silver because it’s quite soft so I can dome it slightly if I want. I also create negative relief dials and silver is the right colour for a lot of my designs. After this I attach dial feet appropriate to the movement I’ll be using. All dial designs are created in Inkscape. I then decide how I will recreate this for the watch. The first watch I posted (I jokingly call it ‘decotime’) is a negative relief dial, so I print it onto water slide decal paper, and apply this to the silver dial. The decal is then protected with numerous coats of acrylic lacquer, which is flatted and polished after it’s fully cured.1 point

-

Yes possibly screwing down or pressing the main bridge with the escape wheel upper pivot not in the hole, hence breaking it. Watches have very little tolerance to mistakes. Proceed with extreme caution, do not ever force anything or make assumptions without verifying well first. The bridge must fall in place almost by itself, and even before it does, just touching any of the wheel must get all the others moving.1 point

-

Hi From your pictures I say that the top pivot of the escape wheel is broken off hence it is unable fit into the plate and wobbles. I take it this is a Chinese clone if so parts are difficult if not impossible to fine/get unless you can find a donor watch. cheers1 point

-

With regard to the drying the chamber comes up to full temperature very slowly. So this is switched on first and after three x 5 mins of washing/ rinsing it is just about ready for the drying stage. The speed of the baskets can be adjusted and I have found it best to spin slowly for a couple of minutes in the first wash before upping the speed. A slow spin for 5 mins in the heat chamber works really well with all parts dry. What I like about this machine there is nothing automatic so you are in full control of the process. If a movement is particularly dirty you can wash for longer etc etc.1 point

-

I remember discussing Swiss fakes in other posts. I've been researching and cannot yet come up with an American make that used cylinder movements either. I was sure there was at least a couple, but maybe not. Now, as far as English producers, I've heard of Dwerrihouse (sp?) who in fact would sell Dutch cylinder movements for the English market, casing them in "Colonial" brand cases. And that *might* explain why it says "Fast & Slow" on the regulator. But the more I look at this, the more it temps me to speculate whether it might be a very early Swiss Fake. But all in all, I really don't know yet what to make of it.1 point