Leaderboard

Popular Content

Showing content with the highest reputation on 03/05/21 in Posts

-

A few months ago I spotted what I considered to be, a rather nice looking chronograph watch for sale. On the dial, the name was, Ravisa. Inside, the movement was a Harley Ronda 726. I bought it as non working and soon got busy, stripping it down. There was no strap fitted, but that didn't matter for now............one thing at a time. This watch incorporates two coils and, when checked, one of them proved to be open circuit. With the use of a stereo microscope, I was able to see the breaks. Yes, breaks.............both of them! Somehow, both ends had both become disconnected. Using my soldering iron, I was able to pick up the ends and successfully reconnect them........which my ohm-meter confirmed. After that, it was cleaned and reassemble/oiled. Once done, the battery was fitted and let's see what we have. Unfortunately, the chronograph section didn't work, but the watch did. At first, this wasn't apparent because the coil pulses for the watch section are spaced about ten seconds apart. After thinking carefully, I could only think of one thing being responsible for the chronograph section not working...............the circuit. Now, for some curious reason, I never checked the circuit when the watch was stripped and I had the chance to. Whenever I strip a quartz watch down, I always check the circuit to make sure that it is working. Why, then, didn't I do so with this one? (Murphy's law!) Well, it's my own fault and now I had to strip it down again to get at the circuit which, in this watch, is buried a few layers down and takes quite a bit of getting at. I got the circuit out and checked it for pulses. Yes, one section was 'pulsing' (The watch section) but the chronograph section was emitting nothing, apart from a high pitched whine. Damn! After a long search, I found a firm in San Francisco ( S.T. Supply) that had the the circuit and got busy ordering it. It took about three weeks to arrive and, once it did, I eagerly fitted it to the watch. It's a tricky business assembling this watch, but it got done. Right, I fitted the battery again and this time the chronograph section sprang to life................success! Everything was working, so I left it to 'soak test' for a while. A couple of days passed by and the watch was working fine. I saw a really nice, shiny S/S bracelet with black ceramic sections and immediately thought how nice that would compliment the black bezel on the watch. The only problem was that the watch measured 19mm across the lugs and the strap was 20mm across. I couldn't find the same bracelet with 19mm and I just had to have that bracelet. A long story cut short, I very carefully altered the watch case and the bracelet and, voila, job done. With its new glass and shiny bracelet, the watch looks absolutely smashing. I just love this watch and I intend to keep it. I wear it daily now, while giving my mid 1960's Valjoux 72 a well earned rest.1 point

-

1 point

-

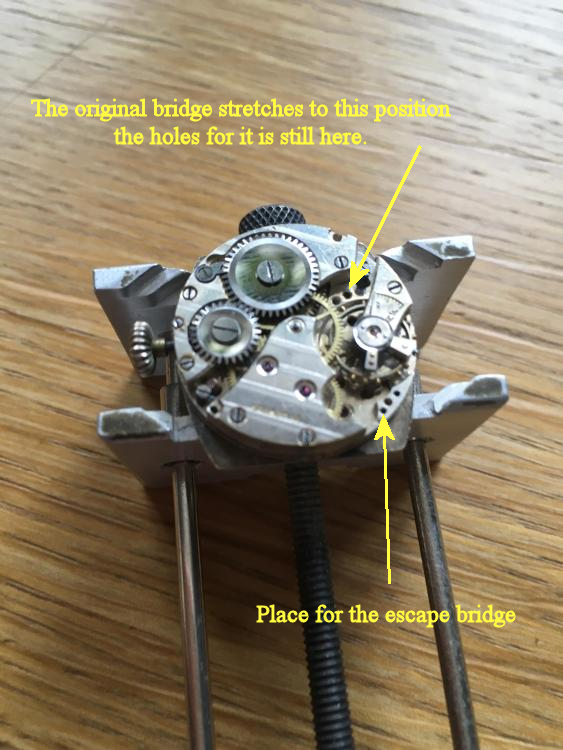

As said before your trainbridge is modified but the one doing it left the holes for the original bridges. I would not think it was factory done then the watchmaker would have thought about a detail like that and covered them up, I know I would. The escape wheel is not in place so that adds to the different look to. In the 20's - 30's there were lots of experiments going on, the only AS movement I noticed being used was the AS340 in a ROLEX Marconi jump hour, there are probably more of them but haven't seen some official list. Here is a site with cool quirky watches like the Rolex Marconi. http://www.crazywatches.pl/rolex-marconi-jump-hour-as340-1920s1 point

