Leaderboard

Popular Content

Showing content with the highest reputation on 05/16/19 in Posts

-

Just to update you all. Thanks to HSL kindly sorting out a balance complete for an eta2408, I’ve now brought this attractive gents accurist back to life. Thanks HSL, much appreciated sir! Sent from my iPhone using Tapatalk2 points

-

Since I have a restless brain I today decided it was time to practice on an ETA2824-2 Movement. I pulled the practice 2824-2 movements box out and blindly picked a specimen. But soon I realized the pictures probably are so many it would be hard to upload. So I made it to a two part PDF series instead. Part 1 2824-2 Disassemble.pdf Part 2 2824-2 Assemble.pdf1 point

-

A Finn gave me the recipe the Finnish watchmaking school uses for clocks. It works well and is quite gentle. For anyone interested it's: 1 liter 99% iso alcohol 3 liters distilled water 60g oleic acid 50g oxalic acid Everything heated in a stainless pot until quite warm, then ammonia, mixed in last, adding until the solution turns clear (about 80g of 25% ammonia) The ammonia and oleic acid form a soap, and the ammonia is sort of neutralized so it doesn't eat into brass parts. The oxalic acid is a gentle rust remover.1 point

-

So far this thread seems to have concentrated on what to clean the jewels with, but I think you also need to be aware of what your enemy looks like. I've linked to the bit that shows some good examples of oil turned to snot, but it is worth watching the whole thing if you have the time. Also look through some of Mark's videos, he shows examples of manufacturing debris in one of his Seagull movement videos (which I can't track down at the moment). This video gives a very concise view of what you may be missing. The issue is that often what I think is clean, isn't. This is where good magnification and good light comes in to play. Half a dozen trips through the ultrasonic, and any number of magic secret sauce cleaning fluids, may simply not be getting at the dirt in the first place. Old oil is strange stuff. Sometimes it goes colloidal and viscous, sometimes it goes dry and powdery, sometimes it turns to tar, sometimes it is more like varnish or plastic, and in the latter form, it seem that only mechanical intervention will actually ensure that you get the dratted stuff removed as it appears to become impervious to both lighter fluid and detergent. The "green cheese" and other dirt that gets in to places like the keyless works, and from there pretty much everywhere else, and the flakes of corrosion and machining swarf, and bits of ablated plating, are also sometimes almost completely impervious to cleaning fluids, as are human hairs and clothing fibers. When all else fails, you cant beat old school careful inspection and mechanically cleaning by hand.1 point

