Leaderboard

Popular Content

Showing content with the highest reputation on 06/16/19 in all areas

-

Thanks for all the suggestions, just to bring this up to date ...... The movement is fitted into a mounting ring fitted from the back and on this particular watch the stem and crown are all in one piece. After much cleaning with wood and plastic scrapers and a bit of pressure I managed to remove the mounting ring and the movement from the case. I took photo's at every point of the strip down so hopefully it will go back together in a logical sequence and all the parts are seperated into small groups to aid in reassembly, now to start cleaning all the black stuff out of the components and plates. The glass came out from the front of the watch and seems to have a steel ring fitted to the inside diameter of the glass, is this a removable part ?2 points

-

My advice is this. Whenever you are about to start on a new mechanical watch repair, make sure all your screwdrivers and tweezers and other tools you might use are de-magnetised. It is also good practice to de-magnetise the watch movement before attempting any repair. It will also save you time.2 points

-

Complete novice here. After watching a few of Mark's videos on Youtube (great work, by the way) it appears that some of his tools are slightly magnetized. My question is, in general what tools to you want to be magnetized and which not? Obviously, brass tweezers are going to be non-magnetic. Also I can see the value of having at least one pair of tweezers slightly magnetized. Advice?1 point

-

A soak in diesel fuel, naphta for day or two, ends the old story of heads popping off the screws. I remove balance cock pallets and soak the rest, give one dip in a fluid I can stand the odor of. Any cheap multipurpose oil would do. I use several solutions, detergent seperately and brush extesively.1 point

-

the ring is part of the case, holding mvt. in. the proper crystol fits over it. vin1 point

-

Looks like a fun project. I suspect there is little that would stop it passing modern electrical safety standards, so long as it is earthed, has the correct rated fuse, and a suitable mains cable attached. How does the speed controller work? Some of these old speed controllers use an interesting arrangement of compressible carbon disks as a variable resistor. I have an old Singer sewing machine that uses this arrangement, and a slightly newer Kenwood Chef mixer that uses a triac speed controller. Both are 1970s vintage, and both work well. I would inspect any capacitors associated with the motor assuming there are any, and perhaps replace those with modern suitably rated ones, but the rest I would suspect is fine. If the motor runs, then it will probably keep running. If this is a brushed motor, you might like to take the opportunity to clean the commutator with a bristle brush (not a steel wire one) and inspect the motor carbon brushes too. If the brushes are badly worn or damaged, they can kill the commutator pretty quickly.1 point

-

1 point

-

1 point

-

Some parts are interchangeable between calibres in the same model family and some aren't. The Jules Borel web site has a very useful facility for working out what parts will fit what movements. http://cgi.julesborel.com/ The beat rate of a movement is determined by the balance assembly and is primarily a function of the inertia of the balance wheel (determined by the size and mass of the wheel) and the length and strength of the hair spring. It is a specific design feature of any given movement. So I happen to have an 1803 and a 1950 in my to do box at the moment, so with a spare half hour this evening I did some tooth counting..... With both of these movements the center seconds wheel drives directly off the escape wheel pinion. On the 1803 the the Center seconds wheel has 80 teeth and the escape wheel pinion has 8 leaves, so the escape wheel rotates at 10rpm. The escape wheel has 15 teeth, so that's 150 teeth passing through the pallet per minute, which is 2.5 teeth per second. It takes 2 beats of the balance to get 1 tooth through the pallets, so that's 5 beats per second, or 18000 BPH. On the 1950 the Center seconds wheel has 72 teeth and the escape wheel pinion has 6 leaves, so the escape wheel rotates at 12rpm. The escape wheel has 15 teeth, so that's 180 teeth passing through the pallet per minute, which is 3 teeth per second, so that's 6 beats of the balance per second, or 21600 BPH. If you use a 1950 escape wheel in an 1803 without changing anything else then you have the escape wheel turning at 10rpm (determined by the beat rate of the balance) but only 6 leaves instead of 8 leaves on the escape wheel pinion. This means that in 1 minute the escape wheel turns 10 revolutions, or 60 leaves leaves worth of engagement with the center seconds wheel, which has 80 teeth, so the seconds wheel will only make 0.75 of a full rotation. You need another 20 leaves worth of escape wheel pinion rotation to get one full rotation of the seconds wheel, which takes an additional 20 seconds. So with this combination it will take 1 minute 20 seconds for the seconds hand to make 1 revolution of the dial when the balance wheel rate is correct (18000BPH).1 point

