Leaderboard

Popular Content

Showing content with the highest reputation on 12/30/20 in Posts

-

Today, some German pin lever action, in the shape of a Kienzle "Markant" mechanische herren "Strapazier-Armbanduhr", probably 1960s or thereabouts. It is relatively small for a "Herren" (mens) sized watch, with 16mm lugs. Given the somewhat "industrial" construction and the fact that it is still going strong I think it meets the claim of being a "Strapazier-Armbanduhr" (hard wearing wrist watch).4 points

-

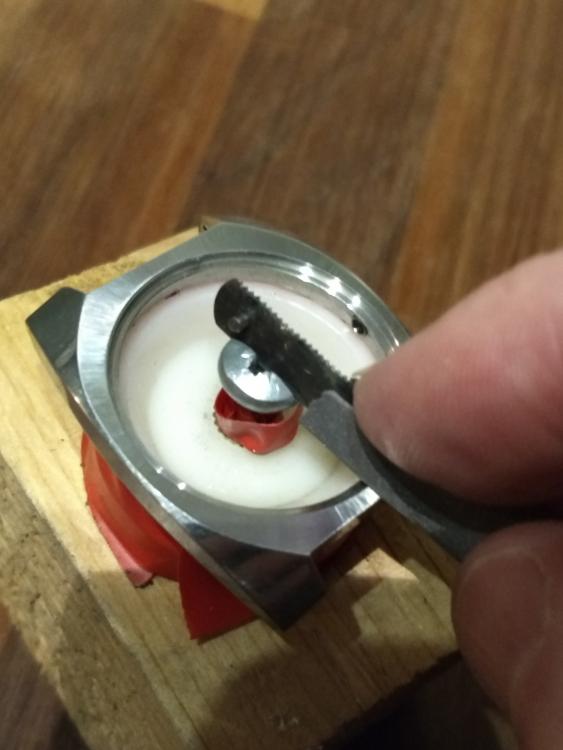

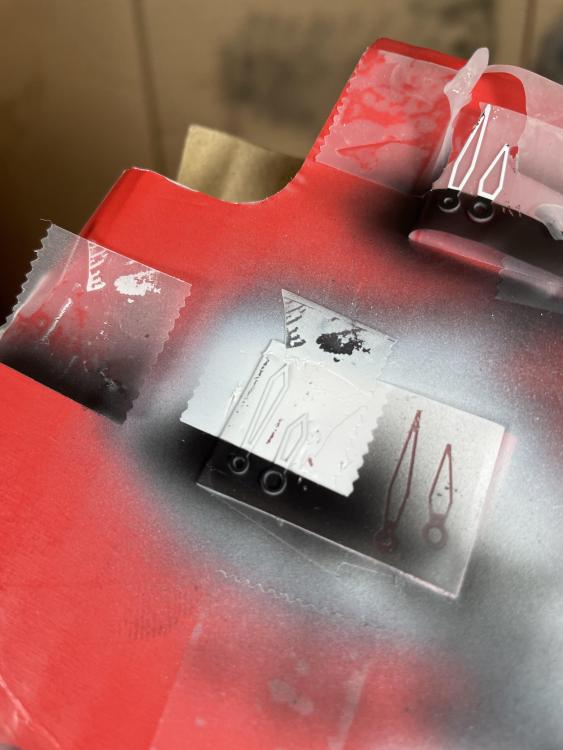

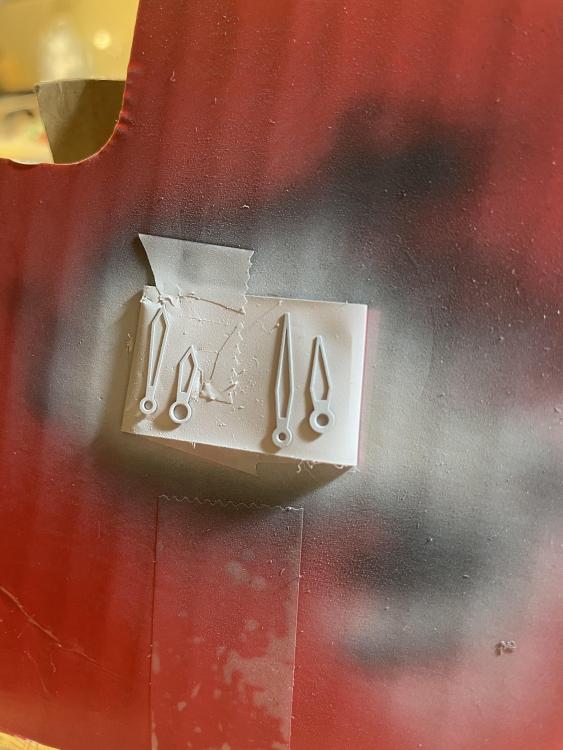

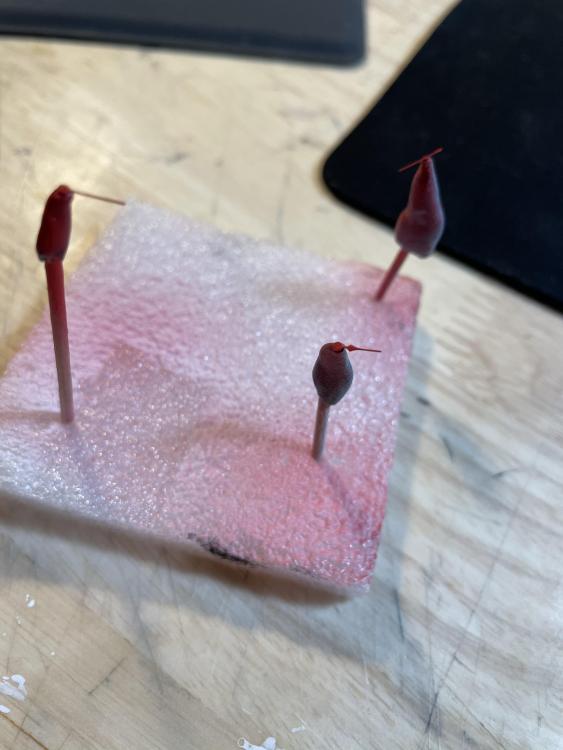

Hi, Just wanted to share my experience of radial brushing on a Seiko 7005-8160P. I built a little jig using a block of wood, plastic case press, and Wood screw. I think the pictures are quite explanatory. The red tape was used just take up the slack. Using a junior Jigsaw blade with some 600 grit paper wrapped around it and short 5mm strokes back and forward as the case is rotated slowly. Using the long slot I made in the screw head as a guide. The height of the screw is adjusted so that the Jigsaw blade is flat against the case and not at an angle. It's working pretty well. Will post a picture of the finished case.3 points

-

3 points

-

In this video, the presenter makes a replacement hairspring for his verge escapement pocket watch entirely by hand. I found this in my late night YouTube trawling recently and thought it didn't have nearly enough views. https://www.youtube.com/watch?v=fM7tsGYNAPc2 points

-

