Leaderboard

Popular Content

Showing content with the highest reputation on 11/27/17 in all areas

-

Why demagnitize quartz movements . Think that is a bad advice? The risk of destroying something is high. The stepper motor has magnets inside like a electric motor. If the get demagnitized it's caput. besides there is a very little wheel on the stepper motor that easily breaks. High speed could kill it faster then a blink of an eye.2 points

-

You can bend the tips of the hour hand slightly to clear the chrono hand, or you can also take a fine-cut file and reduce the height of the stem a little so that is doesn't interfer. You can bend the hands while still on the watch with brass tweezers. Be careful not to slip and scratch the dial. J2 points

-

1 point

-

Friends and family have taken an interest in some of the watches I've serviced and since they've only known Quartz pieces I thought I'd fix something up for them for the holidays. So I purchased a couple of Seiko divers a few weeks back off of eBay with the intent of getting them back into spec. One came from the Philippines and the other India and both were in a bad way based on the sellers' images. The first (from the Philippines) turned out to be a pretty good deal as it the entire movement and case was salvageable. It was nothing special to look at the start, that's for sure, but it will spiff up pretty nice in the end. Unfortunately, the picture here (in the condition it arrived) hides the fact that one of the dial feet has gone missing. The correct solution to this problem is to solder the foot back in place but me being a fool with a soldering iron I opted for a strong two part epoxy instead. The dial may or may not be original but it's in fair shape and needs only to have the luminous paint removed and reapplied (I've not done this before so we'll see how it goes). The hands will be polished and replated as they are a real mess. The movement is in excellent shape and has sprung back to life with a proper cleaning. The only part of that endeavor which was out of the norm was the removal of "dial glue" from the movement with a bit of acetone. I'm currently just awaiting the replacement bezel insert and a new 2.25mm watch crystal to finish this up. Unfortunately the watch from India- well that was a whole 'other story! It was clear right off the bat that there was an issue with the dial as it sits crooked in the case. I thought this was the result of another missing dial foot but it was much worse than that- both feet are missing although it may not have mattered because the wrong movement was in the case as well. The diver should have a 7002 (17 Jewel Automatic with Date) movement but instead has a 7019 (21 Jewel, Automatic, Day-Date) fitted. Close examination revealed a bit of (ahem) over-oiling? Just when you think you've seen the worst case of excess lubrication in a watch movement a new case comes along. I'm still only about halfway through this repair so I'll follow-up with some images as they come. With the dial feet lost and the dial bathed in thick oil, I considered it a lost cause and proceeded unafraid with a cleansing using isopropyl alcohol- it actually cleaned up fairly nice but will need quite a bit of work to be considered "good enough" for daily use. Some foolish person apparently tried to remove the lime using car keys or some such tool and scratched the dial terribly. (sigh) I've since finished servicing the 7019 movement although the mainspring had failed and I'm not certainly I'll bother with a replacement as the movement will probably just be flipped to offset the cost of the proper 7002 movement. More to come soon...1 point

-

Have an old H. E. Peck pocket watch and while adjusting the hairspring, I broke it right at the regulator. So I re-pinned the new end and installed it. It was running with poor amplitude, so i tweeked it to get the hairspring colet over the upper Balance jewel. This worked really well and now i have a swing around 400 degrees (same arm range). However, the watch now runs fast. So what would you recommend i do next: add washers or something else. Sent from my iPhone using Tapatalk Pro1 point

-

Hello everyone, I am a begineer watchmaker in Istanbul. Cheers Sent from my iPhone using Tapatalk1 point

-

The Rolex timing screws have a very tiny amounts of adjustments because they are so close they don't need a lot of adjustments. Older watches larger balance wheels the mass of the screws a variety of other things the adjustments are different. For a clue I'm attaching something from Hamilton watch company. Meantime screws nice chart showing the effect of turning these. Then the threads on the meantime screws are different than regular screws to allow them to be adjusted but lots of adjustment they will become loose with time. Then I'm attaching an image of your own balance wheel you do have two meantime screws which will give you a tiny bit of adjustment. Then you will note at the bottom of the chart Hamilton comments about using timing washers. The only problem with timing washers are they are really tiny and the maximum per pair is three minutes per day. Then you can use more than one pair but usually in the assortments that you find on eBay for instance all the larger sizes are gone. Timing screws at least for American pocket watches were available. Compared to a timing washer they add a lot of time to the balance wheel image attached from Elgin watch company. Notice the timing is seconds per hour versus per day. To give you an idea of physically the size of the screws are looking for an experiment remove one pair of screws. As a reminder everything you do with the balance wheel has to be on both sides to keep it poised In other words both sides the balance wheel have to be the same. So see how much faster the watch runs with two screws missing it should be quite dramatic the screws look to be rather large in size. I suspect you going to need really small screws compared to what you have.1 point

-

You guys are overcomplicating this. Ive reduced the stem height on hands with a fine cross-hatched file and it DID reduce the overall sitting height. ThEre is no need to broach, and all that can happen is the hand may no longer sit snugly on the pivot. I've also slightly bent the tips of sweep second hands to that they clear crystal/glass and also slightly bend them upward IF they happen to hit each other.... I'm taking small amounts of torque not using a ham-fisted approach...sheesh! J1 point

