Leaderboard

Popular Content

Showing content with the highest reputation on 10/15/20 in Posts

-

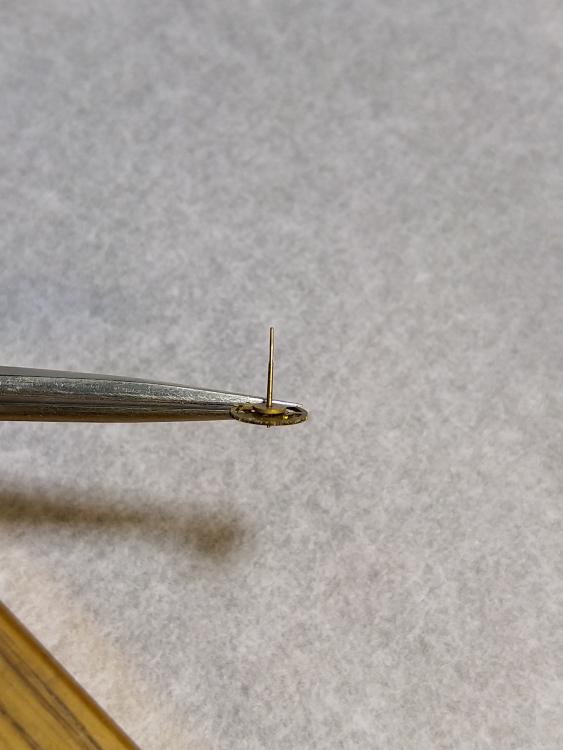

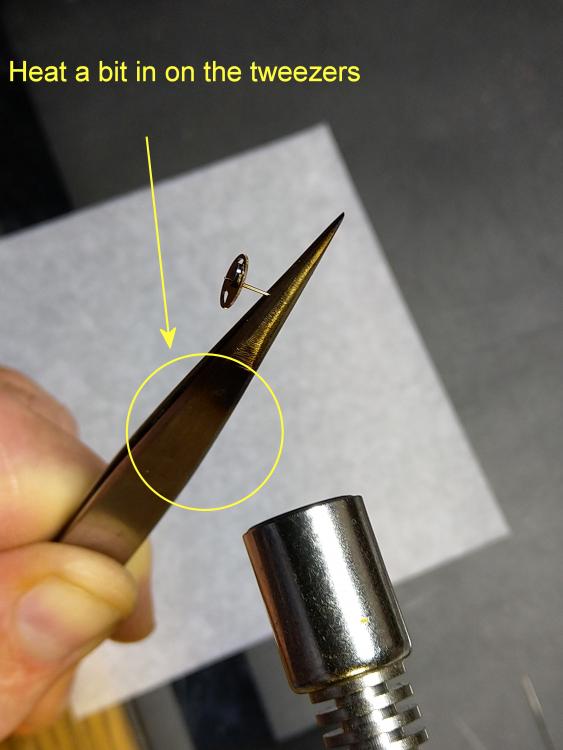

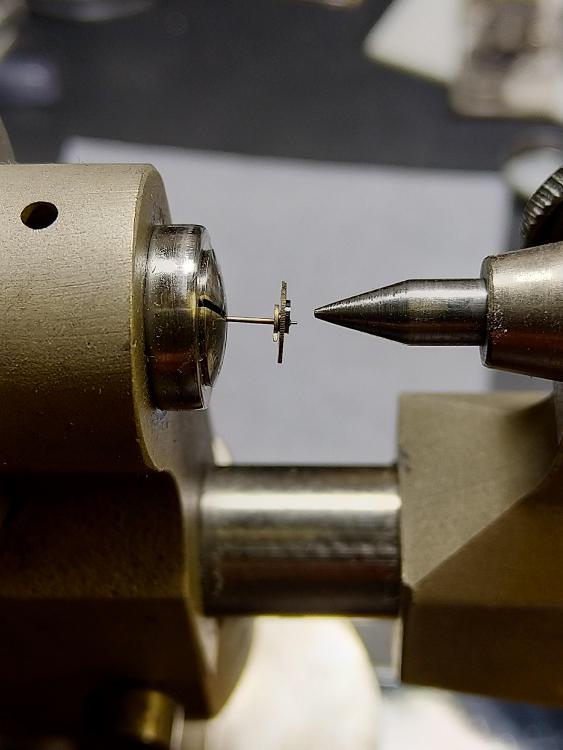

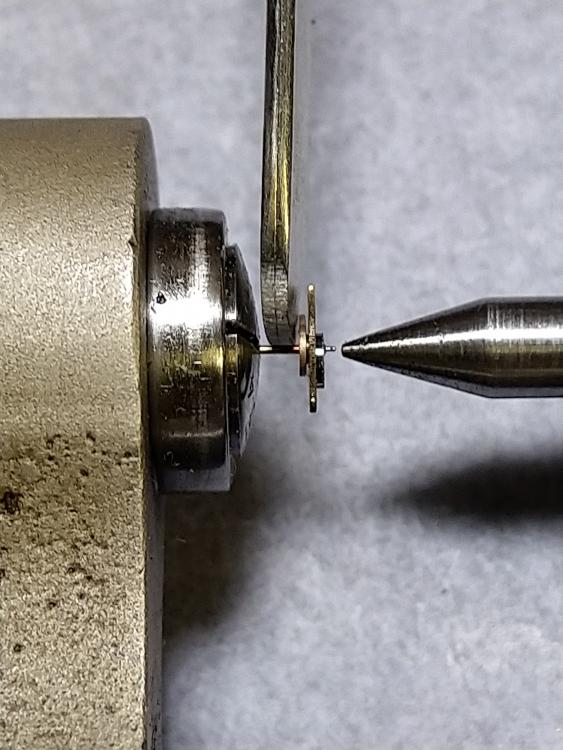

I think I have a similar technique which I can show. I have a slightly bent seconds wheel from a Landeron 48. I hold the pivot firmly in some discarded tweezers. Next, I apply heat on the tweezers, I use a torch but one can use an ethanol burner too. Just make sure you apply the heat a bit away from the actual pivot. When the tweezers are so hot you can’t hold them let go of the grip. The pivot is now softer and can be worked on without breaking, just make sure it hasn’t a blue color since then it has become too hot. Fasten it in your lathe, choose a chuck slightly bigger than the pivot diameter. Since the pivot now is softer and not to hardened you can adjust the straightness by lightly tapping at it when you found its high point. One just rotates the lathe by hand until the pivot is above the index pin. After you rotated it a couple of times by hand and lightly tapped on it will become straighter for every turn. And that is one way to do it.2 points

-

Hi Is it possible to remove the back and supply a picture of the movement as is. It will help in identifying the movement type and therefor the Battery.2 points

-

The Bergeons above are specifically for checking balances for flatness, and in the case of split balances for trueness in the round (a solid balance that isn't round or is eccentric is a bigger problem than what these can handle). The pivots are held by the conical portion, and quite a bit of force can be exerted on the rim to bring it true. The adjustable "finger" is for a visual reference while truing. The truing itself is done simply by finger or with non marking stout tweezers. The one below is a typical caliper for checking and truing train wheels. It holds by the end of the pivot, in V shaped cups. The little tool with the dovetail filed in is the traditional visual reference, it is simply slid around until a point is near the wheel rim, the wheel turned by hand, and checked for flatness. That little dovetail tool is usually one of the first projects a student makes in school, I don't think they sell them (I think my daughter made this one a couple of years ago as a project, hahah). Adjustment is carried out with stout tweezers, with one tip pressing in the center by the pinion, the other side of the tweezer is lifting on the rim at an arm. If a bend is discovered between two arms then the correction is at both arms. Bending between arms is a good way to kill the wheel. Obviously a bit of feel is developed to not strain the pivots. To check pivots for straightness the best is to run them in a lantern in either a Jacot tool or in the turns. If you have a good lathe with good collets that can be used too, I regularly check and straighten balance pivots in my lathe.2 points