Hi guys. Yesterday I dove head into correcting the massive 7ms beat error on a 23 Jewel Elgin Veritas Pocket Watch. I examined the jewel location without removing any plates or the palate fork and used the arm of the palate fork as a reference to find the banking pins Centre and the delta from that center to where the impulse pin was, at rest. Taking note of the delta, I then safely disassembled the balance from the bridge and worked on rotating the hairspring collet 5 degrees counter clockwise; to effectively move the impulse jewel 5 degrees in the clockwise direction. I then reassembled the movement and tested the watch with 3 different software application; eTimer, Swiss Connect and Timegrapher. The results were good as I got the relative beat error inside 1ms. I made a one hour video showing all the work. Here you go, please enjoy.2 points

-

2 points

-

2 points

-

For what its worth, I've used PLA (wood glue), clear nail polish and UV cure nail polish, all of which work reasonably well. The trick is to make sure the mix is nice and "gloopy", as it needs to bridge the gap without dripping. I've only ever used lume powders, not pre-mixed stuff, and I suspect that this makes life a little easier as you can always add more lume powder to thicken the mix, or more of the fluid to thin it. In the case of PLA, you could also add water. Nail polish can be thinned with acetone if you need a very wet mix. I've no idea if acetone works with the UV cure but I suspect that it may, since I think the UV cure stuff appears to be removable with standard nail polish remover, which is generally just 99% acetone with a little scent and colouring thrown in to jack up the price. My worry with PLA is that it may be hydroscopic and if so, might cause steel hands to rust. I've no evidence to support this idea, it is just a possibility.2 points