-

I don't know if anyone had noticed, but I haven't been on here for a few weeks as I have been distracted by something else on and off for the last few months and it has been taking a lot more of my attention over the last few weeks, but its nearly finished now, so I have time to come back to here. In November last year whilst browsing 'Gumtree' (Australia's version of Craigslist owned by Ebay) I looked up 'BSA' to see all the nice motorbikes I can't afford to buy and in amongst them was a BSA bicycle. It was made in the 1960s so not a 'real' BSA bicycle, but a BSA badged Raleigh Bike as BSA had sold them the rights to make bikes in 1959 or 1960, but it still has the BSA logo head badge and BSA written in the cranks and best of all it was cheap. So I snapped it up. The bike had the incorrect seat, stem, handlebars and wheels, so I really was just buying it for the frame, forks and cranks. When I started to strip it down I got a surprise in the bottom bracket in the form of a dead lizard (skink) it was still pretty fresh so I can only think as I removed the seat a few days before stripping the rest of the bike it climbed on the bike and fell down the seat tube and got stuck. With the bike stripped down it got given a wash and about 8 hours polishing with T-Cut on the frame being careful not to damage the pinstriping and all the chrome was given a long bath in a weak solution of oxalic acid then just a rinse with clean water and a wipe with a rag and it all came back looking like new. Then I sourced the correct 650A rims out of the UK, a 1966 Sturmey Archer 3 speed AW hub, period correct front hub and after servicing the hubs sent the wheels off to be built. Meanwhile I got the correct seat post and a new Brooks seat as the bike would of had originally, the correct style handlbars and I took a liberty and bought some Brooks plump handgrips and a new English made brass bell then sounds cleaning and loudly enough to be fitted to any good clock. Since taking this photo I've fitted the chain and measured what size brake calipers I need and they are in the post along with a replacement handlebar stem and once they are fitted the bike will be ready to ride. It's cost me probably more to fix this bike between the parts and tools I purchased to work on it than a new reasonable quality bike, but this bike is way cooler than any new bike I could buy, plus it looks good leaning against my 1961 C15 BSA.1 point

-

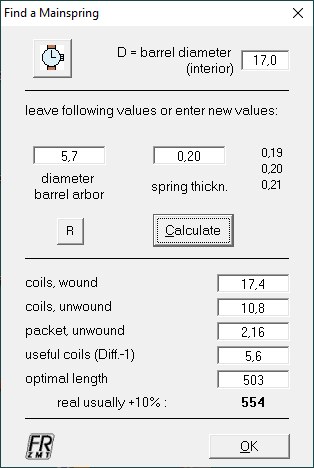

Yes, it’s very possible that it’s broken previously and had been shortened. In short, for a given thickness (0.2mm in your case), there is an optimal length which will give you the longest running time. Too short and you don’t get enough turns. Too long and you occupy too much space in the barrel and limit the number of turns. The length has negligible effect on torque developed, unless taken to extremes. So, aim for the optimal length (in my opinion).1 point

-

In this video I completed the repair of a mint 24 Jewel Bunn Special...not a cheap watch. As well, it had a broken setting wheel, broken upper balance jewel, bent upper pivot, and loose hairspring collet. Lots of fun. Previous videos address the full cleaning of the watch. As well, I used a Jacot Tool to straighten a slightly bent balance staff pivot. Worked well. Final Chapter - 24 Jewel Bunn Special Pocket Watch Repair https://youtu.be/BVkDWqUNxZA1 point

