Leaderboard

Popular Content

Showing content with the highest reputation on 10/24/21 in all areas

-

As @Nibbler has pointed out your labels are the wrong way round. The beat error is adjusted with the stud carrier which is the one on the left, the rate is adjusted with the regulator which is the one on the right. Other than that check for stuck H/S coils which could be due to magnetism or contamination with oil/dirt etc. Also that the H/S is not contacting anything as it breaths in and out. It should be flat and parallel to the balance wheel rim, and it shouldn't come into contact with anything other than the regulator pins.3 points

-

I’m 59 years old and grew up in the jewelry business. My father owned a jewelry store all my life I worked for him many years doing repair work. he learn how to do watch repair in the Navy during World War II, he worked on a navy ship repairing instruments and the gentleman who taught him was a Watch repairman by trade. He went on after the Navy working in a jewelry store in Dallas Texas doing watch repair then later bought his own jewelry store. I started working for him in the mid to late 70s and wanted to learn the repair business for watches but that was also the time when quartz watches were becoming big in the market and he was losing a lot of business in the watch repair side. He did not want to teach me the watch repair business because he said I would never make any money at it as people or more and more moving to quartz watches. At the time I guess to him it made sense. Later when more people were moving back to automatics and hand wind movements his health was not that great and did not really teach me. Over the years I learned a little bit on my own but still don’t know a lot. I have always had a fascination with watches and still do to this day, I have owned everything from Timex to Rolex’s and just recently bought an old Stowa that I’m trying to work on. I’m having an issue with the timing on it which I will bring up in another section on the forms. Glad to be here, Kevin2 points

-

They really are the wrong way round. I have just looked again at your pic with the test result and if the snow storm at the bottom of the screen shot is your trace then you can't really draw any sensible conclusions from the result other than the movement needs a proper clean and service. The trace appears to be so irregular that the timing machine is actually unable to deduce an amplitude. You want to see two clean, regular lines of dots (or just one if the beat error is zero), and an amplitude of 220 degrees or more before you start to worry too much about daily rate.2 points

-

Someone else can chime in here but are the labels reversed on your picture? Matt2 points

-

Hi welcome to the forum. If you go to the BHI web site they list accredited watch repairers by area (worldwide).Hope this helps.2 points

-

My pocket watch came from my mother's family. It's been in the family for close to 100 years. My mother was born in 1918 and the watch was given to her by her aunt. A local clock and watch repair technician said that he thought it might be Swiss and that it broke his heart that he couldn't fix it. He said that it was a cylinder type escapement with a hollow spindle and that the balance wheel was broken, probably from having received a sharp knock. Can anyone help with finding someone who would consider repairing such a watch.2 points

-

Likely because your are more rationale than emotional, and it is my impression that most people are not. I sometimes say that the truly crucial decisions are always made with the stomach.2 points

-

That is correct. Before worrying about timing and beat error, one must look at the general pattern, which says that it's running on dried lubricants, or none at all. That causes pivots and stones to wear, eventually making a more costly repair needed.1 point

-

A recently serviced watch shouldn't run like that. I'm an amateur but no way would those readings be acceptable to me. Travelling around the world won't affect a watch and being 52 years is nothing, it's a fairly modern watch. Getting it sorted now will save you time/money in the future... you might even be able to do it yourself. There's a ton of experts on this forum willing to help.1 point

