Leaderboard

Popular Content

Showing content with the highest reputation on 10/11/20 in Posts

-

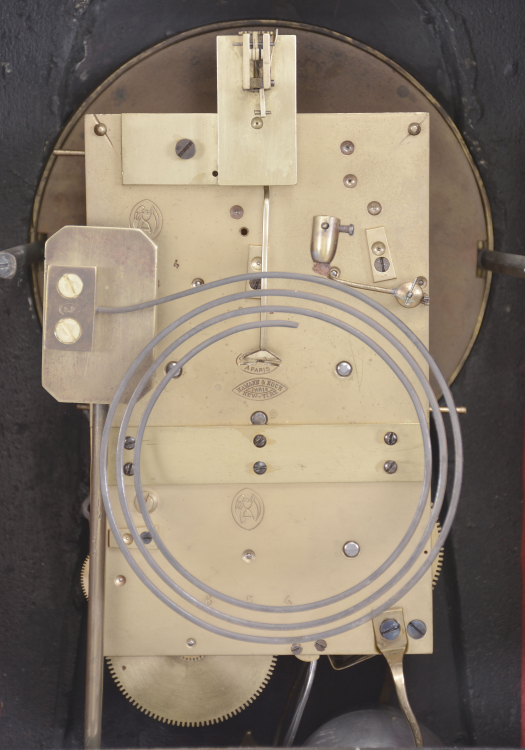

This is a large 8 bell spring driven bracket clock, they turn up now and again but no one has ever put a definite answer to who made them or which country they came from, this one is signed on the dial with the retailer"Moyle Chichester" the movements are never signed but just display a hour glass and sythe trademark: The movement is in two parts the bottom third of the movement consists of the chime mainspring barrel, chime drum, fly, hammers and bell nest it is connected to the top half of the movement which is pretty much bar a few modifications a quarter strike Ting Tang the large bracket across the movement is what holds the two parts together. This accounts for the rather close grouping of the winding holes on the clock face the chime mainspring is wound via an arrangement of intermediate wheels. The clock has a anchor escapement with a heavy pendulum with no adjustment other than via a Brocourt type adjustment with slow fast adjustment on the front of the clock face The wheel work and pivots are very fine though out the clock There is plenty of speculation as to who made these clocks but they usually turn up with english retailers names on the dial one name most often cited as a maker is a company called "Muller and Kern" Breslau which was part of Germany but is now Poland, the trademark site Mikrolisk attributes Muller and Kern to the trademark but that conclusion was based on the fact that someone had once seen one of these clocks with both trademark and name on the same plate but no photo has ever linked the two, people also state that Muller and Kern never produced their own movements they just bought and sold movements by other manufacturers. Personally there is much about these movements that makes me think they must be french the wheel work and pivots seem just too fine to be German to me.1 point

-

Found this one on a Swedish auction site. "DESCRIPTION: Müller & Kern, Breslau, Germany (current day Wroclaw, Poland) for Hamman & Koch, New York & Paris, chiming mantel clock, 8 day, time and strike with chime playing on eight nested bells, spring driven brass movement in a heavy black slate case with brass trim on a stepped and molded base with turned bun feet, polished black slate dial with incised roman numerals, gilt hands, all topped by a large cast gilt eagle with outstretched wings." "1 point

-

It is certainly an aid to servicing when putting plates together and lining up pivots with pivot holes when the plates are pinned rather than screwed together, when they are screwed together the pillars can sometimes be a pain to keep in place.And being pinned allows more room to spread the plates while still keeping alignment makes it easier to get the pivots in.1 point

-

Regarding the problem JohnD is right, only the coil from the same family will work as they are specific, Best source a donor module. I have attached the service sheet which will give you the values should you wish to test the coil your self. Seiko 8123A - Technical Guide.pdf1 point

-

Only the correct coil will physically fit, so that is your only option. Your best bet is to look for another 8123, 8122 or 8121, all of which use the same coil (8123 day/date, 8122 date only and 8121 no day or date). You should be able to pick up a 'tatty' but running, gold plated version quite cheaply on eBay.......1 point

-

Did some searching and found this. Is your hour counter creeping, or running at the right rate?1 point

-

definitely looks like it's all they are but it can't just fall out by itself? I'm attaching the service guide in case you don't have it. on page 8 shows how the circuit comes off. If you remove that you can see the sliding pinion as they call it that's part number two on the list it might've rotated and that would be a reason the stem wouldn't go in. In any case I give you a better view of what's going on. You do not need to remove the watch from the case you just take the circuit off and the associated metal shield over the coil. _c_t_ct_955112_fde_491181_10.pdf1 point

-

The movement that came with this watch has an amplitude problem that causes it to gain a lot. My timegrapher isn't even able to sync to it. I didn't care try to work on the movement without more knowledge and experience, so I ordered scrap movements of the same type to work on. I've been able to build a movement from those. This built movement works better than the one in the watch, but it isn't perfect however, its amplitude waxes and wanes, and the watch gains and loses time along with the amplitude changes. For example, it might say 278 and +3 seconds, then jump up to 302 and +22 seconds, then down to 265 and -13 seconds. I'm keeping it wound and on the timegrapher to see if this settles out. I've also demagnetized the movement. All the parts have been cleaned and I've oiled the movement with D5 and 9010 in the appropriate locations. I've not been able to get this watch back together again yet as its dial feet are friction fitted and are loose in the movement. I've ordered some adhesive pads from Esslinger's. Here are some pictures of the case and dial that I've attempted to take with the macro function on my old camera. They've not come out great, but they may be good enough for an expert or two to give me an opinion on their provenance.1 point

