Leaderboard

Popular Content

Showing content with the highest reputation on 12/14/20 in all areas

-

While we are on the subject of syncronous clocks.........Got this Ferranti Model No2 (1934 to 1936) Bakelite clock coming.......And also this Model No 12 Talbot Pewter cased one (1934 to 1936) coming as well......I suspect the perfect dial on the No 2 clock will find it's way onto the pewter one......3 points

-

I have spent many, many hours in my workshop restoring this clock after it arrived totally wrecked (see pic). There are still issues that need resolving. 1. the minute hand Is not correct and is just a modified hand that came with the clock and as yet I have still not found a replacement that fits. 2. The chiming sequence goes out of sequence now and again. The issue might be when in the strike mode it runs very, very fast so it might be skipping the count wheel, maybe !!!.. or The fly wheel bushings might need replacing!!! However lessons learnt. When sticking alabaster together use epoxy glue BUT mix it with some alabaster powder. This hides the joins (almost) When replacing the pendulum the numbers found on the rear of the case are really useful. This particular clock has 4.8 and using the PDF (see attachment) it gave me the length required and also the BPM expected. Using the Clock master app on my iPhone it was almost spot on with regard to timekeeping. If careful spelter can be drilled and have a thread tapped into it. When gold leafing use fresh size and after applying leave for at least 15 mins before attaching the leaf. To get a smooth finish I found my finger gave the best results. BEFORE AFTER FrenchClockBeatRates2.pdf.pdf.pdf1 point

-

1 point

-

1 point

-

You have metal on metal in no jewel movements, oil is a must.1 point

-

I have repaired more vintage watches than I care to remember. I never oil the pallet fork pivots. I check to see if the fork is free to move when the movement position is changed to allow the fork to move back and forth. It must be free to move without hesitation. The only exception is pallet forks with cap jewels. On those, I put a drop of 9010 on the corner of a piece of watch paper. Then, I drag the paper over the jewel to leave a slight film of oil on the jewel. The pivots do not rotate and there is very little pressure on the cap jewels. The oil film, if done properly, still allows for free movement of the fork.1 point

-

They seem to have produced this particular model for quite a while. I even spotted one with a Junghans quartz module in it, which looked to be original. The one I picked up has a Bakelite or perhaps urea formaldehyde cased mains module, so maybe a little earlier than 1970, perhaps fifties or sixties. That mains cable is almost certainly a later addition.1 point

-

We used to sell Metamec clocks in the shop where I served my apprenticeship. This one dates from the 1970's. Basic mains movement nothing much to them.1 point

-

The little vice I use is made by Horia. It's not cheap but very excellent. Mine is 21 years old and gets used several times a day, every day. I have seen similar/copies in catalogs since I bought mine for about half the price, but can't remember where now. It's a typical tool young watchmakers might make in school (if they have free time) as it's a good exercise and very worth the effort- but you would need a milling machine to make one. https://www.horia.ch/en/Products/Tools/Tools/Vice.html For diamond abrasives on a budget Eternal Tools is hard to beat. I can't remember if you have a lathe or not, if so you can buy cheap diamond paste from numerous suppliers and use it on a lap as I wrote above. You will want a separate lap for each grit, the whole idea is it embeds into the lap- there's no cleaning it off. Eternal has diamond wheels and round laps down to D9 or 2000 grit, which would be fine for shortening a stone. You need finer, at least 3 micron to work the functional surfaces. https://www.eternaltools.com/1 point

-

Its not pretty, but it is interesting. An early hardwood and Bakelite cased Metamec electric clock. I'm intrigued by the idea of powering it from a 240V 50Hz source derived from a USB power bank. Failing that, then I guess I'll just run it the more conventional way. Needless to say, it cost next to nothing, however it seems there are quite a number of collectors of Metamec clocks. Now.. I REALLY do have to stay away from ebay. ?1 point

-

You maybe absolutely right about two part stem. Check CousinsUK parts list for this caliber and you will see options: - Stem, Male Inner ( 1159 ), Omega 1480 - Tap 9 Female Stem Extension - Tap 9 Female Stem Extension (No Shoulder) https://www.cousinsuk.com/category/filter/omega-movement-parts1 point