-

1 point

-

I hate the parts restrictions as much as anybody, but they didn't come out of a vacuum. In the 70s the quartz crisis hit very hard. Manufacturers were closing left and right, and within a short time a quartz watch could be had for less than a mechanical, 10 times more accurate (or more?), and require only a battery change here and there. There were articles in trade journals on how to shorten the time time it took to perform an overhaul on mechanical watches- customers didn't want to pay the "going price" anymore. Partial disassembly or even cleaning entire movements became common with the introduction of final rinses that supposedly lubricated the movement correctly. By the 80s watchmaking schools were seeing a huge drop in applicants, older watchmakers were advising young people to find another trade, schools were closing or cutting their curriculum to the bone and essentially producing hacks. Rolex did begin restricting parts. At first it was checking on the actual ability of the watchmaker and seeing that they were adequately equipped. Then it got tighter and tighter, with requirements of making significant investment in seldom used equipment, more training, etc., then finally in the 2000s it has come to only supplying parts to watchmakers working in a Rolex dealer, with all the equipment and doing training and so forth. So it was a process over decades, and not done out of greed, but to guarantee a top level of service. I can say that having viewed the insides of some Rolexes that were 10+ years old or 10+ years after factory service, they look fantastic- Kifs still well oiled, oil sinks clean and oil filled, all great. A friend who worked for Rolex as a trainer told me they clean the movement 3 times for an after sales service. Pre-clean, then disassemble and inspect, peg all holes, pith all pinions, check the functions, replace any and all worn parts and certain parts regardless just as a precaution, clean again, then a final clean in pristine solutions. Epilame used where appropriate. Get some oil on top of the jewel?- back through the machine. Other makers have tried to follow suit, but without systematically building up the internal structure to handle the workload. So there are a lot of unhappy owners of Tag Heuers and other brands out there, who wait an unreasonably long time for a service, then get a watch back that many times has been given a subpar service. 20 years before the quartz crisis it was common to have your watch serviced once a year or so. It was OK to use lesser cleaning methods, and maybe not be as picky with oiling technique, as the watch was going to be redone in a matter of months. Also, the use of natural lubricants meant that oil would tend to thicken up and stop the watch before wear occurred. Now, if you miss something the watch might grind itself to dust on certain parts. So, rambling a bit, but just wanted to stick up a little for Rolex, as they have gone this route truly to ensure that their watches are at the level they desire (and I have nothing to do with them, I might see a couple a year and don't own one). At the end of the day I agree with the often used comparison to car parts. A friend has a couple of Porsches and does most of his own service work (he's also a watchmaker, haha), and he never has an issue getting any part for his cars. That anyone can buy anything for a device that is potentially lethal to the owner and others, while some mid-tier watch company doesn't want to supply parts to "ensure quality" is rotten. It used to be mentioned in discussions like these that buyers should vote with their wallet and only buy from makers who do supply parts, but it's gotten to where that pretty much eliminates everything. For the moment Omega is the star; with a reasonable outlay for some specific tooling for dealing with cases, and a modernly equipped shop, and a reasonable amount of training, you can get a parts account with them. A friend has one, and says they are also very easy to deal with and fast with getting the parts out. The same guy had an account with Zenith- but they decided to make their parts account holders invest in thousands of bucks worth of tooling (Ok...), and also order a minimum dollar amount of parts per year, which would equate for him to doing only Zenith work, haha. So he let it go. A shame.1 point

-

The main point is it denies the customer the freedom of choice. Some inherent a nice Rolex/ Omega and would just like to see them running but do not have the finances to pay Rolex etc their fees.1 point

-

Oh, and if worse comes to worse and a new cylinder plug (with intact pivot) cannot be found in that size, I know a guy who sells whole cylinders. You could swap it out. https://www.ebay.com/itm/174272093664?chn=ps&var=473301475411&norover=1&mkevt=1&mkrid=711-117182-37290-0&mkcid=2&itemid=473301475411_174272093664&targetid=1264870805664&device=c&mktype=pla&googleloc=9016165&poi=&campaignid=13920139115&mkgroupid=126556537844&rlsatarget=pla-1264870805664&abcId=9300613&merchantid=101693647&gclid=Cj0KCQjwiNSLBhCPARIsAKNS4_fgLEOjc4xogbchjqAEN78wijmmM7bPAMVZyhO_qNWiYq3mOyTBNlcaApUiEALw_wcB1 point

-

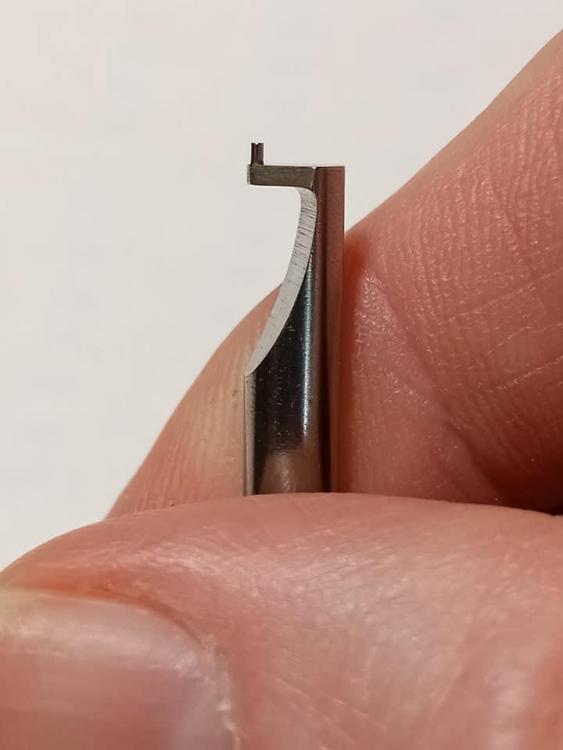

Don't give up hope too soon. There are a few of us who are equipped to deal with cylinder escapements. The search may take some bit of time, and the price may not be that cheap, but I'm sure you'll find someone in the UK who can take it on. I have worked on cylinder escapements myself. I even possess a few. It happened like other members have said: once you gain the special tools or knowledge, the particular jobs start finding you. I just managed to get a NOS set of Bergeon punches a little while back, to fill in for ones I was missing. I also have special stumps to go with my K&D Inverto. These punches are likely the tools your other repairman lacked when he explained he could not repair it. I would offer to take the job, but I am in the USA, and shipping has been a nightmare lately and things have been getting lost more often now, for me anyway, than in the past. So sending it over here may not be a good idea yet, until that all gets sorted. I sent pictures of the kind of punches used for cylinders, and the cylinder watches in my modest collection, if you find them interesting.1 point