-

2 points

-

Hi Wayne, It is always best to include photos on the movement and or caliber number with the question as it eases our diagnosis. cheers1 point

-

Easiest approach to diagnosis is to remove the winder module, remove the two black screws and lift the module. Show picture. Otherwise, Try winding through ratchet screw with a driver. Try releasing power by pushing winding wheel away from ratchet wheel. Try turning the barrel with pegwood. Report back your observations, if you will. Regards joe1 point

-

That is indeed the correct answer in all cases. With the watch in hand it has to be opened anyway, and even without pictures or searching, the battery recess can be measured and the battery found from the attached table. 1_Battery Cross Reference Guide.pdf1 point

-

1 point

-

1 point

-

I straighten pivots in the lathe, not with it running, just holding the part and turning it by hand to see where to bend and when it is straight. I use heavy nickel tweezers, or sometimes Dumont #8 tweezers which are specifically for this. Most important is to heat the tweezers tips in an alcohol flame until they are almost too hot to hold, and bend a little, check, bend a little, check. Some pivots are too far bent to save, but if they are saveable the heated tweezers make a world of difference. The heat isn't enough to affect the temper of the steel, it does help it relax while bending though.1 point

-

watch without potage Error code 600 (Error 600: Microsoft Word has encountered a problem and needs to close) watch with postage Error code 1010 (ERROR_BADKEY 1010 (0x3F2) The configuration registry key is invalid) mens Citizen gold plated watch broken glass_filesmens Citizen gold plated watch broken glass.html mens Citizen gold plated watch broken glass_files1 point

-

1 point

-

1 point

-

I looked at a Seiko Case service guide for the B0 case but in this one it looks a little bit different. Maybe there might be some tips and tricks in it. SEIKO Watch Case Servicing Guide.pdf1 point

-

You also need to use silicone grease to help the gasket slip over the lip and with bezel rotation1 point

-

As jdm remarked fit the gasket into the case (chamfer side up) make sure it is seated, What I do is moisten the edge of the glass and fit it square on the gasket in the case and apply the press slowly checking the fit and there is no possibility of crimping. all the best.1 point

-

First fit he gaskets to the part that has a shoulder to seat and stop it. Check if there a chamfer to help the other part fit. You need a good crystal press and much attention.1 point

-

1 point

-

2. Could be IWC as they used the Fish on their crowns but most I've seen hav a flat top and sharp corners. Anilv1 point

-

1 point

-

1 point

.thumb.jpg.e55eb6bf9fe359105c29e888446029bb.jpg)

.thumb.jpg.b34cd9c92d7e24db70cdea9c20fba12d.jpg)

.thumb.jpg.ecdb61f8b7c244fe5dbe9311d763795d.jpg)