Leaderboard

Popular Content

Showing content with the highest reputation on 04/03/17 in all areas

-

Hello, here you are just starting out on a very interesting profession and I wish you all the best. Me I've had my time and I'm retired. You will never stop learning there will always be something new. This is a very friendly forum and it has an abundance of info and many on here like to help. Photos are a great help if you can provide them with any problems you have with movements. We also have a section for those interested in clocks.3 points

-

It worked great!!! After struggling for one hour with the balance spring, I finally manage to sort them all out. And after a tiny regulation. The watch is going on the second, and have done for many hours. Thanks a lot for you kind word.... This web site rules!!!!2 points

-

I recently bought a ESA 9210 powered Omega Speedsonic chronograph in a rather sad state. the Oscillator deck of this one is horribly discoloured and blackened in places, the battery strap screw is broken off on the main plate below the osc deck. Just to see what was possible with this one, I removed the oscillator plate to see the main plate below. This had faired a little better, having gone a light rainbow colour and not heavily corroded thankfully. I decided to check the oscillator plate, resonator, coils, index etc. The coils amazingly had continuity and of the correct resistances, resonator is clean, index is dull tarnished colour. I gave the plate and the rest a clean--which didn't really clean it much, but built it back up with at least clean jewels and fresh 9010 for index and second.. It wouldnt run, even though the coils passed resistance checks, no oscillation, no hum very low current drain of 3uA. Replaced the RC coil, It wouldn't run, still only 3uA. Replaced the TR coil, now we had life, it runs, and taking 6uA, Strange, the original TR coil checks fine so does the transistor but just wont work. I reinstalled the osc deck back to the watch, and jury-rigged a makeshift battery strap--my thinking is to assess the general operation (or not) of the rest of the movement, particularly the Chrono stages, prior to tearing into it for real. Ive read many a story of the chrono decks of these movements and would rather not have to pull that apart.... Well, The watch runs and keeps time, however on starting the chrono, will run for 5-10 seconds then stop, reset/flyback works as it should, the constant seconds display stays running when chrono stops, so looks like we got to tear into its devils-doings, the chronograph deck, with its weird vertical clutches and other oddities!....1 point

-

If you read the comments at the bottom of link it says he took it off an another automatic mainspring. The problem with modern alloy mainsprings is attaching it, it is much easier to rivet or repair an older blue steel type mainspring like watchmakers used to do years ago, but most of these type including new old stock have lost there strength/shape over time and are now useless.1 point

-

Welcome aboard Eddie, I was where you are now a few years ago, its a very rewarding career, but can also be very unforgiving. Take your time, learn as much as you can, and don't ever get yourself stressed, slowly slowly.1 point

-

Welcome Eddie, You certainly have a long learning curve to negotiate but many here to help & advise on this friendly forum. Enjoy.1 point

-

1 point

-

Welcome aboard Eddie, there are plenty good folk here willing to share their knowledge.1 point

-

Yes Roger....this was a pain, but I manage to get et right in the end....Im so pleased....thanks a lot1 point

-

That's a beautiful movement with some really interesting features, see more here http://watchguy.co.uk/guest-post-lemania-273000-the-moon-watch-caliber-321s-lesser-known-cousins/ If the watch is gaining time, then the problem will not be with the canon pinion, it is more likely to be an issue with the hairspring / balance. That "anti-catch" feature on the regulator is pretty unusual. You will need good magnification to see all this (x10 minimum), but make sure that the hairspring only touches between the regulator pins and doesn't touch the balance, anti-catch pins or itself anywhere else. I assume that the watch kept approximate time before you started? Sometimes we see watches with an incorrect part fitted which can cause large errors. "A" = Avance; move the lever this way to make the watch go faster "R" = Retard; move the lever this way to make the watch go slower. Sometimes you see F & S also, but the important thing to remember is that if you make the effective spring length longer then the watch will run slower. However, you will not have enough adjustment on the regulator to take out 2 hours in 12 hours1 point

