Leaderboard

Popular Content

Showing content with the highest reputation on 03/10/17 in all areas

-

Bought a lot of watches off the bay recently... nothing special just a bunch of 6309s and 700x. What I wanted was the round cased diamatic in the lower center, I have one already but I really like these round cushion cases. Well I finally got it, I knew the crystal was trashed but the dial seemed good. A lot I've seen have the chapter ring damaged and sometimes totally polished out. This seems fine looking beyond the crystal. Even the lume seems fresh with none of that black fungus stuff. I've seen these hand referred to as 'syringe' hands, quite apt. It has a 7006 movement .. higher jewel count than the 7009. Opening it up I found the rotor loose in the case but my hopes of a quick fix were soon dashed when I found that the rotor post had become detached from the plate. I think it was originally electro welded, not staked . I 'know' I have a 7006 somewhere which is in a poor case and I could easily use the main bridge off that but I can't lay my hands on it.. So a 7009 plate will have to do for now. I always thought that pivots for open jewels are different from pivots which run in capped jewels but inspecting the wheel-pivots from the 7006 and 7009 show no difference so the 7009 bridge was installed with the 7006 wheels. I had to re-clean and demagnetise the balance as the watch was running way too fast but its running fine now. A new generic crystal was fitted and its good to go. The leather strap was something I had on my desk.. will need to look for another one. I may polish the case a bit but then again I may leave it with the slightly used look to contrast with the new crystal and decent hands/dial combo. Have a good weekend folks! Anilv2 points

-

Gotta agree with these guys, for what it's worth, I have been a member of several MB's and I would not have stayed at WRT this long, if there wasn't something I could gain from it, even as an amateur repair person, not to mention the diverse personalities and colorful commentary. Your have to admit there is no other site like this and I don't try to curry favor with anyone. Curry: to seek to gain favor by flattery or attention We all get discouraged at sometime or another, when you get stuck trying to do repairs or things in general just don't seem to work no matter what you do. I've wanted to get out of watches altogether a few times but my determination to conquer the seemingly impossible tasks won't let me, maybe it's just me. I do know one thing: you can't be successful at repairs, if you give up. You can PM me with why you want to not be a part of this, maybe I can help change your mind. Dave2 points

-

There's nothing really like WRT on the web. Most sites are "Just look how pretty my watch looks today" why delete your account ? Sent from my SM-T585 using Tapatalk2 points

-

2 points

-

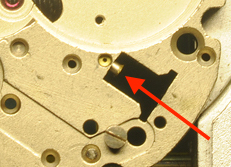

Recently, working on a Molnija 3602, which has a push-button stem release, I couldn't get the winding stem back in. The keyless works were in the neutral or "winding" position. Had to strip the hands, the dial and found the clutch-wheel detached from the clutch lever, or the other way around if you like. After several dry-runs I noticed that in order to get the winding stem back in successfully, the keyless works had to be in the "time-setting-position". In this position the clutch-wheel was pushed firmly, and hold in place against the main plate. In the neutral or winding position, any movement to the clutch-wheel, while inserting the stem, caused the clutch-wheel to disengage from the lever. By having the clutch-wheel pushed firmly against the main plate, inserting of the stem didn't cause this disengagement. Also some main-plates do have a protruding bushing where the tip of the winding stem sits in, but this bushing also centralizes the clutch-wheel in the time-setting-position; Working on another watch and speaking to a fellow enthusiast, I was advised to make sure to engage the keyless works in the time-setting-position before pulling the stem. Failure to do so, and the chances were high that I wouldn't be able to get the winding-stem back in, with the obvious consequences of having to remove the hands, dial etc etc. My question are; are there any advised procedure what's the best & safest ? Pro's & con's? Are there "One size fit all" procedures ?? Please your thoughts and or comments ? Thanks on beforehand1 point

-

1 point

-

Hey thanks everyone. I guess it would be like trying to find replacement parts for a modern toaster. Their probably aren't any because you just throw the thing away. The clips on my watch look very similar to the ones in Rogart's second picture. I think JDM's idea of fabricating one out of a tube would be a pretty cool idea, though possibly above my current skill level. I may play around with that though in my spare time. I think that to get it in service for now I will just try to put some metal e-clips on there and see what happens. Thanks1 point