-

And if you're a manufacturer of watches, you can point at that as proof that only you can do the service properly. I believe most people who can afford to buy, for example, a Rolex, don't care much about the service cost, and I think most people believe that Rolex does a better job than others would. Telling Rolex owners that if parts were freely available, they could save a bit of money and service time during the ownership of their watch, just doesn't make any difference to them. I'm sure they think spending a bit extra is worth the peace of mind having Rolex (the "ultimate expert"!) do the job. The truth is that there are plenty of examples of service and repair jobs done sloppily by Rolex and other manufacturers. Recently I bought an almost new (2019) Sinn 556 A for my own pleasure from a private seller on Chrono24. The guy I bought it from had in his turn bought it new directly from Sinn. When I got it in my hands, I had a good look at the movement and found dust and skin residues. So, I thought the owner might have tried to regulate it or work on it himself. When asking him about it, he replied: "Oh no, I never opened the watch. There is too much respect because of the technique" It turned out that the owner had sent it back to Sinn for a review and adjustment as it is was five seconds fast per day . Obviously, the person at Sinn doing the regulating was not in a dust-free environment and wasn't wearing finger cots. Even I, as an impassioned hobbyist, would have done a better job in this respect.1 point

-

Loctite would be my method. Just clean the tube and case with a degreaser such as mentholated sprit before applying the loctite.1 point

-

It wasn't always the case but experience does make you more cynical, I guess! My neighbour is a fanbois of a certain fruity tech-firm and always has to have the latest 'shiny'. He despairs at me because my reaction to his latest purchase is never the one he wants1 point

-

I've been reading about that and I think it's due to be resolved before xmas unless Swatch can throw another spanner into the works. Won't this all come home to roost though in another decade when all the new high-end watch owners realise that their 'investment' has been de-valued because no-one can get the thing to work any more? Rolex recently released a statement regarding the supply shortage. It's right that they don't want to compromise on quality but if they can't meet demand how are they going to cope with the additional burden of after-sales servicing if they insist on it all being done in-house?1 point

-

These are great too if you want to start a polish carefully: https://www.cousinsuk.com/product/buff-sticks-bergeon?code=B492651 point

-

Their loss could be your gain, remember to take pictures and post us the results!1 point

-

The case openers are less than £20. Mine was a set of six with an adaptor. As soon as I bought it the Rolex's started appearing in my workshop. A very bazar coincidence. I think you have dodged a bullet if you don't have to regulate the timing. It's a bit of a pest as you change it by adjusting the weight screws on the balance wheel. Generally there is only one regulator pin and that is for changing the beet error. This is quite a good article if you are interested: https://www.minus4plus6.com/regulation.php I noticed the steel is generally of a higher quality (I guess you must be paying for something rather than just the name haha), and a bit harder to polish. I always thought this was a good thing as it can give you a bit of an error margin as it's a lot harder to go too far. I generally use a Dremel with these or simular https://www.ebay.co.uk/itm/223596786388?hash=item340f6832d4:g:1lsAAOSw94ddNXwt Very good for fine removal of dings and scratches without loosing the sharp edges. Takes a while but the results are stunning.1 point

-

It all started back in the 70's when Rolex decided to go ahead and not to supply parts for their watches. As far as I know they were the first, and it didn't take long before parts started to become unavailable from suppliers. By doing this they restricted having their watches repaired. You had to take it to a stockist that sold Rolex watches, back in the 70's there were only two jewelry shops in Devon one in Sidmouth and another in Exeter.1 point

-

I had articles published in the BHI magazine on this subject when it first emerged that Swatch was going to restrict parts and sadly my predictions have come true. Cousins have had a long ongoing court battle with Swatch and and far as I can tell it is still not resolved. Many independent experienced watch makers see what was coming and retired. Hence the shortage and there are now many cowboys out there destroying watches. For example a quartz watch come to me that had a screw crown and the so called watch repairer (a well known high street shop in the UK) had just ripped the crown out stripping the thread. Horology have joined the throw away society thanks ironically the Swiss.1 point

-

1 point