-

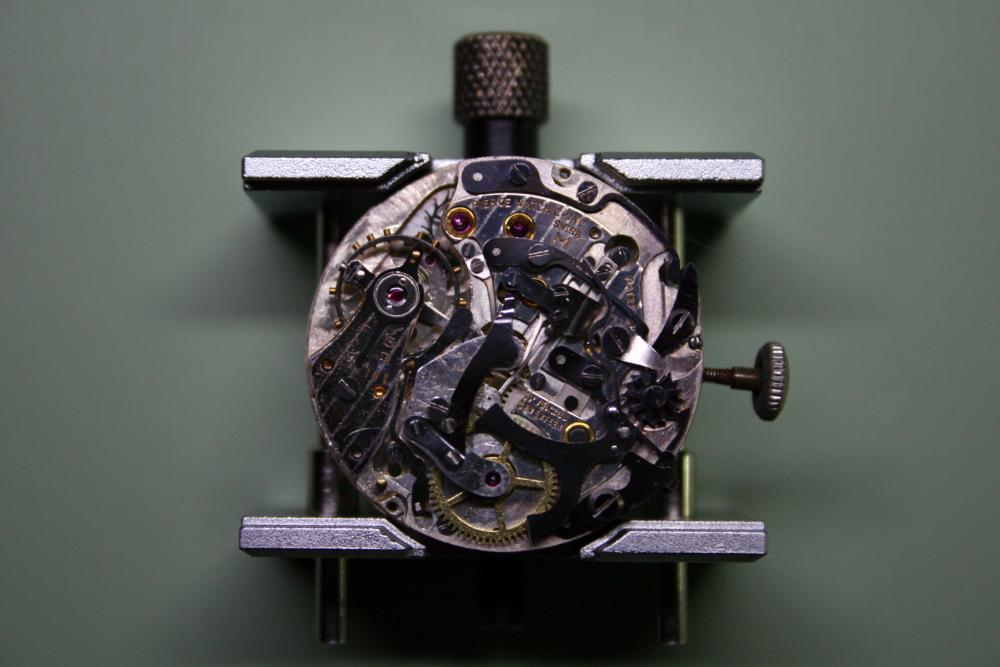

I've done a lot of Pierce Navigator repairs in the last year but this one was a bit special as it was the first I completed for someone other than myself. The watch is an heirloom and as such was received in much better condition than the those I've purchased off the bay. The bracelet was broken and would eventually be replaced and right off the bat I noticed that the sweep second hand was missing. The crown was also stuck in the setting position and therefore it was impossible to wind the watch. With the caseback off I could see that the chronograph staff and pinion had actually been removed sometime back. Also missing was the intermediate wheel which activates the minute recording wheel when the chronograph is engaged. My guess is that the rubber clutch for the chronograph had failed sometime in the past and the watchmaker simply removed the other bits as opposed to attempting a fix. I also noted a chip in the upper balance cap jewel. I've never seen a defect such as this before. With the dial removed, the normal accumulation of dirt and debris came to light. The setting lever snapped back into place smartly and with that I was able to check the timing. With the movement out I turned my attention to the case and pushers. The spacers for the pushers often become jammed inside the pusher button as the result of an accumulation of grime beneath the button cap. The springs, which sit between the spacer and the button, are made of stainless steel and generally hold up well over the years. I've discovered that a good soak in vinegar will usually free the spacers and springs from the buttons. With the pushers soaking I turned my attention back to the movement. As I said before, this Pierce 134 is in much better condition than those I've restored in the past. It's clear the owner has taken good care of the watch over the years. Generally I'll follow the Esembl-O-Graf (volume 15) in reverse order when disassembling a Pierce movement. I've done a few now and am getting used to the process. Looking the parts over I didn't find any that required immediate replacement so the only order placed was for a mainspring and crystal (in addition to the missing chronograph staff, pinion, and intermediate wheel). The old crystal was in fair shape but a little loose in the bezel so I opted for a new one. The damaged cap jew was chipped only on the topside and therefore I opted not to replace it. The parts were whisked off to the L&R cleaner and I turned my attention back to the pushers. The vinegar bath succeeded in freeing the spacers and springs from the buttons. I set the parts out for cataloging after cleaning and drying. At this point I'll also do any rust remediation. This movement was in fine shape but the levers for the chronograph did suffer from a bit of oxidation. The rusted bits were placed in a bath of vinegar for a good soak, then any pitting was smoothed using the Dremel tool or a rub on the Arkansas stone. The replacement chronograph staff, pinion, and intermediate wheel arrived in time for assembly. The staff needed a new clutch plate. In the past I've cut these out of nylon and although this is an adequate solution, it makes the final adjustment a lot more difficult since the nylon has so much less give than rubber. A while ago I began experimenting with rubber o-rings as a substitute. I use a rubber o-ring which had a thickness of 2mm. By sharpening an Exacto knife and lubricating it with a bit of watch oil I can cut through the o-ring with very little compression. This results in a disk that is thin enough and flat enough to use as a clutch plate for the chronograph. A punch I made on the lathe is used to place the center hole. Unfortunately since I made the o-rings before I began this service, I didn't have any images of the procedure. Assembly is straightforward provided all the gremlins have been discovered beforehand. The pallet, escape wheel, and cap jewels receive epilame treatment. The balance wheel is cleaned separately with One Dip. Put back together I noted a funky reading not the timegrapher. The culprit was a slightly bent pivot on the pallet. I replaced the pallet with one from my own stock and this resolved the problem straight away. I let the watch run overnight before beginning on the chronograph layer. It comes together a little slower as there are many more parts to lubricate and adjust. A missing sweep second hand can be a real problem with Pierce watches as the center post is 0.35mm (which is large). Fortunately I had a hand in my stock from a parts movement that would do- once I attached a post to it! I have some brass tubing that has an inside diameter of 0.35mm so I just needed to turn the outside diameter down on the lathe and rivet the post to the hand. Here I test the fit of the hand prior to painting. Once that was settled I discovered the post on the minute hand was loose also. A new post was turned on the lathe for it as well. Problems with the chronograph became apparent after fitting the hands. The culprit in this case turned out to be a damaged center jewel. This must have occurred during assembly as the jewel checked out after cleaning. Bad luck. The jewel is pressed in from the topside and so it must be removed by pressing from the bottom side (dial side). Unfortunately the jewel sits at the bottom of a long tube which required me to turn a special adaptor piece on the lathe for my Seitz tool. A replacement jewel was sourced from a donor movement and I was back in business. The owner decided on a replacement crown and a new strap and the watch finally came together. I have a bit of a thing for Pierce watches but at the same time I don't think it's much of a coincidence that the watches housing a Pierce 134 movement only seem to exist from the late 40's and early 50's as they can be a bear to get running right. In the end I was really pleased with this service though.1 point

-

1 point