-

Thanks again for all your advice. I have gotten a lot of help and not contributed a lot, sofar. I was just so stressed trying to decide by today on whether to keep the watch or not, because tomorrow I will leave on a trip. After march 29 I will contribute more and post pics of my mic and the watch. I may have some useful tips on mic positioning, and some other ideas. At least MY piezo mic is supersensitive. It is a japanese brand I bought from a distributor in Stockholm a couple of years ago, I just need to find the info ln the brand and model.1 point

-

1 point

-

1 point

-

Ok, you scared me! :)) But what's the computer resources got with the wrt account? I believe you've been lied to.... by your computer! Kill it! Before Skynet takes control... scarry!1 point

-

1 point

-

I'm sorry to tell you that you are showing all the signs and symptoms of the early stages of the watchmaking sting!! Unchecked this leads to getting basic tools, buying cheaper movements to fool with and progressively escalate to full on obsession. Good luck! The thread I believe is in WUS here: Do you need a tourbillion? https://r.tapatalk.com/shareLink?share_fid=13788&share_tid=3874922&url=http%3A%2F%2Fforums%2Ewatchuseek%2Ecom%2Fshowthread%2Ephp%3Ft%3D3874922&share_type=t I hope the link works coming from Tapatalk Sent from my iPhone using Tapatalk1 point

-

I don't really know if they indicate a good or bad quality toubillon. My feeling is that they at least indicate "good enough". The noise you hear when moving the watch can be any number of things in the watch hitting each other (perfectly normal things, like gear teeth rattling). I don't know what the longevity of a tourbillon is, especially an inexpensive one, but whatever it is, it will be more costly to service than a plain escapement.1 point

-

1 point

-

1 point

-

You cannot delete an account but we can disable your account - please submit a support ticket to request. Sent from my iPhone using Tapatalk1 point

-

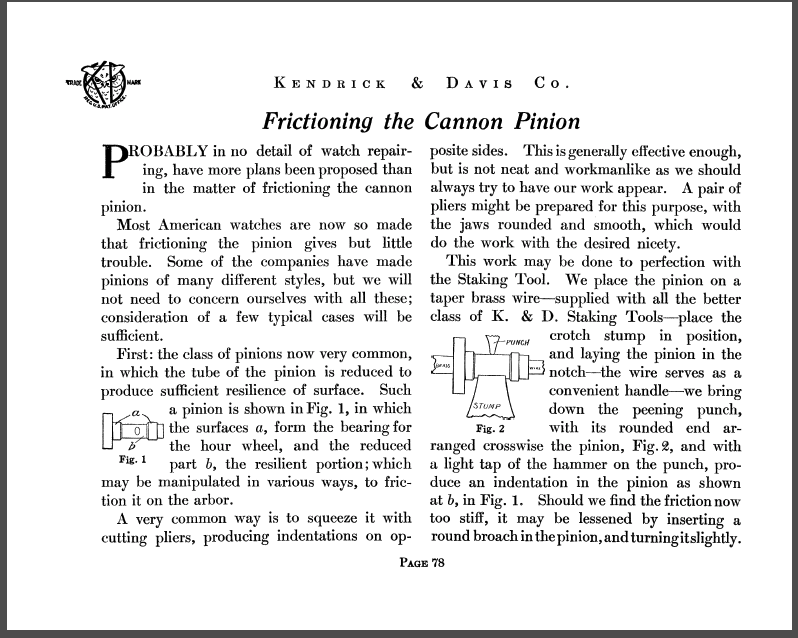

Hi I think I actually succeeded in tightening it. At least it turns the the centre wheel now and I'm hoping the watch will set as well. I had to hit it a bit harder than a light tap. I held it with a pair of tweezers and that seemed to work fine. I actually used the sharp point punch and while I held the pinion on a flat stump. Anyway, it's tighter. Dave1 point

