Leaderboard

Popular Content

Showing content with the highest reputation on 10/12/21 in all areas

-

Slow day at the office again today. So I practised some micro welding. I got this Bally's ladies watch for about $10. The caseback says Bulova but the movement says PUW 211O2T. The movement is in great condition but the battery clamp was broken. So I fashioned the broken part out of a flatten piece of stainless steel wire and micro tig welded it to the old battery clamp. Not the prettiest specimen but it works.4 points

-

I haven't done one of these for a while..... My latest acquisition with a Record 107 movement, and on my first attempt at making a strap (no apologies for the dodgy stitching). Came in as a non-runner, turned out to be a broken M/S so easily sorted. I was tempted to have a go at re-plating the case but I think it carries off the brassing rather well.3 points

-

If you are going to use that method do it in a plastic bag. Usually it is sufficient to keep a finger on the barrel lid to prevent the flyers.2 points

-

Hi Personally I would clean it by hand using the Naptha and pegging the holes when done. The plates in cuckoo clocks are fairly thin so need a bit of care. Agood brushing should suffice. I have two of these clocks and hand cleaned them and used windles oil (the best) . whats the movement looks like a regula 8 day1 point

-

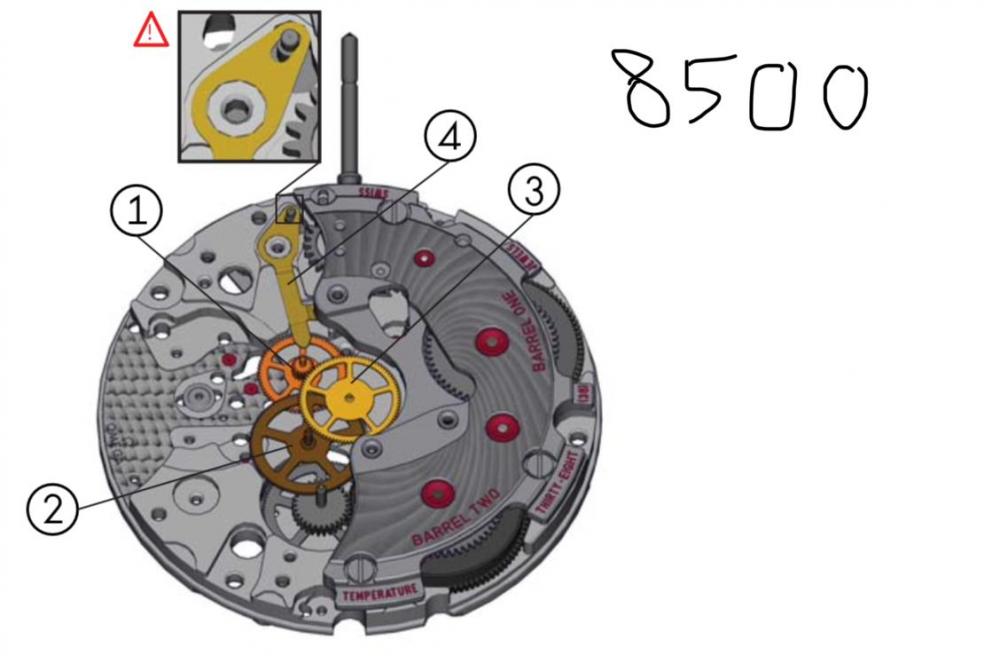

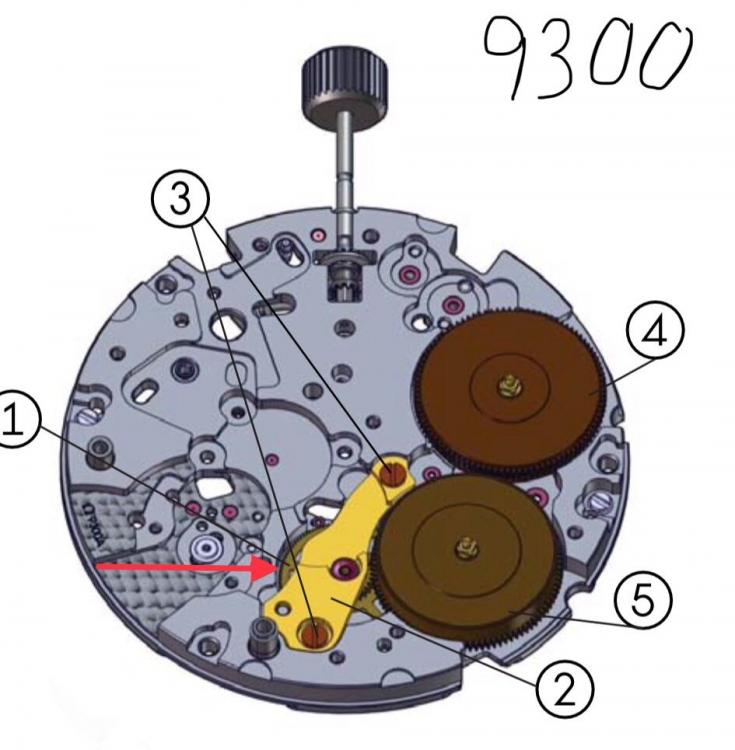

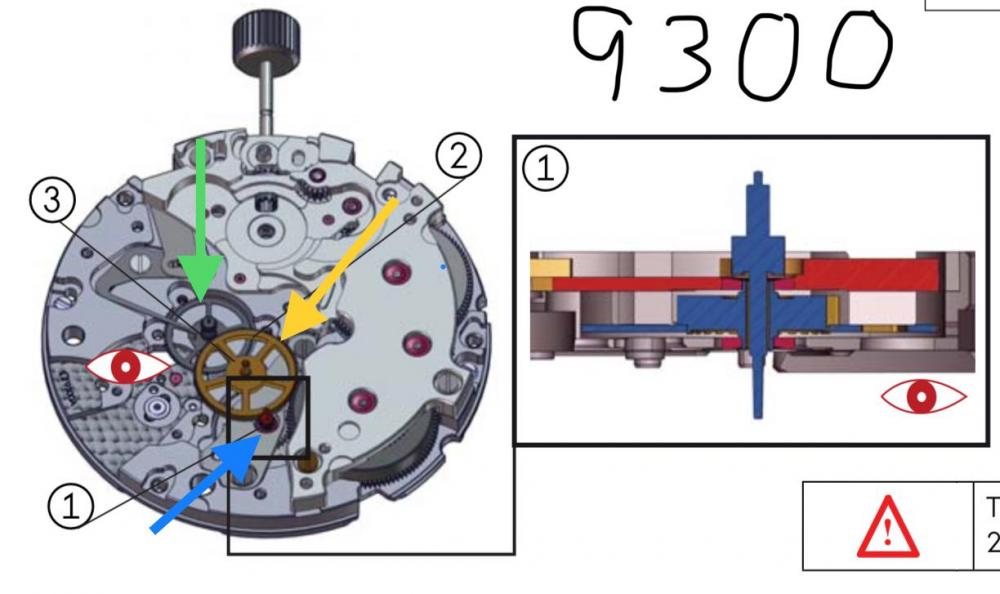

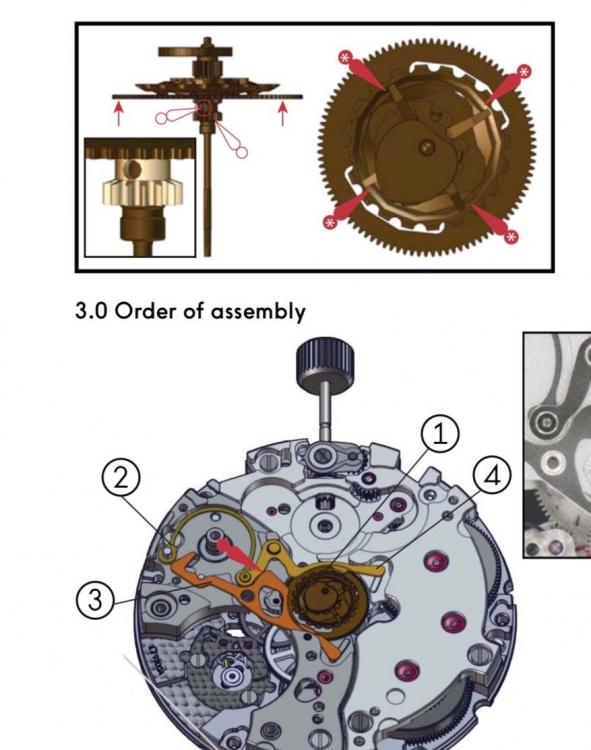

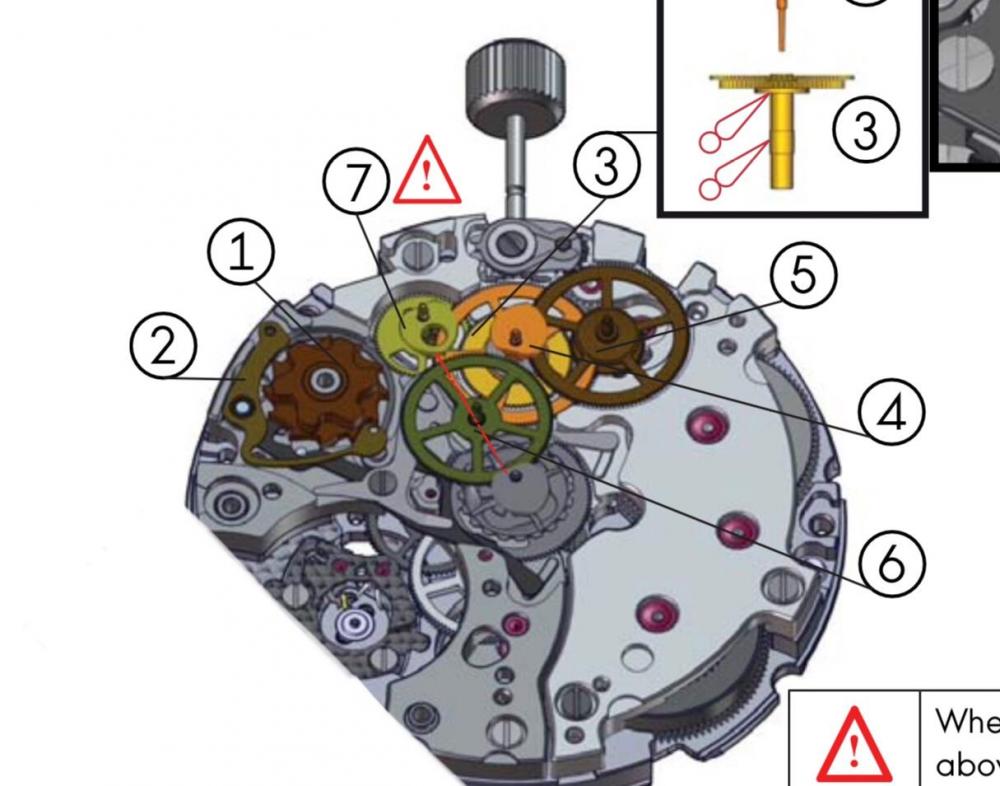

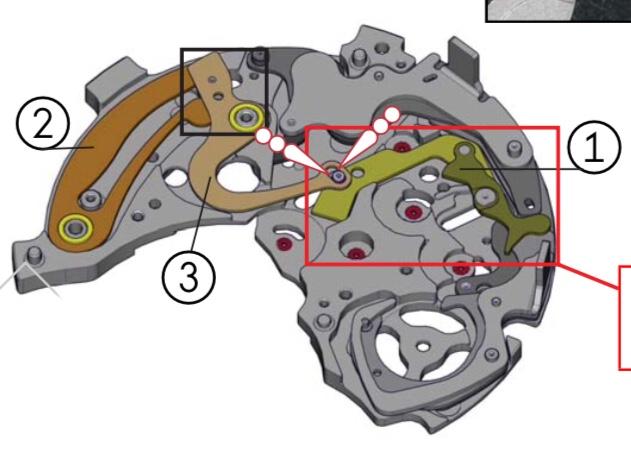

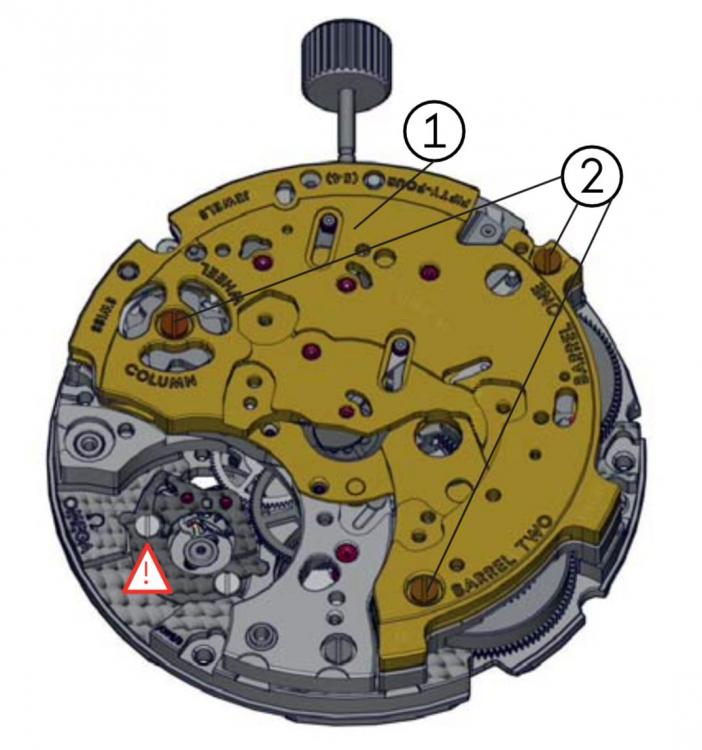

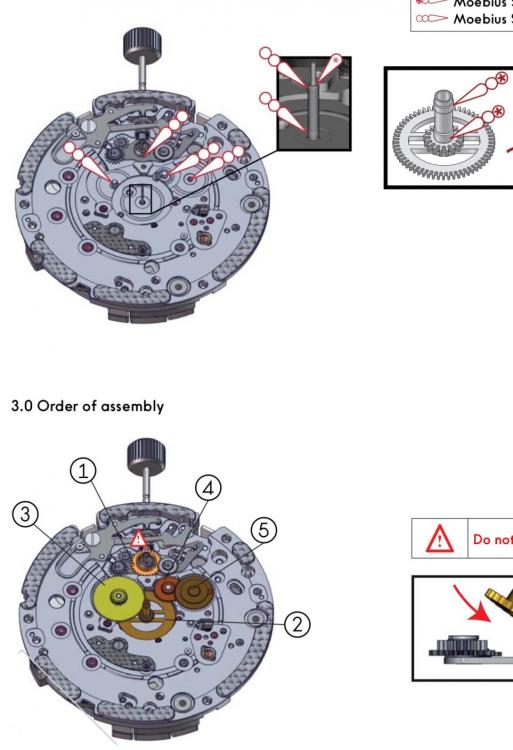

After looking through the technical documentation for the 8500 and 9300, I have come to the conclusion that while the 9300 is not a modular chronograph, it is certainly an integrated chronograph with a sandwiched (layer construction), sharing