-

1 point

-

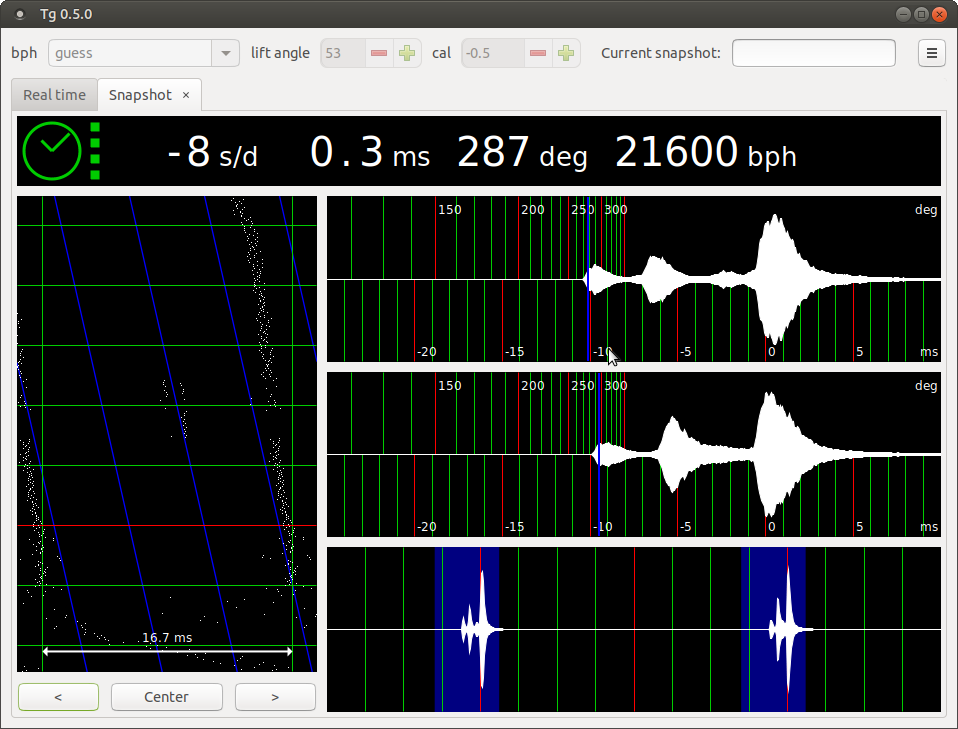

Today I barely managed to resist the urge to don my ten gallon hat and chaps and head off to the pub with no beer. The "Rodeo" is getting a ride round the range on my wrist today. It is actually pretty well behaved in terms of keeping time. That mystery 17 jewel french movement performs about -10 to +15 s/day hovering near 0.3 ms and managing a fairly healthy 287 degrees of swing at 21600bph. The bizarre transparent burgundy case sometimes makes it appear that the crown is backlit by an LED. A strange but interesting addition to the 404 club collection.1 point

-

Anytime were working with American pocket watches it's nice to have the serial number especially when looking for parts. Then because this is not your normal 12 size it's extra thin looks like you're right it's a friction jewel setting. So image extracted from a listing so we get the diameter and the thickness. Then the other minor problem with Illinois all the different part numbers to make for a confusing mess.1 point

-

Robbed... positively fried I would say. However, on the plus side, I can use it as an excuse to tell terrible sausage jokes... Capitalism, Socialism, and Communism have a meeting for tea at noon. Capitalism and Communism arrive on time, but Socialism is nowhere to be found. Finally he arrives, out of breath and apologetic." I'm sorry," says Socialism, "I was standing in line for sausage." Capitalism says - "What's a line?" And Communism says - "What's a sausage?" ... or ... There were two sausages in a frying pan. One sausage turned to the other and said "man its hot in here", the other sausage looked shocked turned and said.. "Now there's something you don't see every day... a taking sausage!!" ... or if that doesn't tickle you ... There's this butcher and one day just as he is about to close the shop for the day a dog came in with a note in his mouth. The note read "Can I have a steak and three sausage links please?" The butcher took the note and gathered the things. When he turned back around he was surprised to see a twenty dollar bill in the dog's mouth. The dog grabbed the meat in a bag and left the shop. The astounded butcher decides to close up his shop and follow the dog. The pair soon came to a bus stop. The dog looked at the schedule and sat down on the bench. The first bus came and the dog got up and trotted over to the front of the bus, looked at the number and sat back down. Another bus came and again the dog looked at the bus number and saw it was the right one. He got on, the butcher closely following. The bus rumbled on and the dog jumped up walked to the front of the bus, leaped up and rang the bell to stop the bus. The dog got out with the butcher in tow and headed off down the street. After some time they turned in to a driveway. The dog bounded down the tarmac to the door and clattered the letter box. The dog did it again and hopped up on a fence to peer in the window. The canine knocked on the window with his paw then jumped back on to the tarmac, grabbed the meat and walked up to the door. The door opened and a man walked out and started to yell at the dog. The butcher ran up to stop him. The butcher said "What are you doing? This dog is amazing!" "What are you talking about? This is the second time this week that he's forgot his key!" BTW - Pro tip.. Do NOT Google "Sausage watch"... just saying...1 point

-

1 point

-

Looks really good! Just the collet is not yet quite centered. Frank1 point

-

Used the new tool today. Had to chamfer the hole to prevent the collet from spreading when I tightened the the screw. Sent from my iPhone using Tapatalk Pro1 point

-

1 point