-

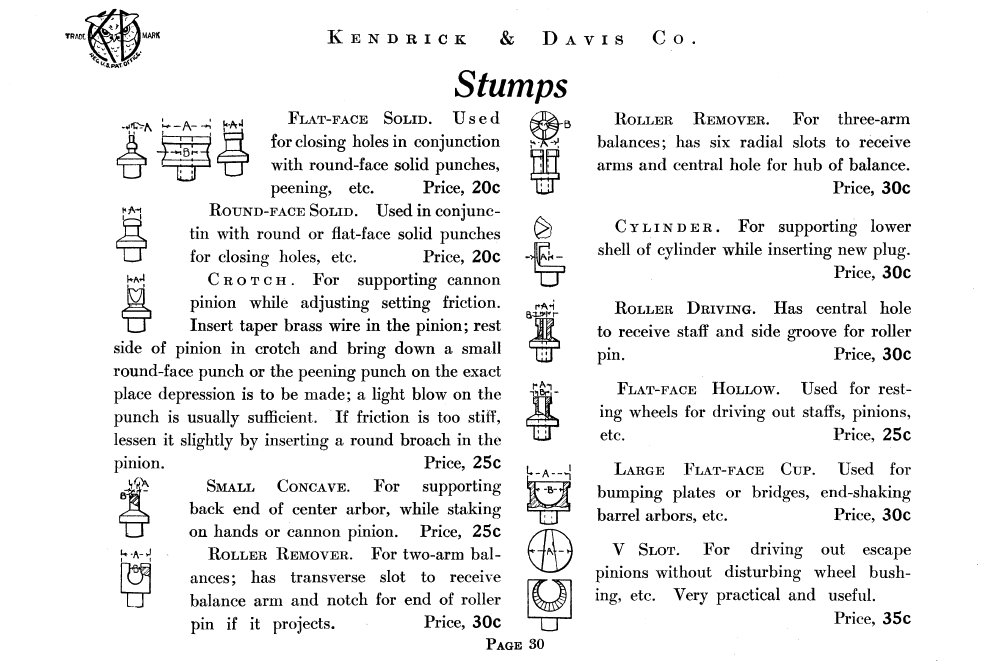

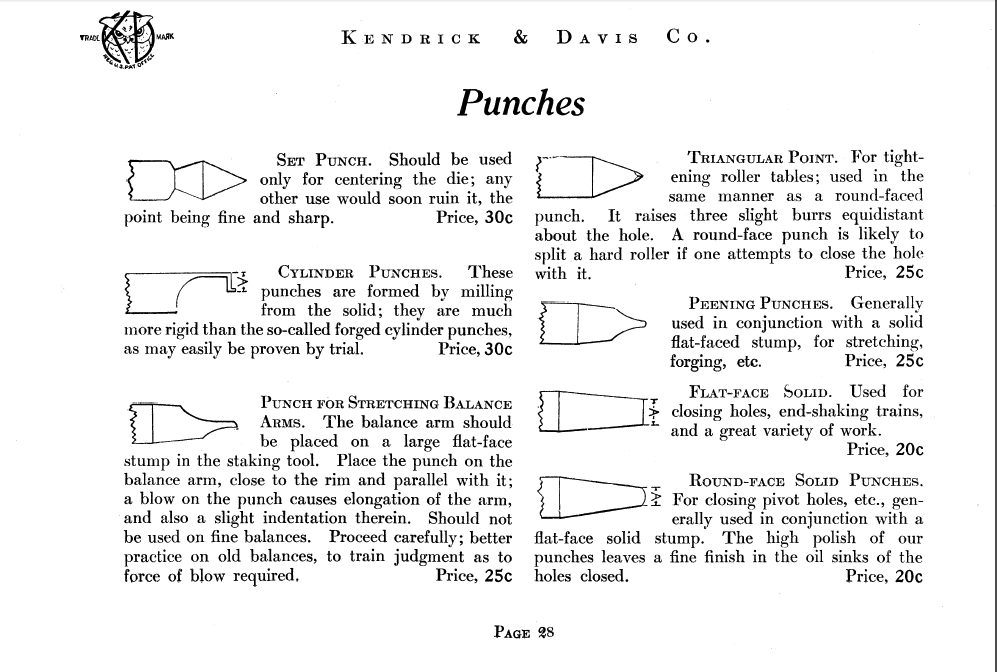

Aloha Folkvisor , You have a staking set so check to see if you have the stump [crotch ] , and punch [ peening ] , used to tighten the cannon pinion . And don't forget to insert something inside the pinion to maintain the round shape . I use a Lei needle we get here in the Islands to make flower Leis , but a heavy duty needle set used for leather or canvas would work . You want to use a small brass hammer so you don't distort the ends of your punch . Use light taps , but the needle inside the pinion is insurance against distorting the shape . Go to pg. 75 for Info...... StakingToolsAndHowToUseThem1910FullTextSearchable.pdf1 point