a strong connection with its 8500 brother. If you compare the layout of the 8500 and the 9300, you will find some remarkable similarities, as well as some interesting differences. The wheel train of the 8500 is shown below, with a very traditional direct seconds construction, of the sort seen in an ETA 2824. The seconds hand wheel (fourth wheel) can be seen directly in the middle of the 8500. In the 9300, on the other hand, the wheel train lay out is very similar, although different bridges are used to secure each of the wheels. The intermediate wheel (off -center wheel) is labeled with a red arrow: The intermediate escape wheel in the 9300 is labeled with a green arrow, the third wheel(s) is labeled with an orange arrow; interestingly, the small seconds in the 9300 is achieved via an indirect seconds pinion (blue arrow): from my understanding, the seconds pinion appears to go through the hollow intermediate wheel. The wheel train bridge is then fitted over: The fourth wheel is actually achieved via the the vertical clutch mechanism, which is the central chronograph second hand: Notice the pinion on the vertical clutch that interfaces with the third wheel via a cut-out on the bridge, and the pinion on the intermediate escape wheel that interfaces with the wheel of the vertical clutch. The rest of the chronograph train is then fitted on top of the train wheel bridge and the barrel bridge: Finally, the assembled chronograph bridge/platform with all the hammers and springs is assembled over the chronograph train: Finally, the dial side motion work (train) is achieved from the third wheel, similar to the 2824: Hopefully others who are similarly interested in modern watch movements will find this helpful, as I have no found any other discussion on the 9300 online.1 point

-

Hi The tech sheets for your interest. Along with JohnR725s information should give you the answers. 8597_Omega 9300, 9301, 9900, 9901.pdf1 point