-

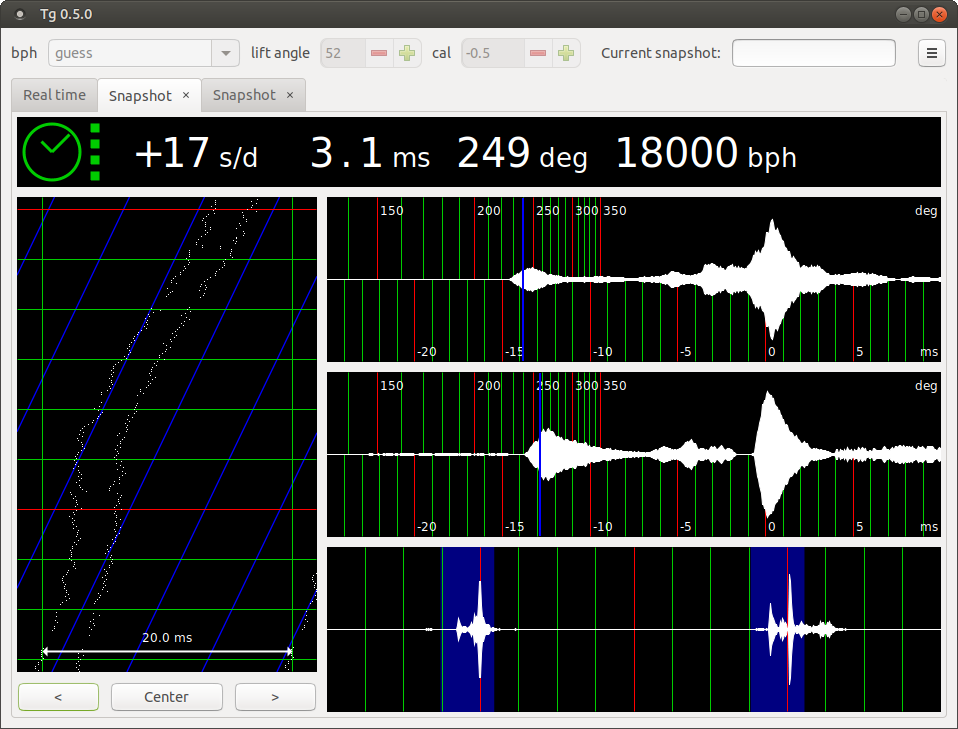

Today I have a Ruhla/UMF "Falux" branded pin lever based on a late variant of their Caliber 24 design and produced in the GRD around 1978. The movement looked familiar, and indeed is very similar to a Saxon branded Ruhla I restored at back in november. I found a couple of nearly identical versions of this dial on line, with Saxon and other logos. It runs reasonably well, but the balance objects if I try to get the beat error below about 3ms, so there is probably a little wear or eccentricity issue there. I didn't delve any deeper as I suspect it might not be possible to improve on the results owing to the somewhat rudimentary nature of the balance. It whirs away at a somewhat pedestrian 18000 bph with an almost cartoonish and very audible tick-tock, but has kept pretty reliable time over the last day or so. Edit: Given the spec of the movement, I think this particular one is well within spec. Escapement: Pin Pallet Escapement with a Safety Blade and Roller Balance Spring: Temperature Compensating Accuracy: +240 sec/ – 120 sec/day Number of Beats per Hour: 18,000 Diameter of movement: 24mm Height of movement: 6mm -2 to +4 mins per day. That is a pretty big target to hit.1 point

-

You are lucky it was just tap water. Salt water and you would have been in real trouble. It would be best to clean it again to be on the safe side. Omega’s as you know are expensive so care needs to be taken.1 point

-

I agree with J, furthure, I place the backside of the dial under direct sunlight ( under cover) for a day, dial shows no sign of moisture damage Now, moisture penetrates through pores in the paint, flakes appear much later. What luminious material is used on hands ? The sooner you clean the movement the better. Shock breakes a part or two, water ruins all. Regards1 point

-

It's an Omega with a chronometer grade 7750. There's no damage to the dial, so you're very lucky you caught the moisture and opened it in time. I strongly suggest you take it apart and service again to avoid possible rust, heartache, pain, and $$$ later on. J1 point

-

Ive been working 7750s for a year now. Ive rebuilt 3 so far. 1 from almost scratch. Im no expert but i have just about every peice of tech data out there and tons of spares if youre looking for anything. Youll get just about all the expert help youll need here. A lot of very experienced and generous folks on this forum. You def come to the right place. Please keep us posted.... Sent from my SM-G950U using Tapatalk1 point

-

1 point

-

My father recently asked if I would service his wrist watch which he bought from the NAAFI at RAF Akrtiri in Cyprus during his national service days. The watch came to me as ticking, but the oil on the keyless works had gummed up like tar, making it almost impossible to wind without fear of doing some damage. Anyway, here are a few before and after photos. Sent from my iPhone using Tapatalk1 point

-

So it seems you have an untainted Valjoux in you Collection, so nucejoe now we need some movementporn,pictures!1 point

-

After I watched a couple of Mark Lovicks videos on making a watch with parts sourced on eBay I figured I'd give it a try. I made two. This is my favorite. It's a divers watch with an eta 2824-2 movement. I'm quite proud of it. I picked up an H link shark mesh bracelet. I'm calling it the deep blue desk diver. Lol1 point

-

You need to work it out with patience, it have degrade to sticky tar. Use a small nail with a bent, sharpened tip. Some heat with a lighter may help. When looking for a replacement on Cousins look under Swiss crowns, not gaskets.1 point

-

Thank you, you have an observant eye and good question. Based on the before pic it does not look like the same chapter, but honestly, I can remember anymore. As part of this process I have collected a number of these Citizen’s i.e. complete watches, cases and parts. I am a Seiko guy but have grown to appreciate the 8110A, there a bit more complex . Take care and all the best1 point

-

Thank you for your kind words. If you recall you helped me out early on in this project which resulted me in tearing down a number of these 8110A while leaning to master them. All my best to you,1 point

-

1 point

-

1 point