-

1 point

-

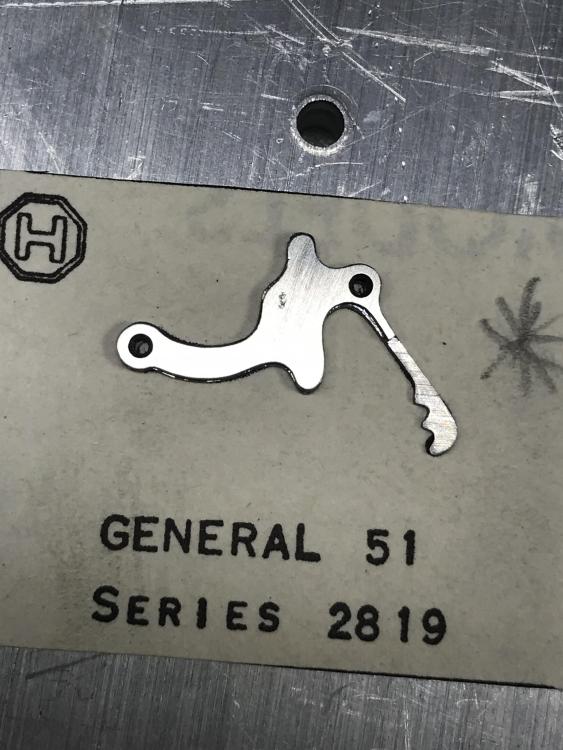

It's actually even cheaper for "2824.2: Enter 2824, then search, then select 2824.2 or simply click on this link: https://www.cousinsuk.com/search?SearchTerm=ETA280412576 Date Jumper ( 2576 ), ETA 2804.1 ETA280412576 In Stock £2.951 point

-

1 point

-

Let me see if I have a dial for the Ingersoll/Ronda 1217-21 I might swap for the Timex crystal. The Ronda is probably save-able. The keyless work is most likely corroded, but remove the balance and fork and soak the keyless work in penetrating oil, or dare I say it WD40 and it should loosen up. Moisture from sweat tends to be salty, and that can lead to some pretty nasty corrosion. It may look like it took a bath in H2SO4 but I suspect it was probably something more mundane. Sekondas are notorious for borked keyless work due to this very problem. Speaking of borked Sekondas, this is my latest impulse buy. Described as "SEKONDA 19 JEWELS USSR VINTAGE MENS MECHANICAL WRISTWATCH - Working when wound." I guess that is a little closer to the truth than the mechanical watches that are described as "needs battery". It should be a gold plated case and almost certainly a Raketa 2609 HA inside. So long as the keyless work hasn't turned to porridge then with a new crystal and a fresh band it will make a nice addition to the 404 club.1 point

-

1 point

-

XR11630W is also known as: XR1130W, R28, WSR265H, XR113OW so far as I can see.1 point

-

1 point

-

1 point

-

1 point

-

Generally speaking you can replace a pallet stone with another of the same width, and that has been shaped for the appropriate side of the fork (entry or exit). Let's say for your average vintage watch, a replacement stone from Seitz or other assortment will probably be just fine. You do run into issues with certain escapements for higher end watches from back in the day or modern watches with higher beats and more teeth in the escape wheel; often older high end escapements might have significantly different face angles from "common", and modern escapements have very different angles for sure. Usually it's possible and normal to replace an entire fork for a modern watch. With vintage/antique it can be very advantageous to fine tune the angle on the impulse face. One issue with replacement stones is that they are sometimes just too long overall, and need to be shortened. This is usually done on the end that fits in the fork as it just needs to be approximately squared off; I do it with a fine diamond grinding wheel (7 micron) holding the stone in a tiny vice. I suppose it could be done with a fine diamond file, but these will tend to chip the stone and while not affecting the function it is unsightly.1 point

-

As pallet setting tools are not easy to find, I screwed a handle to an old brass pocket watch main-plate. You can sit the lever pivot in one of the holes, so that the pallet jewels sit flat on the plate. I then heat it over a meths burner. It's not difficult, but go easy with the heat - shellac melts surprisingly easy (75-90C)1 point