Leaderboard

Popular Content

Showing content with the highest reputation on 11/04/20 in all areas

-

I've attached the BHI article mentioned above. another one is from Omega I've attached that also. BHI The Practical Lubrication of Clocks and Watches Version 2008.0.pdf cousinsuk.com Omega 8645_WI_40_rules for lubrication.pdf2 points

-

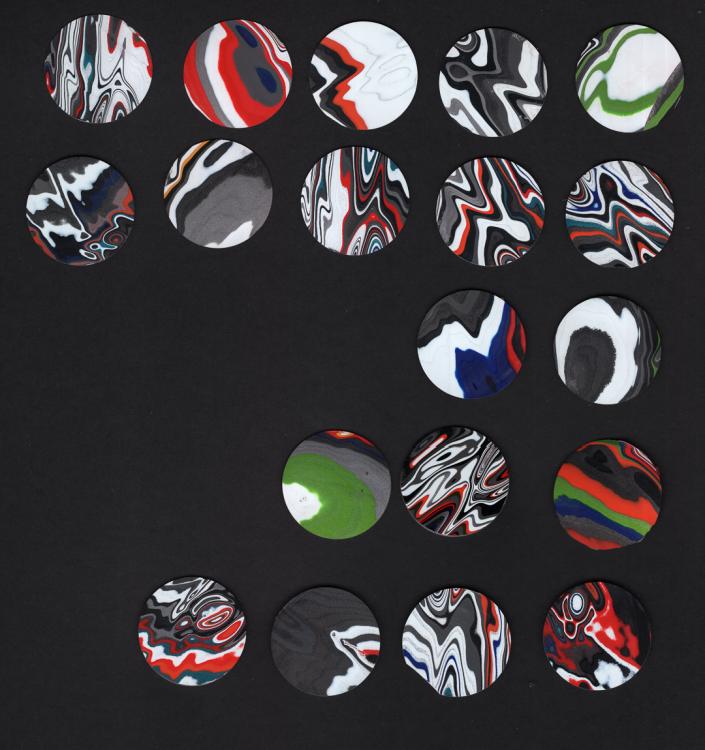

Quick update: I've cut my first series of fordite veneers, and I'm in the fun-but-difficult stage of assembling my first run of dials. Here's a scan of my first workable batch of fordite sections (ranging in thickness from 0.3mm to 0.5mm). The final patterns of these will change, as I'll be grinding them down to their final height. (This is a good thing, as some of the patterns below are pretty uninspiring. It'll also be heartbreaking, as some of my favorites below will likely shift too.) It's coming together!2 points

