Leaderboard

Popular Content

Showing content with the highest reputation on 06/27/20 in Posts

-

These movements you quoted are very old (1940/50s era) so they are much more inclined to fault when not handled properly.my first question is are you cleaning and oiling these before reassembling? If not then that can be your issue to begin with but here’s what i think...... the one that stops on the side = bent balance staff and/or broken jewel why? Because you did not set the balance properly before screwing down the bridge. It’s should be ticking as soon as you seat it correctly if there is power from the mainspring. I always wind up the watch and check action of the pallet before installing the balance. Once you see it running put the screw in and gently rest your finger on the bridge while you screw it down, sometimes they wiggle as you screw it down and the staff can pop out of the pivot. Just use the weight of your finger do not apply any additional pressure. Do not screw it down all the way at first, screw it until bridge is secure remove finger the tighten it as much as you can from there...balance screws should be tight too loose can cause watch to stop. the one that runs fast = magnetized or sticking hairspring coil why? Because you didn’t clean the movement. Or demagnetize the movement and or your tools. You could also be warping the hairspring when you remove it or not setting it down properly after you remove it. It should be laid on its back with wheel sitting into the balance cock pivot, or put up on a balance tack...some are against this but i have used a balance tack forever and never once had an issue....i just wouldn’t leave it there too long. When a movement runs fast look very closely at the coils expanding and contracting - a cell phone video with slow motion works good. Make sure none of the coils are sticking and also make sure the expansion is even on both sides. when not laid properly the hairspring can get off center and coils will contract much more on one side causing it to run fast.3 points

-

My restored Seiko Kinetic purchased and worn since 2004 SMY093P1 Rotor removed and running from a non rechargeable battery. Sapphire crystal fitted. Sent from my Moto G (5) Plus using Tapatalk2 points

-

It's not like it's hurting the rest of us. It's not like they're selling snake oil either. People who buy this stuff know what they're paying for. As long as there's not deception involved I don't see the problem here.1 point

-

1 point

-

Your DS Caimano seems genuine to me, a good reason be confident is that counterfeiters normally target higher than €250 quartz watches.1 point

-

It will be metric, to the NHS Swiss norm for watchmaking. An 0.50mm thread has a pitch of 0.125, so that sounds like what you've got (0.40mm is 0.10 pitch, and 0.60mm is 0.15). Back then one would encounter sometimes "half sizes", like 0.55mm but I doubt you have that. The image is a screenshot from the Asco Schuch catalog- they are the go to guys for small watchmaking taps and dies and they provide a lot of useful info. www.schurch-asco.com1 point

-

Repairer should fix it. If it stops at 23 hr only, the fault is with date change mech. In case it stops at hr 11 as well, the fault can also be of causes elsewhere.1 point

-

1 point

-

Hi, the reason is that I don't wear the watch everyday anymore like I used to. In my experience the kinetic batteries seem to go bad if not regularly charged. So for me it would be a waste of money to fit a new kinetic battery. Sent from my Moto G (5) Plus using Tapatalk1 point

-

1 point

-

FYI the same type of search and information is also available on Cousins UK. The advantage of using them is that unlike Boley parts availability and price is shown immediately, and then available to anyone, no need to prove anything to get an account opened. I recommend that one checks well which sizes are in these assortments before buying, because most often these are just for dress watches and not diver's. Yes it is, just like on he caseback gasket one should use a tiny amount of watch silicone grease.1 point

-

I think one can take a look at the previous posting of a Benrus like this, Rogart63 added an link showing the service of this movement...1 point

-

there is nothing that prevents you from making assessments before cleaning or servicing. Like for instance this watch looks really bad so the assessment is cleaning might fix the problem. if you do a search we've discussed using the demagnetizer. background history of the watch is always helpful. In other words what was it doing before you played with the demagnetiser ? Then when you see a display like this where you can sort of see lines basically the numbers are a waste of time. If you can't discern a pattern in the graphical display timing machine is not more intelligent than you usually and that means the numbers will be garbage.but if we are going to go by the numbers amplitude is way too low to really get anything meaningful you should be up closer to 200 minimum. So the assessment above cleaning would be a good place to start.1 point

-

Hello all, I know it's 'only' an electrical one but to say I'm overjoyed is a bit of an understatement. My Grandfather gave me this, his 1982 retirement watch, 20 years ago as an empty case and strap - the innards had apperently been slowly demolished over the years by a leaky battery and where nowhere to be found. At the start of the locky-down thing I decided it was time to do a bit of research to see if the parts could be found to rebuild it, bit of a baptism of fire as a total newby. It soon became evident that this search should have been done years ago because Omega restricted parts coupled with a dearth of NOS parts was a real headache! Through all this research I also realised just how rare the case and bracelet style were so persisted for months, getting my claws on some old, rough, nasty and for want of a better word, crap bits and pieces. As we know the circuit and coil are getting really rare but even more rare it seems are the winding pinions and dials for them, and even the crap parts are ludicrously expensive. You know how you get into something, buy bits, realise your up to your neck in it but realise you're to far in it to retreat? Suffice to say, I've had so much support from several people in the watchmaker community so with their help and shear dogged, billigerence and blatant stubbornness it is finally running. Still some work to do - the date needs to start changing at half 11 because it takes two hours to change, the seconds hand needs lining up better with the minute markers and I've toyed with the idea of restoring the dial, with some lacquer and minute markers missing (or maybe not, as it's a sign of its individuality!) Having enjoyed it for a while I'll also take it all apart again and service it, only because of Lawson''s brilliant walk-through on the 1337 movement on this forum. Never really thought of a bi-colour watch like this as my style, but with the blood, sweat, tears and more sweat and tears that has gone into it, I've decided I love it to bits. Thank you all for your never ending inspiration and such generous shared knowledge Mark Lovick and everyone - great bunch of people you lot!1 point