-

it would be really nice if the message board would notify somebody if they're being quoted in a message as it was a miracle I found this at all? typically when I come to the message board I will occasionally notice the new messages on the right-hand side but usually I go right to watch repair and look for questions without answers. Or questions that have a limited quantity of answers because I assume everything that has lots of answers probably has an answer. But occasional will see something on the right-hand side that looks interesting that all look at it. strangely enough somebody else did this a couple weeks ago and I noticed it and I have their answer like I might have found an answer for you perhaps. did you know professional watchmakers can specialize? like for instance my specialty where I work is a vintage. Vintage is sometimes misleading typically it means pocket watches. But it could also mean tuning fork watches and occasionally quartz watch if they have to have it serviced and we can't swap the movement. Then Mather specialty is absorbing a heck of a lot of knowledge which comes in handy for answering questions. Fortunately for us you're asking about an older watch. If it was a new watch it would be problematic to get anything at all. Swatch group is paranoid with technical documentation and to get it you have to access it by username and password specifically would have to have access to an account. Then in the accounts come in various levels which determine how much technical documentation you can even access. Then if you managed to get this documentation their paranoid and they watermark every single page. So if you're lucky enough to find somebody that has such an account they're not going to share that information very far and risk finding out why Swatch group is paranoid and watermarks every single page. Fortunately as I said this is older watch they but we can find the documentation's somewhere else? the first link for anyone who doesn't know what the movement looks like the second link is cousins I would be searched for one of your movements and there is a PDF you can download. I'm not going to attach it to the message board because PDFs take up a lot of space on the message board. Then while you're here search for the other Omega movement you asked about because are both there. A little light reading and 42 pages there longer than what I normally see. I suppose it depends upon what you mean by modular? If I think of modular chronograph movement I think of something like the third link. n other words a company that makes modular chronograph movements independent of the watch company and then there brought together. I've seen a technical sheets for the chronograph movement I just can't remember what number it's under to find it. Then the Omega movements are interesting as well as I would call them more of layered construction. typically when you look at older designs of chronographs you have a watch that can function 100% by itself. Then the chronograph is built on the back side of the watch. Occasionally it will have components going through the front side for extra functions or something. But here you'll notice they don't even put the balance wheel in until everything else is been assembled. It doesn't look like he can get the watch movement to run without putting in all the layers the chronograph. https://watchbase.com/omega/caliber/9900 https://www.cousinsuk.com/document/search?SearchString=9900 https://journal.hautehorlogerie.org/en/the-dubois-depraz-chronograph-module-switzerlands-best-kept-secret/1 point

-

The arbor has to be on a flat hard surface, so that when you press on the teeth on the rim of the barrel, the arbor will be pushing up against the barrel cover. I recommend you use this method with the barrel complete inside a tiny ziplock bag.1 point

-

if you look carefully at the eta 2804 document one of the reasons they may not surface treat the Canon pinion assembly is that they're basically lubricating everything with HP oil. The center wheel jewel is lubricated the friction points of their center wheel and the shaft itself it goes on. we also get problems of how occurred is the tech sheet and seeing as how Swatch group typically doesn't like us do not going to update the tech sheets on the eta website you'll have to have access the newer documentation. what you might be seeing on the escapement lubrication is originally if you have an old enough document I believe it's 9010 for the pallet stones. Later on it was 941 then they came out with the 9415 supposedly for higher frequency watches only. Then Debbie documentation that was either or and now it's just the grease. But maybe it's because all the watches are higher frequency now or they know watchmakers are cheap and are only going to use one lubricant anyway. I snipped out to images from two separate Omega documents which shows you that they're not entirely truthful? The old one in black and white although thanks to Acrobat screwing up its black and yellow light yellow notice what they surface treated in the 50s? Then the other image is from 2019 notice the before and after so before and unfortunately this is a coaxial escapement example that's why there is that weird escape wheel slid treating the pallet fork and escape wheel in the early example. Then currently they treating just about everything except the balance wheel and the bridge and some other mystery components. Yes the Omega or Swatch group service center the final rinse of I think it's a separate machine is filled with this stuff and they go through it by the gallons huge quantities they use. It's because they feel that with the newer cleaning methods though remove the surface treatment that the factory put on so there replacing it. But you do get a discrepancy from the 50s look at all the stuff they're treating then later on they say all look we just treating a few things and now they're back to treating everything again. But in real life the factory service treats way more things than your aware of. Notice the reference to surface treating the balance pivots that's to keep the oil from running down the pivots. If you look carefully at the eta manufacturing guide for watch it will tell you that the balance staff the entire thing was surface treated just because it's easier to treat the entire staff than just the pivots. But notice in the technical sheets there is no mention at all of surface treating those pivots? Minor discrepancies in technical documentation.1 point