-

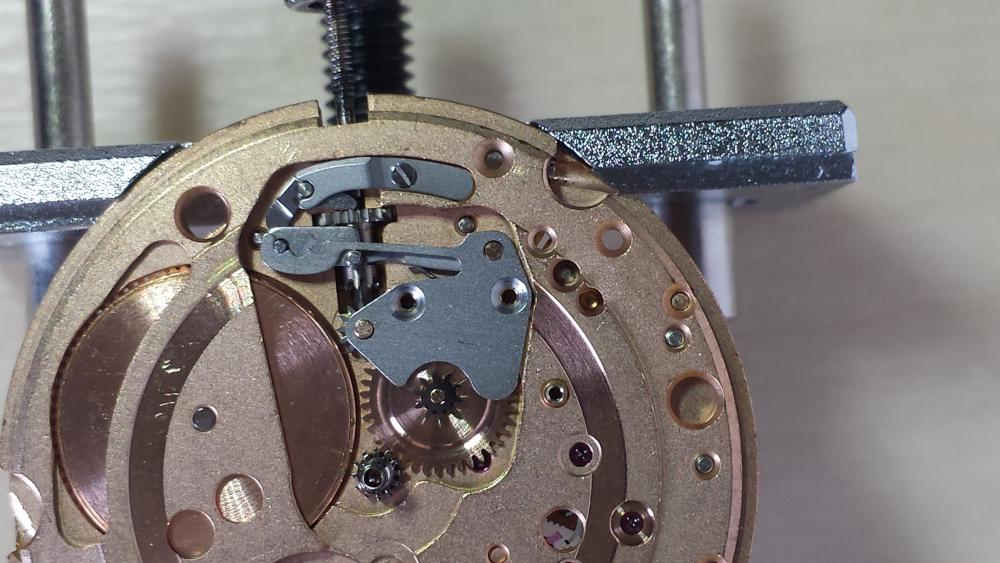

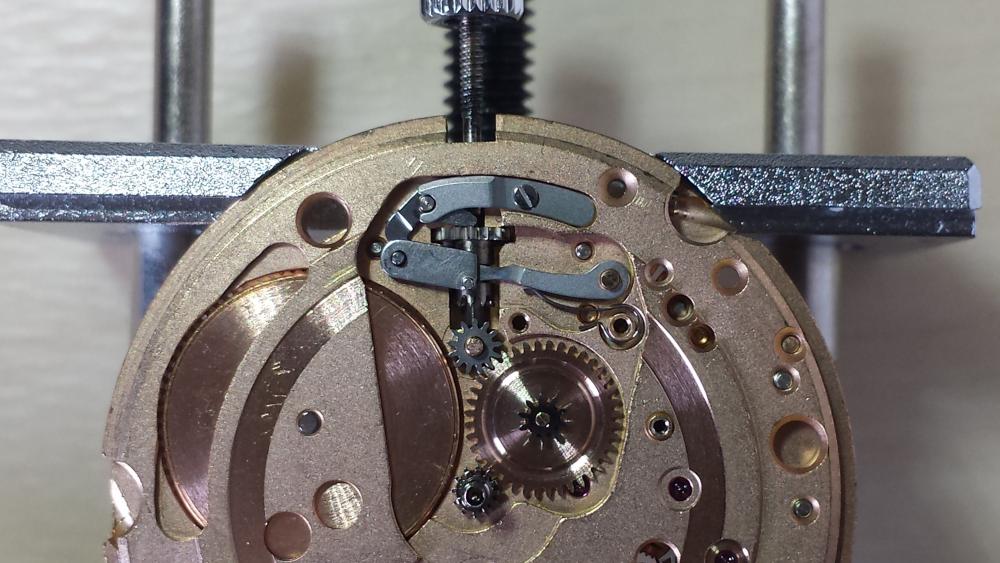

Hi there, during the service of a ladies watch with an ETA 1201 I noticed that the banking pin on one side was bent outwards, so I straightened it. Then when assembled I was checking the movement before the balance went back in and the pallet did not unlock. So I realized then that it was bent for that reason. There is no room for adjustment of pallet stones, so I bent it back. Placed the balance back in and bingo, runs beautifully Moto to the story is all is sometimes not as it seems.2 points

-

2 points

-

So, I firstly want to extend thanks to @oldhippy for taking a look at this before I parted ways with my hard earned bucks. I wanted to get ONE set, with which I could stake and set jewels with (and take to the grave). Otherwise, you end up spending double in the long run. Bear in mind I do know how this thing works; however, have no experience using it. Yet. My sights are set on some dead Chinese clone movements taking up space which will be my first victims (enter diabolical laugh here)! This thing is in outstanding condition. Seller double-boxed and bubblewrapped it nicely. Wooden storage box itself is quite lovely- solid, not veneered. Some lemon oil and polish and it should look like new. Photo is "as-unwrapped" condition. The tool itself is gorgeous. Really looks to be new. Light brasso (Honestly, probably not needed) and then hard wax and it'll look brand new(er). The table shows all the graining from when it was originally ground. A couple tiny specs of rust only. Literally as good as new. The table lock works perfectly. Stake guide is tight, and has light surface rust inside (found when I passed a very snug fitting stake through the bore). It has no perceptible wear. Definitely good. And this can run inverted stakes. The fully Monty. The bad: I need to snug the set screw for the jeweling attachment a bit. I think all the stakes and stumps are here. Minor damage to the Bakelite stake holders, but I have superglue and I'm not afraid to use it. Then I'll load a collet in the lathe and start polishing all the stakes n stuff. I have the original manual with it, so I'll be able to tell if I'm missing anything. Currently, only the skill set is missing. Who doesn't like getting a new tool!?!? I'm pretty happy at the moment, despite a global pandemic.1 point

-

1 point

-

1 point

-

The Case Servicing Guide is a different document. It is not caliber specific, it is case code specific. The case code can be found on the case back. The 7546 was produced around the time that Seiko went to a new code system and it is confusing which code is the code to use. My 7546 that looks similar to his has a code placement similar to the new system and old system except One code is in a circle rather than a box. That case code leads you to a square case style that doesn't look anything like the watch. The case code following the "old" system is the correct one. Thankfully, the guide is full of pictures/diagrams because I need that. I couldn't put the link address because it goes straight to a .pdf download for me. At first, I suggested searching for "Seiko Casing Guide". That will lead you to older documents up until the early '70s. Seiko changed the name to "Case Servicing Guide" in the late '70s early '80s. Both are useful to have saved. He will need the 7546 movement guide in the near future. This caliber responds extremely well to a clean and service. And it is very easy to do. I agree about a lathe and I have one. I took a shortcut when the Seiko S-220 die set came up. It is shaped and sized perfectly for Seiko case and crystal work. I'm not sure I could duplicate the dies on my lathe. Lack of skill mostly.1 point

-

No need to even leave this forum, the guide has been posted repeatedly and can be found using the search box top right. Here it is again. 1982.03 Seiko Case Servicing Guide.pdf And the module service guide Seiko 7546A - Technical Guide.pdf it's common to have to make one own own tools, in this case a die. Although a lathe is required - a wonderful tool to have and learn about.1 point