-

1 point

-

1 point

-

1 point

-

Hello and welcome Jason, I'm in a similar boat to yourself, though I have caught the bug now. I've started out with the cheaper tools. I only tinker with cheap watches. I've managed to disassemble and reassemble a few now, and I'm pleased if I get one working and keeping reasonable time. Gradually building up to more complex things as my confidence grows. Much along your line of thought. From experience I can vouch for the Anchor grease and a number of their tools which are functional, there are better out there for sure. I'm slowly upgrading as needs and budget allow. I was cleaning the movements by hand, using little jars of lighter fluid and IPA. I recently invested in a cheap ultra sonic cleaner, which has improved the cleaning by a long way, even if the buzzing is annoying. Enjoy and have fun1 point

-

Hello Jason and welcome to the forum. Find attached two documents for you, hope you find them of interest regarding your new hobby. They will give you the basics to start with. 1612608791_ToolsfortheHobbyist.pdf TZIllustratedGlossary.pdf1 point

-

1 point

-

I wanted to update everyone who offered suggestions on my Wenger Swiss Military watch issue. I called Wenger service and was told it would cost $28.00 to diagnose the failure to run issue. I explained that this watch had never been worn since it was manufactured. The gentleman showed no interest in this, just the reply “it could run up to hundreds of dollars to fix” ! Thinking locally, I contacted a jeweler who measured the battery, replaced it with a exact size, set the time. We both watched the second hand move for about five seconds and stop. Off the back came and he repeated the process again. Same results. The next thing I witnessed was him giving the watch a rap on his work bench. He looked closely at the dial and smiled. $10.00 later everything is golden. I appreciate everyone’s time following this watch adventure..Jack1 point

-

I've just finished watching your video jd. Excellent work as always. As I said in the comments on Youtube it wasn't boring for me. How about some brass plates for your vice they won't leave marks on your jacot tool.1 point

-

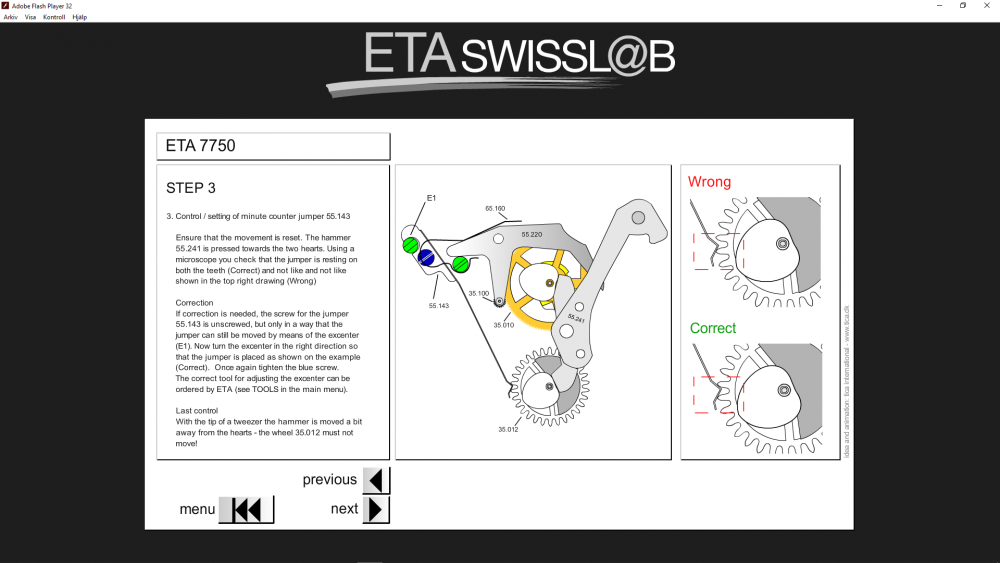

For those who were curious of what the 7750 flash-files contained and didn´t have time to download the swf files I did a small compilation of the Swissl@b application a while ago. In this PDF you also get some extra information. So no need for a flashplayer..... ETA 7750 HSL EDITION.pdf And after a quick glance at this issue here is an alternative if you really want to look at these files. For windows users I attached the reader in the zipfile. Just unzipp the zip file to a good place on your harddrive, read the attaced short instructions and happy viewing. [email protected]1 point