-

1 point

-

I will dive in like a child into a pond, not knowing the depth but having the excitement of the dive alone in mind. Sent from my iPhone using Tapatalk Pro1 point

-

Reducing the pivot length wont make any difference in the hand height, since the pivot is conical. Best way is to make the hole on the hand a bit bigger with a broach. Bending the hand on the pivot is a bad idea. Lifting the tip of the hand exert a great torque at the pivot making it to bend... worst, it can stick in the hole or break. The rule always applies that dont make any change on the original parts which were doing fine before the service. Make change to he parts which are new!1 point

-

1 point

-

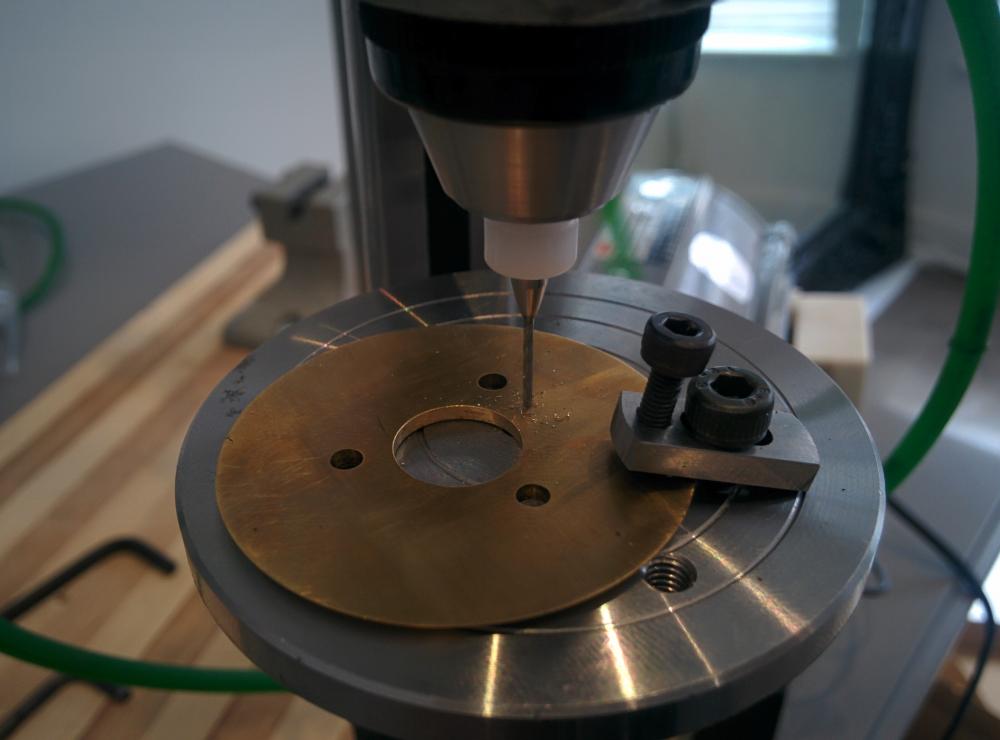

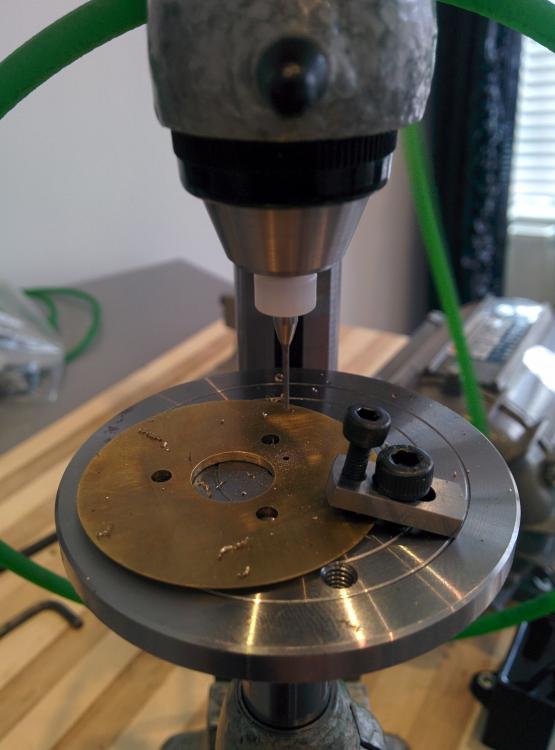

There are some holes left, great! Add the screws and poise it man! Poise it after You are in a good rate range! It looks from here that You will have to reshape the end curve as well.1 point

-

Just starting to learn. I've dis/reassembled a Chinese 6497. Waltham pocket watch up next. Im certain to have questions and hope they'll be a few who can answer from time to time. Best Charlie1 point

-

before you apply too much torque; keep asking till you get and answer on the screw direction. if you have already tryed, its sprobably too tight or rusted. use penitrating oil and heat before you try again. vin1 point