-

Google this "seiko case servicing guide" There is a link from seikoserviceusa that will get you to a good casing guide. If your watch is the same as mine, it should be Case Code G I could not find a die that fit correctly in my chinese made press. The Seiko S-220 fits perfectly. And on this one, the die has to fit perfectly. The ring that holds the glass is very thin1 point

-

Drill rod without any other specification in the U.S. would generally refer to O1 steel, which is about perfect for punches and stumps. Sounds like you had some trouble machining it (it's pretty nice to machine), maybe you have prehardened stuff? Should cut like butter with HSS. For punches you would generally harden the business end, leaving the rear soft. Temper to a straw or dark straw color. They need to resist deforming when rivetting blue tempered steel, but not shatter. I've actually been meaning to order some from the U.S. as the usual suppliers (MSC, McMaster) have it in 0.001" increments and it's easy to get a size that hits the nominal 4.70mm they are. I have a K&D punch here that measures right on 4.702mm and a Star that is at 4.698mm. I've never figured out the chicken/egg deal with staking sets. All the U.S. manufacturers I know of used 4.7mm stakes and 4mm locating diameter on stumps. 3/16" is 4.763mm, but that won't fit. 4mm is 4mm. Odd. It seems the watch companies were using a mix of metric and inch from early on, as 8mm became a norm for small lathe collets, among other examples. One mystery nobody has solved is the thread on Schaublin W20 collets. Those were based on a U.S. design, from Waltham if I'm not mistaken- their American Watch Tool Company, which branched off into Wade (larger lathes) and Derbyshire (still in existence) for the smaller lathes. Anyway, the thread is a very strange 1.666mm pitch, which is weird in both metric and inch. I was very surprised when I bought my screwcutting lathe here to find that its leadscrew is actually an inch screw, all else being metric, and the thread chart shows very clearly 1.666 as one of the standard threads is can cut.1 point

-

To be fair the three I priced they are the only ones I would call antique to me the rest are modern.1 point

-

Casio sponsored one of our expeditions with watches for the group. The manual was 3X5 inches, but about 3/4” thick! changing time zones took some reading...1 point

-

It is complicated. Too complicated to describe. Look for the "Seiko Casing Guide". The case back will have a letter code that guides you to the correct procedure. I think I know what model that is and I have one that I did. Be warned, there are no new gaskets available for the bezel assembly and it is nylon so shouldn't be reused. Generic crystal gaskets are similar but don't work well. I ended up buying a nylon gasket set and tried at least 3 different sizes before I found one tight enough and it was nowhere near the size I measured. Lastly, the only die size that works is in the Seiko S-220 tool kit. Generic or plastic dies don't fit correctly.1 point

-

1 point

-

1 point

-

1 point

-

To get your mov.t working again you don't need any oil, you need a good balance, plus tools and the skill to put it back together. And you need a timegrapher to judge if it is just running or running OK. You can worry about oils later, if and when your present piece is running OK, and/or you want to continue working on mechanical watches. In the meanwhile have a good read at our pinned topic below that has answers to all your question, and then some. Movements do not "have a crown position", only the date ring and day disc may change. NH36 comes with calendar for crown at 3 and will get into your watch again just fine. As mentioned it cost about GBP 24, not 80.1 point

-

I'm not sure what's going wrong. As long as you have the spigot in the hole in the date corrector, it should work. Have a look at the attached document, It explains how it works OMEGA Calibes 551-751.pdf1 point

-

it was not dirty, simply the original lubricant is graphite loaded. Seiko barrels are sealed, not meant to be opened and especially in your case you will not gain anything from having done that, but will distort and contaminatte the mainspring by putting it back by hand. All that and much more has been dabated already so many times, as you would have found if you were to use the search function.1 point

-

Bold! Dive right in! Hairsprings like that are where lessons are learned. CousinsUK sells seiko balance completes at reasonable prices. I got one there recently. Won't come with the cock though. For that you'll need to find an eBay seller breaking movements. Counsins is probably also your best bet for various other parts. That said, I'm with the crowd on just getting a new movement. Your odds of success look to be quite low at the moment, and you'll go through a lot of balance completes before you have that guy running again. With two dead 7S26s in my desk, I feel like I can speak with some authority on that particular subject.1 point

-

Do not try further or you will break and get aggravation even more. Buy an NH36 movement on Aliexpress for about USD 25. Which from other reports can cause further troubles due to poor quality, plus requires tool and experience to be installed.1 point

-

1 point

-

There been a couple of lead designers for the F1 series. For the first series it was Eddy Burgener. The Lead designer for the series 3 to series 5 was Christoph Behling , with a sidekick in Peter Vardai (Series 4) . From series 6 it is Guy Bove and his sidekick Hiroshi Fujiwara. About the creative direction changes one just have to ask em, meanwhile one could read ablout it on places like... http://christophbehlingdesign.com/blog/archives/tag/formula-1#.X393PWgzZhE1 point

-

0 points