-

Yes, when I do modern ETA movements I surface treat the parts that ETA decree should be surface treated. For example, I have documented what I do in this ETA 2804-2 service walk-through (2nd picture) and this ETA 2836-2 service walkthrough (1st picture). Still, I'm surprised to see that certain parts that aren't surface treated in the documentation, like the underside of the cannon pinion with driving wheel, gets Moebius HP-1300 rather than a grease. Perhaps ETA missed to document the surface treatment of these parts!? I've noticed that their technical communications on occasion contain some contradictions ans omissions, like the lubrication of the pallets and lubricating the same part at the same spot with two different lubricants. It shall be interesting to see how well Sellita documents their movement service once I get a chance to service one of them.1 point

-

I do hope if you're following their lubrication requirements that you follow all of their requirements? In other words they're not using grease which usually has the habit of staying wherever you put it there using oil. But there also surface treating just about the entire watch so that the oil stays wherever it's put. it's one of the irritations I have with technical documentation is it doesn't always tell the complete story. It's only relatively modern times where they start to reference that their surface treating just about the entire watch. They been doing this since the 50s but usually it was in a separate documentation. So you do have to be careful when you follow the manufacturer's recommendation that you follow all of the recommendations. I think what you're seeing is is the results of this grease having this property of being thixotropic. below I have a couple of links the manufacturers webpage for the various greases and a Wikipedia link explaining what that word means. you'll notice from Wikipedia the grease has interesting properties of not being always grease sometimes it's basically oil. Which is what I think you're seeing is the separation of the oil from the solid parts. I've noticed this on other greases that they have like the 9415 that we use on escapement's. Also the 8200 mainspring grease that always has the oil floating on the surface and has to be mixed up. it might have been mentioned before but basically the 9504 is the 9501 with the extra powder mixed in. Then I'm sure that the uneven grain size is either optical illusion or just lumps of powder because usually powdered lubricants have to be super fine to do their job. https://www.moebius-lubricants.ch/en/products/greases https://en.wikipedia.org/wiki/Thixotropy1 point

-

That is what I was expecting to see it is a French strike. It has rack striking and has a self beat pendulum. The crutch is threaded onto the the pallets so when you touch the pendulum to start of the clock the pendulum will auto set itself in beat. It also has the normal fine adjustment for regulating just above the 12 which is called a Brocot suspension which was invented by Louis Achille Brocot around 1817. The original key will be double ended one end for the winding the other for the fine adjustment and it would be made of brass.1 point

-

One of things on my giant list of "things to learn how to do" is micro welding. It might be awhile before I get to it, but your repair does inspire me to keep welding on the list. Thanks!1 point

-

Wow... I'm a "grinder and paint make me the welder I ain't" welder with a MIG on big clunky machines. That is something to be proud of.1 point

-

Hi Thought I’d post about this tool I’ve bought via Aliexpress. I think it was listed as a Horia clone but seems very well made to me. I have a second hand Horia with a 3mm bore, this has a 4mm. Can’t see that much difference really, but I actually bought it more for the anvils and pushers which cost a fortune for the Horia ones. I got it in a sale so all items together cost me £140. Even if I’d been charged VAT etc. it would only have been an extra £35ish. The price for brand new Horia 4mm tool, pushers and anvils on Cousins is currently £1800, so a bit of a saving. The whole lot seem well made and finished, measurements are accurate.1 point

-

I understand what you mean and I think that, provided you have the equipment as you say, it is a good idea to know how to make items yourself. You never know when you might have to do so, particularly with obsolete parts for old watches. However if you can easily pick the items up for less than a couple of quid a piece like I did in this instance I am not going to spend the time and effort making it. If that makes me not a ‘real watchmaker’ that’s fine as I wouldn’t claim to be one anyway - whatever’s simplest and easiest suits me fine ;).1 point

-

Yes, I remember seeing that thread before now thanks, interesting stuff. As I said I already have a Horia tool, and a Seitz set as well. Personally I prefer the micrometer style control of the Horia over the lever style as I find the more precise control useful for a number of operations. As mentioned I was attracted to this tool mainly for the pushers and anvils, a lot more sizes than come with the Seitz, although not the variety and a fraction of the price of the Horia equivalent. What struck me was the standard and finish of all components, better than I expected for the price. Although I am usually an advocate of good second hand tools over cheaper, less well made new ones, I do wonder with this one. Anyway I thought it was worth mentioning as an option because of quality and value.1 point