-

I’ll take a guess. The hole above the “H”- press down gently while pulling the crown. I could be wrong too so get the loupe on and some light in there.1 point

-

Hi you may find this helpful should something decide to go AWOL 1075_ValJoux 7750 Pages 8-13.pdf 1077_ValJoux 7750 Pages 19-23.pdf1 point

-

if you had asked the question without the video the answer would've been different. Normally attempting to clean wristwatch dials would end disastrously. Dials like what he has in the video those are brass disk with a silver metal finish. The black numbers are printed on and then there's a lacquer protective finish. Normally any kind of cleaning would have to take the lacquer off if you what the silver to look untarnished. If you're not careful which is basically trying to do this you can end up with the numbers floating away because they really don't like to be cleaned. then if you can brighten up the silver which you can do with silver cleaning solutions it would ideally real actor the dial. None of which she shows here it's almost a magical process. seeing as how there's a website maybe you could ask their. If you get an answer report back please https://www.nicholashacko.com.au/1 point

-

This is the second video by this watchmaker I've seen where a couple of liquids are used to clean a dial. https://www.youtube.com/watch?v=zD3ZuTp8PcA A 6 minutes and 15 seconds into the video he uses a pale red and pale blue liquid to clean a badly deteriorated dial. He then air dries it. I'm very curious what might have been used. Does anyone know? Any ideas?1 point

-

it may be possible to modify the parts but as you've noticed people like Matt think that they should get paid for whatever the heck they're doing what a silly concept that is. let's look at the modification route versus manufacturing from scratch. Both components have gears. Cutting new gears would be a pain so let's keep the old gears. one form of modification would be to cut off the tubing part. Make new tubing or cylinders. The hour wheel is considerably easier because it's typically made out a brass tube or cylinder part has straight sides they would be much easier to do. You would probably have to bore out the gear part so that your new tube would press in. Then perhaps a low temperature solder would be all that you would need. then the canon pinion that's going to be harder. Typically it's made out of steel. The tubing park can be relatively thin it's not smooth I think it because of a pain to make a new one. Then attaching it to the gear is problematic because this is where the friction part for the hands setting is you're going to put a lot of torque on the gear versus the tubing part. Probably laser welding of the two would be the only thing that work maybe. then as another form a modification. Perhaps just put extensions on both components. one of the ways to combine two separate tubings together would be if one of them is tapered on the outside the other is tapered on the inside and they literally friction fit together. Possibly Loctite but be extremely careful that the Loctite is all cleaned up and removed as it can be very bad if it gets on the center wheel components. Some experimentation would be required here but that might be another option. the best way would probably be to look in the Chinese who clone the watch and see if they make a taller version and solve your problem.1 point

-

1 point

-

I have decided to take on a bit of a challenge and ad my contribution to the horological world by designing a custom build using the venus 170. I have spent the last 3 months studying, learning, slaving, crying, destroying, getting to this point in my watchmaking/repairing level. My first attempt was to tackle the Mount Everest (at least to me it is) of movements the 7750. I was met with a lot of belittlement and criticism by a few in other forums. To their point they were correct in many areas however I don't think I would have gone about it in any other fashion. I still have yet to conquer that beast, however I have learned a ton. I am almost there with the 7750. After attempt 6 I have decided to put that movement to the side. I have also spent a great deal of time working on the Elgin 462, which has also been quite a learning experience, and I have also yet to achieve success on that platform. After doing some research and learning about the castle wheel, column wheel, pillar wheel or whatever other terms it goes by I decided to pick up one more challenge. After doing some research and checking the wallet I stumbled onto the ARISTO Imports Chronograph with the venus 170 movement. My goal is to restore this movement and to include it in a custom build. I have ordered several other spares and intend to use them to reach my goal. In addition I intend to finish with a robust walkthrough of this movement. I have already reached out to many folks on this forum as well as reviewed scott mcafee's thorough thread on the movement. I originally wanted to add onto scott's thread but after reading some posts I have leaned that this is not the correct way to go about recording this venture even though logic would say keeping like information together seems well......logical. Anyhow I would ask that anybody and everybody include their comments and knowledge and even opinions. I have thick skin and welcome any and all input. I will do my best to give credit where credit is due. I will start by adding a copy of the Esembl-O-Graf I downloaded from the Ohio State Library. I found several copies but this one has the best quality. I have also included a copy of Ebauches parts breakout guide (If that's what its called). Thank you all in advance. Venus 170.pdf 170.pdf1 point

-

A little correction- shellac is the secretion of the lac bug, after it eats sap.1 point

-

Naphtha is not a water solvent, so will not work for that purpose. Heat also softens shellac, so I would bear that in mind. Also, you might burn your house down. I’d maybe just do a second water rinse and a longer heat/dry.1 point

-

0 points