-

1 point

-

1 point

-

1 point

-

Very useful ideas. I like his simple flat spring wire making jig. A very simple but neat idea, which seems to produce surprisingly good results. Part two, the manipulation of the paper hairspring is a very good reference for anyone who wants to play with hairspring manipulation without risking damaging a precious watch spring. I may have a play with ideas for producing consistent curves without too much manual manipulation. It would be good to be able to produce flat springs with minimal fuss and faff.1 point

-

More case information for you, which may or may .not be of use Roamer Case Numbers to Case Parts.pdf1 point

-

I would think any IWC is a good bet seeing the prices they command, https://thewatchbloke.co.uk/2015/05/05/iwc-mecaquartz-chronograph/ Have a look at this link If you are contemplating a repair job might be able to pick up a few pointers. cheers1 point

-

One of my best friends used to say to me have you been cleaning the S H I T out of the cuckoo clocks today.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

This pallet fork is poised in all positions of the watch. Looks so "out of this world" ?1 point

-

Hi that looks like its screwed on but I have seen backs like that which were snap on, so lets assume its screwed on and requires either a key or a Jaxa set to remove it. A cheaper alternative is to super glue a nut of you choice to the back and leave for a hour so its good and set. Now using a spanner on the nut unscrew the back. The nut can be removes using nail varnish remover and the back cleaned up. Another alrernative is the sticky ball pressed on the back and turned, even a rubber sucker pressed on and twisted might work. I have never known the nut method fail yet If it assumed it is pressed on tight and the case knife wont shift it a bezel /case back tool will do the job. I have the red one and it works very well. available from cousins or ebay.1 point

-

1 point

-

Relevant to choosing another size, these are generalities: the mainspring barrel size (last number, 9mm ) is the size that the new mainspring is packaged. You press it into your barrel. Must be equal or smaller than the ID of the barrel you are fitting a mainspring into. Smaller is OK, it will expand to fill the barrel when inserted. Length (3rd number, 300 mm) should be close to the number specified. Shorter is OK, probably just a little longer is OK also. Corresponds to the power reserve, how many hours the watch will run on a full wind. Thickness/Strength (.10mm) is the thickness of the metal spring. This represents how much power or torque the mainspring will deliver to your movement, if the width, material and age of the spring are the same. Thicker will deliver more torque, eventually resulting in a higher amplitude of your balance, eventually leading to overbanking. Thinner, low amplitude, poor performance. Condition of the movement, the gear train, number of complications, oil condition, will all effect how this effects your movement. Width/Height (1.45mm) this is the height of the coiled mainspring so it must be smaller than the inside height of your barrel. Next size smaller (-0.05mm) here shouldn't be a problem, the spring will be marginally looser in the barrel, otherwise it should be fine. Technically you would want to compensate for the reduction with a thicker spring, to keep the torque the same (essentially keeping the cross-sectional area of the spring the same), and there is a formula to calculate all this, although you'd probably be fine without engineering the replacement, depends on how fussy you like to get with <1% differences. You shouldn't have to change more than 1 of the length/width/height values to find a replacement for an unavailable spring, usually the length being the easiest and least consequential in terms of effect on the operation of the movement. You may also find an older Dennision/White-A-loy numbering system for mainsprings in the Bestfit catalog and elsewhere, you can use to find NOS mainsprings on ebay. There's lookup tables to translate it to metric. Your target would be "511M" or "511K" I believe (where the letter is the length, M=317mm and K=292mm ). I'm not sure about those, there's usually no cost savings, and who knows how old they are or how they have been stored, but they are available.1 point

-

The Hallmark is a Chester mark for 1900, the TPH sponsors mark within a cut corner rectangle was registered in 1899 T.P.H without the rectangle was registered in 1904. https://www.silvermakersmarks.co.uk/Dates/Chester.html1 point

-

1 point