-

1 point

-

@JerseyMo has it right, from a distance and at a glance these two are incredibly simiUn Unlike the Movie "Twins" with Danny Devito and Arnold Schwarzenegger, both these are handsome, stylish, healthy and strong, one is sensible and affordable there other is a status symbol and has held it's value Omega on the left, Timex on the right... They look like eyes, starting at me, following me!1 point

-

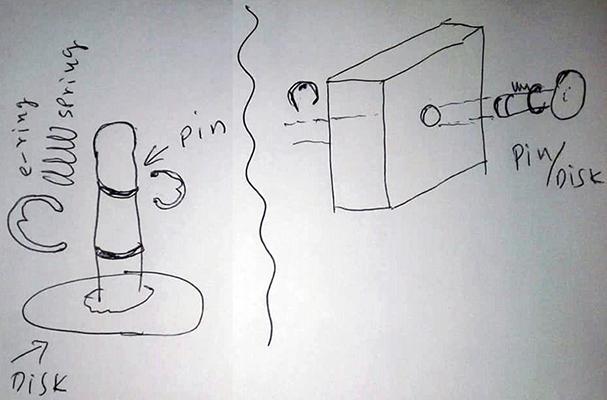

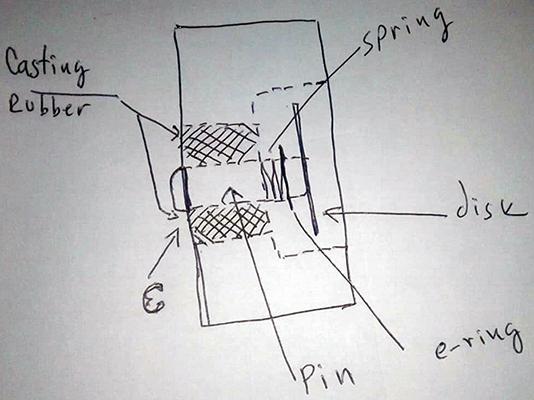

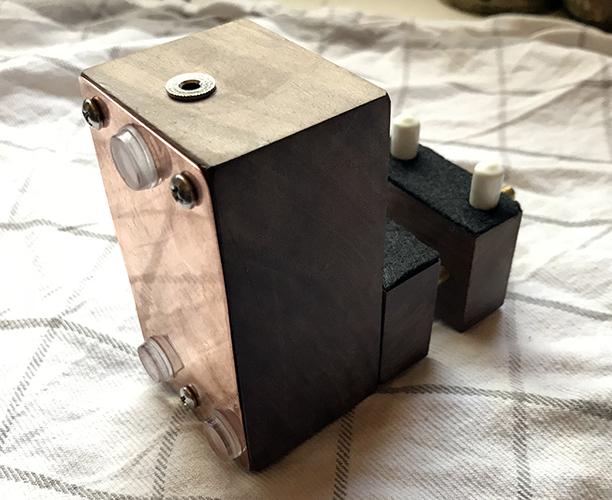

I've already posted this on another popular watch forum, but I think it better fits here. I'm sorry if this post get too lengthy due to all the images. Hey everyone! I would like to share a project that I've been working on for a while. After a few different variations, I think that this is my final design for the time being. Project background: For many in this hobby, applications like Toolwatch are great because they allow you to determine daily rate, but it doesn't provide anything beyond that. Those of us who enjoy tinkering with watches should have a way to also check the amplitude and beat error. Sure, I could have purchased a timegrapher from China but I thought it would be a fun project to attempt constructing one myself (with the help of several resources). I used these microphone stand plans for reference and made some changes. There are also plans for a DIY pre-amp on the Watch-O-Scope website, but I followed the instructions from my good friend Guido (also posting on this thread) and modified a PYLE pre-amp by removing a capacitor from one channel and replacing the electrolytic capacitor with a ceramic capacitor on the same channel. The first iteration gave promising results but I wasn't entirely pleased with it. It seemed like the audio levels were somewhat inconsistent and I would get a ringing or echoing noise depending on the amount of pressure against the piezo disk (the contact microphone element). After some discussion with a friend, we came to the conclusion that many professional timing stands never have direct pressure against the piezo element - instead, the metal clamp that holds the watch is coupled with the piezo using a different piece of metal that transfers the vibrations. We came up with these sketches for a better design. Completed and polished pin before attaching it to the piezo. Pin installed. Soldered some thin cables from broken earbuds to a 3.5mm connector mounted in the stand. The results are good. Now it's time to add a copper plate to the back to reduce electromagnetic interference. Another good idea is to add some felt so I don't scratch any crystals when testing the dial down position. Finally, the build is complete! I'll admit that this might not be the most beautiful creation, but it's definitely functional and it does exactly what I need it to do. I have ideas for further improvements, but they are not necessary and are really just a challenge to get the cleanest audio signal (there's still quite a bit of static). Waveform from Watch-O-Scope (highly recommended software, made by a fellow WUS user). This is amazing software that I pair this microphone stand with. An alternative is TG Timer, but Watch-O-Scope definitely is the better option. Quick audio recording I made: Test Recording #1 - Mega.nz1 point

-

Hello everyone, I was wondering if anyone has any experience or at least heard of finding a converter so that the microphone stand from a Watch Expert machine can be plugged to a computer. I recently got my hands on a Witschi. It has great fidelity and the mic is excellent. I have been using WOS for some time now and I really like it, but the shortfall is the mic. So, I did some search of a possible adapter to connect the mic to the computer and use WOS. The mic has a 5 pin plug. I couldn't find much... Thanks in advance! JG1 point